Ensuring optimal performance of compact machinery requires a thorough understanding of its components and functions. This section aims to provide insights into various aspects that contribute to the effective operation and longevity of such equipment.

Regular upkeep plays a crucial role in preventing unexpected breakdowns and enhancing the efficiency of the machine. By adhering to recommended practices, operators can maintain peak functionality and reduce wear and tear over time.

Additionally, familiarizing oneself with troubleshooting techniques is essential. Recognizing common issues and their solutions allows users to address problems swiftly, ensuring minimal downtime and continued productivity.

Maintaining machinery is essential for ensuring longevity and optimal performance. This section outlines a comprehensive strategy for upkeep, emphasizing regular checks and proactive measures to enhance functionality.

- Assessing Routine Tasks

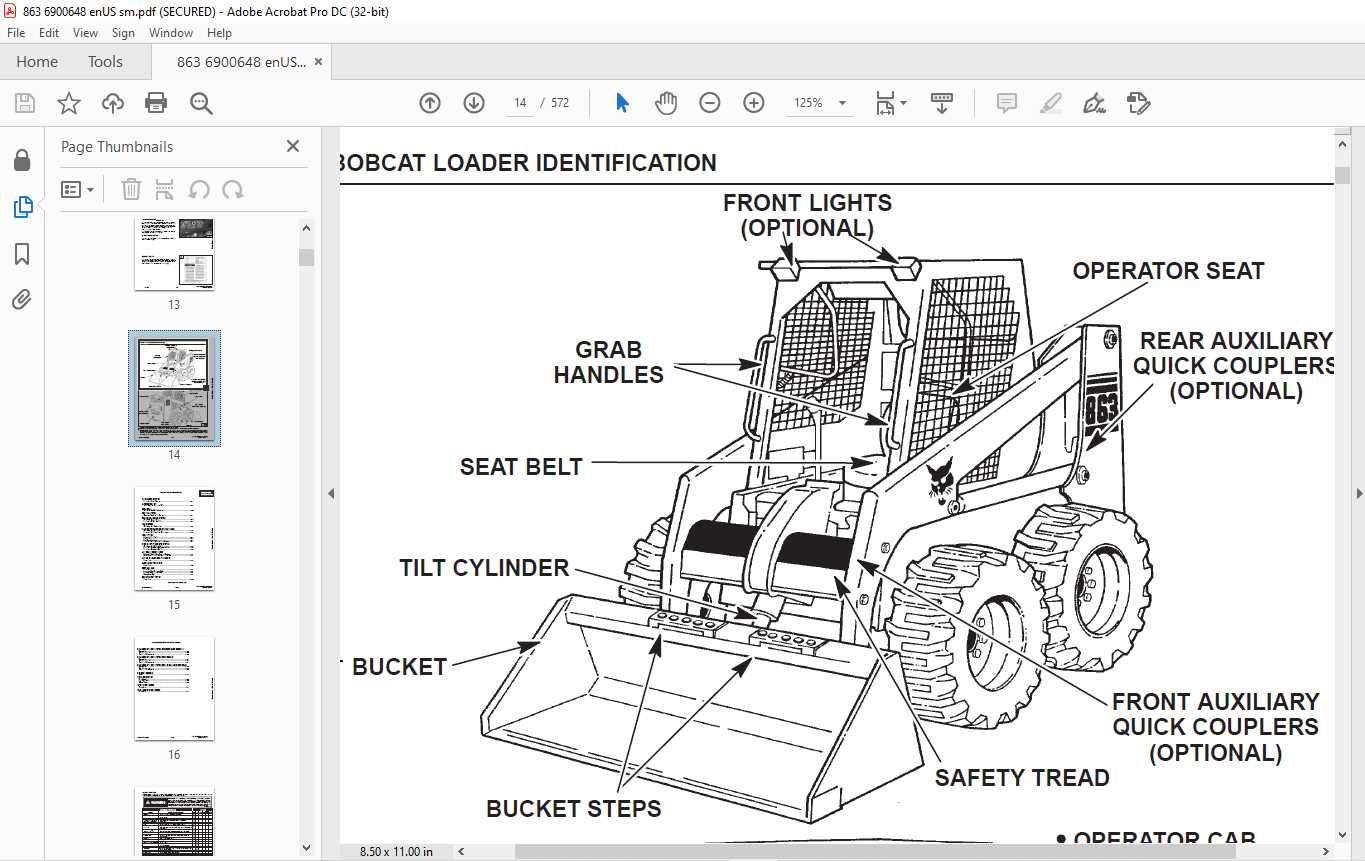

- Identifying Key Components

- Utilizing Quality Materials

- Implementing Safety Protocols

- Scheduling Regular Inspections

- Understanding Fluid Levels

- Recognizing Wear and Tear

- Executing Basic Repairs

- Consulting Expert Guidance

- Documenting Maintenance Activities

By following this structured approach, operators can effectively maintain their equipment, minimizing downtime and maximizing productivity.

Common Issues and Solutions

When operating heavy machinery, various challenges can arise that affect performance and efficiency. Understanding these common problems and their potential remedies is essential for maintaining optimal functionality and extending the lifespan of the equipment.

Hydraulic System Failures: One frequent issue involves the hydraulic system, which may exhibit signs of leaks or reduced pressure. Regularly inspecting hoses and connections can help identify leaks early. If a drop in pressure is noticed, checking the fluid levels and ensuring proper maintenance can resolve the issue.

Electrical Malfunctions: Another common concern is electrical failures, often indicated by warning lights or equipment not starting. Troubleshooting involves checking the battery, connections, and fuses. Cleaning terminals and replacing faulty components can restore functionality.

Engine Performance Problems: Engine-related issues may manifest as poor starting or stalling during operation. Routine maintenance, such as replacing filters and ensuring the fuel supply is adequate, can alleviate these problems. Keeping the engine clean and well-tuned is vital for reliable performance.

By being proactive in identifying and addressing these prevalent concerns, operators can ensure smoother operation and minimize downtime.

Essential Tools for Repair

When maintaining and fixing machinery, having the right instruments is crucial for efficiency and effectiveness. This section outlines key implements that facilitate various tasks, ensuring a smoother process for troubleshooting and enhancement of functionality.

Basic Hand Tools

Hand tools form the foundation of any maintenance kit. They allow for a range of tasks, from simple adjustments to complex repairs. Here are some essential hand tools to consider:

| Tool | Purpose |

|---|---|

| Wrenches | Tightening and loosening bolts and nuts |

| Screwdrivers | Fastening or removing screws |

| Plier Set | Gripping, twisting, and cutting |

Power Tools

In addition to hand tools, power tools can significantly expedite tasks and enhance precision. Here are some recommended power tools:

| Tool | Purpose |

|---|---|

| Drill | Boring holes and driving fasteners |

| Angle Grinder | Cutting and grinding metal |

| Impact Wrench | Effortless loosening of stubborn fasteners |

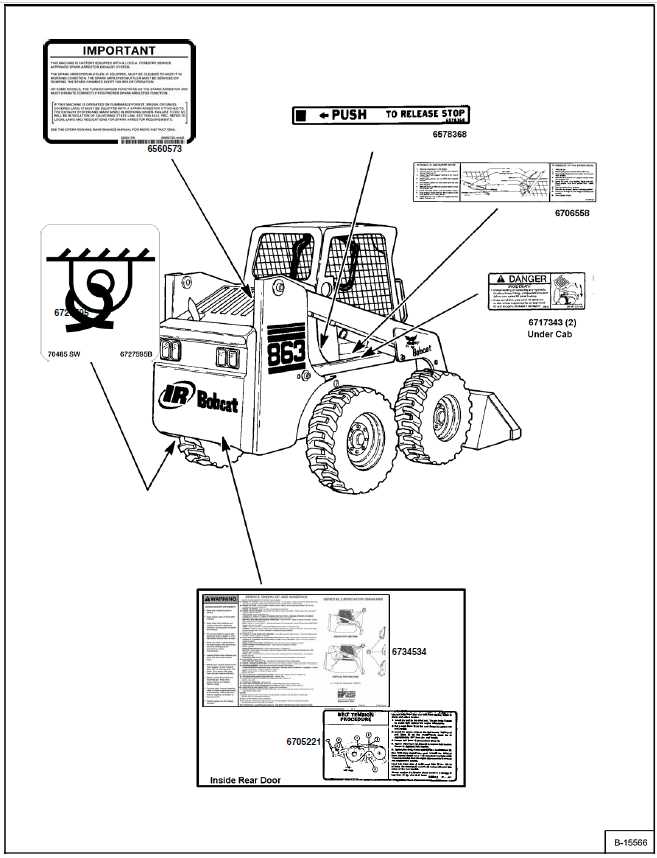

Safety Precautions During Repairs

Ensuring a secure environment is essential when performing maintenance tasks on machinery. Adhering to safety guidelines not only protects the individual carrying out the work but also extends the lifespan of the equipment. Awareness of potential hazards and taking preventive measures can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is vital. This includes wearing safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects, and steel-toed boots to prevent foot injuries. A hard hat may also be necessary in environments where overhead hazards exist.

Work Area Organization

Maintaining an organized workspace is crucial for safety. Ensure that tools and materials are stored properly and that the area is free of clutter. Adequate lighting should be provided to enhance visibility, and any spills should be cleaned immediately to prevent slips and falls.

Step-by-Step Troubleshooting Guide

This section offers a comprehensive approach to identifying and resolving common issues that may arise with your equipment. By following a systematic method, you can effectively diagnose problems and implement solutions, ensuring optimal performance and longevity.

Initial Assessment

Begin by conducting a thorough examination of the machine. Pay attention to the following areas:

- Check for any visible signs of damage or wear.

- Listen for unusual sounds during operation.

- Inspect fluid levels and ensure they are within recommended ranges.

Troubleshooting Steps

- Power Issues:

- Verify that the machine is properly connected to a power source.

- Examine fuses and circuit breakers for any signs of failure.

- Performance Problems:

- Assess hydraulic fluid quality and levels.

- Check filters for clogs and replace if necessary.

- Component Functionality:

- Test individual parts for proper operation.

- Consult the specifications to ensure compatibility.

Routine Maintenance Checks

Regular maintenance is essential for ensuring optimal performance and longevity of equipment. By adhering to a structured routine, operators can identify potential issues before they escalate, thereby enhancing reliability and efficiency.

Visual Inspections

Conducting thorough visual inspections is a fundamental aspect of maintenance. Check for any signs of wear, leaks, or unusual noises. Pay close attention to hoses, belts, and connections, as these components often indicate the overall health of the machinery.

Fluid Levels and Quality

Monitoring fluid levels is crucial for smooth operation. Regularly assess the oil, coolant, and hydraulic fluids to ensure they are at appropriate levels and free from contaminants. Replacing fluids according to the manufacturer’s guidelines can prevent mechanical failures and maintain peak performance.

Parts Replacement Process

The procedure for replacing components in machinery is crucial for maintaining optimal functionality and performance. This process ensures that all parts work harmoniously together, contributing to the overall efficiency of the equipment.

Initially, it is essential to identify the specific components that require replacement. Inspection of the machinery should be conducted regularly to determine any signs of wear or damage. Once the necessary parts are identified, preparation for the replacement is key.

Before proceeding, ensure that the appropriate tools and replacement parts are available. Safety precautions must be observed, including disconnecting power sources and wearing suitable protective gear. Following this, the damaged components can be removed carefully, avoiding any unnecessary force that may harm surrounding parts.

After the old parts are taken out, install the new components by following the manufacturer’s guidelines. Proper alignment and secure fastening are critical to prevent future issues. Finally, conduct a thorough check to confirm that all parts are functioning correctly before putting the machinery back into operation.

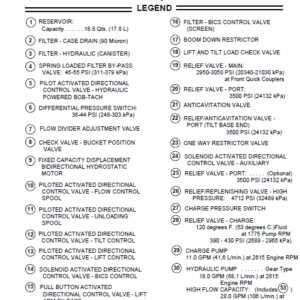

Hydraulic System Troubleshooting

Identifying and resolving issues within a hydraulic system is crucial for maintaining optimal performance. Various symptoms can indicate underlying problems, and understanding these can help in effectively addressing them.

- Fluid Leaks: Check for any visible signs of hydraulic fluid escaping from hoses, fittings, or seals.

- Pressure Fluctuations: Monitor the pressure gauge for irregular readings, which may suggest blockages or pump issues.

- Noisy Operation: Unusual sounds during operation may indicate low fluid levels or air trapped in the system.

- Slow Response: A delay in hydraulic functions can point to problems with the pump or control valves.

For troubleshooting, it is essential to follow a systematic approach:

- Inspect the hydraulic fluid levels and replenish as needed.

- Examine hoses and connections for wear or damage.

- Test the operation of valves and actuators to ensure they are functioning correctly.

- Perform a pressure test to confirm that the system is within the specified range.

By addressing these common issues, one can enhance the reliability and efficiency of the hydraulic system.

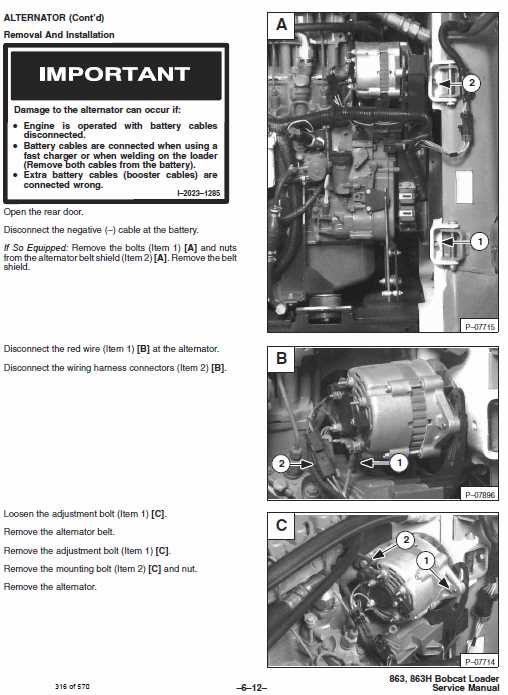

Electrical Components Overview

This section provides an insight into the essential electrical elements that facilitate the proper functioning of machinery. Understanding these components is crucial for ensuring optimal performance and reliability in various operations.

Key Electrical Parts

The electrical system comprises various components, including batteries, switches, and wiring harnesses. Each part plays a significant role in powering the machine and enabling control over its functions. Regular inspection and maintenance of these elements are vital to prevent potential failures.

Safety Considerations

When working with electrical systems, safety should always be a priority. It is important to follow proper protocols to avoid electrical shocks or damage to components. Ensuring that all connections are secure and free from corrosion can significantly enhance safety and functionality.

Engine Performance Enhancements

Improving the efficiency and output of a machine’s power unit can significantly boost its overall performance. By focusing on various modifications and upgrades, operators can achieve enhanced responsiveness and fuel efficiency. These enhancements not only elevate operational capabilities but also prolong the engine’s lifespan.

One effective approach involves optimizing the air intake system. Upgrading to a high-flow air filter allows for increased airflow, resulting in better combustion and power generation. Additionally, fine-tuning the exhaust system can reduce back pressure, enabling the engine to expel gases more efficiently.

Another strategy is to consider the use of performance chips or engine tuning software. These tools can adjust fuel maps and ignition timing, leading to improved throttle response and acceleration. Regular maintenance, including the use of high-quality lubricants and timely fluid changes, also plays a crucial role in sustaining optimal performance.

Lastly, incorporating a performance radiator or intercooler can help manage operating temperatures more effectively, thus ensuring that the engine maintains peak performance under various load conditions. By implementing these enhancements, operators can unlock the full potential of their equipment, leading to more productive and efficient operations.

Best Practices for Long-Term Care

Ensuring the longevity and optimal performance of machinery requires a systematic approach to maintenance and care. By adhering to a set of well-defined practices, operators can significantly enhance the durability and efficiency of their equipment over time.

Regular inspections play a crucial role in identifying potential issues before they escalate. This proactive strategy not only prevents costly repairs but also extends the lifespan of the machine. Here are some key practices to consider:

| Practice | Description |

|---|---|

| Routine Maintenance | Establish a schedule for regular checks and servicing to keep all components in optimal condition. |

| Fluid Checks | Monitor and replace fluids as needed, ensuring all systems operate smoothly. |

| Cleaning | Keep the equipment clean to prevent the buildup of debris that can cause mechanical failures. |

| Proper Storage | When not in use, store machinery in a dry and secure location to avoid weather-related damage. |

| Operator Training | Invest in training for operators to ensure they understand best practices for handling and maintaining the equipment. |

By following these guidelines, operators can ensure their machinery remains reliable and efficient throughout its operational life, ultimately saving time and resources in the long run.