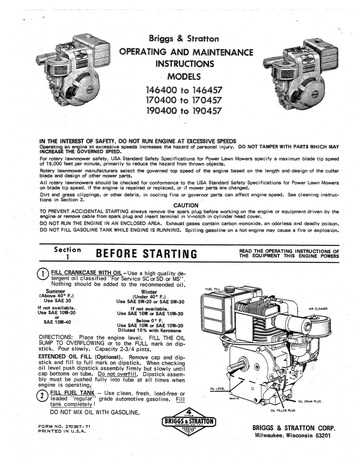

This section aims to provide essential insights and instructions for maintaining a specific type of small engine. Proper upkeep is vital for ensuring optimal performance, longevity, and efficiency. Users will benefit from detailed information that empowers them to troubleshoot and resolve common issues encountered during operation.

Throughout this guide, readers will find step-by-step procedures, helpful tips, and clear explanations designed to facilitate the maintenance process. Whether addressing minor adjustments or more complex tasks, this resource serves as a valuable reference for individuals seeking to enhance their understanding and skills in engine care.

By following the outlined steps and recommendations, users can gain confidence in their ability to manage engine-related challenges effectively. This knowledge not only promotes smoother operation but also fosters a deeper appreciation for the intricacies involved in engine mechanics.

Understanding Briggs and Stratton 550EX

This section aims to provide a comprehensive overview of a specific model of small engines, commonly used in outdoor power equipment. These engines are recognized for their reliability and performance, making them a popular choice among users. By exploring the features and functionalities of this engine type, one can gain valuable insights into its operation and maintenance.

Key Features

This engine model is designed with several notable characteristics that enhance its usability. It typically includes an efficient fuel system, durable construction materials, and user-friendly controls. Understanding these features can help users maximize their experience and ensure optimal performance during operation.

Common Applications

Common Issues and Symptoms

This section explores prevalent challenges faced by users, along with the corresponding signs that may indicate underlying problems. Recognizing these symptoms early can help in efficient troubleshooting and maintenance.

Starting Difficulties

One of the most frequent issues is difficulty in starting the engine. Symptoms may include unusual sounds or complete silence when the ignition is activated. This can often result from fuel supply problems, faulty spark plugs, or battery issues.

Overheating Concerns

Overheating can lead to significant damage if not addressed promptly. Signs include excessive smoke, a burning smell, or a sudden drop in performance. Common causes may include low oil levels, blocked air filters, or cooling system failures.

Tools Required for Repairs

To effectively perform maintenance and fix various issues with your engine, it’s essential to have the right equipment on hand. Having the correct tools not only streamlines the process but also ensures that tasks are carried out safely and efficiently.

Basic tools that should be included in your toolkit comprise a screwdriver set, which allows for adjustments and disassembly, and a wrench set for securing and loosening bolts. Additionally, pliers can be invaluable for gripping and manipulating small components.

For more complex tasks, you may need specific items such as a spark plug socket, which aids in changing the spark plug, and a compression tester to evaluate engine performance. A cleaning kit is also useful to maintain optimal functionality by removing debris from critical parts.

In summary, ensuring you have the appropriate tools not only enhances your efficiency but also helps in extending the lifespan of your engine.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing common issues that may arise with small engines. By following a systematic process, you can identify and resolve problems efficiently, ensuring optimal performance and longevity of your equipment.

Initial Assessment

Before diving into detailed diagnostics, conduct a preliminary evaluation. This step helps to pinpoint potential sources of malfunction.

- Check fuel levels and quality.

- Inspect the oil for contamination or low levels.

- Examine air filters for dirt or blockages.

- Ensure the spark plug is clean and properly connected.

Troubleshooting Steps

- Verify that the fuel is reaching the carburetor.

- Clean or replace the air filter if necessary.

- Inspect the ignition system for faulty components.

- Test the battery and connections for corrosion or looseness.

- Assess the exhaust for blockages that could affect performance.

By methodically following these guidelines, you can effectively troubleshoot and resolve issues with your equipment, restoring it to full functionality.

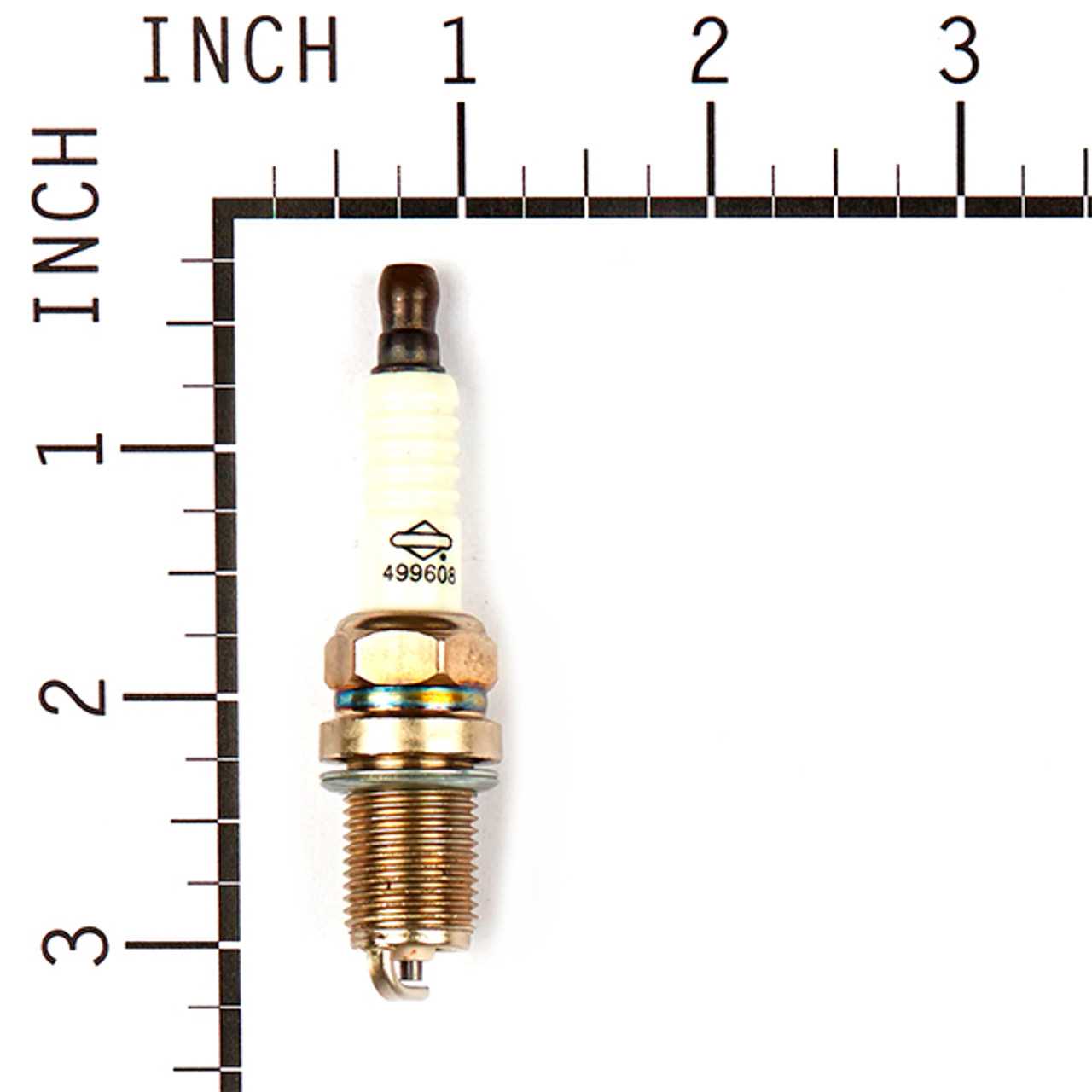

Replacing the Spark Plug

Replacing the spark igniter is a vital maintenance task that ensures optimal performance of your small engine. Over time, this component can wear out or become fouled, leading to starting difficulties and reduced efficiency. Regular checks and timely replacement can help maintain the engine’s reliability.

Tools Required

- Socket wrench

- New spark igniter

- Gap gauge

- Torque wrench

- Safety gloves

Steps for Replacement

- Ensure the engine is cool and remove the ignition key.

- Locate the spark plug, typically positioned at the top of the engine.

- Disconnect the wire from the spark igniter by pulling it off gently.

- Use a socket wrench to remove the old igniter by turning it counterclockwise.

- Inspect the old igniter for signs of wear or carbon buildup.

- Prepare the new igniter by checking and adjusting the gap with a gauge if necessary.

- Install the new igniter by threading it into place and tightening it with the wrench.

- Reconnect the ignition wire securely to the new igniter.

Regular maintenance, including spark igniter replacement, is essential for the longevity of your engine. Following these steps will ensure your equipment runs smoothly and efficiently.

Fuel System Maintenance Tips

Proper upkeep of the fuel delivery system is essential for optimal performance and longevity of your engine. Regular maintenance not only ensures reliable operation but also helps prevent costly repairs down the line. Here are some effective strategies to keep your fuel system in top shape.

Start by checking the fuel filter regularly. A clogged filter can restrict fuel flow, leading to poor engine performance. If you notice any signs of blockage or deterioration, replace it promptly to maintain smooth operation.

Keep an eye on the fuel lines for any signs of wear or leaks. Cracks or damage can lead to fuel loss and potential hazards. Ensure that all connections are secure and that lines are free from obstructions.

Using fresh fuel is crucial. Stale or contaminated fuel can cause starting issues and affect engine performance. If your equipment has been sitting for an extended period, consider draining the old fuel and refilling with fresh, clean gasoline.

Lastly, clean the carburetor periodically. Accumulated debris can affect the air-fuel mixture, leading to inefficient combustion. Regular cleaning will help maintain optimal performance and extend the life of your engine.

Changing the Oil Effectively

Maintaining optimal performance of your engine involves regular oil changes. This process ensures that the internal components remain lubricated and free from harmful deposits. Regular oil replacement not only prolongs the life of the engine but also enhances its efficiency.

Gathering Necessary Tools

Before starting the oil change, gather essential tools such as an oil pan, a wrench, a funnel, and the appropriate type of lubricant. Having these items at hand simplifies the procedure and minimizes the risk of spills.

Steps for a Successful Change

Begin by running the engine for a few minutes to warm up the oil; this helps it flow more freely. Next, turn off the engine and remove the oil fill cap. Position the oil pan beneath the drain plug, then carefully unscrew the plug to let the used oil drain completely. Once drained, replace the drain plug securely. Finally, using the funnel, pour the new lubricant into the engine, ensuring to adhere to the recommended capacity. Replace the oil fill cap and dispose of the old oil properly.

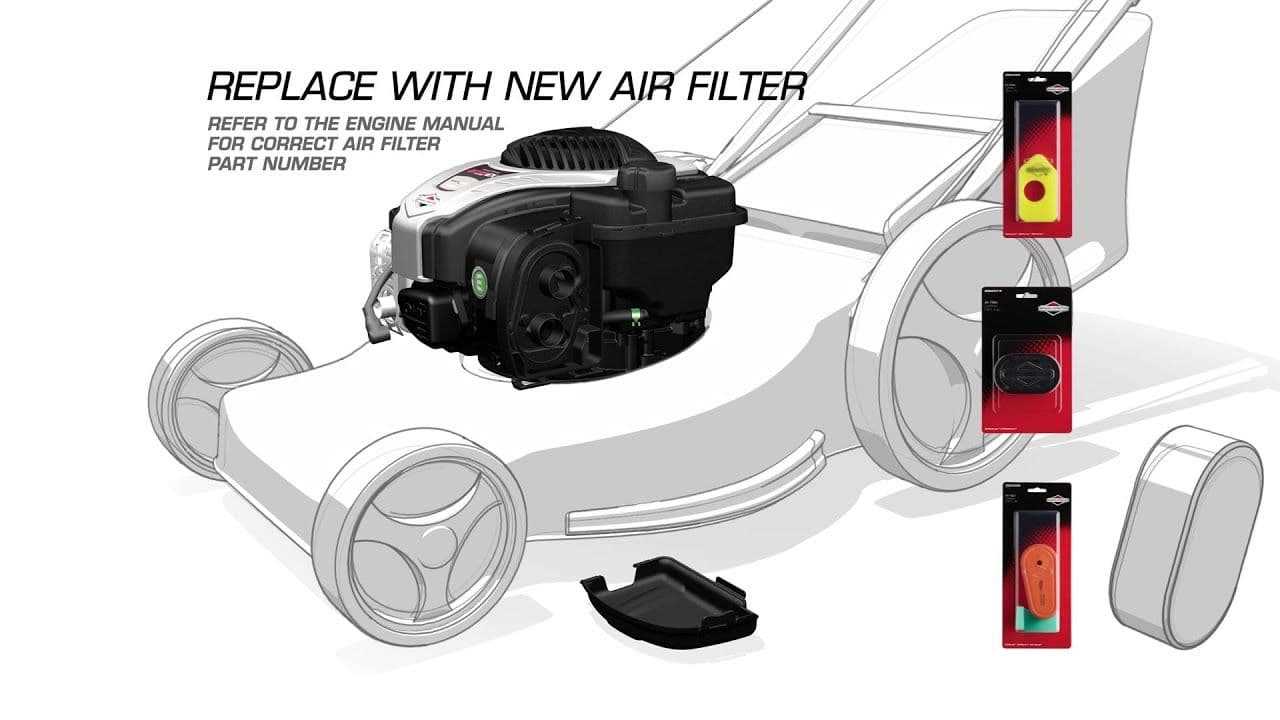

Air Filter Cleaning Procedures

Maintaining the cleanliness of the air intake component is crucial for optimal engine performance. A clean filter ensures that the engine receives adequate airflow, enhancing efficiency and longevity.

Follow these steps to properly clean the air intake element:

- Begin by gathering the necessary tools: a soft brush, mild detergent, and clean water.

- Carefully remove the air intake component from the engine. Refer to your device’s specifications to ensure proper handling.

- Using the soft brush, gently remove any loose debris and dirt from the surface.

- Prepare a solution of mild detergent mixed with clean water. Soak the filter in this solution to loosen any stubborn particles.

- After soaking, rinse the filter thoroughly with clean water to remove all soap residues.

- Allow the filter to air dry completely before reinstallation. Avoid using heat sources, as they may damage the material.

- Once dry, reinstall the air intake component securely, ensuring all connections are tight.

Regular maintenance of the air intake part not only improves performance but also prolongs the life of the engine. Perform these cleaning procedures periodically to keep your machine in top condition.

Identifying Electrical Problems

Diagnosing issues within the electrical system is crucial for restoring functionality. This involves recognizing symptoms that may indicate underlying faults, ensuring a thorough examination of the components involved. By systematically addressing potential sources of trouble, you can effectively troubleshoot and resolve issues that impede operation.

Common Symptoms of Electrical Malfunctions

Common indicators of electrical difficulties include intermittent starting, flickering lights, or unusual noises during operation. These signs often suggest problems such as loose connections, worn wiring, or failing components. Observing these symptoms closely can guide you toward identifying the root cause of the issue.

Steps for Troubleshooting

Begin troubleshooting by checking all connections for tightness and signs of corrosion. Inspect wires for fraying or damage, and test the battery to ensure it holds a charge. Additionally, utilizing a multimeter can help measure voltage and continuity, pinpointing areas that require attention. This methodical approach enhances the likelihood of swiftly resolving electrical challenges.

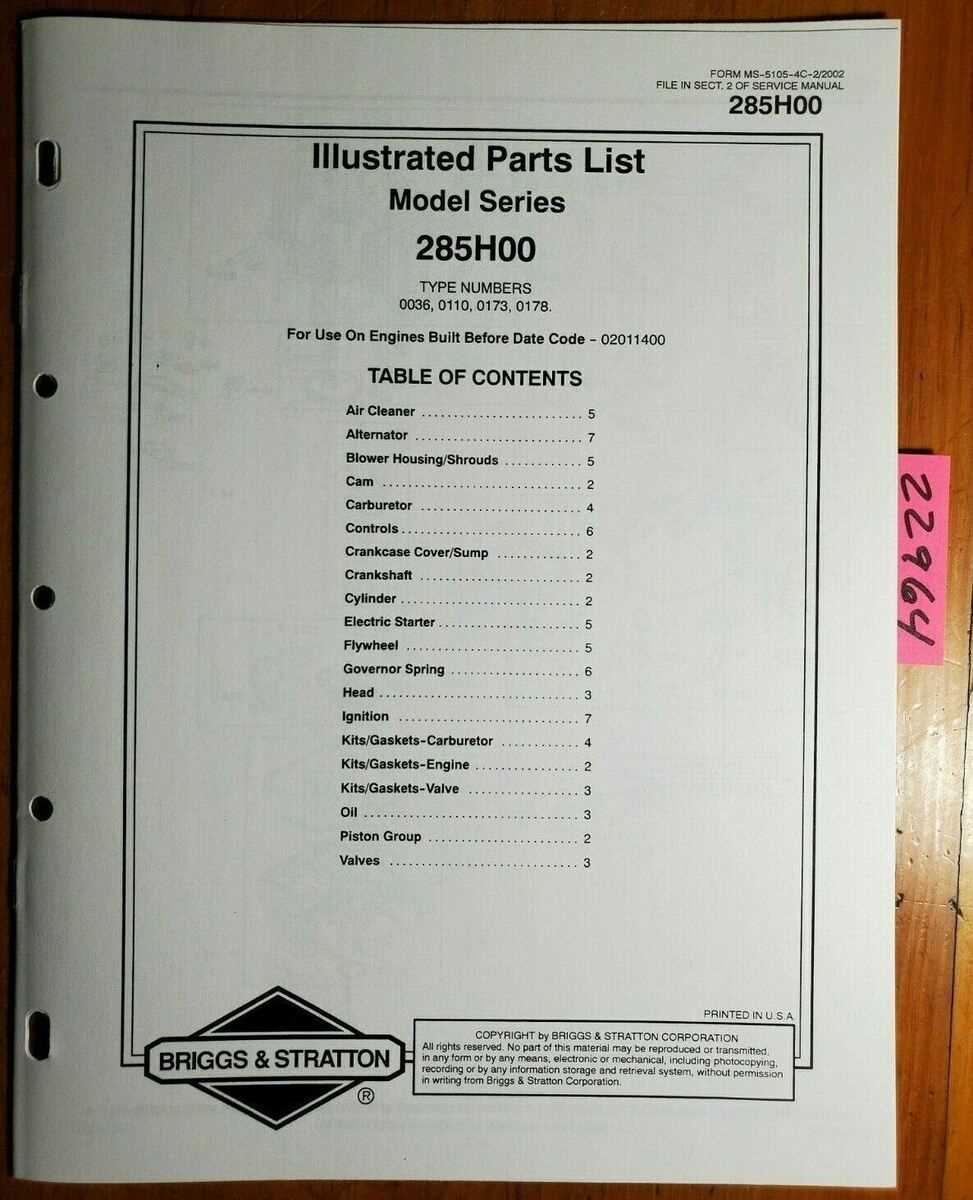

Examining the Carburetor

The carburetor plays a crucial role in the overall performance of small engines, blending air and fuel for optimal combustion. Understanding its components and functions can significantly enhance maintenance and troubleshooting efforts.

| Component | Function |

|---|---|

| Float Chamber | Regulates the fuel level to ensure consistent delivery. |

| Jet | Controls the amount of fuel entering the airstream. |

| Throttle Valve | Regulates airflow and engine speed. |

| Choke | Aids in starting the engine by enriching the fuel mixture. |

Regular inspection of these components can prevent common issues such as stalling and poor performance. It is advisable to clean the carburetor periodically to maintain efficiency and prolong the lifespan of the engine.

Engine Assembly Disassembly Guide

This section provides a comprehensive overview of the steps involved in taking apart and reassembling a small engine. Whether for maintenance, troubleshooting, or complete refurbishment, understanding the correct process is essential for achieving optimal performance.

Before beginning, ensure you have the necessary tools and a clean workspace. Follow these steps to disassemble the engine safely:

- Disconnect the spark plug to prevent accidental ignition.

- Drain the fuel tank and remove any remaining fuel from the carburetor.

- Take off the engine cover and remove any external components, such as the air filter and exhaust system.

- Carefully detach the cylinder head by unscrewing the bolts in a crisscross pattern to prevent warping.

- Remove the piston assembly, noting the orientation of the rings for reassembly.

- Take out the crankshaft and check for any signs of wear or damage.

Once disassembled, inspect each component for issues such as cracks, corrosion, or excessive wear. Clean all parts thoroughly before proceeding with the reassembly process.

To reassemble the engine, follow these guidelines:

- Ensure all gaskets and seals are replaced to prevent leaks.

- Install the crankshaft, ensuring it rotates smoothly within the engine block.

- Reattach the piston assembly, making sure the rings are properly aligned.

- Secure the cylinder head, following the proper tightening sequence for the bolts.

- Reconnect all external components and refill the fuel tank with the appropriate mixture.

After reassembly, perform a thorough check to ensure all connections are secure and components are functioning correctly before starting the engine.

Preventive Measures for Longevity

Ensuring the durability of your equipment requires consistent care and attention. Implementing effective practices can significantly extend the lifespan and performance of your machinery. Regular maintenance and proactive steps play a crucial role in minimizing wear and tear, ultimately saving you time and money in the long run.

Below are essential strategies to consider for optimal upkeep:

| Measure | Description |

|---|---|

| Regular Oil Changes | Replacing the oil at recommended intervals helps maintain engine efficiency and reduces friction. |

| Air Filter Maintenance | Cleaning or replacing the air filter ensures proper airflow, preventing dirt buildup that can harm performance. |

| Fuel Stabilization | Using fuel stabilizers prevents degradation and buildup in the fuel system, especially during storage. |

| Inspecting Belts and Cables | Regularly checking for signs of wear helps identify potential issues before they lead to failure. |

| Cleaning the Exterior | Keeping the outer surfaces clean prevents corrosion and promotes heat dissipation, enhancing overall operation. |

By following these practices, you can ensure reliable functionality and prolong the life of your machinery, providing peace of mind during usage.

Frequently Asked Repair Questions

This section addresses common inquiries related to the maintenance and troubleshooting of small engines. It aims to provide helpful insights for users seeking guidance on various issues they may encounter.

| Question | Answer |

|---|---|

| What are the common symptoms of engine failure? | Common signs include difficulty starting, unusual noises, or irregular operation while running. |

| How can I improve starting performance? | Ensure the fuel is fresh, check the air filter, and inspect the spark plug for any signs of wear. |

| What should I do if the engine overheats? | Check for blockages in the cooling system, ensure proper oil levels, and clean any debris around the engine. |

| How often should I perform maintenance tasks? | Regular maintenance should be carried out every season or after every 25 hours of operation, whichever comes first. |

| What can cause fuel leaks? | Fuel leaks can result from damaged hoses, loose connections, or issues with the fuel tank. |