Maintaining the longevity and functionality of heavy machinery is essential for optimal performance and safety. Proper care involves not just routine checks but also understanding the intricate components that contribute to the overall efficiency of the equipment. In this section, we will delve into the critical aspects of upkeep, ensuring that your machinery remains in peak condition.

Effective maintenance practices can prevent unforeseen issues and enhance the lifespan of your equipment. Familiarity with the various systems and mechanisms at play allows operators to identify potential problems before they escalate. This proactive approach is key to achieving seamless operation in demanding environments.

Furthermore, knowledge of common troubleshooting methods can empower operators to address minor malfunctions independently. With the right information at hand, tackling challenges becomes manageable, ultimately reducing downtime and increasing productivity. As we explore the guidelines and insights necessary for thorough oversight, you will gain a comprehensive understanding of how to sustain your machinery effectively.

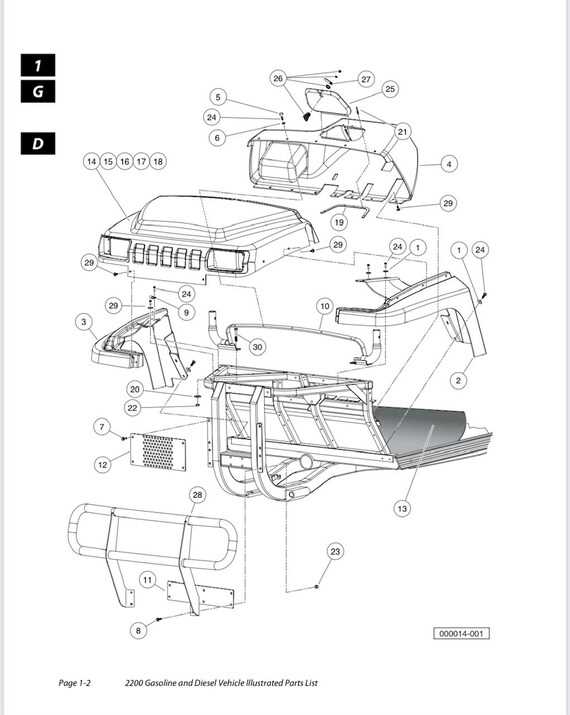

Understanding Bobcat 2200 Components

Gaining insight into the various elements that comprise a compact utility vehicle is essential for ensuring optimal functionality and longevity. Each component plays a vital role in the overall performance and efficiency of the machine, contributing to its ability to navigate diverse tasks and terrains. Familiarity with these parts empowers operators and technicians alike to identify issues, perform maintenance, and enhance operational effectiveness.

Key Elements of the Machine

At the heart of the vehicle lies the engine, which serves as the powerhouse, converting fuel into the energy required for movement and operation. Complementing the engine, the hydraulic system facilitates the manipulation of various attachments, allowing for a wide range of applications, from lifting to digging. Understanding the interaction between these key components is crucial for maximizing performance.

Supporting Systems

In addition to the main powertrain and hydraulic systems, several supporting elements enhance functionality. The electrical system provides the necessary power for controls and indicators, ensuring seamless operation. Furthermore, the undercarriage and chassis offer stability and support, affecting maneuverability and load-bearing capacity. Recognizing how these systems work in concert can greatly aid in troubleshooting and maintenance.

Common Issues with Bobcat 2200

When operating a compact utility vehicle, users may encounter various challenges that affect performance and reliability. Understanding these frequent problems can help in timely diagnosis and resolution, ensuring optimal functionality.

- Electrical Problems: Issues with the battery, wiring, or fuses can lead to starting difficulties or intermittent power loss.

- Hydraulic System Failures: Leaks or blockages in the hydraulic lines may cause diminished lifting capability or erratic operation of attachments.

- Engine Performance: Poor acceleration, stalling, or unusual noises often indicate underlying issues with the engine components or fuel system.

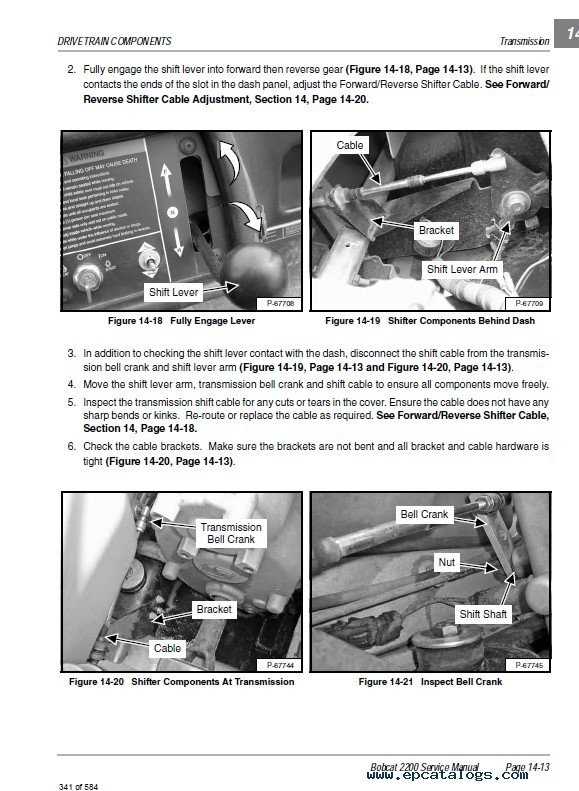

- Transmission Issues: Difficulty in shifting gears or unusual vibrations can point to problems within the transmission system.

- Worn Tires: Improper tire inflation or tread wear can affect traction and maneuverability on various terrains.

Addressing these common issues promptly can significantly enhance the longevity and effectiveness of the vehicle. Regular maintenance checks are essential to prevent these problems from escalating.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and efficient operation of any equipment over time. By following consistent maintenance practices, you can prevent potential issues before they become costly repairs, enhancing both performance and lifespan.

1. Routine Inspection

Frequent inspections are the cornerstone of effective maintenance. Check for signs of wear and tear, including loose or damaged parts, and make adjustments as necessary. Identifying minor issues early can prevent major breakdowns and extend the functionality of components. A thorough inspection also ensures that any parts susceptible to degradation are promptly attended to, helping maintain smooth operation.

2. Lubrication and Cleaning

Regularly lubricate moving parts to reduce friction and prevent premature wear. Accumulated dirt and debris can impede operation, so it’s vital to clean key components periodically. Using the appropriate lubricants and cleaning agents protects against corrosion and wear, allowing the equipment to run more smoothly and efficiently. This not only minimizes energy loss but also maximizes lifespan.

Implementing a systematic maintenance schedule with these tips in mind can significantly improve the reliability and longevity of your equipment. Proper care not only minimizes unexpected downtime but also optimizes the overall performance, ensur

Essential Tools for Repairs

For any equipment maintenance, having the right tools is crucial to achieving successful results. Properly selected tools not only make the task more efficient but also help ensure safety and accuracy during each step. A well-prepared toolkit is essential for handling various technical tasks and addressing issues confidently.

Wrenches and Screwdrivers: High-quality, adjustable wrenches and a full set of screwdrivers are indispensable for both basic and complex adjustments. Look for tools with comfortable grips to reduce hand strain during extended use.

Pliers and Wire Cutters: Durable pliers and sharp wire cutters assist in electrical adjustments and wire management, making them essential for a wide range of tasks. Long-nose pliers can be particularly useful for reaching confined areas.

Multimeter: A reliable multimeter is invaluable for diagnosing electrical issues. With its ability to measure voltage, resistance, and current, this tool provides the insights needed to troubleshoot efficiently.

Torque Wrench: Ensuring that bolts and screws are fastened to precise specifications is critical for long-term stability. A torque wrench enables the accurate application of pressure, reducing the risk of overtightening.

Lubricants and Cleaning Agents: Keeping components clean and lubricated prevents wear and tear, contributing to smoother operation. Choose quality lubricants and cleaning solutions designed for the specific parts being maintained.

Equipping yourself with these fundamental tools enhances your ability to tackle mechanical tasks effectively, promoting both accuracy and safety throughout each stage of the maintenance process.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to identify and resolve common issues, ensuring smooth and reliable operation. Follow each step carefully to diagnose potential sources of malfunction and address them effectively.

| Step |

Description |

Action Required |

| 1 |

Inspect the Power Source |

Check connections, cables, and battery levels. Ensure power flows correctly to all components. |

| 2 |

Check Fluid Levels |

Examine hydraulic, coolant, and oil levels. Refill or replace fluids if necessary to prevent overheating or mechanical issues. |

| 3 |

Examine Filters |

Look for any dirt or blockages in air and fuel filters. Clean or replace filters to maintain optimal performance. |

| 4 |

Inspect the Control Panel |

Ensure all switches, levers, and display indicators work correctly. Replace or repair non-functional parts. |

| 5 |

Test the Motor Function |

Start the engine and listen for any unusual noises. Address abnormal sounds immediately by inspecting moto

Engine Care and Maintenance Practices

Proper care of an engine significantly extends its lifespan and ensures optimal performance over time. Routine maintenance and attentive inspection of various components can help avoid unexpected breakdowns and costly repairs.

- Check and Change Oil Regularly: Oil is essential for lubrication, reducing friction, and maintaining engine temperature. Make sure to inspect the oil level frequently and replace it according to the manufacturer’s suggested intervals.

- Monitor Coolant Levels: Coolant prevents the engine from overheating, especially during extended use. Ensure the coolant is filled to the recommended level and inspect for any leaks in the system.

- Inspect the Air Filter: A clean air filter is crucial for efficient fuel combustion. Regularly examine the filter for dust and debris, cleaning or replacing it as needed to maintain proper airflow to the engine.

- Examine Spark Plugs: Spark plugs are integral to ignition and should be inspected periodically. Replace any worn or damaged plugs to ensure smooth and consistent engine operation.

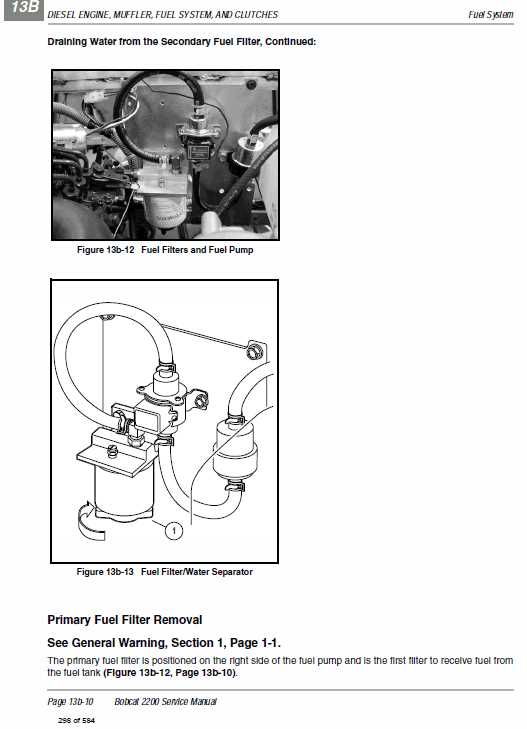

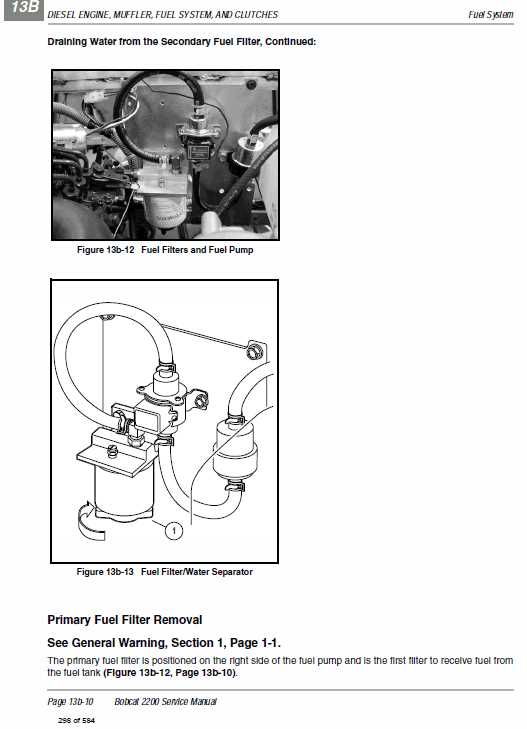

- Maintain the Fuel System: Ensure the fuel lines and filter are free from blockages, and use clean, high-quality fuel to prevent contamination and promote efficient fuel combustion.

- Inspect Belts and Hoses: Belts and hoses can wear out over time, leading to poor engine performance or potential failure. Regularly examine them for cracks or fraying and replace any components showing signs of wear.

- Battery Maintenance: Check the battery terminals for

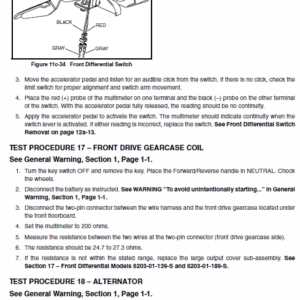

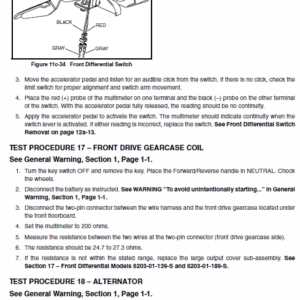

Electrical System Diagnostics

Understanding the workings of the electrical system is essential for pinpointing and resolving common issues that may arise. This section provides a guide to identifying and diagnosing electrical problems, from examining wiring connections to checking the functionality of components in the system.

The process of diagnosing electrical systems involves a structured approach to testing connections, circuits, and components for continuity and reliability. Here, the key steps are outlined to support efficient troubleshooting and resolution of potential electrical issues.

| Diagnostic Step |

Description |

| Inspect Connections |

Check each connection for corrosion, secure attachment, and continuity. Loose or oxidized connectors can disrupt the flow of electricity, leading to erratic function. |

| Test Voltage Levels |

Using a multimeter, measure the voltage across various points to ensure they match the expected values. Discrepancies may indicate faulty wiring or malfunctioning components. |

| Examine Fuses and Relays |

Inspect all fuses and relays, replacing any that are damaged or blown. Fuses protect the circuit from overcurrent, and relays control power to different sections of the system. |

| Assess Battery Health |

Ensure the battery is charged and functioning correctly, as low voltage can affect overall system performance. Check for signs of wear or damage. |

| Test Circuit Continuity |

Verify that current flows uninterrupted through each circuit. A break in continuity may result in intermittent issues, requiring further inv

Hydraulic System Troubleshooting

In many utility vehicles, the hydraulic system plays a crucial role in enabling efficient operation by transmitting power where it’s needed. When this system malfunctions, it can lead to a decrease in performance or a complete halt in functionality. This section will guide you through common hydraulic issues and effective steps to identify and resolve them.

Common Hydraulic Problems

Hydraulic systems may develop issues such as low pressure, fluid leakage, or unusual noises. Low pressure can indicate blockages, a worn pump, or air in the system. Fluid leakage often results from damaged seals or hoses, while excessive noise typically signals cavitation or air in the lines. Recognizing these issues early can prevent further damage and keep the system running smoothly.

Step-by-Step Diagnostic Process

To diagnose hydraulic issues, start by checking the fluid levels and quality. Low or contaminated fluid can reduce efficiency and cause wear. Next, inspect all visible hoses and connections for leaks or cracks. Tightening or replacing worn components may resolve minor issues. If problems persist, test the pump for adequate pressure and examine the filters for blockages. Keeping a regular maintenance schedule and following these steps can greatly reduce the risk of hydraulic failures.

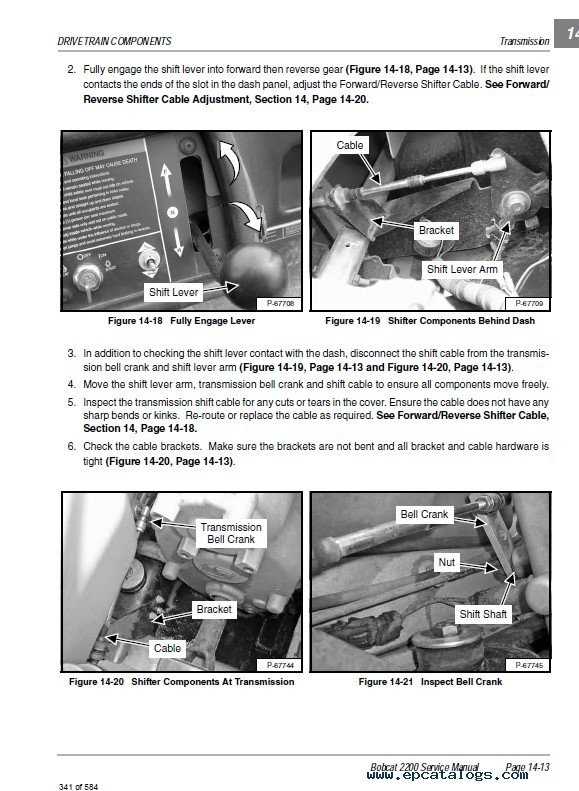

Transmission Maintenance Techniques

Effective maintenance of the transmission is essential for ensuring consistent vehicle performance and longevity. By understanding the proper procedures for inspecting, cleaning, and lubricating transmission components, operators can prevent common issues and extend the system’s life. Regular attention to these areas helps avoid costly repairs and supports smoother operation over time.

Below are some key techniques and steps for maintaining a vehicle’s transmission system, designed to aid in preventive care:

| Maintenance Task |

Description |

Frequency |

| Fluid Level Check |

Regularly check the transmission fluid level and top up as needed. Ensure that the fluid remains clean and free from contaminants. |

Every 1,000 miles |

| Fluid Replacement |

Replace old fluid with fresh, high-quality transmission fluid to maintain optimal performance and lubrication. |

Every 30,000 miles or as specified |

| Filter Inspection |

Inspect and clean or replace the transmission filter to ensure that it effectively removes debris and prevents blockages. |

Every 15,000 miles |

| Seal Inspection |

Check seals and gaskets for wear and replace them if any signs of leakage or damage are present. |

Annually |

| Safety Precautions During Repairs

When maintaining or servicing any equipment, ensuring a safe work environment is essential to avoid potential hazards. Adhering to safety guidelines minimizes risks and helps create a secure atmosphere for those involved in the process. Understanding and following specific precautions is crucial for personal protection and the well-being of others around the workspace.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective equipment is a foundational step in enhancing safety during any technical procedures. Gear such as gloves, safety goggles, and ear protection should be selected based on the type of task and potential risks involved. Wearing PPE protects against physical harm, including exposure to sharp components, loud noise, or hazardous fluids.

Safe Workspace Preparation

Before starting any task, thoroughly inspect the workspace to ensure it is free of unnecessary clutter or obstacles. Clear surroundings allow for smooth and efficient movements, reducing the chance of slips or trips. Additionally, ensure adequate lighting and ventilation are available to enhance visibility and air quality, helping to prevent accidents and promote a focused work environment.

Remaining vigilant throughout each step of the process helps in identifying and addressing risks as they arise, making safety a priority at every stage.

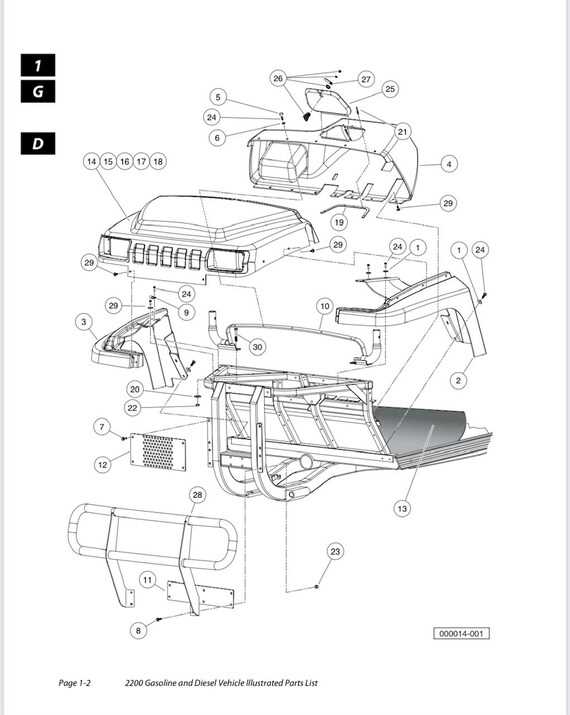

Parts Replacement and Sourcing

Ensuring reliable performance involves timely identification and replacement of worn or faulty components. Whether dealing with a specific part or assessing overall functionality, understanding when and where to source quality replacements is essential for effective maintenance.

When searching for parts, consider both compatibility and durability. It’s often beneficial to consult trusted suppliers who offer components matching original specifications to guarantee fit and function. Additionally, verifying that each replacement part meets the necessary standards is vital to maintaining optimal performance over time.

For those handling maintenance independently, local vendors and specialized online stores can provide access to a range of reliable parts. Many suppliers offer detailed information, helping to match specifications precisely. Whenever possible, choosing components with warranties or customer support can add assurance during installation and extend the usability of the equipment.

Operator’s Manual Overview

This section provides a detailed guide on operating and maintaining equipment, focusing on essential information that ensures safe and efficient use. It outlines the necessary procedures, including daily checks, operational instructions, and tips for troubleshooting common issues. With a clear emphasis on practical application, this guide assists users in mastering their equipment while promoting longevity and reliability.

Basic Safety Guidelines

Adhering to safety recommendations is fundamental to preventing accidents and ensuring smooth operation. The following points summarize key safety aspects:

- Always inspect components for wear or damage before each use.

- Familiarize yourself with the controls and their functions prior to operation.

- Wear appropriate protective gear, including gloves, goggles, and suitable clothing.

- Ensure that the work area is free from hazards that could interfere with performance.

Maintenance and Routine Checks

Regular maintenance is essential to keep equipment in optimal condition. The following steps highlight critical areas for inspection:

- Fluids: Check levels of hydraulic fluid, engine oil, and coolant. Top off as needed to maintain proper levels.

- Filters: Inspect air and oil filters regularly, and replace them according to the recommended schedule.

- Tires: Verify tire pressure and inspect for signs of puncture or wear.

- Batter

After Repair: Testing and Verification

Once the necessary adjustments have been completed on the machinery, it is crucial to conduct a thorough evaluation to ensure everything is functioning as intended. This stage not only confirms the effectiveness of the modifications but also identifies any potential issues that may require further attention. Systematic testing and verification contribute significantly to operational safety and performance reliability.

Initial Assessment

Begin with an initial assessment to check for any visible irregularities. Inspect all components, including connections and fluids, to verify that everything is correctly assembled. Pay close attention to areas where parts were replaced or serviced, ensuring there are no leaks or unusual noises during operation.

Functional Testing

Following the initial evaluation, proceed with functional testing of the equipment. This process should include a series of operational tests under various conditions to ensure all systems respond accurately. Monitor key performance indicators, and make note of any deviations from expected behavior. If any issues arise, re-evaluate the recent work to identify and rectify the cause promptly.

|

|

|