Ensuring optimal performance of your extended cutting instrument is essential for efficient tree trimming and maintenance tasks. This guide provides a comprehensive overview of the common issues that may arise with such tools and offers practical solutions to keep them in peak condition. Understanding the nuances of their construction and operation can significantly enhance your experience and prolong the lifespan of your equipment.

In the following sections, we will delve into various components and their functions, highlighting the importance of regular upkeep. By addressing wear and tear and recognizing signs of malfunction early, you can avoid costly repairs and improve safety during use. This resource aims to empower users with the knowledge needed to tackle maintenance challenges confidently.

Whether you are a seasoned professional or a casual user, familiarizing yourself with the intricacies of your cutting apparatus will enhance your skill set. With the right guidance, you can manage minor setbacks independently and ensure that your tool is always ready for action. Let’s explore the essential aspects of keeping your equipment in prime working condition.

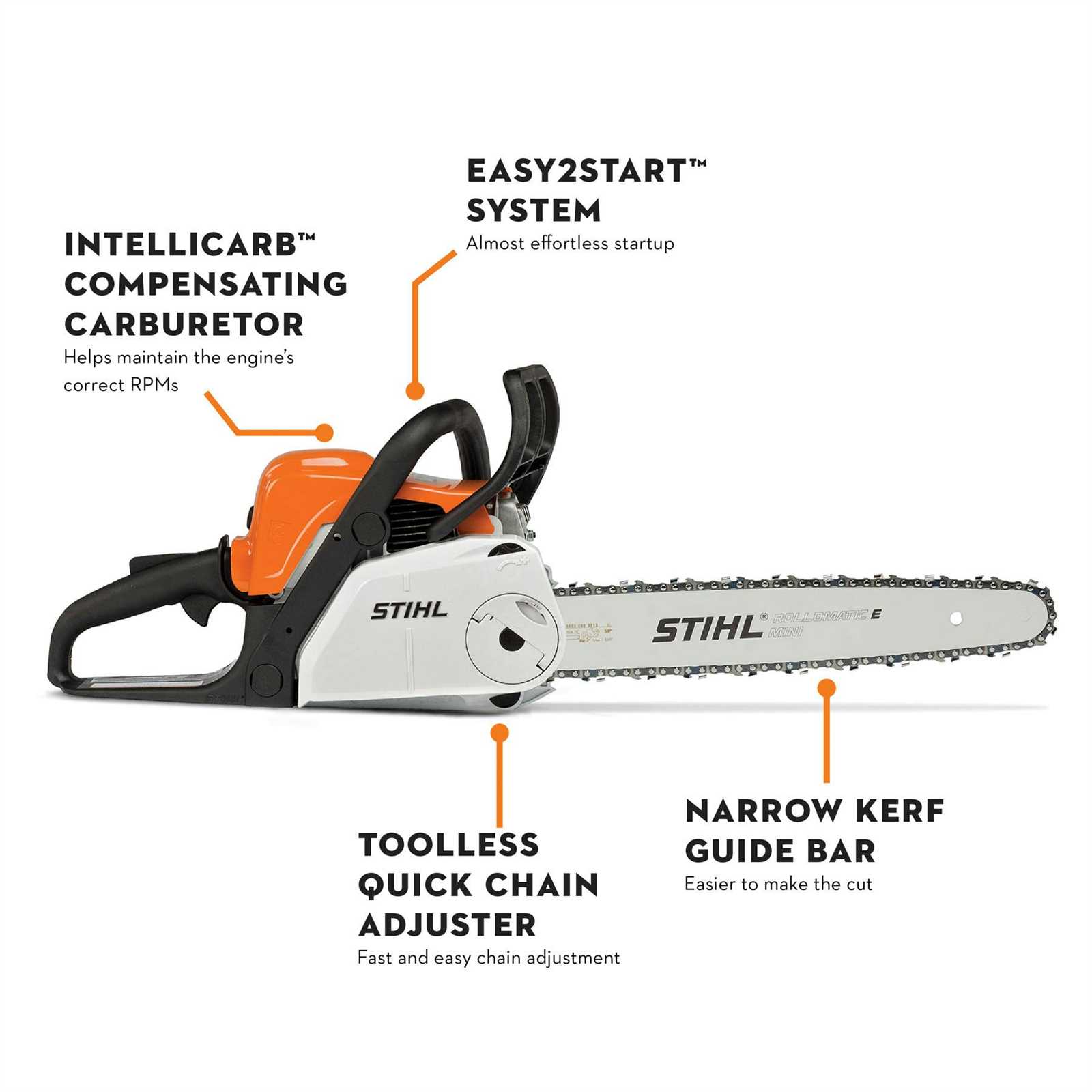

Understanding Your Stihl Pole Saw

Gaining insight into your cutting tool is essential for effective usage and longevity. Familiarity with its components and functions enhances performance and ensures safety during operations. This section will delve into the key features, maintenance tips, and operational guidance for optimal efficiency.

Key Components

- Engine: The powerhouse of the tool, providing the necessary energy for cutting.

- Bar: The extended part that supports the cutting mechanism, allowing for reach and precision.

- Chain: The moving element that performs the cutting action, essential for clean cuts.

- Handle: Provides grip and control, ensuring user comfort and safety.

Maintenance Tips

- Regularly check and clean the air filter to ensure optimal airflow.

- Keep the chain well-lubricated to prevent wear and tear.

- Inspect the bar for signs of damage or wear, replacing as necessary.

- Sharpen the cutting chain periodically for efficient performance.

Understanding these aspects will not only improve your experience but also prolong the life of your tool. Regular maintenance and knowledge of its components are key to successful operation.

Common Issues with Pole Saws

Working with long-reaching cutting tools can present a variety of challenges that users may encounter during operation. Understanding these frequent problems is essential for effective troubleshooting and maintenance. By being aware of potential difficulties, operators can ensure their equipment functions optimally and safely.

1. Engine Performance Problems: A common issue is the engine not starting or stalling during use. This can result from fuel-related issues, such as stale gasoline or clogged fuel filters. Regularly checking fuel quality and ensuring the fuel system is clean can help prevent these disruptions.

2. Chain Issues: Another prevalent concern involves the cutting chain. It may become dull or improperly tensioned, leading to inefficient cutting or increased wear on the tool. Regular sharpening and adjustment are vital for maintaining performance and prolonging the lifespan of the equipment.

3. Vibration and Noise: Excessive vibrations or unusual noises during operation can indicate underlying mechanical problems. Loose components or worn-out parts can contribute to these symptoms, necessitating thorough inspections and timely repairs to ensure safe operation.

4. Safety Features Malfunction: Safety mechanisms, such as throttle controls and chain brakes, are crucial for user protection. If these features fail to operate correctly, it poses a significant risk. Regular checks and servicing are important to maintain these safety systems.

5. Electrical Issues: In electric models, problems can arise with wiring or the power supply. A faulty connection or damaged cord can hinder performance. Regular visual inspections can help identify and rectify these issues before they escalate.

By staying informed about these common challenges, users can better prepare for maintenance needs, ensuring that their equipment remains efficient and safe for all cutting tasks.

Essential Tools for Repairs

When it comes to maintaining and fixing equipment, having the right instruments is crucial for ensuring efficiency and effectiveness. Proper tools not only facilitate the process but also enhance the longevity and performance of your machinery. This section highlights the fundamental devices that every enthusiast should have on hand for successful maintenance tasks.

Basic Toolkit Components

A well-rounded toolkit includes a variety of instruments designed to address different challenges. Here are some of the essential items you should consider:

| Tool | Purpose |

|---|---|

| Wrenches | For tightening and loosening bolts and nuts. |

| Screwdrivers | For assembling or disassembling components. |

| Pliers | For gripping, twisting, and cutting wires. |

| Socket Set | For handling various fasteners with ease. |

| Torque Wrench | To ensure fasteners are tightened to the correct specifications. |

Specialized Tools for Advanced Tasks

In addition to basic tools, having specialized instruments can greatly assist in more complex tasks. Here are a few that might be beneficial:

| Tool | Purpose |

|---|---|

| Multimeter | For diagnosing electrical issues. |

| Chain Tool | For adjusting and maintaining the cutting mechanism. |

| File | For sharpening blades and edges. |

| Fuel Mix Container | For proper storage and mixing of fuel. |

| Safety Gear | For personal protection during maintenance activities. |

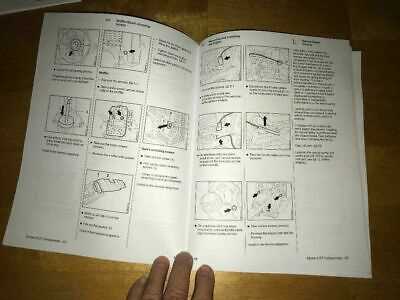

Step-by-Step Repair Process

This section provides a comprehensive guide to restoring your equipment effectively. Following a systematic approach ensures that each component is addressed properly, enhancing both functionality and longevity. The outlined steps will help you diagnose issues, replace worn parts, and ensure optimal performance.

Assessment and Diagnosis

The first step involves a thorough examination of the tool. Begin by inspecting the exterior for any visible damage or wear. Listen for unusual sounds during operation and note any performance irregularities. Keeping a detailed record of your findings will facilitate troubleshooting and streamline the subsequent steps.

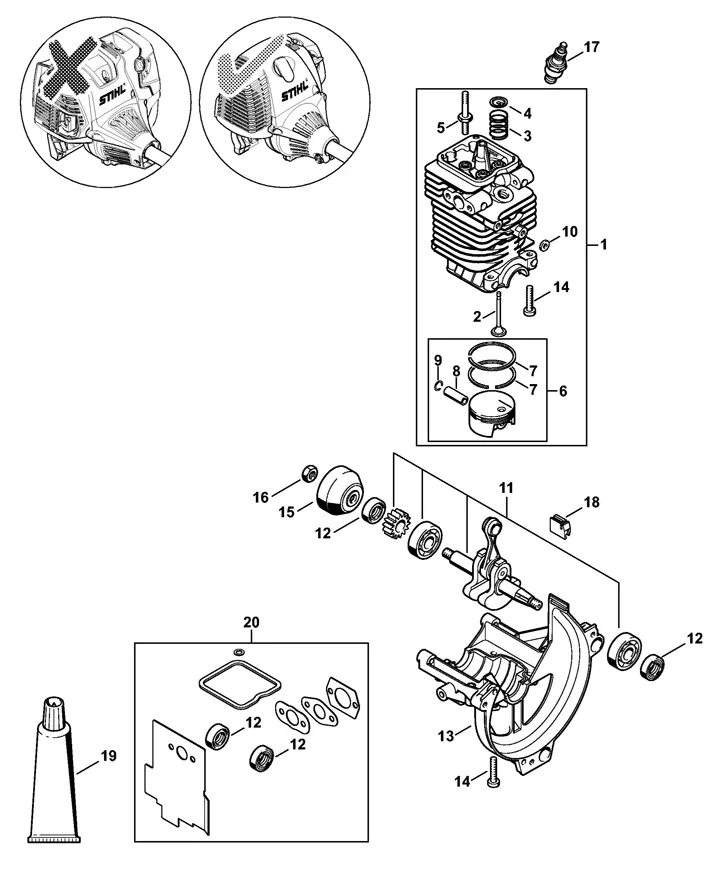

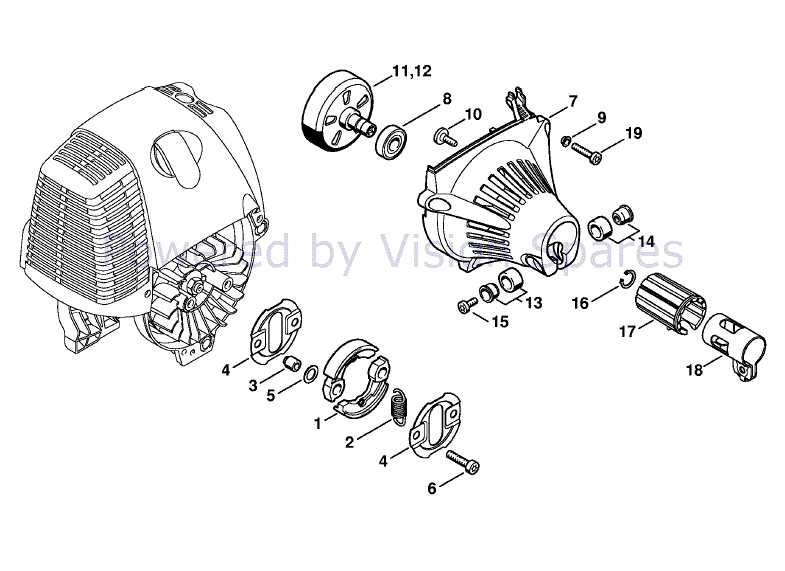

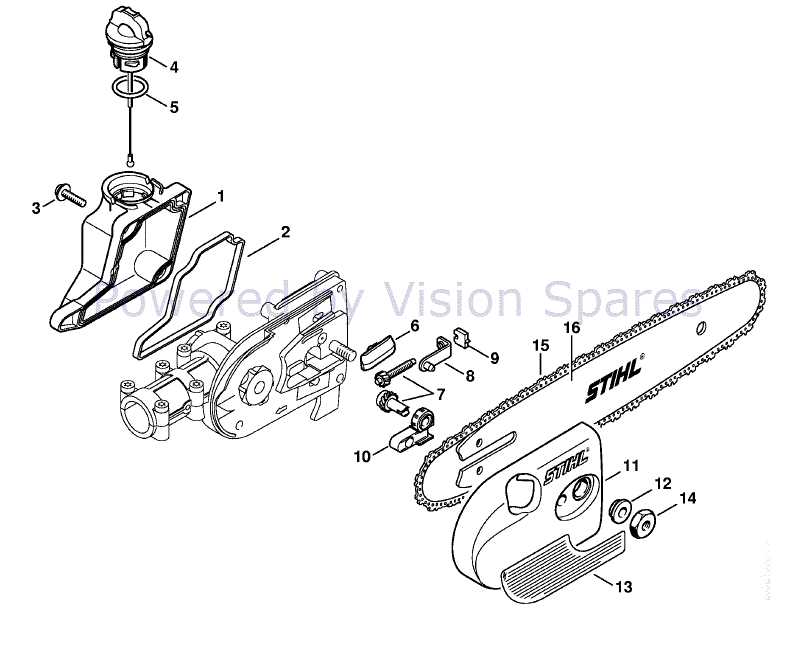

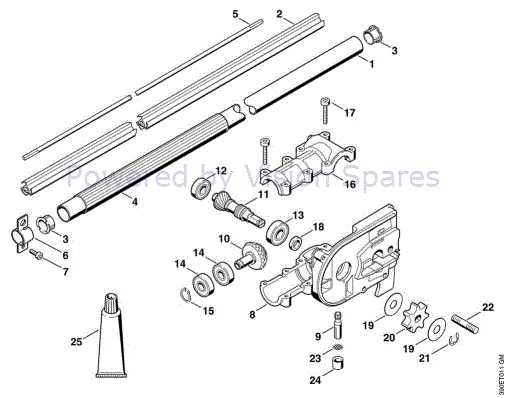

Disassembly and Component Inspection

Once the issues are identified, proceed to disassemble the unit carefully. Utilize appropriate tools to avoid damaging components. As you detach each part, inspect it for signs of wear or failure. Replace any compromised items with quality substitutes. Ensure all connections and fittings are clean and free of debris to maintain optimal functionality.

Reassembly should follow a reverse order of disassembly, ensuring that each part is securely in place. Conduct a final test to confirm that everything operates smoothly.

Maintaining Your Pole Saw

Regular upkeep is essential for ensuring the longevity and performance of your cutting tool. By adhering to a structured maintenance routine, you can enhance efficiency, reduce the risk of breakdowns, and ensure safety during operation. This section outlines key practices that will help keep your equipment in optimal condition.

Routine Inspections

Conducting frequent checks is crucial. Examine the apparatus for any signs of wear or damage. Look for frayed cables, loose fittings, or any unusual sounds during operation. Addressing minor issues promptly can prevent them from escalating into significant problems, ultimately saving you time and resources.

Cleaning and Lubrication

Keeping your tool clean is vital for its functionality. After each use, remove debris and dirt that can accumulate on the components. Additionally, ensure that all moving parts are adequately lubricated to minimize friction and enhance performance. Using appropriate cleaning agents and lubricants will significantly extend the life of your device.

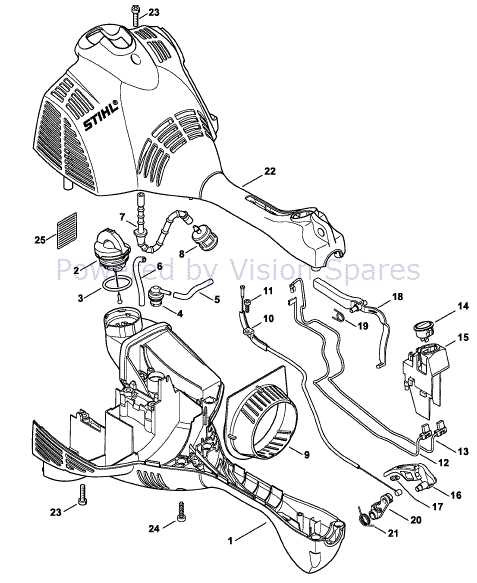

Identifying Parts and Components

Understanding the various elements and their functions is crucial for effective maintenance and troubleshooting of your equipment. Each piece plays a significant role in the overall operation, and recognizing these components can help in diagnosing issues more efficiently.

Main Body: The central structure houses essential mechanisms and serves as the foundation for assembly. It’s vital to inspect for any signs of wear or damage, as these can impact performance.

Power Unit: This element generates the necessary energy for operation. Familiarity with its specifications and maintenance requirements is essential for optimal functionality.

Cutting Mechanism: Comprising blades or other cutting tools, this part is crucial for the actual performance. Regular checks for sharpness and alignment can enhance cutting efficiency.

Handle: Designed for grip and control, the handle’s condition can affect user comfort and safety. Ensure it remains intact and free from cracks or excessive wear.

Safety Features: Equipped with various mechanisms to prevent accidents, these components must be regularly tested. Understanding their placement and function is key to maintaining a safe working environment.

By familiarizing yourself with these components, you can ensure your equipment remains in peak condition and address any issues promptly.

Safety Tips During Repairs

Ensuring safety while conducting maintenance tasks is paramount for both personal protection and the longevity of the equipment. Following proper precautions can help prevent accidents and facilitate a smoother workflow.

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and ear protection to shield yourself from debris and noise. |

| Work in a Well-Lit Area | Ensure your workspace is adequately illuminated to avoid missteps and enhance visibility of components. |

| Disconnect Power Source | Before starting any task, make sure to unplug or deactivate the power supply to prevent accidental startups. |

| Keep Workspace Organized | Maintain a tidy work area to minimize the risk of tripping or losing important parts. |

| Follow Instructions | Adhere to guidelines provided by the manufacturer to ensure proper handling and assembly. |

By following these guidelines, you can significantly reduce the risk of injury and ensure that your maintenance activities are conducted efficiently and safely.

How to Troubleshoot Problems

Identifying and resolving issues with your outdoor equipment can enhance performance and prolong its lifespan. This section provides a systematic approach to diagnosing common faults, ensuring you can effectively manage and rectify any challenges that arise during use.

Identifying Symptoms

Begin by observing any irregularities in operation. Unusual noises, erratic movement, or inconsistent power levels can indicate underlying problems. Careful monitoring of these symptoms is crucial in pinpointing the root cause. Documenting any changes in performance will aid in effective troubleshooting.

Common Issues and Solutions

Once symptoms are noted, compare them to typical issues that might occur. For instance, if the engine struggles to start, it may be due to fuel-related problems. Check fuel quality and ensure proper mixture ratios are maintained. For power loss, inspect air filters and spark plugs, as these components often affect efficiency. Taking a methodical approach allows for quicker resolution and less downtime.

When to Seek Professional Help

Understanding when to call in an expert can save you time, effort, and potential hazards. While many minor issues can be tackled independently, certain complications require specialized knowledge and experience. Recognizing the signs that indicate a need for professional intervention is crucial for maintaining equipment efficiently and safely.

| Signs Indicating Professional Help is Needed | Explanation |

|---|---|

| Persistent Malfunctions | If problems continue after basic troubleshooting, it may indicate deeper issues. |

| Unusual Noises | Strange sounds during operation often signal mechanical failure or misalignment. |

| Excessive Vibrations | Vibrations beyond normal levels can lead to further damage if not addressed. |

| Fuel or Oil Leaks | Leaks may pose safety hazards and indicate serious underlying problems. |

| Inconsistent Performance | Difficulty maintaining power or efficiency suggests a need for expert diagnostics. |

Taking the step to consult with a professional can ensure that your equipment operates at its best, extending its lifespan and enhancing safety for the user. Prioritize your well-being and the performance of your tools by recognizing these critical signs.

Resources for Further Assistance

When tackling maintenance and troubleshooting tasks, having access to reliable resources can make all the difference. This section provides a compilation of helpful tools, guides, and communities that can enhance your understanding and support your efforts in addressing issues effectively.

Online forums and discussion boards dedicated to gardening equipment often feature experienced users who share insights, tips, and solutions to common problems. These platforms can be invaluable for obtaining real-world advice and learning from the experiences of others.

Additionally, video tutorials on popular platforms can offer visual guidance, demonstrating step-by-step processes for various tasks. These resources can simplify complex procedures, making them more approachable for users of all skill levels.

Lastly, official manufacturer websites frequently provide downloadable documents that include detailed specifications, safety precautions, and troubleshooting tips. These documents can serve as a trustworthy reference to ensure proper handling and maintenance.