This section aims to provide an in-depth understanding of the necessary procedures for maintaining and troubleshooting specific equipment. Ensuring optimal performance is crucial, and having a solid grasp of the components involved will empower users to address common issues effectively.

Knowledge of various parts and their functions plays a vital role in the upkeep of machinery. By familiarizing oneself with each element, operators can quickly identify potential problems and implement appropriate solutions.

Furthermore, step-by-step instructions and best practices will be highlighted to assist users in achieving the ultimate reliability and longevity of their devices. This guide serves as a valuable resource for both novice and experienced individuals seeking to enhance their understanding and skills in equipment maintenance.

Overview of Craftsman ZTS 7500

This section provides a comprehensive understanding of a specific model known for its versatility and robust design, ideal for various tasks and maintenance needs.

The featured unit is characterized by several key features:

- Powerful engine suitable for heavy-duty applications

- Ergonomic controls for enhanced user experience

- Durable construction ensuring longevity

- Wide range of attachments and accessories available

Users can expect optimal performance in diverse environments, making this model a preferred choice among enthusiasts and professionals alike.

Regular upkeep is essential to maintain efficiency and prolong the lifespan of the equipment. Key maintenance tips include:

- Routine inspections of moving parts

- Frequent cleaning to prevent debris accumulation

- Timely oil changes to ensure smooth operation

By adhering to these guidelines, users can maximize the potential of this versatile tool.

Common Issues and Troubleshooting Tips

When working with outdoor power equipment, users may encounter various challenges that can hinder performance. Understanding these common problems and knowing how to address them can significantly enhance the longevity and efficiency of the device.

| Issue | Description | Troubleshooting Steps |

|---|---|---|

| Starting Problems | The equipment fails to start or run smoothly. |

|

| Overheating | The unit becomes excessively hot during operation. |

|

| Strange Noises | Unusual sounds during operation may indicate an issue. |

|

| Poor Performance | Equipment does not operate at expected levels. |

|

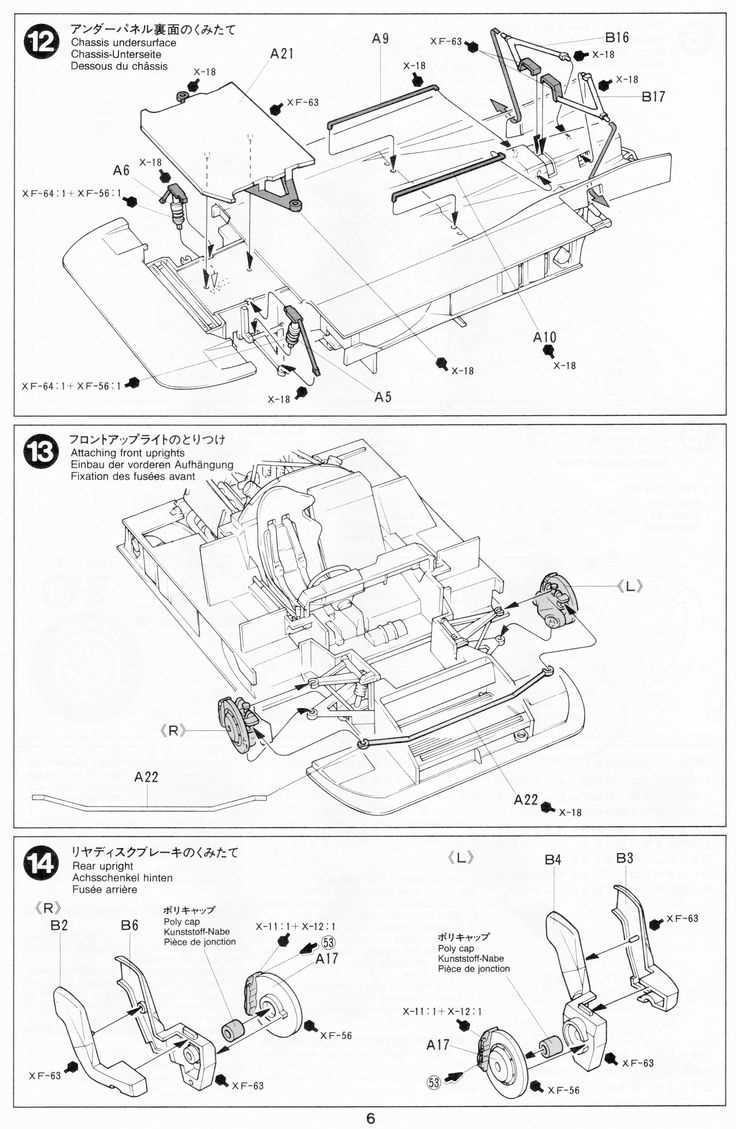

Step-by-Step Repair Process

This section outlines a systematic approach to addressing issues with your equipment. By following these clearly defined stages, you can effectively troubleshoot and resolve common problems that may arise during operation.

1. Identification of the Issue: Begin by observing the symptoms that indicate something is wrong. Take note of any unusual noises, performance drops, or error messages. Understanding the specific problem is crucial for determining the right course of action.

2. Gathering Tools and Materials: Before starting, ensure you have all necessary tools and replacement parts at hand. This preparation will streamline the process and minimize interruptions during the work.

3. Disassembly: Carefully take apart the relevant components to gain access to the affected area. Keep track of screws and small parts to avoid losing them. A methodical approach will help ensure that reassembly is straightforward.

4. Inspection: Examine the disassembled parts for signs of wear, damage, or malfunction. Pay close attention to any components that appear faulty and may need replacing or repairing.

5. Execution of Repairs: Based on your inspection, proceed with the necessary repairs. This may involve replacing parts, tightening connections, or cleaning components to restore functionality.

6. Reassembly: Once the repairs are completed, carefully put all parts back together. Ensure that everything is secured properly and in its designated place to prevent future issues.

7. Testing: After reassembly, conduct a thorough test of the equipment to verify that it is functioning as intended. Monitor for any recurring issues and address them promptly if they arise.

8. Documentation: Finally, keep a record of the work performed, including any parts replaced or repairs made. This documentation can be valuable for future reference and maintenance.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for effective maintenance and troubleshooting. Whether tackling minor adjustments or more complex fixes, a well-stocked toolkit can significantly ease the process and improve outcomes.

Basic Hand Tools

Every toolkit should include fundamental hand tools such as screwdrivers, wrenches, and pliers. These essentials are versatile and can address a variety of tasks. A good set of screwdrivers in different sizes and types will ensure you can handle both standard and specialized fasteners, while wrenches provide the leverage needed for tightening or loosening nuts and bolts.

Power Equipment

In addition to hand tools, incorporating power equipment can enhance efficiency. Items like electric drills and saws allow for quicker, more precise work. When selecting power tools, consider their ergonomics and durability, as these factors will affect your overall experience and effectiveness during maintenance tasks.

Maintenance Guidelines for Longevity

Ensuring the prolonged functionality of your equipment requires regular upkeep and attention. By following specific maintenance practices, you can enhance performance and extend the lifespan of your machinery. These guidelines offer a systematic approach to caring for your device, enabling it to operate efficiently over time.

Regular Cleaning

- Remove debris and dirt from the exterior and interior components.

- Use appropriate cleaning agents to avoid damage to sensitive parts.

- Inspect and clean filters regularly to maintain optimal airflow.

Routine Inspections

- Check fluid levels, including oil and coolant, and top off as needed.

- Inspect belts and hoses for signs of wear and replace them promptly.

- Ensure all connections are secure to prevent leaks and failures.

By adhering to these guidelines, you can help maintain your equipment in excellent working condition, ensuring reliability and efficiency for years to come.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines can create a secure environment and facilitate efficient work. It is essential to be aware of potential hazards and take proactive measures to mitigate risks.

First and foremost, always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and sturdy footwear. This attire acts as a barrier against sharp objects and harmful substances. Additionally, keep the workspace organized and free from clutter to minimize the chance of tripping or falling.

Before beginning any work, disconnect the power source to eliminate electrical hazards. Use tools and equipment that are in good condition to avoid malfunctions that could lead to injuries. Familiarize yourself with the operation of tools to ensure they are used safely and effectively.

Finally, if uncertain about any procedures or if facing unexpected issues, consult a knowledgeable individual or reference reliable resources. It is better to seek guidance than to risk safety by attempting something beyond one’s expertise.

Parts Replacement and Compatibility

When maintaining and servicing equipment, understanding the process of component substitution is crucial. Ensuring that each part is suitable and compatible with the specific model enhances performance and longevity. Various elements may require attention, ranging from belts and blades to electrical components and housing.

To successfully replace parts, it is essential to verify compatibility with existing specifications. This can often involve consulting manufacturers’ guidelines or utilizing parts databases that provide detailed compatibility information. Careful selection of components not only prevents malfunctions but also optimizes the overall functionality of the machinery.

Additionally, utilizing original parts is generally recommended, as they are designed to fit precisely and function optimally with the system. However, high-quality aftermarket alternatives can also be viable, provided they meet the necessary standards. Always ensure that replacements are thoroughly vetted to avoid any compatibility issues that could lead to premature wear or damage.

Understanding Electrical Components

Electrical elements form the backbone of any device, playing a crucial role in its functionality. Grasping the basics of these components enables users to troubleshoot issues, perform maintenance, and enhance overall performance. This section delves into key elements commonly found in various systems.

Types of Electrical Components

Different components serve specific purposes within electrical systems. Recognizing their roles helps in understanding how they interact and contribute to the device’s operation.

| Component | Function |

|---|---|

| Resistor | Limits the flow of electric current |

| Capacitor | Stores and releases electrical energy |

| Diode | Allows current to flow in one direction |

| Transistor | Acts as a switch or amplifier |

Importance of Proper Functioning

Each component’s optimal operation is essential for the overall efficiency of the system. Understanding how to identify malfunctioning parts can lead to timely repairs and prolonged equipment lifespan.

Hydraulic System Overview and Repair

The hydraulic system is a vital component that facilitates the movement and operation of various mechanisms. Understanding its functionality and maintenance requirements is crucial for optimal performance. This section provides insights into the key elements of the hydraulic setup and guidelines for troubleshooting and service.

Key Components of the Hydraulic System

- Hydraulic Fluid: The lifeblood of the system, enabling power transmission.

- Pump: Converts mechanical energy into hydraulic energy, generating flow.

- Actuators: Components that convert hydraulic energy into mechanical movement.

- Valves: Control the flow and direction of hydraulic fluid throughout the system.

- Reservoir: Stores hydraulic fluid and allows for heat dissipation.

Common Issues and Solutions

- Fluid Leaks: Inspect hoses and connections regularly. Replace damaged parts promptly.

- Low Fluid Levels: Check the reservoir frequently and refill as needed to prevent air from entering the system.

- Pump Malfunction: Listen for unusual noises and monitor pressure. If issues arise, consider pump replacement or servicing.

- Blocked Filters: Regularly clean or replace filters to ensure proper fluid flow and system efficiency.

By maintaining these components and addressing common issues promptly, you can enhance the longevity and effectiveness of the hydraulic system. Regular inspections and proactive measures are essential to avoid significant malfunctions.

Engine Care and Troubleshooting

Maintaining optimal performance of an engine is crucial for its longevity and reliability. Regular inspection and addressing potential issues can prevent major malfunctions. This section provides insights into essential maintenance practices and common troubleshooting techniques that can enhance the functionality of your machinery.

Routine Maintenance Practices

To ensure smooth operation, implement the following maintenance activities:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours of use | Replace old oil to prevent buildup and ensure lubrication. |

| Air Filter Inspection | Every 25 hours of use | Check for dirt and debris; clean or replace as needed. |

| Spark Plug Replacement | Every 100 hours of use | Replace worn plugs to ensure efficient ignition. |

| Fuel System Cleaning | Every 50 hours of use | Clear the fuel lines and filter to avoid clogs. |

Troubleshooting Common Issues

Identifying and resolving issues promptly can save time and costs. Consider these common problems and their solutions:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Engine Won’t Start | Fuel supply issue | Check fuel levels and lines for blockages. |

| Unusual Noises | Loose components | Inspect and tighten bolts and screws. |

| Overheating | Insufficient coolant | Ensure proper coolant levels and check for leaks. |

| Excessive Smoke | Poor combustion | Check spark plugs and adjust fuel mixture. |

Customer Service and Support Resources

Accessing reliable assistance and support is crucial for users seeking help with their devices. Whether it’s troubleshooting issues, seeking advice on maintenance, or understanding product features, a variety of resources are available to ensure a smooth experience. This section highlights key support options to enhance user satisfaction and address common concerns.

Contacting Support

For direct assistance, reaching out to customer support is often the most effective route. Users can contact representatives via phone or online chat, where trained professionals are ready to provide guidance and solutions. Ensuring that you have your product details on hand will facilitate a more efficient support experience.

Online Resources

In addition to personal support, numerous online resources can help users navigate common challenges. Official websites typically feature comprehensive FAQs, instructional videos, and downloadable guides. Community forums also offer valuable insights, as fellow users share their experiences and solutions.

Frequently Asked Questions About Repairs

This section addresses common inquiries related to maintenance and troubleshooting of various equipment. It aims to provide clarity and assist users in resolving typical issues they may encounter during the upkeep process.

What are the common symptoms of malfunction?

Users often report unusual noises, decreased performance, or failure to start as primary indicators of a problem. Recognizing these signs early can help prevent further damage and facilitate easier solutions.

How can I perform basic troubleshooting?

Begin by checking the power source and ensuring all connections are secure. Inspect for visible wear or damage and consult the provided guidelines for specific diagnostic steps. Document any unusual findings to assist in further assessments.