When it comes to maintaining high-performance cleaning equipment, understanding the intricacies of your machine is essential. This section aims to provide a thorough overview of techniques and guidelines for ensuring optimal functionality. Whether you are encountering minor issues or seeking to perform routine upkeep, having access to detailed instructions can make a significant difference in extending the lifespan of your device.

Equipped with knowledge about common challenges and their solutions, users can confidently navigate potential obstacles. This resource is designed to empower individuals with the skills needed to handle a variety of maintenance tasks, from simple adjustments to more involved repairs. By familiarizing yourself with these processes, you enhance both the performance and reliability of your cleaning apparatus.

Incorporating a proactive approach to care not only prevents breakdowns but also improves efficiency. Through systematic troubleshooting and preventive measures, users can maintain peak performance and avoid costly repairs. This guide serves as a vital tool for anyone committed to achieving excellence in equipment maintenance.

Karcher 395 Repair Manual Overview

This section provides a comprehensive summary of the guidelines and instructions for maintaining and fixing high-pressure cleaning equipment. Understanding these resources can significantly enhance the longevity and performance of your device.

Key Components of the Guide

- Introduction: Overview of the equipment’s features and specifications.

- Troubleshooting: Common issues and their solutions.

- Maintenance: Regular care practices to ensure optimal functionality.

- Parts Replacement: Instructions for identifying and replacing worn components.

Importance of Following Guidelines

Adhering to the outlined procedures can prevent malfunctions and enhance efficiency. Regular maintenance not only ensures safety but also contributes to better cleaning results. Understanding the intricacies of your unit will empower users to tackle minor issues independently, saving both time and resources.

Essential Tools for Repairing Karcher 395

When tackling maintenance tasks on high-pressure cleaning devices, having the right instruments at your disposal is crucial. These tools not only streamline the process but also ensure that each aspect of the equipment is addressed effectively. Below is a compilation of essential implements that will facilitate the upkeep and enhancement of your cleaning apparatus.

1. Screwdrivers: A set of various-sized screwdrivers is indispensable for loosening or tightening screws in different components. Both flat-head and Phillips screwdrivers should be included to cover all possibilities.

2. Wrenches: Adjustable wrenches and socket sets will help in dealing with bolts and nuts that secure various parts. These tools provide the leverage needed to tackle even the most stubborn fittings.

3. Pliers: A good pair of pliers can be invaluable for gripping, twisting, or cutting wires and hoses. Needle-nose pliers, in particular, are excellent for reaching tight spaces.

4. Multimeter: This electronic testing tool is essential for diagnosing electrical issues. It helps measure voltage, current, and resistance, ensuring the electrical components function correctly.

5. Cleaning Brushes: Specialized brushes assist in removing debris from filters and nozzles. Keeping these parts clean is vital for optimal performance.

6. Lubricants: A quality lubricant is necessary to maintain moving parts. Regular application helps reduce wear and tear, prolonging the life of the machine.

7. Safety Gear: Always prioritize safety by using protective eyewear and gloves. This will protect you from potential hazards while working on the equipment.

Equipping yourself with these essential tools will not only make maintenance tasks more efficient but also enhance the longevity and performance of your cleaning unit.

Common Issues with Karcher 395

When using high-pressure cleaning equipment, users may encounter several frequent challenges that can affect performance and efficiency. Understanding these common problems is crucial for maintaining optimal functionality and ensuring longevity of the device.

Frequent Challenges

- Poor Pressure Output: Users often notice a significant drop in water pressure, which can be caused by clogged nozzles or air in the system.

- Overheating: Extended use may lead to overheating, potentially resulting in automatic shutoff mechanisms engaging to prevent damage.

- Leaks: Water leakage can occur at various connection points, often due to worn seals or improper assembly.

- Unresponsive Motor: In some cases, the motor may fail to start, which could stem from electrical issues or a faulty power source.

Maintenance Tips

- Regularly inspect and clean the nozzle to prevent clogs.

- Ensure the machine is not used for prolonged periods without breaks to avoid overheating.

- Check and replace seals as needed to prevent leaks.

- Verify power connections and inspect electrical components if the motor fails to operate.

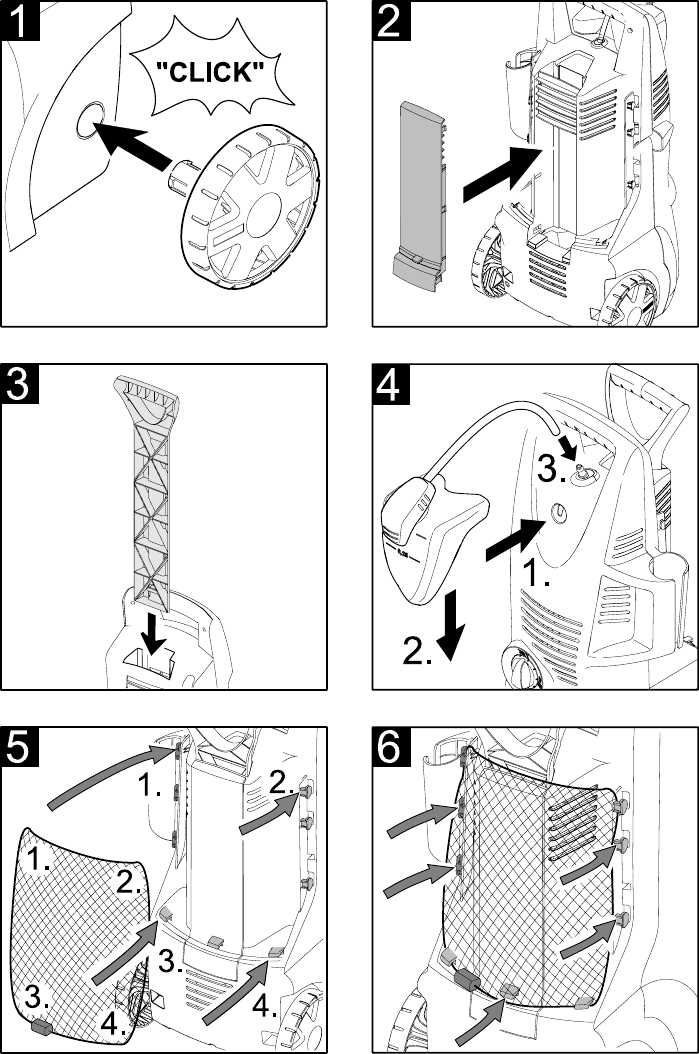

Step-by-Step Disassembly Process

This section outlines a systematic approach to dismantling a cleaning device. Understanding the process ensures that each component is handled properly, minimizing the risk of damage and facilitating effective reassembly. Following these steps will help maintain the device’s functionality and longevity.

Preparation and Safety Measures

Before starting the disassembly, ensure that the device is unplugged and completely cooled down. Gather the necessary tools, such as screwdrivers and pliers. It is advisable to wear protective gear, including gloves and goggles, to safeguard against any sharp edges or small parts that may spring loose during the process.

Step-by-Step Disassembly

1. Remove the Outer Shell: Start by unscrewing any visible screws on the exterior casing. Carefully detach the outer shell, taking note of how it is aligned for easy reassembly.

2. Disconnect Internal Components: Once the outer shell is removed, identify the internal components that need to be taken apart. Disconnect any electrical connections first, followed by the mechanical parts. Label each component as you remove it to avoid confusion later.

3. Inspect and Clean: After disassembly, take the opportunity to inspect each part for wear and tear. Clean any debris or buildup to ensure optimal performance upon reassembly.

By following these detailed steps, you can effectively disassemble the device and prepare for maintenance or replacement of parts as needed.

How to Replace Worn Components

Maintaining the efficiency of your equipment often requires attention to worn-out parts. Over time, components can degrade due to regular use, leading to decreased performance or even malfunctions. Understanding how to properly replace these elements is crucial for restoring functionality and prolonging the lifespan of your device.

Identifying Worn Parts is the first step in the replacement process. Regular inspections can help you spot signs of wear, such as cracks, discoloration, or unusual sounds during operation. Once you’ve identified a problematic component, gather the necessary tools and replacement parts before proceeding.

Disassembling the Device requires careful attention to detail. Follow the manufacturer’s guidelines for disassembly to avoid causing further damage. Make sure to keep track of screws and small parts to simplify reassembly. It’s advisable to take photos during this stage to ensure you can accurately put everything back together.

Replacing the Component involves removing the old part and installing the new one. Ensure that the replacement part is compatible and meets the specifications of the original. Take care to secure it properly to prevent future issues.

Reassembling the Device should be done with precision. Refer back to the notes or images taken during disassembly to ensure that every component is returned to its correct place. After reassembly, perform a thorough check to confirm that everything is secure and functional.

Testing the Equipment is essential after any replacements. Run the device through its standard operations to verify that the new component is functioning as expected. This step ensures that the issues related to wear have been effectively resolved, restoring optimal performance.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your cleaning equipment requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan of your device and maintain its optimal performance.

- Regular Cleaning: After each use, clean all accessible parts to prevent dirt and grime buildup. Pay special attention to filters and nozzles.

- Check Fluid Levels: Regularly inspect and refill necessary fluids, including detergents and oils, to ensure smooth operation.

- Avoid Overloading: Use the equipment within its specified limits to prevent strain and potential damage.

- Store Properly: When not in use, store the machine in a dry and cool place. Avoid exposing it to extreme temperatures or moisture.

- Inspect Cables and Hoses: Regularly check for wear or damage on electrical cords and hoses. Replace any worn components to avoid accidents.

- Annual Service: Schedule a professional inspection at least once a year to identify and address any potential issues before they escalate.

By adhering to these maintenance tips, you can enhance the reliability and efficiency of your equipment, ensuring it serves you well for years to come.

Identifying Electrical Problems

Understanding and diagnosing electrical issues is crucial for maintaining the functionality of your equipment. Recognizing the signs of malfunctions can prevent further damage and ensure efficient operation. This section provides guidance on how to detect common electrical anomalies effectively.

Common Symptoms of Electrical Issues

Several indicators may suggest electrical faults. Look for unusual noises, such as buzzing or clicking, which can signify a malfunctioning component. Additionally, inconsistent performance or unexpected shutdowns are critical signs that warrant immediate attention. Discoloration or burnt smells around electrical parts can also indicate overheating or failure.

Testing and Diagnosis Techniques

To accurately identify electrical problems, utilize a multimeter to check voltage and continuity. Ensure that all connections are secure and free of corrosion. Performing a visual inspection of wiring and components can also help spot damage or wear. When in doubt, consulting a professional technician can provide valuable insights and solutions.

Cleaning and Care Procedures

Proper maintenance and cleaning are essential to ensure the longevity and efficiency of your equipment. Regular care not only enhances performance but also prevents potential issues that may arise from neglect. This section outlines effective practices for keeping your device in optimal condition.

Daily Maintenance Tasks

Implementing a routine of daily checks can significantly extend the life of your machinery. Here are key tasks to incorporate:

| Task | Description |

|---|---|

| Inspect Hoses | Check for cracks or leaks to prevent pressure loss. |

| Clean Filters | Remove debris to maintain airflow and efficiency. |

| Check Fluid Levels | Ensure that all necessary fluids are at appropriate levels. |

| Inspect Nozzles | Clear any blockages to ensure consistent performance. |

Periodic Deep Cleaning

In addition to daily tasks, regular deep cleaning is vital for maintaining performance standards. Consider the following practices:

| Procedure | Frequency |

|---|---|

| Full Unit Cleaning | Every month |

| Detailed Inspection | Every three months |

| Replace Worn Parts | As needed |

| Store Properly | After each use |

Understanding the Karcher 395 Parts Diagram

Grasping the intricacies of a component layout is essential for effective maintenance and troubleshooting of equipment. A well-structured diagram serves as a vital reference, illustrating the various parts and their relationships, thereby facilitating a deeper understanding of the assembly’s functionality. Familiarity with this visual guide empowers users to identify components, streamline repairs, and ensure optimal performance.

Key Components Overview

Each element within the diagram plays a specific role, contributing to the overall efficiency of the system. Recognizing these parts not only aids in repairs but also helps in anticipating potential issues before they escalate.

| Part Name | Function |

|---|---|

| Motor | Drives the main operational functions. |

| Pump | Pressurizes water for cleaning applications. |

| Hose | Transports water from the unit to the nozzle. |

| Nozzle | Regulates water flow and pressure for effective cleaning. |

| Filter | Prevents debris from entering the system. |

Importance of Familiarity

Becoming acquainted with the parts diagram not only simplifies repair processes but also enhances the user’s capability to perform routine checks and preventative maintenance. This knowledge is crucial in extending the lifespan of the equipment and ensuring reliable performance over time.

Safety Precautions During Repairs

When undertaking maintenance tasks on any equipment, it is crucial to prioritize safety. Proper precautions can significantly reduce the risk of accidents and injuries, ensuring a secure working environment. Awareness and adherence to safety guidelines play a vital role in protecting both the individual and the equipment.

Before beginning any work, ensure that the equipment is powered down. Disconnecting it from the power source eliminates the risk of accidental activation, which could lead to severe injuries. Additionally, allow any hot components to cool before handling them.

Wearing appropriate personal protective equipment (PPE) is essential. This includes safety goggles to protect your eyes from debris, gloves to shield your hands from sharp edges or hot surfaces, and steel-toed boots to guard your feet. Proper attire enhances safety during the entire process.

Always work in a well-ventilated area to minimize the risk of inhaling harmful fumes or dust. If working with chemicals or cleaning agents, consult the safety data sheets and follow recommended handling procedures. Keep your workspace organized to prevent accidents caused by tripping over tools or parts.

Lastly, remain focused and avoid distractions. If you feel fatigued or unwell, it is advisable to postpone the task until you are fully alert. Prioritizing safety ensures a smoother, more effective maintenance experience.

Where to Find Replacement Parts

Finding suitable components for your cleaning equipment can be crucial for maintaining its performance and longevity. There are various avenues to explore when searching for high-quality parts that ensure your device functions optimally.

One of the most reliable sources is the official website of the manufacturer, which often provides an extensive catalog of parts along with detailed specifications. Additionally, authorized dealers and local retailers specializing in cleaning equipment may carry a selection of necessary items, offering convenience and expert assistance.

Online marketplaces and auction sites also present a wide range of options, often at competitive prices. However, it is essential to verify the authenticity and quality of the parts being offered. Forums and community groups dedicated to equipment maintenance can also be valuable resources for recommendations and tips on sourcing hard-to-find items.