Ensuring optimal performance of your small engine requires a thorough understanding of its components and systems. This section serves as a comprehensive resource for enthusiasts and technicians alike, offering insights into the intricacies of upkeep and common issues faced by users. With the right knowledge, anyone can tackle minor complications effectively and enhance the longevity of their equipment.

From identifying typical symptoms of malfunction to executing step-by-step solutions, this guide emphasizes practical approaches to keep your machinery in top shape. Each topic is designed to empower users with the confidence to undertake essential tasks, fostering a hands-on attitude towards maintenance.

As you delve into this material, you will discover various strategies and techniques aimed at simplifying the diagnostic process. By familiarizing yourself with the inner workings, you will be better equipped to address challenges and enjoy uninterrupted operation. Embrace this journey of learning, and ensure your engine continues to deliver peak performance.

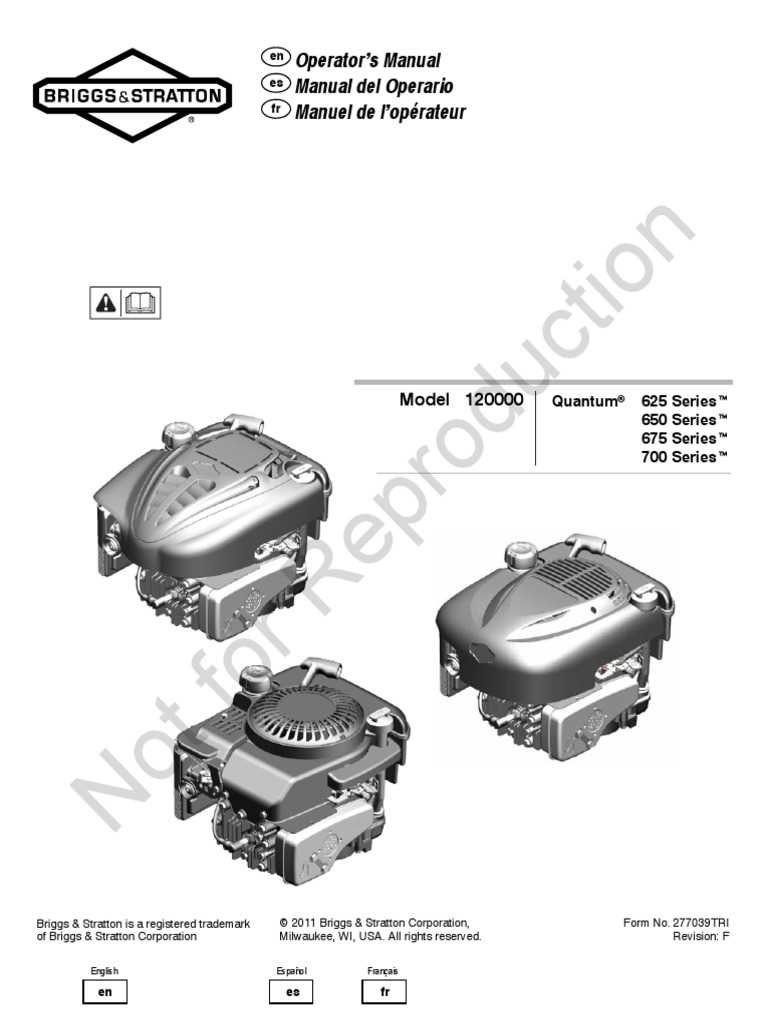

Understanding Briggs and Stratton 675 Series

This section delves into the intricacies of a well-regarded power equipment engine, exploring its components, functionality, and common issues. Knowledge of this engine is essential for enthusiasts and professionals alike who wish to ensure optimal performance and longevity.

Key Features

- Efficient fuel consumption for extended operation

- Robust construction designed for durability

- Ease of maintenance and accessibility of parts

- Versatile applications in various outdoor equipment

Common Components

- Cylinder Head: Essential for combustion efficiency.

- Piston: Responsible for creating the power stroke.

- Crankshaft: Converts linear motion into rotational energy.

- Air Filter: Ensures clean air intake for optimal performance.

Understanding these elements is crucial for diagnosing issues and performing necessary upkeep. Proper knowledge empowers users to handle basic troubleshooting and maintenance tasks effectively.

Common Issues in 675 Series Engines

Engines in this category can exhibit several typical problems that may hinder their performance and reliability. Understanding these common faults can help users address issues promptly, ensuring optimal functionality and longevity of the equipment.

Fuel System Problems: One frequent issue involves the fuel delivery mechanism. Clogs in the fuel lines or dirty filters can lead to inadequate fuel supply, resulting in stalling or poor engine performance. Regular maintenance of the fuel system is essential for smooth operation.

Starting Difficulties: Many users encounter challenges when starting the engine, often due to a weak battery or faulty ignition components. Ensuring that the spark plug is in good condition and that the battery is charged can mitigate these issues.

Overheating: Engines may experience overheating due to insufficient cooling or blockages in the cooling fins. It’s crucial to keep the cooling system clean and ensure proper airflow to prevent damage from excessive heat.

Oil Leaks: Leaks can occur from gaskets or seals, leading to oil loss and potential engine damage. Regularly checking oil levels and inspecting for leaks can help maintain the engine’s health.

Vibration and Noise: Unusual vibrations or sounds may indicate loose parts or worn components. Regular inspections can help identify and address these issues before they escalate into more serious problems.

Essential Tools for Repairs

Having the right equipment is crucial for any maintenance or troubleshooting task. Proper tools not only enhance efficiency but also ensure that the job is done accurately and safely. This section highlights the fundamental instruments that can make any mechanical fix a smoother process.

Basic Hand Tools

At the core of any toolkit are basic hand instruments. A good selection includes screwdrivers, wrenches, and pliers. These tools are essential for loosening or tightening components and for accessing hard-to-reach areas. A well-organized toolbox allows for quick access to these necessities, minimizing downtime during work.

Specialized Equipment

In addition to general hand tools, having specialized equipment can greatly assist in certain tasks. For example, a multimeter is invaluable for diagnosing electrical issues, while a compression tester can help assess engine health. Investing in these specific tools can lead to more precise repairs and longer-lasting results.

Step-by-Step Maintenance Guide

This section offers a comprehensive approach to keeping your engine in optimal condition. Regular upkeep not only extends the life of your equipment but also enhances its performance. Follow the outlined steps to ensure that every component functions effectively and efficiently.

Essential Tools and Supplies

- Wrench set

- Screwdriver set

- Oil filter

- Air filter

- Spark plug

- Fresh oil

- Cleaning brush

- Protective gloves

Maintenance Steps

- Safety First: Disconnect the spark plug to prevent accidental starts.

- Check Oil Level: Remove the dipstick, wipe it clean, reinsert, and check the level. Add oil if necessary.

- Replace Oil: Drain the old oil and refill with fresh oil, ensuring to use the correct type.

- Inspect Filters: Remove and clean or replace the air filter and oil filter as needed.

- Examine Spark Plug: Check for wear and replace if necessary. Ensure proper gap settings.

- Clean Exterior: Use a brush to remove dirt and debris from the engine housing.

- Check Fuel System: Inspect fuel lines and filter for any blockages or leaks.

- Final Check: Reconnect the spark plug, double-check all components, and ensure everything is secure.

By following these steps, you can maintain your engine’s efficiency and reliability, ensuring it performs well for years to come.

Identifying Engine Components

Understanding the various parts of an engine is crucial for effective maintenance and troubleshooting. Each component plays a significant role in the overall functionality, and recognizing these elements can help in diagnosing issues and ensuring optimal performance.

Main Parts Overview

Engines consist of several key elements that work in harmony to produce power. Familiarity with these parts enables operators to spot problems and perform necessary upkeep.

| Component | Description |

|---|---|

| Cylinder | The chamber where fuel and air mix and combustion occurs. |

| Piston | Moves within the cylinder, transferring energy from combustion to mechanical motion. |

| Crankshaft | Converts linear motion of the piston into rotational motion, powering the engine. |

| Valves | Regulate the flow of air and fuel into the combustion chamber and exhaust gases out. |

| Flywheel | Stores rotational energy and helps maintain engine momentum during cycles. |

Recognizing Additional Components

In addition to the main elements, there are other important parts that contribute to engine efficiency. Knowledge of these can further aid in effective diagnostics and repair strategies.

| Component | Description |

|---|---|

| Ignition System | Provides the spark necessary to ignite the fuel-air mixture. |

| Fuel System | Delivers fuel to the engine, ensuring proper mixture with air. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

| Lubrication System | Reduces friction between moving parts, prolonging engine life. |

| Exhaust System | Channels waste gases away from the engine, reducing emissions. |

Troubleshooting Starting Problems

Starting difficulties can arise from various issues that may hinder the performance of small engines. Identifying the root cause is essential for efficient resolution. This section will guide you through common problems and their possible solutions to get your equipment running smoothly again.

Common Causes of Starting Issues

- Fuel Supply Problems

- Ignition System Failures

- Battery Issues

- Clogged Air Filter

- Worn-out Spark Plug

Troubleshooting Steps

- Check Fuel Levels

- Ensure there is enough fuel in the tank.

- Inspect the fuel for contamination or old age.

- Examine the Ignition System

- Inspect the spark plug for wear and proper gap.

- Test ignition coils for continuity.

- Inspect the Battery

- Check battery connections for corrosion.

- Ensure the battery is fully charged.

- Clean the Air Filter

- Remove and inspect the air filter for dirt and debris.

- Replace or clean as necessary.

By following these steps, you can systematically address starting problems and enhance the reliability of your engine.

Replacing Spark Plugs Effectively

Changing the ignition components in small engines is a crucial maintenance task that can significantly enhance performance. This process ensures optimal combustion and engine efficiency, ultimately prolonging the lifespan of the equipment.

Here is a step-by-step guide to effectively replace the ignition components:

| Step | Action |

|---|---|

| 1 | Gather necessary tools: socket wrench, new ignition components, and a gap gauge. |

| 2 | Disconnect the power source to prevent accidental starts. |

| 3 | Remove the old component using the socket wrench, turning it counterclockwise. |

| 4 | Check the gap on the new part with the gauge to ensure proper fit. |

| 5 | Install the new component by threading it in clockwise until snug. |

| 6 | Reconnect the power source and test the engine for functionality. |

Following these steps will help you achieve a smooth replacement, ensuring your engine operates efficiently and reliably.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for optimal performance and longevity of your equipment. By implementing regular maintenance practices, you can ensure efficient operation and prevent costly repairs down the line.

1. Regular Inspection: Periodically examine fuel lines and connections for signs of wear or leaks. Any deterioration can lead to serious performance issues or safety hazards.

2. Clean Fuel Filter: A clogged fuel filter can restrict flow, affecting engine performance. Clean or replace the filter as recommended by the manufacturer to maintain efficient fuel delivery.

3. Use Fresh Fuel: Stale fuel can lead to problems such as starting difficulties and poor combustion. Always use fresh fuel and avoid leaving it in the tank for extended periods.

4. Add Fuel Stabilizer: If storing equipment for a long time, consider adding a fuel stabilizer. This helps prevent degradation and keeps the fuel fresh for when you need it.

5. Check for Contaminants: Ensure that the fuel is free from dirt, water, and other contaminants. Using a fuel filter can help, but it’s important to monitor the quality of the fuel regularly.

6. Drain Old Fuel: Before prolonged storage, drain old fuel from the tank and carburetor. This prevents gumming and clogging in the system, ensuring a smooth start when you’re ready to use it again.

By following these tips, you can enhance the reliability and efficiency of your equipment, ensuring it runs smoothly when you need it most.

Cleaning the Air Filter

Maintaining a clean air filter is essential for optimal engine performance. A clogged or dirty filter can restrict airflow, leading to decreased efficiency and potential engine issues. Regular cleaning ensures the engine receives sufficient air, promoting better combustion and prolonging its lifespan.

Tools Needed

- Clean water

- Mild detergent

- Soft brush

- Cloth or paper towel

- Protective gloves

Cleaning Steps

- Remove the air filter from the housing carefully.

- Inspect the filter for any damage or excessive wear.

- Gently tap the filter to remove loose dirt and debris.

- Prepare a mixture of warm water and mild detergent.

- Submerge the filter in the solution and use a soft brush to clean it.

- Rinse the filter thoroughly with clean water to remove all detergent.

- Allow the filter to air dry completely before reinstallation.

- Once dry, reinstall the filter securely in its housing.

Regularly checking and cleaning the air filter can help maintain peak engine efficiency and reduce the risk of mechanical problems.

Oil Change Procedures Explained

Regular maintenance of small engines is essential for optimal performance and longevity. One critical aspect of this upkeep is the process of replacing old lubricant with fresh oil. This procedure not only ensures the engine operates smoothly but also prevents damage caused by contaminants and degraded fluids.

Why Oil Changes Matter

Changing the oil in your engine is vital for several reasons:

- Reduces friction between moving parts.

- Enhances engine efficiency.

- Prevents overheating.

- Extends the lifespan of the engine.

Step-by-Step Procedure

Follow these steps to complete an oil change effectively:

- Gather Necessary Tools:

- New oil suitable for your engine.

- Oil filter (if applicable).

- Oil catch pan.

- Wrench set.

- Funnel.

- Rags for cleanup.

- Prepare the Engine:

Start the engine briefly to warm up the oil, which aids in draining. Then, turn off the engine and allow it to cool.

- Drain Old Oil:

Place the oil catch pan under the drain plug. Remove the plug carefully and let the old oil flow into the pan.

- Replace the Oil Filter:

If your engine has an oil filter, remove the old one and install a new one, ensuring a proper seal.

- Add New Oil:

Using a funnel, pour the new oil into the fill port. Refer to the manufacturer’s guidelines for the correct oil type and quantity.

- Check Oil Level:

After adding oil, use the dipstick to verify the level is within the recommended range.

- Dispose of Old Oil Properly:

Take the used oil to a recycling center or a designated disposal facility.

Following these steps will help maintain the efficiency and health of your engine, ensuring it runs smoothly for years to come.

Safety Precautions During Repairs

Ensuring a safe environment while conducting maintenance is crucial to prevent accidents and injuries. Adhering to proper protocols not only safeguards the individual but also enhances the longevity of the equipment being worked on.

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Disconnect the power source before beginning any task to avoid unexpected starts.

- Work in a well-ventilated area to prevent inhalation of harmful fumes.

- Keep the workspace organized to minimize tripping hazards and misplaced tools.

- Use the right tools for each task to prevent injury and damage.

By implementing these guidelines, individuals can delve into their maintenance tasks with confidence, ensuring both safety and efficiency. Following these measures leads to the ultimate successful completion of any maintenance endeavor.

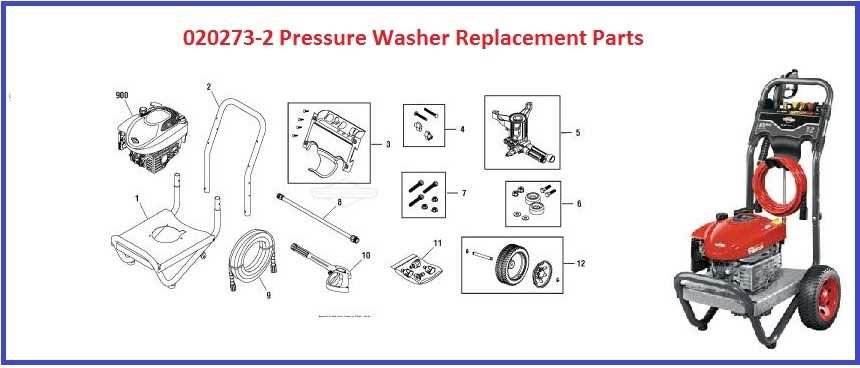

Where to Find Replacement Parts

Finding the right components for your outdoor equipment is essential for maintaining its performance and longevity. Whether you’re dealing with a small engine, lawn mower, or other machinery, sourcing quality parts can significantly affect your repair experience. Here are some reliable options to consider when searching for the necessary replacements.

Online Retailers: Numerous websites specialize in providing parts for various types of machinery. These platforms often feature detailed catalogs that allow you to search by model number or component type, ensuring you find exactly what you need. Always check customer reviews and ratings to gauge the reliability of the retailer.

Local Dealers: Authorized dealers or service centers often stock genuine components for specific brands. Visiting a local outlet not only supports community businesses but also allows you to receive personalized assistance from knowledgeable staff who can help identify the correct parts for your needs.

Aftermarket Suppliers: If you’re looking for cost-effective alternatives, aftermarket suppliers offer a range of compatible parts. While these may vary in quality, many reputable manufacturers provide reliable components at a lower price point. Researching brands and reading customer feedback can guide your selection.

Online Marketplaces: Websites like eBay or Amazon feature numerous listings for various components, both new and used. This option can be beneficial for hard-to-find parts or discontinued models. Be sure to verify the seller’s reputation and return policy before making a purchase.

Community Forums: Engaging in forums dedicated to equipment maintenance can yield valuable advice and recommendations. Experienced users often share their sources for parts, helping you discover reliable suppliers you might not have considered.

In summary, finding replacement components involves exploring multiple avenues, from online platforms to local dealers. Conduct thorough research to ensure that you acquire the right parts for effective repairs.