In the realm of industrial machinery, ensuring optimal performance and longevity is crucial for any operation. Understanding the intricacies of maintaining complex systems not only enhances efficiency but also prevents costly downtime. This section aims to equip users with the knowledge necessary to tackle various maintenance challenges.

Proper upkeep of mechanical devices involves familiarizing oneself with their components and troubleshooting techniques. By mastering these skills, operators can address issues proactively, reducing the likelihood of unexpected failures. This guide provides valuable insights into effective strategies for sustaining equipment health.

Furthermore, the importance of adhering to manufacturer recommendations cannot be overstated. Utilizing a structured approach to service and upkeep allows users to maximize the lifespan of their tools. This compilation serves as a vital resource for those seeking to enhance their proficiency in maintaining essential machinery.

Understanding Ingersoll Rand Equipment

Comprehending the various types of machinery and tools produced by a leading manufacturer is essential for effective utilization and maintenance. This segment aims to shed light on the core aspects of these devices, focusing on their functionality, design, and application across various industries.

Types of Equipment

The range of devices offered by this manufacturer encompasses several categories, each tailored to meet specific operational needs. Below is a summary of the main types of equipment:

| Equipment Type | Primary Use |

|---|---|

| Compressors | Providing compressed air for various applications |

| Generators | Supplying electrical power in remote locations |

| Pumps | Moving fluids in industrial settings |

| Tools | Facilitating assembly and disassembly in manufacturing |

Importance of Understanding Equipment

Grasping the operational principles and maintenance requirements of these machines can significantly enhance their performance and longevity. Users equipped with knowledge about the intricacies of their tools can better troubleshoot issues, optimize productivity, and ensure safety in their working environment.

Importance of a Repair Manual

Having a comprehensive guide is crucial for maintaining and troubleshooting equipment. Such documentation provides detailed instructions that can help users navigate complex processes and avoid common pitfalls.

The significance of these guides can be highlighted through several key aspects:

- Efficiency: Detailed instructions streamline the process, saving time and reducing frustration.

- Safety: Proper guidelines ensure that individuals follow safe practices, minimizing the risk of accidents.

- Cost-Effectiveness: Understanding how to address issues independently can lead to significant savings on professional services.

- Prolonging Equipment Life: Regular maintenance based on informed practices can enhance the longevity and performance of tools.

- Knowledge Empowerment: Users gain confidence and skills, becoming more adept at handling technical challenges.

In summary, a thorough guide is an invaluable asset for anyone looking to effectively manage their tools and machinery. It not only fosters self-reliance but also contributes to better operational outcomes.

Common Ingersoll Rand Products

Various tools and equipment play a crucial role in numerous industries, providing reliability and efficiency. Among these offerings, several key items stand out for their performance and durability, catering to the diverse needs of professionals and businesses alike.

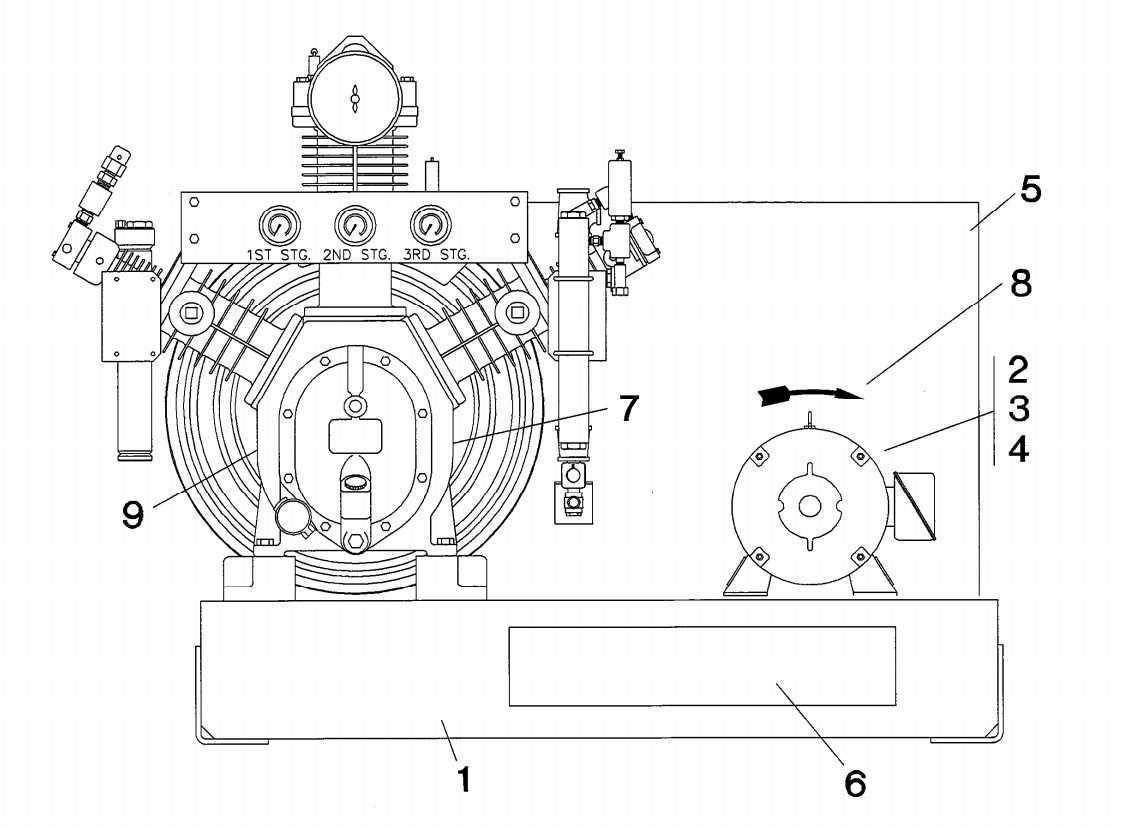

Air Compressors are fundamental in many applications, delivering compressed air for powering tools, inflating tires, and more. These units come in various sizes and capacities, ensuring that users can find the perfect match for their specific requirements.

Impact Wrenches are indispensable for heavy-duty tasks. With their ability to deliver high torque, they make assembling and disassembling equipment effortless, greatly enhancing productivity on job sites.

Pneumatic Tools are essential for a range of tasks, from automotive repair to construction. These tools leverage compressed air to operate, offering advantages such as lighter weight and higher power compared to their electric counterparts.

Generators provide reliable power solutions, ensuring that operations continue smoothly, even in the absence of a main power supply. Their portability and efficiency make them ideal for both temporary and permanent installations.

With a commitment to innovation and quality, these products have earned their place as favorites among professionals across various sectors, helping them achieve their goals efficiently and effectively.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing equipment malfunctions. Following these detailed instructions will ensure that issues are resolved efficiently and safely, enhancing the longevity of your machinery.

| Step | Description |

|---|---|

| 1 | Identify the problem by conducting a thorough inspection of the equipment. |

| 2 | Gather the necessary tools and replacement parts before starting the intervention. |

| 3 | Power down the equipment and ensure all safety protocols are in place. |

| 4 | Disassemble the components carefully, keeping track of all parts and fasteners. |

| 5 | Inspect each component for wear or damage, noting any items that require replacement. |

| 6 | Clean all parts thoroughly to remove debris and old lubricant. |

| 7 | Replace worn or damaged components with new ones, ensuring proper alignment. |

| 8 | Reassemble the equipment carefully, following the reverse order of disassembly. |

| 9 | Reconnect power and test the machinery to verify that the issue has been resolved. |

| 10 | Document the process and any parts replaced for future reference. |

Identifying Common Issues

Recognizing typical problems in equipment operation is crucial for maintaining efficiency and longevity. By understanding the signs and symptoms of potential failures, users can take proactive steps to address these concerns before they escalate into more significant challenges. This section outlines common indicators that suggest the need for further investigation and possible intervention.

| Issue | Symptoms | Potential Causes |

|---|---|---|

| Unusual Noises | Grinding, squeaking, or rattling sounds | Wear of components, insufficient lubrication, misalignment |

| Performance Decline | Reduced output or sluggish operation | Blocked filters, worn-out parts, incorrect settings |

| Overheating | Excessive heat generation during operation | Blocked cooling pathways, low coolant levels, motor issues |

| Leakage | Fluid escaping from connections or housing | Damaged seals, loose fittings, corrosion |

By being aware of these common issues and their indicators, operators can effectively manage the upkeep of their machinery and ensure optimal performance.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for achieving effective results. The selection of tools not only enhances efficiency but also ensures safety during the process. This section highlights the fundamental instruments that should be included in any toolkit for successful servicing.

Basic Toolkit Components

A well-rounded toolkit typically consists of a variety of instruments that cater to different needs. Below is a list of essential items every technician should consider having on hand:

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening nuts and bolts. |

| Screwdrivers | Essential for driving screws and adjusting components. |

| Pliers | Helpful for gripping, bending, and cutting wire. |

| Hammer | Used for driving nails and providing force on components. |

| Measuring Tape | Critical for ensuring precise measurements. |

Advanced Instruments

For more complex tasks, additional specialized tools may be required. Investing in these instruments can significantly enhance the quality of work:

| Tool | Purpose |

|---|---|

| Multimeter | Used for measuring voltage, current, and resistance. |

| Torque Wrench | Ensures bolts are tightened to the correct specifications. |

| Diagnostic Scanner | Helps in identifying issues in electronic systems. |

| Socket Set | Facilitates working on various sizes of fasteners. |

| Safety Gear | Protective equipment to ensure personal safety during work. |

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular attention and care. Implementing a solid maintenance routine can significantly extend the lifespan of your machinery, enhancing performance and reducing the likelihood of breakdowns. Below are some essential practices to follow.

Regular Inspections

- Conduct visual checks for signs of wear or damage.

- Listen for unusual sounds during operation.

- Check for leaks and ensure all connections are secure.

Lubrication and Cleaning

- Use the appropriate lubricants as specified in the guidelines.

- Clean components regularly to prevent dust and debris buildup.

- Replace filters according to the recommended schedule.

By adhering to these simple yet effective practices, you can promote optimal functioning and longevity of your equipment.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential for both the technician and the equipment. By adhering to proper guidelines, one can significantly reduce the risk of accidents and enhance the efficiency of the work being performed.

Before beginning any work, consider the following precautions:

- Always wear appropriate personal protective equipment (PPE), such as gloves, goggles, and hearing protection.

- Make sure the work area is clean and free from any obstacles that could pose a hazard.

- Disconnect power sources to prevent accidental activation of machinery.

- Use tools and equipment that are well-maintained and suited for the task.

In addition to these initial measures, be mindful of the following:

- Read all relevant documentation before starting the task to understand the equipment’s specifications and potential risks.

- Work in well-ventilated areas, especially when handling chemicals or working with materials that may produce fumes.

- Keep emergency equipment, such as fire extinguishers and first aid kits, readily accessible.

- Never work alone; always have a colleague nearby in case assistance is needed.

By following these guidelines, you can create a safer work environment and ensure a more effective maintenance process.

Troubleshooting Techniques Explained

Troubleshooting is a systematic approach to identifying and resolving issues in machinery or equipment. It involves a series of steps that allow one to isolate the problem and implement effective solutions. Understanding the fundamental principles of diagnosing faults can significantly enhance the efficiency and longevity of your devices.

To begin with, it’s essential to gather as much information as possible regarding the symptoms exhibited by the equipment. This may include observing unusual noises, checking for leaks, or monitoring performance indicators. Documenting these observations can help create a clear picture of the situation, guiding the troubleshooting process.

Next, employing a methodical approach is vital. Start by verifying that the power supply and connections are intact. Often, issues arise from simple problems such as blown fuses or loose wiring. If these elements are functional, move on to examining individual components. Using diagnostic tools like multimeters or pressure gauges can assist in pinpointing faults with greater precision.

Another effective technique is to perform a process of elimination. By systematically testing or replacing components, you can determine which part is malfunctioning. This not only saves time but also reduces unnecessary expenses associated with replacing intact parts.

Finally, it is crucial to keep a detailed record of the steps taken and the outcomes observed. This documentation serves as a valuable resource for future troubleshooting efforts and can help prevent similar issues from arising again. Building a comprehensive knowledge base through experience enhances both confidence and capability in resolving equipment challenges.

Parts Replacement Guidelines

Replacing components in machinery is crucial for maintaining optimal performance and extending the lifespan of the equipment. Proper procedures and considerations must be followed to ensure that new parts function effectively and safely. This section outlines key recommendations for successful component substitution.

1. Compatibility Check: Before acquiring new parts, verify that they are compatible with your specific machinery model. Consult manufacturer specifications and cross-reference with existing components to avoid any discrepancies.

2. Quality Assurance: Always opt for high-quality replacements. Using substandard or counterfeit parts can lead to equipment failure and increased operational risks. Choose reputable suppliers and consider original equipment options when available.

3. Safety Precautions: Prior to commencing any replacement activities, ensure that the machinery is powered down and secured to prevent accidental start-ups. Use appropriate personal protective equipment to safeguard against potential hazards during the process.

4. Step-by-Step Instructions: Follow a systematic approach when replacing parts. Document each step taken to facilitate future maintenance and ensure all connections and alignments are properly executed. Refer to relevant guidelines or tutorials when necessary.

5. Testing and Calibration: After replacing any components, conduct thorough testing to confirm functionality. Check for leaks, vibrations, or irregular noises. Calibrate the machinery as needed to restore its original performance parameters.

By adhering to these guidelines, operators can effectively manage component replacements, ensuring their equipment operates reliably and efficiently for years to come.

Accessing Technical Support

When facing challenges with your equipment, obtaining professional assistance is crucial for maintaining optimal performance. This section outlines the various avenues available for accessing expert guidance and troubleshooting solutions to ensure your operations run smoothly.

Contacting Customer Service

Reaching out to customer service is often the first step in resolving issues. Representatives are trained to handle a wide range of inquiries and can provide immediate support. Ensure you have relevant information on hand, such as model numbers and a detailed description of the problem, to facilitate a quicker resolution.

Utilizing Online Resources

The internet offers a wealth of information, including FAQs, instructional videos, and community forums. These resources can be invaluable for self-diagnosis and finding solutions to common problems. Engaging with online communities can also connect you with other users who may have faced similar challenges.

Understanding Warranty Coverage

Warranty coverage serves as a safety net for consumers, offering assurance that products will perform as expected. This protection can vary widely, influencing the buyer’s experience and the long-term value of the investment. Understanding the specifics of warranty provisions is crucial for maximizing benefits and navigating potential claims.

Types of Warranty Coverage

There are generally two main types of warranty coverage: express and implied. Each type has distinct characteristics that define the rights and obligations of both the manufacturer and the consumer.

| Type | Description |

|---|---|

| Express Warranty | A clearly stated guarantee provided by the manufacturer, outlining specific terms and conditions related to the product’s performance and lifespan. |

| Implied Warranty | A legally recognized assurance that the product will meet certain standards of quality and functionality, even if not explicitly stated. |

Key Considerations

When reviewing warranty terms, it’s important to pay attention to coverage duration, conditions for service, and any exclusions that may apply. Being aware of these factors can help ensure a smoother experience should the need for support arise.

Online Resources for Further Learning

In today’s digital age, a wealth of information is available for those seeking to deepen their knowledge and skills in equipment maintenance and troubleshooting. Utilizing online platforms can greatly enhance your understanding and provide practical insights that traditional resources may not cover.

Here are some valuable online resources to consider:

- Video Tutorials: Websites like YouTube offer numerous instructional videos, showcasing step-by-step guides and expert tips.

- Online Forums: Joining communities on platforms such as Reddit or specialized forums allows you to connect with professionals and enthusiasts who share their experiences and solutions.

- Webinars and Online Courses: Platforms like Coursera and Udemy provide structured learning opportunities, often featuring industry experts.

- Manufacturer Websites: Official sites often have resources such as FAQs, troubleshooting tips, and product documentation that can be very informative.

- Technical Blogs: Following blogs dedicated to maintenance and repair can offer ongoing education and updates on best practices and innovations.

Exploring these resources will empower you with the knowledge necessary to excel in your maintenance endeavors, ensuring you stay informed about the latest techniques and developments in the field.