For boat enthusiasts and professionals alike, understanding the nuances of maintaining marine engines is essential. Regular upkeep of these motors can greatly extend their lifespan and enhance overall performance on the water. Learning to care for and troubleshoot your engine can also bring peace of mind, reducing the chances of unexpected issues while out on a trip.

Many marine motor types share similar internal systems, making it easier to apply general maintenance techniques across different brands and models. By familiarizing yourself with these universal practices, you can handle minor adjustments and preventative care without needing immediate professional intervention.

Understanding Your Engine’s Needs is key to keeping it in optimal shape. Knowledge of common issues, from cooling system checks to inspecting electrical connections, allows you to identify problems before they escalate. Additionally, routine maintenance can help prevent common issues related to wear, corrosion, and fuel efficiency.

In this guide, we’ll walk you through essential upkeep task

For those looking to understand watercraft motor maintenance, this guide provides essential information on key areas of boat engine servicing and upkeep. The following sections outline practical approaches, necessary tools, and the most effective strategies for engine care.

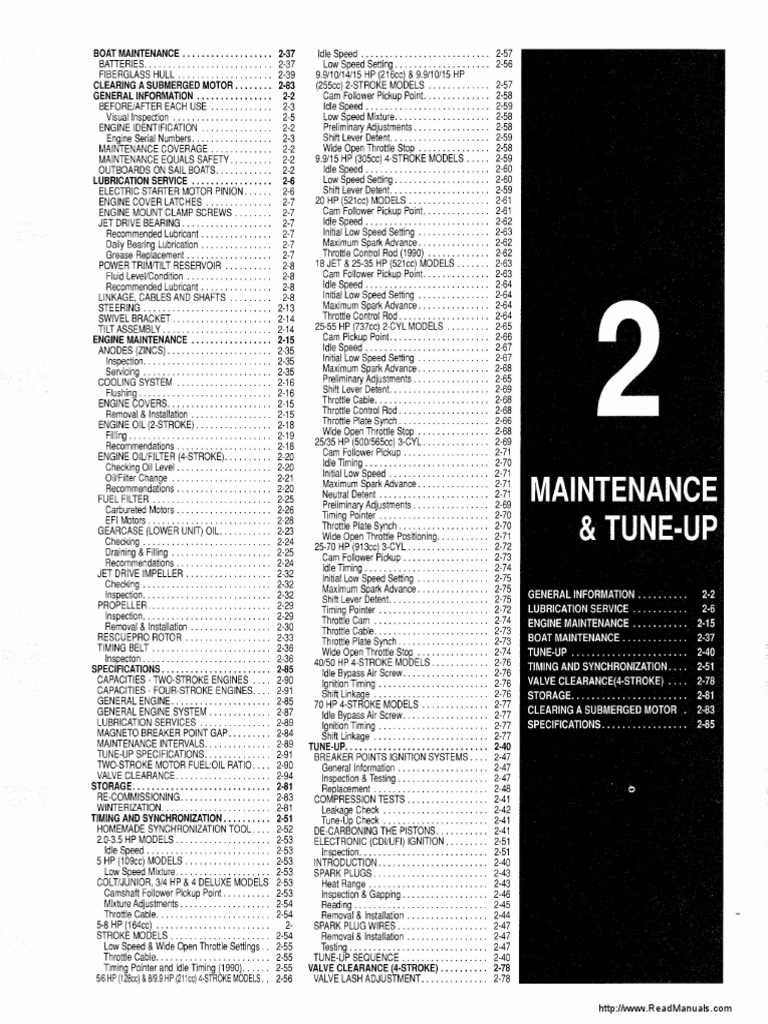

Step-by-Step Engine Maintenance Essentials

Learn the primary aspects of engine maintenance, covering basic inspection routines, critical components, and effective procedures to enhance motor longevity.

- Routine lubrication practices to minimize friction

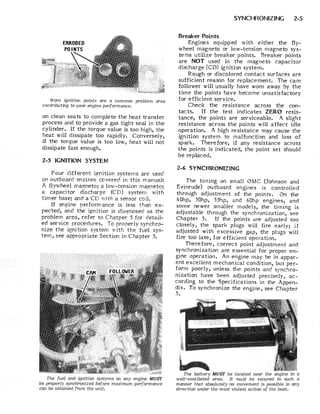

- Inspecting spark plugs and ensuring proper ignition

- Monitoring fuel filters for optimal performance

Diagnosing Common Engine Issues

This section covers frequent problems encountered by boat owners, such as engine start failures, unusual sounds, and performance drops. Tips are included to help identify underlying causes and determine appropriate solutions.

- Check for fuel

Finding Free Repair Resources

Locating comprehensive guides for troubleshooting marine engines can be both economical and effective, especially when utilizing resources available online. Such information can empower enthusiasts and professionals alike to address issues independently, saving time and costs.

- Online Communities: Many forums and discussion groups are filled with knowledgeable individuals sharing advice, tips, and detailed instructions. These communities can be invaluable for finding step-by-step solutions and insights from experienced users.

- Public Libraries: Often overlooked, libraries provide a wealth of resources, including guides on engine maintenance and technical manuals that may not be easily accessible elsewhere. Some even offer digital access to materials, making it convenient to find relevant information.

- Video Platforms: Many instructional videos cover various aspects of marine engine maintenance and servicing. These videos often provide visual demonstrations, making it easier to follow procedures accurately.

- Specialized Websites: Several websites dedic

Understanding Common Marine Engine Issues

Marine motors often experience wear and tear from frequent use and exposure to water environments, leading to certain predictable challenges. Recognizing these issues early can significantly help in maintaining engine performance and prolonging its lifespan. This section covers frequent engine concerns and provides insight into how small adjustments and routine maintenance can prevent larger malfunctions.

Fuel System Troubles: One common issue involves the fuel system, where blockages or poor-quality fuel can disrupt the motor’s functionality. Regular cleaning of fuel filters and using high-grade fuel can enhance engine operation and reduce potential damage.

Cooling System Inefficiencies: Another area to monitor is the cooling system. Marine engines rely on effective water circulation to prevent overheating. Blocked water inlets or faulty impellers may cause the motor to overheat, leading to long-term damage if unchecked. Regular inspections and replacing worn parts as needed can help maintain a steady temperature.

Electrical Connections: Finally, electrical problems are also common, especially in humid environments. Corrosion or loose connections can interrupt power flow, causing unreliable performance. Ensuring tight, corrosion-free connections will help keep the motor functioning smoothly and reliably.

Essential Tools for Outboard Maintenance

Performing effective upkeep on your marine engine requires a selection of reliable tools designed for the unique challenges of working on watercraft. With the right equipment, routine checks and servicing become more efficient, helping to extend the lifespan of your motor and ensure smooth performance on the water.

Basic Hand Tools

For general upkeep, a solid set of hand tools is essential. This includes wrenches, screwdrivers, and pliers that match the bolts and screws commonly found on most marine engines. Opting for corrosion-resistant materials like stainless steel can prevent rust buildup, which is crucial in a marine environment.

Engine-Specific Tools

To address more detailed inspections, consider engine-specific instruments. Spark plug wrenches, oil extractors, and compression testers allow for precise adjustments and diagnostics. These tools not only help identify potential issues early but also make it easier to keep the engine running smoothly over time.

Basic Engine Troubleshooting Techniques

Understanding how to diagnose common issues in an engine is essential for maintaining its functionality and preventing unexpected breakdowns. By identifying key symptoms and systematically inspecting different components, you can quickly uncover the source of the problem and address it effectively.

Step 1: Start by examining the fuel system. Fuel-related issues often cause engines to stall or fail to start. Check the fuel quality, ensure there is no water contamination, and inspect the fuel lines for any signs of blockage or leaks.

Step 2: Assess the ignition system. Faulty spark plugs or disconnected wires may lead to inconsistent firing. Remove and inspect each spark plug for damage or excessive carbon build-up. Replace any that appear worn or damaged.

Step 3: Look at the cooling system. An overheated engine can suffer severe damage if not quickly addressed. Make sure the cooling passages are clear of debris,

Replacing Worn-Out Outboard Parts

Maintaining the functionality of a boat engine is crucial for ensuring optimal performance and safety on the water. Over time, certain components may become degraded or damaged, necessitating their replacement. Recognizing when and how to swap out these parts can significantly enhance the longevity of your vessel.

Identifying Worn Components

Before beginning the replacement process, it’s important to identify which parts require attention. Common signs of wear include:

- Visible corrosion or rust on metal surfaces

- Unusual noises during operation

- Decreased engine performance

- Leaking fluids around joints or seals

Steps for Replacement

Once worn parts are identified, follow these steps for a successful replacement:

- Gather necessary tools and new components.

- Ensure the engine is turned off and cooled down.

- Carefully remove the old part, taking note of its position and any connected components.

- Install the new part, ensuring a secure fit.

- Reconnect any hoses or electrical connections as needed.

- Test the engine to ensure proper functionality.

Step-by-Step Carburetor Cleaning Guide

Maintaining optimal performance of a marine engine involves regular upkeep of various components, with the carburetor being a critical element. A clean carburetor ensures smooth operation and efficient fuel consumption. This guide provides a thorough process for cleaning the carburetor effectively, enhancing the longevity and functionality of your engine.

Necessary Tools and Materials

- Carburetor cleaner

- Soft brush

- Compressed air canister

- Clean rags or paper towels

- Screwdrivers (flat and Phillips)

- Protective gloves and eyewear

Cleaning Procedure

- Begin by ensuring the engine is turned off and has cooled down.

- Disconnect the fuel line and remove the carburetor from the engine.

- Disassemble the carburetor, taking care to note the placement of all parts.

- Spray carburetor cleaner into the jets and passages. Use the soft brush to dislodge any stubborn debris.

- Rinse all parts with cleaner and ensure no residue remains.

- Blow out the passages with compressed air to remove any remaining particles.

- Wipe all components with a clean rag, ensuring they are free of dirt and oil.

- Reassemble the carburetor carefully, ensuring all parts are correctly aligned.

- Reconnect the carburetor to the engine and reattach the fuel line.

- Start the engine and check for proper operation.

How to Maintain Engine Efficiency

Ensuring optimal performance of your marine engine involves regular maintenance and a few key practices that enhance its efficiency. By focusing on these essential aspects, you can prolong the life of your equipment and improve fuel economy.

Regular Inspection and Cleaning

Conduct routine checks to identify any potential issues early. Cleaning the engine components, such as the filters and cooling systems, is crucial. A clean engine operates more efficiently and reduces the risk of overheating, which can lead to significant damage.

Optimal Fuel Quality

Using high-quality fuel can make a noticeable difference in engine performance. Regularly replacing fuel filters and ensuring that the fuel is fresh helps maintain combustion efficiency and reduces carbon buildup within the engine. Consider using fuel additives that are designed to enhance performance and keep the fuel system clean.

Fixing Electrical System Problems

Addressing issues within the electrical system of a marine engine can be essential for optimal performance and safety. Understanding common symptoms and their underlying causes will help in troubleshooting effectively. Below are some typical problems and practical steps for resolution.

- Dead Battery: If the engine fails to start, the battery might be depleted. Check the voltage using a multimeter.

- Corroded Connections: Inspect all connections for corrosion. Clean any that appear oxidized to ensure a solid electrical contact.

- Faulty Wiring: Look for frayed or damaged wires. Replace any compromised wiring to prevent shorts and electrical failures.

- Malfunctioning Switches: Test switches for continuity. Replace any faulty switches that could interrupt the power supply.

After identifying the issue, it is crucial to follow proper protocols for repairs. Ensure that all safety measures are in place before attempting any fixes.

- Disconnect the battery to prevent accidental shocks.

- Use appropriate tools and replacement parts suited for marine applications.

- Reconnect all components securely and test the system thoroughly before use.

By following these steps, you can effectively address and resolve electrical system problems, ensuring a safe and enjoyable boating experience.

Repairing Propeller and Shaft Damage

Addressing issues related to the propeller and shaft is crucial for maintaining optimal performance in marine engines. Damage to these components can lead to inefficiencies and potential failure during operation. Understanding the necessary steps to rectify such problems is essential for any enthusiast or technician involved in vessel maintenance.

To effectively restore the functionality of the propeller and shaft, one must first assess the extent of the damage. This assessment includes visual inspections and measurements to determine the necessary repairs or replacements. Below is a table outlining common types of damage and corresponding solutions:

Type of Damage Recommended Action Minor Dents Use a hammer and block of wood to gently reshape the propeller. Cracks Welding or replacing the damaged part is advised. Corrosion Sand down the affected area and apply a protective coating. Worn Shaft Replace the shaft if it shows signs of significant wear. Once the damage has been evaluated and a plan of action has been established, it is important to gather the necessary tools and materials to execute the repairs effectively. Proper techniques and attention to detail will ensure that the components function smoothly, enhancing the overall performance of the vessel.

Improving Fuel System Performance

Enhancing the efficiency of your fuel delivery system is crucial for optimal engine operation. A well-functioning system ensures that the right amount of fuel reaches the engine, resulting in better performance and reduced emissions. This section explores various techniques to maximize fuel system efficiency, contributing to smoother operation and prolonged engine life.

Regular Maintenance Practices

Routine upkeep is vital for maintaining the integrity of the fuel system. Cleaning fuel injectors and replacing filters at specified intervals prevents clogs and ensures a steady fuel flow. Additionally, checking for leaks and inspecting fuel lines can avert potential issues that may lead to decreased efficiency.

Quality of Fuel and Additives

The type of fuel used significantly impacts performance. Opting for high-quality fuel and utilizing appropriate additives can enhance combustion efficiency. These products can help in cleaning the injectors, preventing carbon buildup, and improving overall engine responsiveness.

Winterizing Your Johnson Outboard Motor

Preparing your marine engine for the colder months is crucial to ensure its longevity and performance. This process involves several important steps to protect the engine from freezing temperatures and potential damage caused by harsh weather conditions.

First, it’s essential to drain all fluids from the engine. This includes removing any remaining fuel and coolant to prevent them from expanding and causing damage. Additionally, consider replacing the oil with fresh lubricant to avoid contaminants that could harm the engine during storage.

Next, clean the exterior of the engine and inspect it for any signs of wear or corrosion. Applying a protective coating can help shield the surface from moisture and salt, which can lead to deterioration over time. Also, ensure that all electrical connections are secure and free from corrosion to maintain functionality.

Finally, store the engine in a dry, sheltered location to keep it safe from environmental elements. Using a cover can provide extra protection, helping to ensure that your engine remains in excellent condition and is ready for action when the boating season returns.