Maintaining machinery is essential for ensuring optimal performance and longevity. Proper guidance can make a significant difference in the efficiency of any device, leading to smoother operation and fewer interruptions. This section aims to provide valuable insights and detailed instructions to assist you in keeping your equipment in top shape.

Familiarity with your device’s components and functions is crucial for troubleshooting common issues. By understanding how each part works together, you can identify problems early and take appropriate action. This knowledge empowers users to manage repairs effectively, minimizing downtime.

Resources dedicated to the upkeep of your machinery often contain step-by-step processes, helpful tips, and safety precautions. Utilizing these resources ensures that you approach maintenance with confidence, equipped with the tools and information necessary for successful intervention. Whether you’re a seasoned professional or a novice, a structured approach to care can lead to significant benefits.

Overview and Features

This section provides a comprehensive look at a versatile lawn care tool designed for efficiency and ease of use. Its innovative design and robust capabilities make it a favorite among both homeowners and professionals alike.

Key Features:

One of the standout characteristics of this equipment is its powerful engine, which ensures reliable performance across various conditions. The cutting system is engineered for precision, allowing for clean and even results on different types of terrain.

Additionally, the unit boasts user-friendly controls that enhance maneuverability, making it suitable for users of all skill levels. With adjustable cutting heights, it offers flexibility for achieving the desired lawn aesthetics.

Durability is another significant aspect, as the materials used in construction are designed to withstand wear and tear, ensuring longevity. The compact design also facilitates easy storage and transport, making it a practical choice for those with limited space.

In summary, this equipment combines power, convenience, and durability, making it an essential addition to any landscaping toolkit.

Common Issues with Toro 20333

When operating garden machinery, users often encounter several recurring challenges that can impact performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and prolonging the lifespan of the equipment.

- Starting Problems: Difficulty in starting the engine is a common complaint. This may result from fuel issues, battery problems, or electrical malfunctions.

- Uneven Cutting: An inconsistent cutting height can lead to unsatisfactory results. This may be caused by dull blades, improper height adjustments, or worn-out components.

- Engine Stalling: Sudden stalling during operation can be frustrating. Potential causes include fuel flow interruptions, air filter blockages, or ignition system failures.

- Excessive Vibration: Noticeable vibrations can indicate loose parts or imbalanced blades, which can affect the machine’s performance and user comfort.

- Overheating: Machines may overheat due to clogged cooling fins or low oil levels, leading to potential damage if not addressed promptly.

By being aware of these prevalent issues, operators can take proactive steps to troubleshoot and maintain their equipment, ensuring a more efficient and effective gardening experience.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed safely and correctly. Below are key instruments that every enthusiast should consider for their toolkit.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for loosening and tightening screws.

- Wrenches: Both adjustable and socket varieties help in gripping and turning nuts and bolts.

- Pliers: Useful for gripping, twisting, and cutting, these tools come in different shapes for specific tasks.

- Multimeter: An indispensable device for measuring voltage, current, and resistance, aiding in diagnosing electrical issues.

- Replacement Parts: Keeping a stock of common spare components ensures quick fixes when needed.

Each tool plays a vital role in ensuring that maintenance tasks are performed smoothly, ultimately extending the lifespan of equipment and enhancing performance.

Step-by-Step Repair Process

Maintaining equipment effectively involves a systematic approach to identifying and addressing issues. This guide outlines a methodical sequence that can be followed to troubleshoot and restore functionality. By adhering to these steps, users can enhance the longevity and performance of their machinery.

| Step | Description |

|---|---|

| 1 | Assess the situation by visually inspecting the unit for any obvious signs of wear or damage. |

| 2 | Gather necessary tools and components required for the task at hand. |

| 3 | Disconnect power sources to ensure safety during the procedure. |

| 4 | Carefully disassemble the unit, noting the placement of each part for reassembly. |

| 5 | Inspect internal components for any malfunctions or areas needing attention. |

| 6 | Replace or repair faulty parts as needed, ensuring compatibility with the model. |

| 7 | Reassemble the unit meticulously, following the notes made during disassembly. |

| 8 | Reconnect the power sources and perform a test to verify that the issue has been resolved. |

| 9 | Document the process and any changes made for future reference. |

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent care and attention. By implementing a few simple practices, you can enhance performance and reduce the likelihood of breakdowns. Regular maintenance not only prolongs the lifespan of your tools but also ensures they operate at their best.

Regular Inspections

Conduct frequent evaluations of your machinery to identify potential issues before they escalate. Look for signs of wear, loose components, or unusual sounds. Addressing small problems early can prevent costly repairs down the line and keep your equipment running smoothly.

Proper Cleaning Techniques

Maintaining cleanliness is crucial for optimal performance. After each use, remove dirt and debris to prevent buildup that can lead to corrosion or blockages. Utilize appropriate cleaning agents and tools that are safe for your specific type of machinery. A clean machine is a reliable machine.

Parts Replacement Guide

This section provides a comprehensive overview for replacing components in your equipment, ensuring optimal performance and longevity. Understanding when and how to change parts is essential for maintaining efficiency and preventing potential issues.

Identifying Components for Replacement

Before beginning the replacement process, it’s crucial to identify which parts need attention. Common indicators include:

- Decreased performance or efficiency

- Unusual noises during operation

- Visible wear or damage on components

- Frequent breakdowns or malfunctions

Steps for Replacing Parts

- Gather Necessary Tools: Ensure you have all required tools and replacement parts ready.

- Disconnect Power: Always unplug or turn off the equipment before starting any maintenance work.

- Remove Affected Component: Carefully detach the old part, following specific guidelines to avoid damaging surrounding areas.

- Install New Part: Place the new component in position, ensuring a secure fit.

- Test the Equipment: Reconnect power and test the functionality to confirm the replacement was successful.

By following these steps, you can effectively replace parts and enhance the performance of your equipment. Regular maintenance will help extend its lifespan and ensure reliable operation.

Understanding Toro Warranty Terms

The warranty provisions provided by manufacturers play a crucial role in ensuring customer satisfaction and product reliability. These agreements outline the responsibilities of the company towards their products and the rights of the consumer, creating a framework for addressing issues that may arise during the product’s lifespan.

Typically, these terms specify the duration of coverage, the types of defects or failures that are included, and any conditions that may void the warranty. Understanding these details is essential for consumers, as it helps them make informed decisions and protects their investment. It is important to note that warranties can differ significantly between various models, so careful examination of the specific terms applicable to each product is necessary.

In many cases, warranties will cover manufacturing defects but may exclude damage resulting from improper use, lack of maintenance, or accidents. Being aware of these exclusions can prevent misunderstandings and ensure that consumers are fully aware of their rights and obligations under the warranty agreement.

Lastly, customers should keep documentation such as receipts and service records, as these can be vital when claiming warranty service. Properly understanding warranty terms can greatly enhance the experience of owning and using a product.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is paramount to protect both the individual and the equipment involved. Adhering to certain guidelines can minimize risks and enhance the overall efficiency of the process. Proper preparation and awareness of potential hazards contribute significantly to a safer working environment.

Before commencing any task, it is essential to familiarize oneself with the necessary safety protocols. This includes using appropriate personal protective equipment (PPE) and understanding the specific risks associated with the equipment being handled. Below is a table outlining key safety measures to consider:

| Safety Measure | Description |

|---|---|

| Wear Protective Gear | Always use gloves, goggles, and sturdy footwear to protect against injuries. |

| Disconnect Power Sources | Ensure all power supplies are turned off and disconnected before starting work. |

| Maintain a Clean Workspace | Keep the work area tidy to prevent accidents and ensure easy access to tools. |

| Use Tools Properly | Familiarize yourself with each tool’s operation to avoid misuse and injury. |

| Work in a Ventilated Area | Ensure proper airflow to avoid inhaling harmful fumes or dust. |

By following these essential guidelines, individuals can significantly reduce the likelihood of accidents and ensure a more effective maintenance process. Always prioritize safety to foster a productive and secure working atmosphere.

Cost-Effective Repair Solutions

Finding budget-friendly options for maintaining equipment can significantly reduce expenses while ensuring longevity and optimal performance. By exploring alternative methods and utilizing readily available resources, you can tackle common issues without breaking the bank.

DIY Approaches

One of the most effective strategies involves leveraging do-it-yourself techniques. Many minor issues can be resolved with basic tools and a little research. Online resources, including video tutorials and forums, provide valuable insights into tackling specific problems. This not only saves money on professional services but also empowers you with the knowledge to handle future challenges.

Community Resources

Another viable option is to tap into community resources. Local workshops and repair cafés often offer guidance and support for individuals looking to fix their devices. Engaging with others who share similar interests can lead to discovering innovative solutions and acquiring parts at lower costs. Building connections within your community can enhance your repair experience while saving money.

Where to Find Replacement Parts

Locating suitable components for your equipment can enhance its performance and longevity. Various avenues exist for sourcing these essential items, ensuring that you can maintain optimal functionality.

- Authorized Dealers: Start by checking with certified distributors who offer genuine items specifically designed for your model. This ensures compatibility and quality.

- Online Retailers: Numerous e-commerce platforms specialize in machinery parts. Look for reputable sites that provide detailed descriptions and customer reviews.

- Local Repair Shops: Visit nearby service centers or repair shops that may stock parts or can order them for you. They often have expert knowledge about what works best.

- Manufacturer’s Website: The official site often has a dedicated section for parts sales. You can find diagrams and part numbers to assist with your search.

- Salvage Yards: Consider visiting salvage yards that deal in machinery. They may have used parts available at a lower cost, which can be a viable option for older models.

Utilizing these resources can simplify the process of finding the right components and ensure your equipment remains in top condition for years to come.

Using the Repair Manual Effectively

Maximizing the benefits of a maintenance guide is crucial for achieving successful outcomes in your equipment upkeep. Understanding how to navigate the resource efficiently can save time and prevent potential issues. By following a systematic approach, users can enhance their troubleshooting and repair processes, ensuring optimal performance and longevity of their machinery.

Begin by familiarizing yourself with the layout of the guide. Most resources are structured to provide clear sections for troubleshooting, parts identification, and step-by-step procedures. Having a clear idea of where to find information is essential.

| Section | Description |

|---|---|

| Troubleshooting | Guidelines to identify common issues and their solutions. |

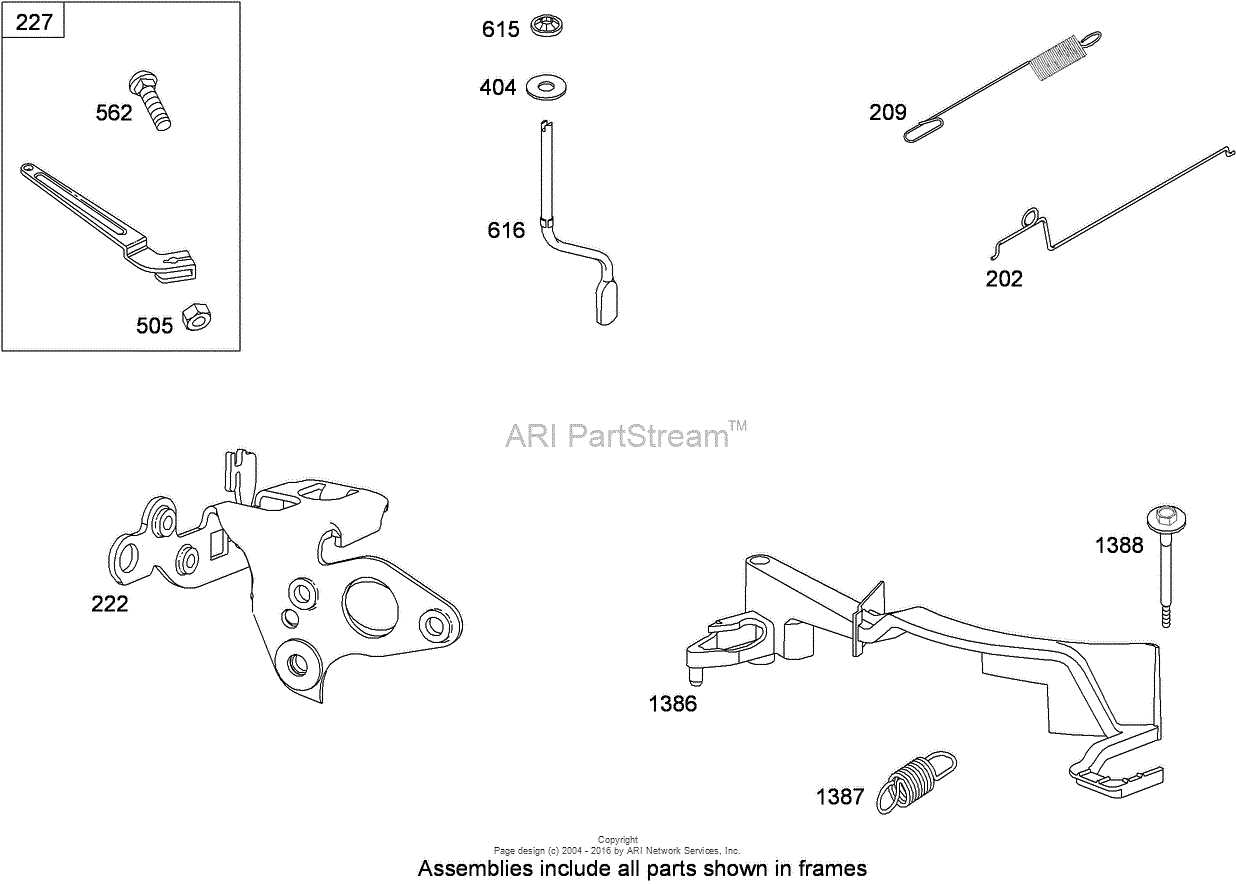

| Parts Identification | A comprehensive list of components with images for easy recognition. |

| Step-by-Step Procedures | Detailed instructions for conducting repairs or maintenance tasks. |

When referring to the guide, make sure to keep your tools and materials ready. This preparation will allow you to follow along with the instructions seamlessly, reducing the likelihood of errors. Additionally, take notes on any specific steps that may require further attention or adjustment based on your unique situation.

Finally, consider revisiting the resource periodically. Over time, you may encounter new challenges or gain additional insights that can further enhance your understanding. By approaching the guide with an open mind and a willingness to learn, you can significantly improve your repair capabilities and confidence.

Customer Reviews and Experiences

This section highlights the thoughts and insights shared by users who have engaged with the product. Feedback from customers plays a vital role in understanding its performance, usability, and overall satisfaction. By examining various experiences, potential buyers can make informed decisions.

Many users have expressed their appreciation for the ease of operation and effectiveness of the device. Here are some common themes from the feedback:

- Reliability: Numerous customers noted the dependable nature of the equipment, citing its consistent performance even in demanding conditions.

- Maintenance: Users highlighted that upkeep is straightforward, allowing them to keep the product in excellent working order with minimal effort.

- Customer Support: Many reviews mention the helpfulness of the customer service team, with users reporting quick responses to inquiries and issues.

- Value for Money: A significant number of customers feel that the benefits provided by the product justify its price, making it a worthwhile investment.

However, some individuals experienced challenges, particularly regarding:

- Initial Setup: A few users found the initial assembly process to be confusing and time-consuming.

- Weight: Some reviews mentioned the weight of the device as a drawback, making it less portable than expected.

Overall, the experiences shared by users provide a comprehensive view, helping others to navigate their choices with greater confidence.