In the world of outdoor machinery, understanding how to maintain and troubleshoot your equipment is crucial for optimal performance. This resource is designed to provide essential insights into ensuring your device remains in top shape throughout its lifespan.

With the right knowledge and tools, you can effectively tackle various challenges that arise during operation. This guide delves into essential techniques, offering step-by-step instructions that empower you to manage any issues with confidence.

By mastering these skills, you not only enhance the functionality of your machinery but also save time and resources. Embrace the ultimate opportunity to learn about care practices that will extend the longevity and efficiency of your device.

Understanding the Honda HS928 Snowblower

The powerful snow-clearing machine is designed to tackle heavy snowfall and ensure that pathways remain accessible. With advanced features and robust construction, it stands out as a reliable choice for both residential and commercial use. This section delves into its key components, functionality, and maintenance, providing insights for users to maximize its performance.

Key Features

This snow-clearing device boasts an impressive engine that delivers exceptional power, enabling it to handle even the most challenging conditions. Its large intake width allows for quick removal of accumulated snow, while the adjustable chute provides versatility in directing the discharged snow. The ergonomic controls enhance user comfort, making operation seamless even in harsh weather.

Maintenance Tips

Regular upkeep is crucial for longevity and efficiency. Check the oil levels frequently to ensure optimal engine performance. Cleaning the auger and chute after use will prevent ice build-up, and inspecting the belts periodically will help avoid unexpected failures. By adhering to a consistent maintenance routine, users can enjoy reliable performance season after season.

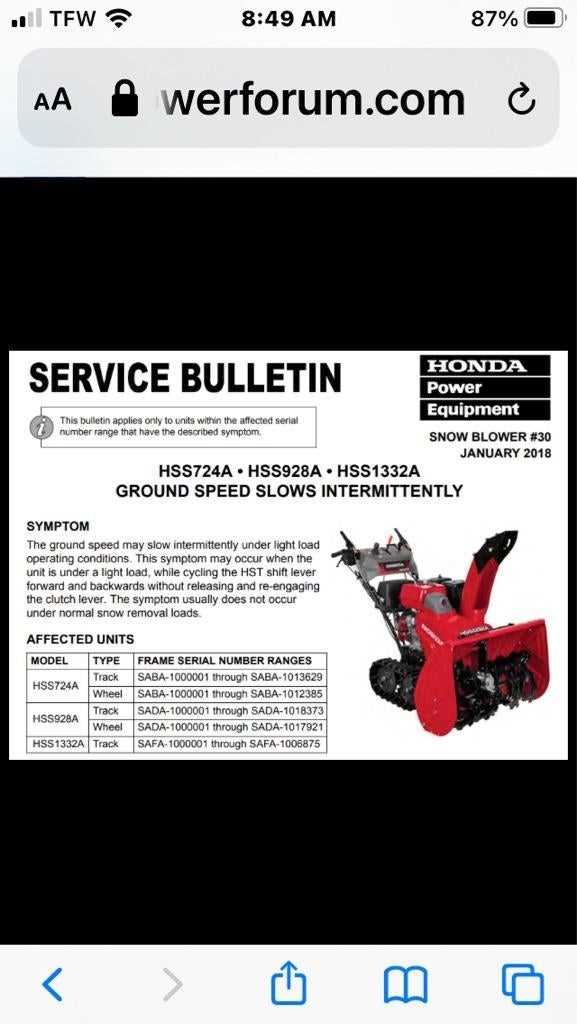

Common Issues and Troubleshooting Tips

When operating snow clearing equipment, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their solutions can help maintain optimal functionality and extend the lifespan of the machine. Below is a guide to some frequent issues and helpful troubleshooting techniques.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Difficulty Starting | Engine won’t turn over or starts but stalls | Check fuel levels, inspect the ignition system, and examine battery connections. |

| Reduced Power | Engine struggles under load | Clean or replace air filter, inspect fuel lines for clogs, and check spark plugs. |

| Unusual Noises | Grinding or rattling sounds | Inspect for loose components, check the auger for damage, and ensure all fasteners are tight. |

| Poor Snow Throwing | Snow is not being ejected effectively | Examine the auger for blockages, adjust chute direction, and ensure belts are in good condition. |

| Excessive Vibrations | Machine shakes during operation | Check for unbalanced parts, inspect the base for stability, and tighten any loose screws. |

Essential Tools for Repairing HS928

When tackling maintenance and troubleshooting tasks for your equipment, having the right instruments is crucial. Proper tools not only streamline the process but also enhance safety and effectiveness. Here’s a comprehensive list of essential instruments to have on hand.

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are important for various screws that may need adjustment or replacement.

- Torque Wrench: Ensures bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

- Pliers: Needle-nose and slip-joint pliers can assist in gripping and manipulating small parts.

- Oil Filter Wrench: Useful for changing filters efficiently without damaging them.

In addition to the basic tools, consider having specialized equipment for more intricate tasks:

- Multimeter: For testing electrical components and diagnosing issues in the ignition system.

- Fuel Line Wrench: Facilitates the safe removal of fuel lines without damaging fittings.

- Jack Stands: Essential for safely lifting and supporting your machinery during service.

- Cleaning Supplies: Brushes and solvents are necessary for keeping components free of debris and contaminants.

Having these tools readily available will make maintenance and servicing much smoother, ensuring your equipment operates optimally.

Step-by-Step Maintenance Guide

Proper upkeep of your snow-clearing machine is essential for optimal performance and longevity. Regular attention to key components not only ensures reliability but also enhances efficiency during operation. This guide outlines the necessary steps to keep your equipment in top condition.

1. Check the Fuel System

Begin by inspecting the fuel tank for cleanliness. Drain any old fuel and replace it with fresh gasoline. Ensure that fuel lines are free from cracks and leaks, and replace the fuel filter if necessary.

2. Inspect the Spark Plug

Remove the spark plug and check for wear or carbon buildup. Clean it with a wire brush or replace it if it appears damaged. Ensure the gap is set to the manufacturer’s specifications for optimal ignition.

3. Clean the Air Filter

Remove the air filter and examine it for dirt and debris. Clean it thoroughly or replace it if it is too worn. A clean filter ensures proper airflow, which is crucial for engine performance.

4. Examine the Blades

Inspect the cutting blades for damage or dullness. Sharpen them as needed or replace them if they are excessively worn. Properly maintained blades ensure efficient snow removal.

5. Lubricate Moving Parts

Identify all moving components and apply suitable lubricant. This reduces friction and wear, prolonging the life of the machine. Be sure to follow the manufacturer’s recommendations for the type of lubricant to use.

6. Check the Belts and Cables

Inspect all belts for signs of wear, cracking, or fraying. Replace any damaged belts immediately. Also, check cables for tension and condition, adjusting or replacing as necessary.

7. Test the Controls

Before using the machine, test all controls to ensure they function smoothly. This includes throttle, auger, and drive controls. Address any issues before starting your next job.

8. Store Properly

At the end of the season, clean the machine thoroughly and store it in a dry, protected area. Cover it to prevent dust accumulation and protect it from potential damage during the off-season.

By following these systematic steps, you can maintain the efficiency and durability of your snow-clearing equipment, ensuring it is ready for the next snowfall.

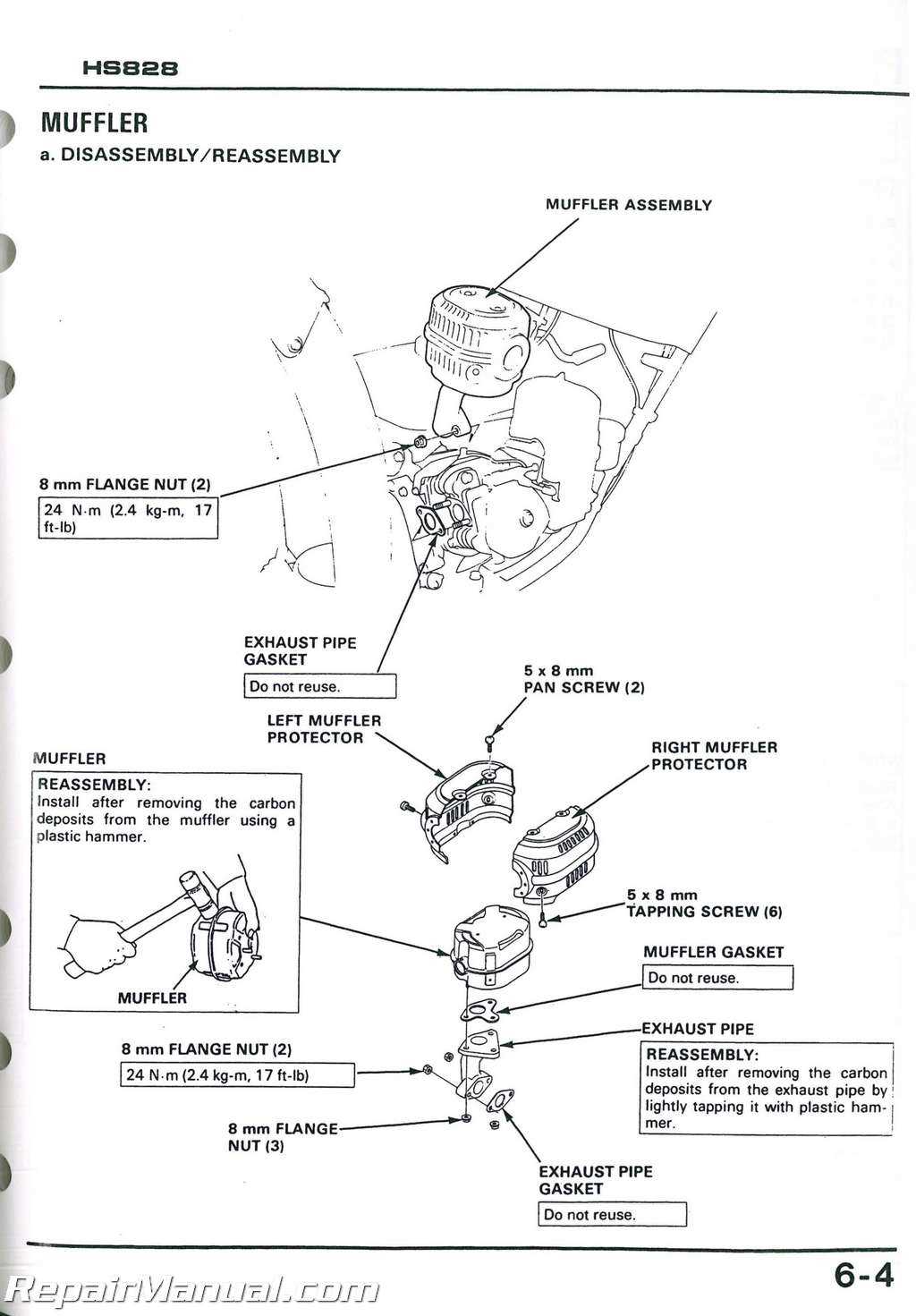

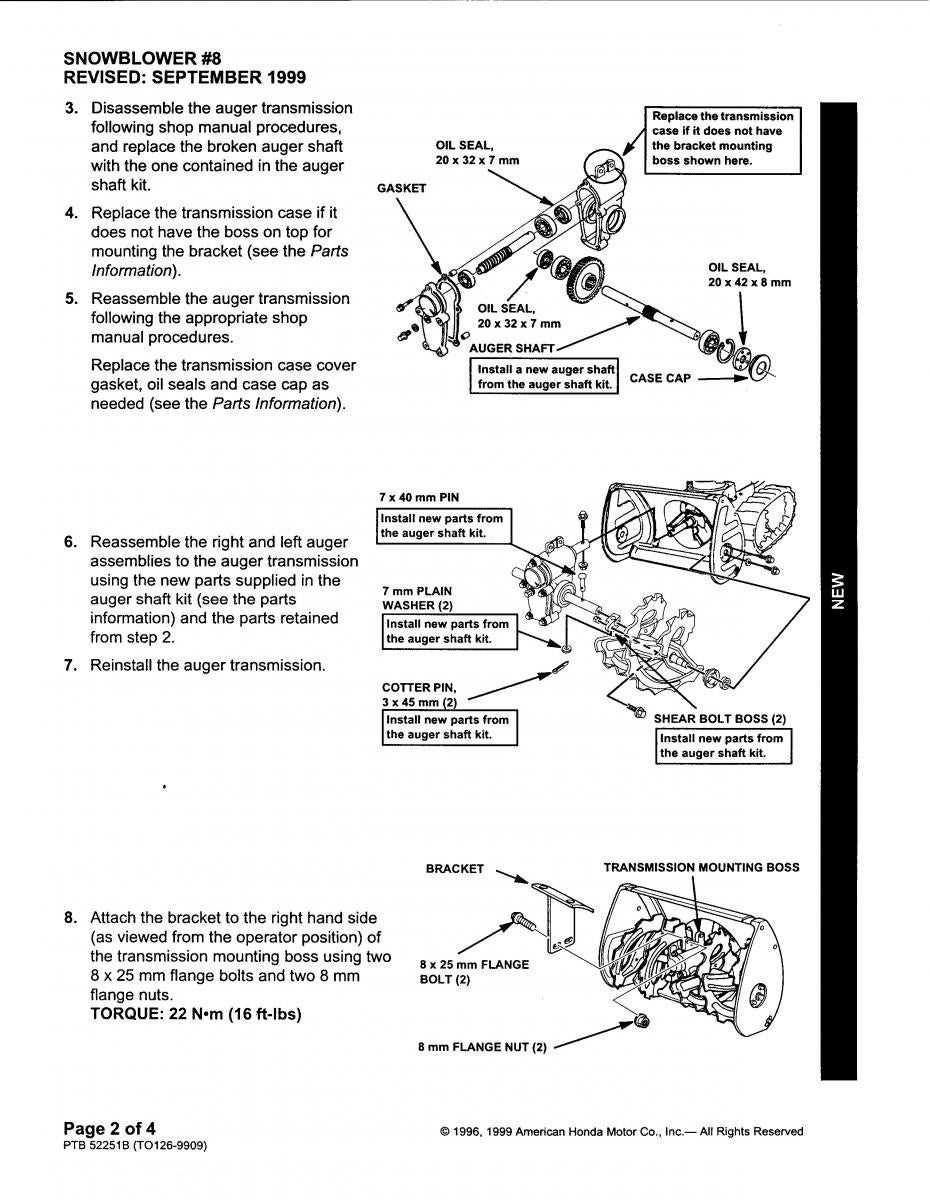

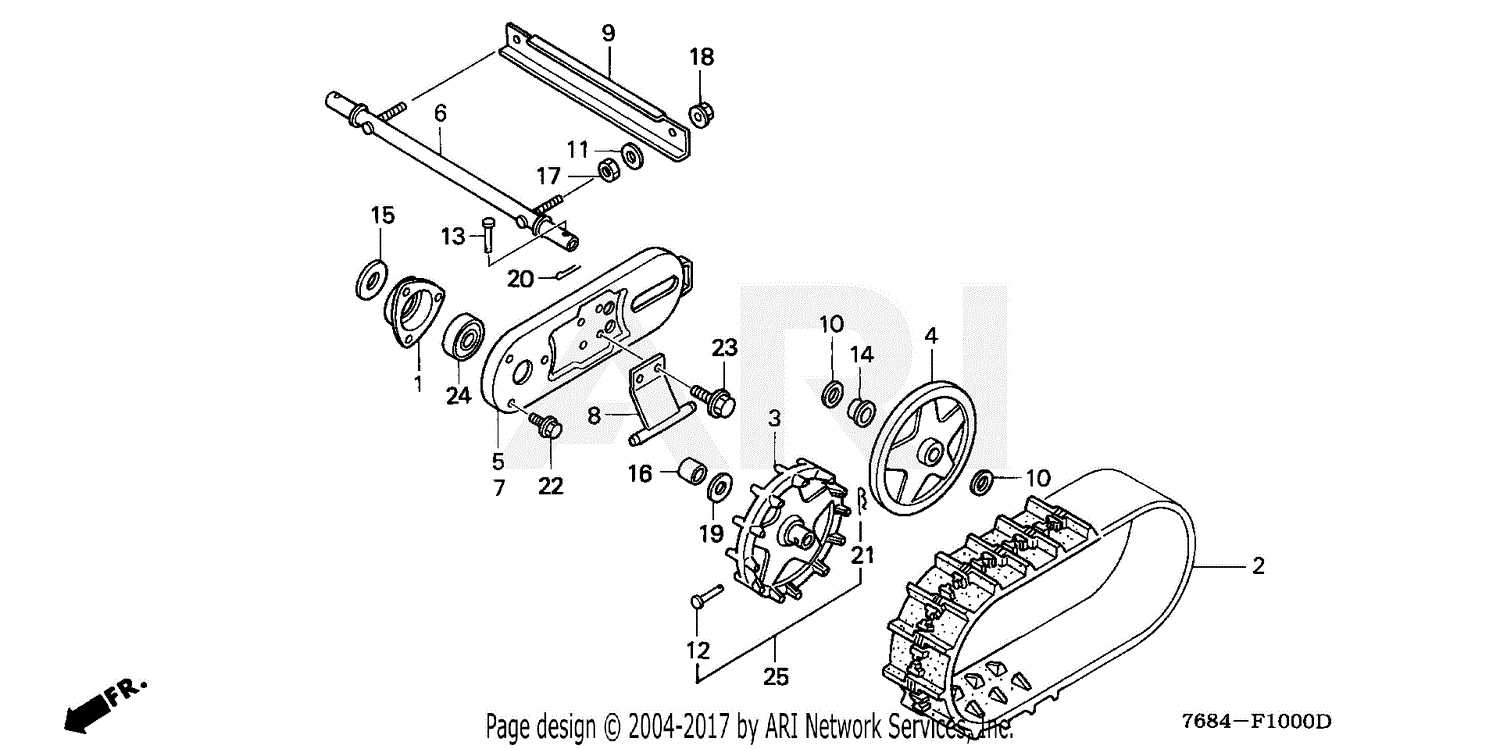

How to Replace the Auger Assembly

Replacing the auger assembly is a crucial maintenance task that ensures optimal performance of your snow removal equipment. This procedure involves carefully removing the old assembly and installing a new one, which can significantly enhance efficiency and effectiveness during operation. Proper execution of this task will not only prolong the lifespan of the machinery but also ensure a smoother snow clearing experience.

Begin by gathering the necessary tools, including wrenches, a socket set, and safety gloves. First, ensure the equipment is powered off and completely cool to avoid any accidents. Locate the screws or bolts securing the auger assembly, typically found on the front housing of the unit. Use the appropriate tools to carefully remove these fasteners.

Once the screws are removed, gently detach the old auger assembly from its housing. Be cautious of any cables or connections that may be attached. Inspect the area for any debris or damage before proceeding to the installation of the new assembly.

Position the new auger assembly into place, ensuring it aligns properly with the housing and any necessary connections. Reinsert the screws or bolts you previously removed, tightening them securely to guarantee a stable fit. After installation, double-check all connections and ensure everything is in its proper place.

Finally, perform a test run of the equipment to confirm that the new assembly functions correctly. This final step will help identify any potential issues before regular use, ensuring that your snow clearing tasks are carried out efficiently.

Engine Care and Performance Enhancement

Maintaining optimal engine function is crucial for ensuring longevity and efficiency. Proper attention to various components can lead to enhanced performance, reduced fuel consumption, and a more reliable operation. This section outlines essential practices for preserving engine health and maximizing output.

Regular oil changes are fundamental in preventing wear and tear. Fresh oil lubricates moving parts, minimizing friction and heat buildup. Additionally, using high-quality filters ensures that contaminants are kept at bay, promoting a cleaner internal environment.

Air intake systems should be inspected periodically. A clean air filter allows for better airflow, which is essential for combustion efficiency. Replacing a clogged filter can lead to noticeable improvements in throttle response and overall power.

Fuel quality also plays a significant role in performance. Using the recommended fuel type and keeping the fuel system clean can enhance combustion efficiency. Adding fuel additives designed to clean injectors and improve octane levels can further optimize engine performance.

Regular inspections of spark plugs and ignition systems are vital. Worn plugs can lead to misfires and reduced efficiency. Replacing them at recommended intervals ensures smooth ignition and better fuel economy.

Lastly, ensuring that the cooling system functions properly prevents overheating, which can cause serious damage. Checking coolant levels and inspecting hoses for leaks will contribute to stable operating temperatures and extended engine life.

Electrical System Diagnostics and Repair

The electrical system of any equipment is crucial for its functionality and efficiency. Diagnosing issues within this system requires a systematic approach to identify faults, ensure proper operation, and implement effective solutions. Understanding the components involved and utilizing the right techniques will facilitate accurate troubleshooting and restoration.

Common Electrical Issues

Identifying the most frequent electrical problems can streamline the diagnostic process. Here are some prevalent issues:

- Poor connections leading to intermittent operation

- Faulty switches that fail to engage

- Worn or damaged wiring causing shorts or breaks

- Defective components like relays and fuses

- Battery-related issues, such as low charge or corrosion

Diagnostic Procedures

To effectively diagnose electrical issues, follow these steps:

- Inspect all visible connections and wiring for signs of damage or corrosion.

- Test voltage at various points using a multimeter to ensure proper power flow.

- Check switches and relays for functionality by bypassing them temporarily.

- Examine components for signs of wear or failure, replacing any that do not meet specifications.

- Consult the schematic to trace circuits and pinpoint malfunctioning areas.

By systematically addressing these aspects, one can effectively resolve electrical issues and enhance the overall performance of the equipment.

Winter Preparation Checklist for HS928

As the cold months approach, ensuring your snow-clearing equipment is ready for action is essential. A comprehensive preparation checklist can help you tackle winter conditions efficiently and safely. By following these guidelines, you can ensure optimal performance throughout the snowy season.

Essential Maintenance Tasks

- Check the oil level and replace it if necessary.

- Inspect the fuel system for leaks or blockages.

- Examine the spark plug and replace it if worn out.

- Clean or replace the air filter to ensure proper airflow.

- Inspect the belts for wear and tension; adjust or replace as needed.

Operational Readiness

- Test the ignition system to confirm reliable starting.

- Ensure all lights and safety features are functional.

- Check the auger and impeller for any obstructions or damage.

- Lubricate moving parts to prevent freezing and ensure smooth operation.

- Familiarize yourself with the controls to enhance efficiency in use.

Safety Precautions During Repairs

When undertaking maintenance or troubleshooting tasks, adhering to safety measures is crucial to prevent accidents and ensure a smooth process. Proper preparation and awareness can significantly reduce the risk of injury and damage to equipment.

- Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and sturdy footwear.

- Ensure the work area is well-lit and free from clutter to minimize hazards.

- Disconnect power sources before starting any task to avoid electrical shocks.

- Familiarize yourself with the specific tools required for the job to use them effectively and safely.

- Keep a first aid kit nearby in case of emergencies.

Additionally, it’s essential to follow these guidelines:

- Read any provided instructions thoroughly before beginning work.

- Double-check that all tools are in good condition to prevent malfunctions.

- Work with a partner when handling heavy components to avoid strain or injury.

- Stay focused and avoid distractions during the maintenance process.

- Dispose of any waste materials properly to maintain a safe environment.

By prioritizing safety, individuals can ensure a more effective and secure experience while conducting their tasks.

Parts Replacement: Where to Buy

Finding the right components for your equipment can be a challenging task. Ensuring that you select high-quality parts from reliable sources is crucial for maintaining performance and longevity. Below are some recommended avenues for sourcing necessary replacements.

Online Retailers

- Specialized Websites: Numerous online platforms focus on outdoor machinery, providing a vast selection of parts.

- General E-commerce Sites: Websites like Amazon or eBay often have user reviews that can help assess the quality of components.

- Manufacturer Websites: Many manufacturers offer direct sales, ensuring authenticity and compatibility.

Local Suppliers

- Authorized Dealers: Visit local dealers who specialize in outdoor equipment; they often carry genuine parts.

- Hardware Stores: Local hardware stores may stock essential components or be able to order them for you.

- Repair Shops: Many repair facilities also sell parts, providing expertise on what you need.

By exploring these options, you can secure the parts necessary for efficient operation and maintenance of your equipment.

Understanding the Warranty and Support

When investing in outdoor power equipment, it’s essential to grasp the extent of the coverage and assistance provided by the manufacturer. This understanding not only ensures peace of mind but also empowers users to make informed decisions about maintenance and care.

Warranty coverage typically includes specific terms regarding repairs, parts replacement, and labor costs associated with defects in materials or workmanship. It’s crucial to familiarize yourself with the duration of the warranty and any conditions that might void it, such as improper use or lack of regular maintenance.

In addition to warranty details, customer support plays a vital role in enhancing the ownership experience. Access to knowledgeable representatives can help address inquiries about troubleshooting, recommended maintenance schedules, and parts ordering. Many manufacturers also offer online resources, such as FAQs and instructional videos, to assist users in getting the most out of their equipment.

Ultimately, understanding the scope of coverage and available assistance can help maximize the lifespan and performance of your equipment while ensuring a smooth ownership journey.

Upgrading Components for Improved Efficiency

Enhancing the performance of outdoor power equipment can significantly boost productivity and reduce operational costs. By focusing on specific elements, users can achieve greater efficiency and prolong the lifespan of their machinery. This section explores various upgrades that can make a substantial difference in functionality and reliability.

Engine Enhancements: Upgrading to a high-performance engine or modifying the existing one can lead to increased power output and better fuel consumption. Consider adding a performance air filter or a more efficient carburetor to optimize airflow and fuel delivery.

Improved Blades: Replacing standard blades with high-quality, sharpened alternatives can enhance cutting performance. Utilizing blades designed for specific tasks can improve efficiency and reduce the time spent on maintenance.

Transmission Upgrades: Enhancing the transmission system can lead to smoother operation and better torque management. Look for options that allow for easier gear shifts and improved power transfer to the wheels, which can significantly impact maneuverability and efficiency.

Maintenance Components: Regularly upgrading wear items such as belts, spark plugs, and filters is essential. High-grade replacements not only improve performance but also contribute to the overall reliability of the equipment.

Technology Integration: Incorporating modern technology, such as GPS tracking or smart diagnostics, can lead to improved operational efficiency. These systems can provide real-time data, enabling users to make informed decisions regarding maintenance and performance optimization.

By focusing on these enhancements, operators can achieve a more efficient and reliable experience, ensuring that their equipment remains at peak performance for years to come.