Ensuring the optimal performance of your outdoor machinery is essential for maintaining a beautiful and healthy garden. This section provides comprehensive insights and step-by-step instructions designed to help you troubleshoot common issues and perform essential maintenance tasks. Understanding your equipment’s mechanics can significantly enhance its longevity and efficiency.

Regular upkeep is key to preventing potential breakdowns and ensuring your equipment operates smoothly. Whether you are dealing with minor adjustments or more complex procedures, having the right knowledge at your fingertips can make all the difference. From basic checks to more involved interventions, every piece of information contributes to a seamless gardening experience.

Following a structured approach to maintenance not only saves time but also enhances the performance of your machinery. By equipping yourself with the necessary techniques and understanding, you can tackle challenges head-on and keep your garden tools in prime condition. Let’s delve into the vital aspects of maintaining your gardening equipment effectively.

This section provides an insightful look into a versatile gardening machine that has become essential for many homeowners. Known for its efficiency and ease of use, this equipment simplifies the task of maintaining outdoor spaces. Understanding its features and functions can enhance your gardening experience significantly.

Key aspects include:

- Engine Specifications: An overview of power options and performance metrics.

- Cutting Mechanisms: Types of blades and their impact on grass health.

- Maintenance Requirements: Regular upkeep tasks to ensure longevity.

- Safety Features: Built-in systems designed to protect the user during operation.

- Accessories and Attachments: Additional tools that can enhance functionality.

By familiarizing yourself with these components, you can maximize the utility of this equipment and ensure it operates smoothly for years to come.

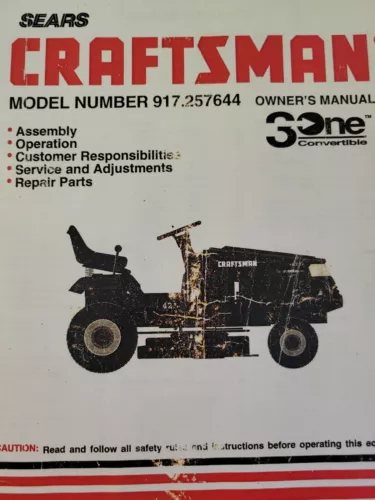

Common Issues with Lawn Tractors

Maintaining a garden vehicle can often lead to various challenges that users may encounter over time. Understanding these common problems can help in effective troubleshooting and maintenance, ensuring optimal performance throughout the seasons.

Engine Problems

One of the most frequent issues involves the engine. It may fail to start, run poorly, or produce unusual noises. Regularly checking the fuel supply, spark plugs, and air filters can significantly mitigate these concerns. Neglecting these components can lead to reduced efficiency and potential breakdowns.

Cutting Mechanism Malfunctions

The cutting system may also experience difficulties, such as uneven grass trimming or complete failure. This could be attributed to dull blades or a clogged deck. Ensuring that the blades are sharp and the deck is clean will promote a smoother operation. Periodic maintenance in these areas can prevent many common problems from arising.

Essential Tools for Repair

When maintaining outdoor equipment, having the right instruments is crucial for effective servicing and troubleshooting. These essential implements not only enhance efficiency but also ensure that tasks are completed safely and accurately.

Basic Hand Tools

A reliable set of hand tools forms the foundation of any maintenance toolkit. Items such as wrenches, screwdrivers, and pliers are indispensable for loosening or tightening various components. A quality socket set can also provide versatility when tackling different sizes of fasteners.

Power Tools and Equipment

For more demanding tasks, power tools can significantly reduce the time and effort required. A cordless drill is particularly useful for making quick adjustments and modifications. Additionally, a reliable air compressor can assist with inflation and cleaning tasks, making it a valuable addition to your toolkit.

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment is essential for optimal performance and longevity. Following a structured approach to maintenance not only enhances efficiency but also prevents potential issues that could arise from neglect. This section outlines systematic procedures to ensure your machine operates smoothly.

1. Check the Fluid Levels

Begin by inspecting the oil, fuel, and coolant levels. Ensure they are within the recommended ranges, as proper fluid levels are crucial for effective operation. If any fluid is low, refill it accordingly, using the appropriate types as specified in your guidelines.

2. Clean the Air Filter

A clean air filter is vital for maintaining engine performance. Remove the filter and check for dirt or debris. If it appears clogged, clean it according to the manufacturer’s instructions or replace it if necessary to ensure a steady airflow.

3. Inspect the Blades

Regularly examine the cutting blades for sharpness and wear. Dull or damaged blades can affect performance and result in uneven cutting. Sharpen or replace them as needed to maintain effective operation.

4. Check the Battery

Inspect the battery connections for corrosion and ensure they are secure. Clean any buildup and check the charge level. A well-maintained battery is crucial for reliable starting and operation.

5. Lubricate Moving Parts

Lubrication of all moving components helps reduce friction and wear. Use the recommended lubricants on pivot points, wheels, and any other areas specified in the guidelines. This practice will prolong the life of your machinery.

6. Examine Tires

Ensure the tires are properly inflated and free of any visible damage. Regularly checking the tire pressure helps maintain traction and stability during operation.

By adhering to these maintenance steps, you can significantly enhance the performance and durability of your equipment. Regular attention to these tasks ensures that your machine remains reliable and efficient for all your needs.

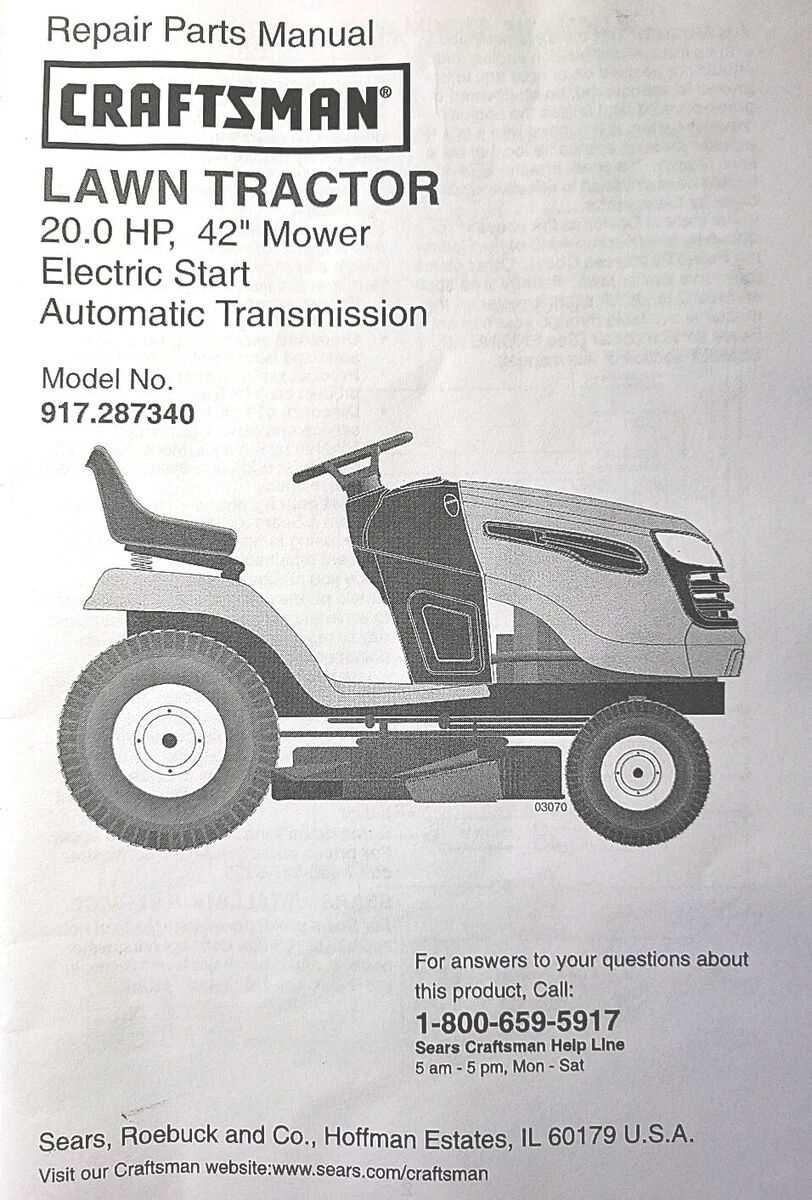

Understanding the Engine Components

Engines are intricate machines that convert fuel into motion, relying on various elements to operate efficiently. Grasping the function of these components is crucial for maintaining performance and troubleshooting issues. Each part plays a significant role in ensuring the engine runs smoothly, from power generation to overall efficiency.

Main Components

Key elements of an engine include the cylinder, piston, crankshaft, and camshaft. Each of these components interacts harmoniously to facilitate the combustion process and convert energy into mechanical work. Understanding their functions can help diagnose problems and enhance performance.

Component Functionality

The following table outlines the primary components and their respective functions:

| Component | Function |

|---|---|

| Cylinder | Holds the piston and is where combustion occurs. |

| Piston | Moves up and down within the cylinder, creating pressure from combustion. |

| Crankshaft | Transforms the linear motion of the piston into rotational motion. |

| Camshaft | Controls the opening and closing of the engine’s valves, regulating airflow. |

Familiarity with these components enhances understanding of engine operation and assists in effective maintenance and problem-solving.

Electrical System Troubleshooting

This section provides guidance on diagnosing and resolving issues related to the electrical components of your equipment. Proper troubleshooting ensures optimal performance and can prevent further complications. Understanding the common signs of electrical failure is essential for effective maintenance.

Begin your troubleshooting by examining the following components:

- Batteries: Check for signs of corrosion and ensure connections are secure.

- Wiring: Inspect for frayed wires or loose connections that may disrupt power flow.

- Fuses: Replace any blown fuses and verify the rating matches the specifications.

- Switches: Test the functionality of switches to ensure they are operating correctly.

When conducting your assessment, consider these steps:

- Disconnect the battery before performing any inspections.

- Utilize a multimeter to check voltage levels across various components.

- Document any irregular readings to identify potential faults.

- Refer to the equipment’s specifications for proper voltage and amperage requirements.

If problems persist, further investigation into the electrical system’s components may be necessary. Addressing issues promptly can prolong the lifespan of your equipment and enhance its efficiency.

Hydraulic System Care Tips

Maintaining the hydraulic system of your equipment is crucial for ensuring optimal performance and longevity. Regular attention to this system helps prevent potential issues that can lead to costly repairs and downtime.

Regular Inspection

- Check for leaks around hoses and connections.

- Inspect fluid levels frequently and top off as needed.

- Look for signs of wear or damage on components.

Fluid Maintenance

- Use the recommended hydraulic fluid for your system.

- Change the fluid at regular intervals to prevent contamination.

- Monitor the fluid’s color and consistency, replacing it if it appears cloudy or dark.

By following these tips, you can enhance the efficiency of your hydraulic system and extend its lifespan.

Seasonal Preparation Guidelines

Preparing your equipment for different times of the year is essential to ensure optimal performance and longevity. By following a few simple steps, you can safeguard your machinery against seasonal wear and ensure it operates smoothly when needed.

Spring Maintenance Tasks

As the warmer months approach, it’s vital to inspect and service your equipment. Begin by checking the fluid levels, including oil and coolant, and replace any filters that may be clogged. Sharpening the cutting elements is crucial for effective operation, as this enhances performance and prevents unnecessary strain on the engine. Additionally, clean the exterior to remove any debris accumulated during the winter months.

Fall Preparation Steps

Before the colder weather sets in, take time to prepare your machinery for storage. Drain any remaining fuel to prevent deterioration, and apply protective oils to vulnerable parts to combat rust. Inspect the battery and clean any terminals to ensure reliable starting in the spring. Lastly, store the equipment in a dry, sheltered location to protect it from the elements.

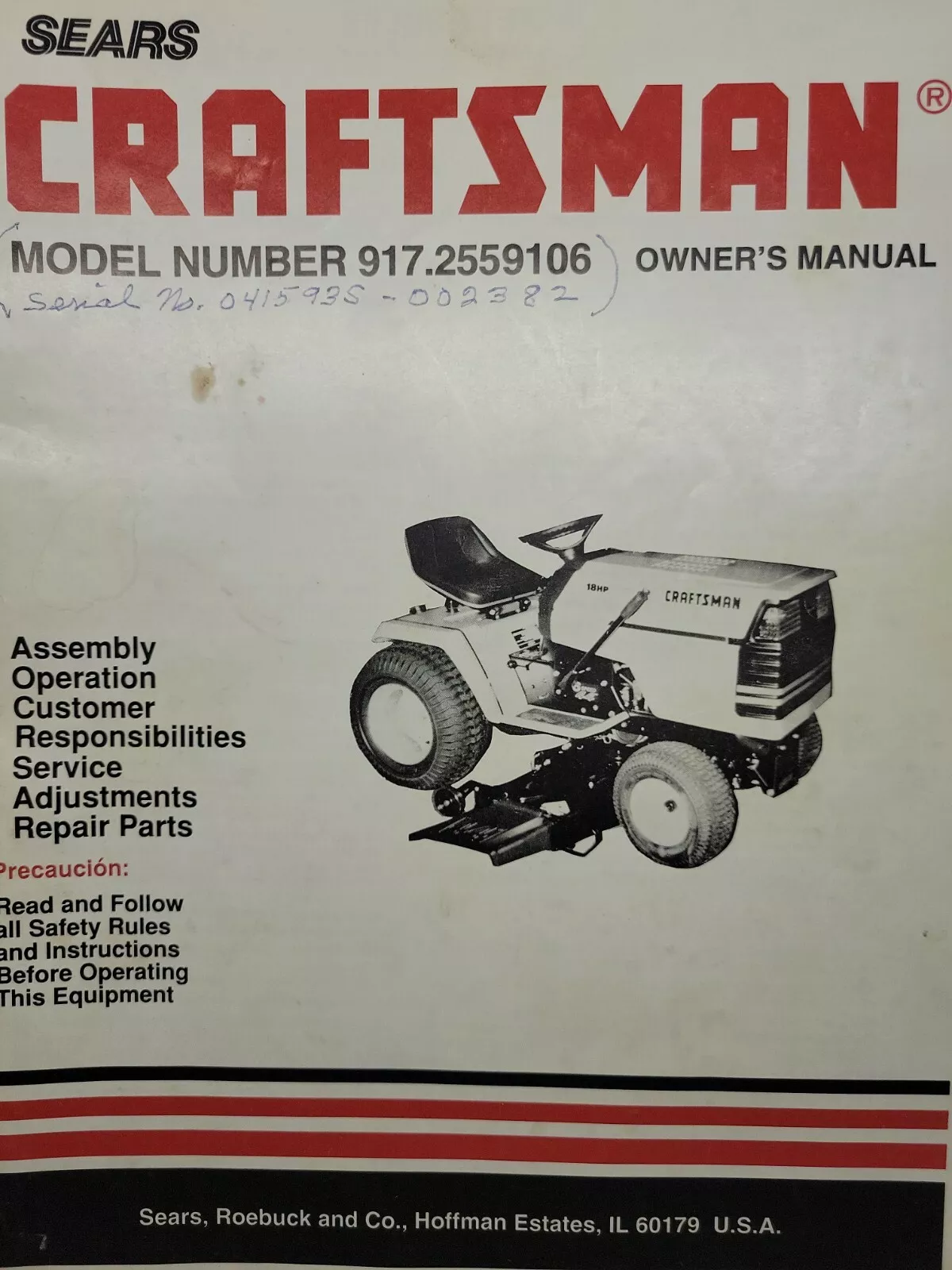

Finding Replacement Parts Easily

Locating suitable components for your equipment can be a straightforward task with the right approach. Many enthusiasts face challenges in sourcing the correct items due to the variety of options available in the market. However, a systematic method can simplify this process significantly.

First, it is essential to identify the specific part number associated with the component you need. This can often be found in the original documentation or online databases dedicated to equipment specifications. By having the exact identifier, you can avoid confusion and ensure compatibility.

Next, explore multiple sources for purchasing these components. Online retailers, local hardware stores, and specialized suppliers often have a vast inventory. Websites that focus on parts for various equipment can be particularly useful, as they provide detailed descriptions and images to assist in your selection.

Additionally, consider joining forums or communities dedicated to enthusiasts of similar machinery. These platforms can be a treasure trove of information, where experienced users share tips on where to find reliable components and offer recommendations based on their experiences.

In summary, by utilizing part numbers, exploring various suppliers, and engaging with knowledgeable communities, you can effortlessly track down the necessary components to keep your equipment running smoothly.

Best Practices for Safe Operation

Ensuring safety during operation is essential for preventing accidents and injuries. Adopting proper techniques and following guidelines can significantly enhance the experience while minimizing risks. This section outlines effective strategies for safe usage, emphasizing the importance of preparation and awareness.

Pre-Operational Checks

Before engaging in any activity, it is crucial to conduct thorough inspections. These checks help identify potential issues and ensure that the equipment is functioning correctly. Here are key elements to assess:

| Check Item | Description |

|---|---|

| Fluid Levels | Ensure oil, fuel, and coolant levels are adequate. |

| Tires | Inspect for proper inflation and tread wear. |

| Belts and Cables | Examine for signs of wear or damage. |

| Safety Features | Verify that all safety guards and features are in place. |

Safe Operating Techniques

Practicing safe operating techniques is vital for reducing the risk of accidents. Here are several recommendations to follow:

- Always wear appropriate personal protective equipment, such as gloves and eye protection.

- Maintain a clear work area free from obstacles and hazards.

- Follow the manufacturer’s guidelines for operation and maintenance.

- Be aware of your surroundings, especially when working near others or in tight spaces.

- Never bypass safety features or operate under the influence of alcohol or drugs.

Customer Support and Resources

This section provides valuable information on available assistance and materials for users seeking guidance with their equipment. Accessing the right resources can significantly enhance the experience and ensure proper usage.

For troubleshooting and maintenance inquiries, customers can reach out to dedicated support teams through various channels, including phone and email. These professionals are equipped to address common issues and provide tailored solutions based on individual needs.

Additionally, an extensive range of online resources is available, featuring instructional videos, FAQs, and forums where users can share experiences and tips. Utilizing these platforms can help in finding quick answers and connecting with fellow users who may have encountered similar challenges.

Finally, users are encouraged to consult the documentation provided at the time of purchase. This material often contains essential information regarding product features and best practices for optimal performance.