Owning a marine engine comes with the responsibility of ensuring its longevity and optimal performance. Understanding the various aspects of upkeep can significantly enhance the lifespan of your vessel’s power unit. This section provides valuable insights into essential practices and techniques for maintaining your outboard engine effectively.

Regular servicing is crucial in preventing unforeseen issues that may arise during use. By adhering to a consistent schedule of inspections and necessary adjustments, you can minimize the risk of breakdowns and ensure smooth operation. Knowledge of common troubleshooting methods can also empower you to address minor concerns before they escalate.

Furthermore, familiarizing yourself with specific components and their functions will aid in identifying potential problems early. Whether it’s monitoring fuel systems or understanding electrical connections, a proactive approach can make all the difference. With the right guidance, you’ll be well-equipped to keep your engine running at its best.

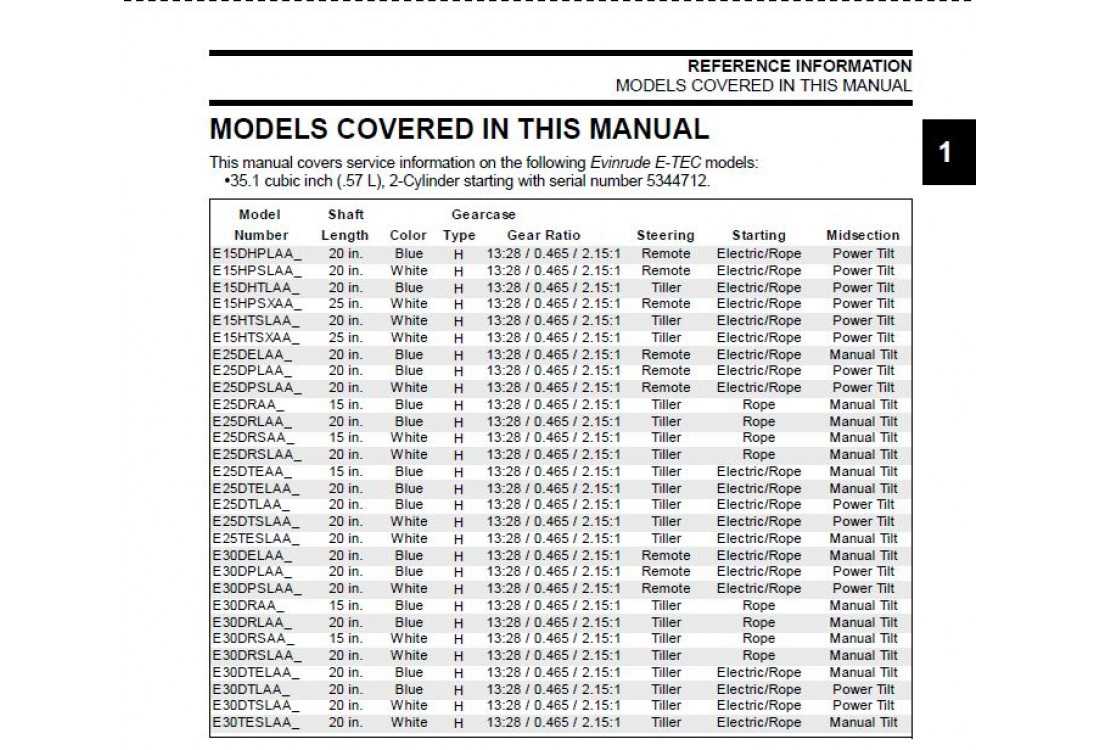

Evinrude Etec Repair Manual Overview

This section provides a comprehensive insight into the guidance available for maintaining and troubleshooting specific outboard motors. It serves as a valuable resource for owners seeking to enhance the longevity and performance of their equipment.

With a focus on best practices and common issues, the document outlines essential procedures that can help users address various challenges. Understanding these techniques is crucial for anyone looking to ensure their motor operates smoothly and efficiently.

Furthermore, this compilation emphasizes the importance of regular upkeep and timely interventions, ultimately contributing to a more enjoyable experience on the water. By following the outlined strategies, users can navigate potential difficulties with confidence and skill.

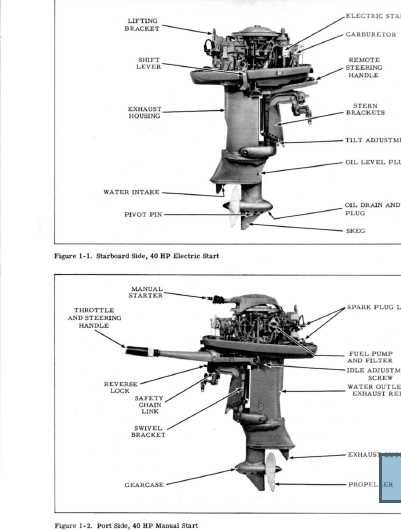

Understanding the Evinrude Etec Engine

This section explores the fundamental aspects of a modern outboard motor system, highlighting its innovative design and performance capabilities. These engines are renowned for their efficiency, reliability, and user-friendly features, making them a popular choice among boating enthusiasts.

Key components of this advanced propulsion system include the following:

| Component | Description |

|---|---|

| Powerhead | The heart of the engine, responsible for converting fuel into mechanical energy. |

| Fuel System | Designed to optimize fuel delivery for enhanced performance and reduced emissions. |

| Ignition System | Ensures reliable starting and consistent performance across various operating conditions. |

| Exhaust System | Effectively manages emissions while providing a quiet operating environment. |

Understanding these elements is crucial for anyone looking to appreciate the technology behind efficient watercraft propulsion.

Common Issues with Evinrude Etec

Owners of outboard engines often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems can help users address issues promptly and ensure smoother operation on the water.

Performance Degradation

One frequent concern is a decline in engine efficiency, which can manifest as reduced speed or power. Factors contributing to this issue may include:

- Clogged fuel filters

- Worn spark plugs

- Inadequate fuel quality

Electrical System Failures

Electrical components can also be prone to malfunction, leading to various operational difficulties. Key aspects to monitor include:

- Battery health

- Corroded connections

- Malfunctioning sensors

By recognizing these common problems, users can take proactive steps to maintain their outboard engines effectively.

Essential Tools for Etec Repairs

To ensure optimal maintenance and functionality of your outboard engine, having the right instruments is crucial. Various tools facilitate troubleshooting and adjustments, making the process smoother and more efficient.

- Socket Set: A versatile tool for various fasteners, essential for loosening and tightening components.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Multimeter: Useful for checking electrical systems and diagnosing issues with wiring or components.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for a wide range of tasks.

- Pliers: Ideal for gripping, twisting, and cutting wires or small components.

- Cleaning Supplies: Brushes and solvents for maintaining cleanliness and performance of the engine parts.

- Safety Gear: Gloves and goggles to protect yourself while working on the machinery.

With these essential tools, you will be well-equipped to address various tasks, enhancing the longevity and efficiency of your equipment.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your outboard engine in optimal condition. Regular upkeep ensures longevity and efficient performance, ultimately enhancing your boating experience.

Begin by inspecting the engine’s exterior for any signs of wear or damage. Clean the casing to remove debris and prevent corrosion. Check the propeller for any nicks or bends, as these can affect performance.

Next, focus on the internal components. Replace the spark plugs according to the manufacturer’s recommendations to ensure a smooth ignition process. Regularly change the oil and filter to maintain engine health and efficiency.

Don’t forget to examine the fuel system. Ensure that fuel lines are intact and free of leaks. Consider using a fuel stabilizer during off-seasons to prevent varnishing in the system.

Lastly, consult the recommended service intervals for specific components like the cooling system and electrical parts. Keeping a detailed log of maintenance tasks can help track progress and ensure nothing is overlooked.

Diagnosing Evinrude Etec Problems

Identifying issues with outboard motors can be a complex task. Proper diagnosis is essential for efficient maintenance and repair. Understanding the symptoms and conducting a thorough examination will help pinpoint the underlying problems.

Common Symptoms to Watch For

Several indicators may suggest malfunctions in your engine. These can include irregular sounds, decreased performance, and starting difficulties. Monitoring these signs closely can provide valuable insights into the condition of the motor.

Steps for Effective Diagnosis

To effectively troubleshoot, begin with a visual inspection. Look for signs of wear, leaks, or loose connections. Next, consider utilizing diagnostic tools to analyze the performance metrics. Document any findings to help guide further investigations.

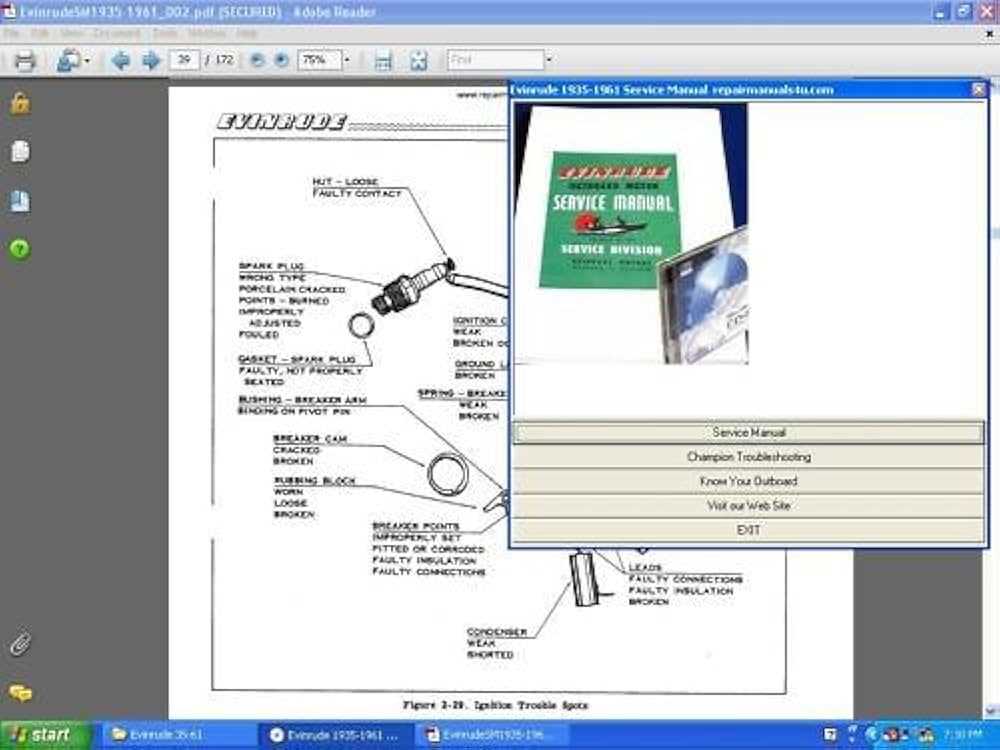

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a watercraft is crucial for ensuring optimal performance. This segment delves into common problems that may arise, guiding users through effective strategies for identification and resolution.

It is essential to conduct a thorough inspection of the components, including connections, fuses, and power sources. Regular maintenance can prevent many electrical failures. Below is a table summarizing potential issues and their corresponding solutions:

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Power Failure | Faulty battery or connection | Check and replace battery; tighten connections |

| Flickering Lights | Loose wiring or poor ground | Tighten connections; ensure proper grounding |

| Start-up Problems | Defective starter or ignition system | Inspect starter and ignition components |

| Overheating | Insufficient cooling or electrical overload | Check cooling system; avoid excessive loads |

Fuel System Adjustments and Repairs

Maintaining an optimal fuel system is crucial for ensuring smooth engine operation and longevity. This section discusses essential modifications and corrective actions that can enhance performance and resolve common issues associated with fuel delivery and efficiency.

Key Components of the Fuel System

Understanding the fundamental parts of the fuel system is vital for effective adjustments. Here are the primary components:

- Fuel tank

- Fuel pump

- Fuel filter

- Fuel injectors

- Pressure regulator

Common Issues and Solutions

Addressing typical problems can significantly improve performance. Here are some frequent issues and their solutions:

- Clogged Fuel Filter: Regularly replace the filter to prevent blockages.

- Inadequate Fuel Pressure: Check and replace the fuel pump if pressure is below specifications.

- Injector Malfunction: Clean or replace fuel injectors if performance is lacking.

By focusing on these adjustments, users can ensure a more efficient and reliable fuel system, enhancing the overall performance of their equipment.

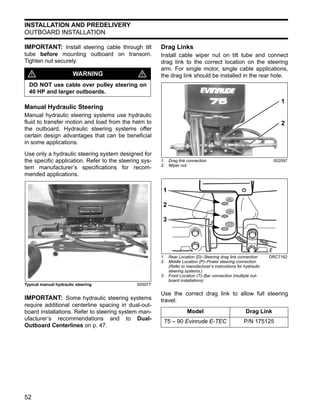

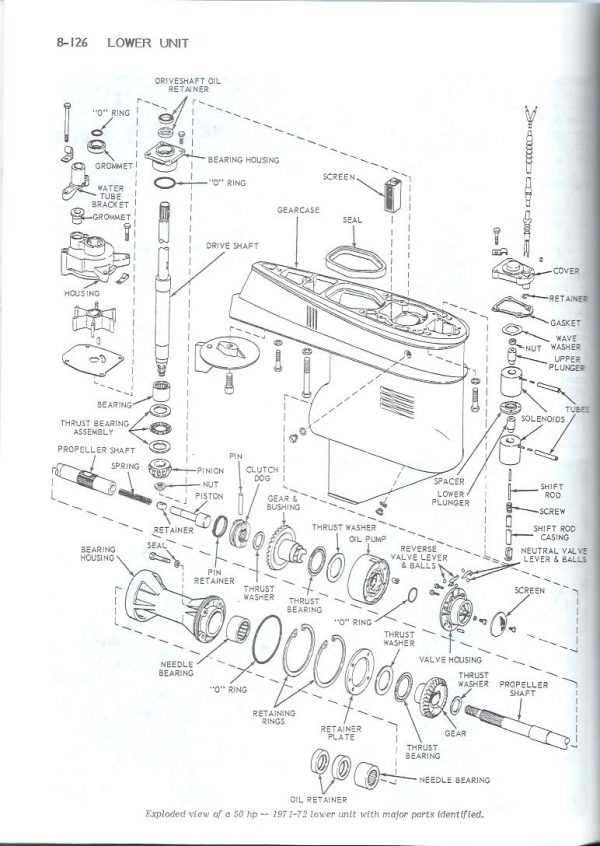

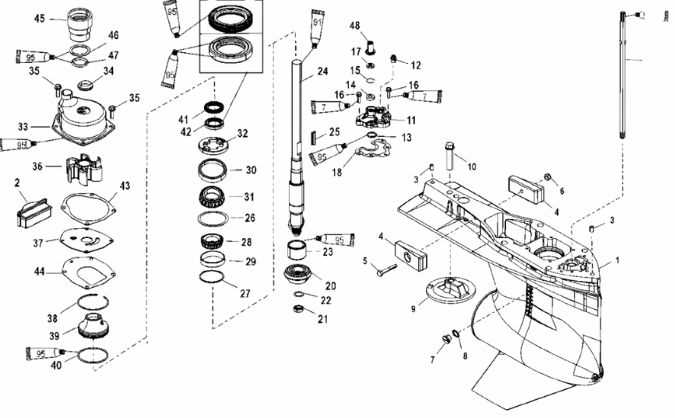

Propeller and Gearbox Maintenance

Regular upkeep of the propulsion system is crucial for optimal performance and longevity. This section outlines essential practices for maintaining the propeller and gearbox components, ensuring reliable operation and minimizing potential issues during usage.

Inspection and Cleaning

Routine inspection of the propeller and gearbox is vital. Check for signs of wear, corrosion, or damage. Clean these components thoroughly to remove debris, salt, and other contaminants that can affect performance. A clean propeller allows for better efficiency and reduces strain on the engine.

Lubrication and Replacement

Proper lubrication is essential for the gearbox to function smoothly. Use high-quality lubricants as specified in maintenance guidelines. Additionally, monitor for any leaks or unusual noises that may indicate the need for replacement of worn parts. Timely intervention can prevent more significant repairs down the line.

Winterizing Your Evinrude Etec

Preparing your outboard engine for the colder months is essential to ensure its longevity and performance. Proper winterization helps protect vital components from freezing temperatures and moisture, preventing damage and ensuring a smooth start when the warm weather returns.

Drain the Cooling System: Begin by removing any water from the cooling system. This can be done by starting the engine and allowing it to run for a short period. This step ensures that no water is left to freeze and cause harm during winter.

Add Fuel Stabilizer: Incorporating a fuel stabilizer into your fuel tank helps prevent the gasoline from breaking down. This step ensures that your engine remains in optimal condition when you are ready to use it again.

Change the Oil: Replacing old oil with fresh lubricant is crucial. This practice removes contaminants that could corrode engine parts over time. Ensure that the new oil is appropriate for your specific engine type.

Inspect and Clean: Take the time to examine the engine and clean any debris or buildup. Pay special attention to the propeller and lower unit, as these areas can accumulate grime and require thorough cleaning.

Store Properly: Finally, consider the storage location. A dry, sheltered space protects the engine from harsh weather and temperature fluctuations. Covering the engine with a breathable cover can also provide added protection against dust and debris.

Finding Replacement Parts

When it comes to maintaining and restoring your outboard engine, sourcing the correct components is essential. The process involves identifying the necessary parts to ensure optimal performance and longevity of your equipment. Various avenues are available to help locate these items effectively.

Online Resources

Numerous websites specialize in marine parts, offering a wide selection of components for different models. Utilizing these platforms can save time and provide valuable information regarding compatibility. Ensure to verify the specifications before making a purchase.

Local Dealers and Distributors

Visiting authorized dealers can be beneficial as they often carry genuine components and have knowledgeable staff to assist with your inquiries. Building a relationship with local distributors can also lead to helpful insights and potential discounts on future purchases.

In conclusion, whether you choose to explore online or visit local suppliers, being informed about your options is key to successfully finding the right parts for your outboard engine.

Safety Tips During Repairs

When working on any mechanical equipment, it is crucial to prioritize safety. This ensures not only personal well-being but also the integrity of the machinery involved. Following specific guidelines can help minimize risks and create a safer environment for all involved.

Preparation is Key

Before beginning any work, ensure you have the appropriate tools and safety gear. This includes gloves, goggles, and sturdy footwear. Familiarize yourself with the equipment and understand the task at hand to avoid unforeseen hazards.

Working Environment

Maintain a clean and organized workspace to reduce the likelihood of accidents. Ensure good lighting and ventilation, and keep all materials and tools within reach. It’s advisable to work in a dry area and avoid distractions during the task.

| Safety Equipment | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and chemicals |

| Goggles | Prevent eye injury from debris |

| Footwear | Provide protection against heavy items |