When it comes to keeping your all-terrain vehicle in peak condition, having access to a thorough resource is essential. This section aims to provide valuable insights and instructions that will help enthusiasts and owners effectively manage their vehicle’s upkeep. By understanding the nuances of maintenance, one can ensure optimal performance and longevity.

Whether you are troubleshooting common issues or conducting routine checks, having a structured approach can make a significant difference. Detailed procedures and specifications play a crucial role in facilitating the repair process. Additionally, familiarizing oneself with the various components and systems enhances the overall ownership experience.

This guide serves as a practical reference for all individuals interested in maintaining their off-road vehicles. By following the outlined techniques and recommendations, users can confidently tackle any challenges that may arise, ensuring their vehicle remains reliable on every adventure.

Overview of the 2004 Polaris Sportsman 700

This section provides a comprehensive insight into a renowned all-terrain vehicle that has garnered significant attention for its performance and reliability. Designed for both recreational use and utility, this model stands out due to its robust features and innovative technology, catering to enthusiasts and practical users alike.

Key Features

Equipped with a powerful engine, this vehicle delivers impressive torque and speed, making it suitable for various terrains. The advanced suspension system ensures a smooth ride, while the ergonomic design enhances user comfort and control. Additionally, the inclusion of modern safety features reflects the commitment to rider security.

Performance and Handling

The dynamic handling characteristics of this vehicle make it adept at navigating challenging landscapes. Its efficient power distribution allows for effortless maneuverability, whether on steep inclines or rugged paths. Overall, this model offers a perfect blend of power and agility, making it a preferred choice for outdoor adventures.

Common Issues and Solutions

In any off-road vehicle, encountering difficulties is a common experience among enthusiasts and users. This section aims to outline frequent challenges that may arise, along with practical solutions to enhance performance and reliability.

Starting Problems

One of the most prevalent issues involves difficulties with ignition. This may stem from a weak battery, corroded connections, or a faulty starter. Regular maintenance, including battery checks and ensuring clean terminals, can mitigate these problems. If the engine fails to turn over, consider replacing the battery or inspecting the starter motor for signs of wear.

Overheating

Another significant concern is overheating, often caused by inadequate coolant levels or a malfunctioning radiator. Regularly checking the coolant system and ensuring that hoses are free from leaks is essential. If overheating persists, examine the thermostat and water pump for any potential failures. Addressing these issues promptly can prevent extensive engine damage.

Essential Tools for Repairs

Having the right equipment is crucial when undertaking maintenance tasks on your vehicle. The proper instruments not only facilitate the process but also ensure safety and efficiency. Here is a list of vital items that should be included in any repair toolkit.

- Wrenches: A variety of sizes, including open-end and socket wrenches, are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips head screwdrivers are essential for handling different types of screws.

- Pliers: These are useful for gripping, twisting, and cutting wire or other materials.

- Torque Wrench: This tool helps ensure that bolts are tightened to the manufacturer’s specifications.

- Jack and Stands: Proper lifting equipment is vital for safely raising the vehicle for underneath access.

- Multimeter: Useful for diagnosing electrical issues and testing circuits.

- Oil Filter Wrench: This tool makes it easier to remove and replace oil filters during servicing.

- Brake Bleeder Kit: Essential for maintaining braking systems by removing air from the lines.

Equipping yourself with these essential tools will greatly enhance your ability to perform necessary maintenance and ensure your vehicle operates smoothly.

Engine Specifications and Maintenance

This section provides a comprehensive overview of the fundamental characteristics and upkeep requirements for the power unit of the vehicle. Proper understanding and regular maintenance are crucial for optimal performance and longevity.

Key Specifications

- Engine Type: Four-stroke, single-cylinder

- Displacement: Approximately 700 cc

- Compression Ratio: 10.0:1

- Fuel System: Electronic fuel injection (EFI)

- Ignition System: Digital ignition

Maintenance Guidelines

- Regularly check and change the engine oil to ensure smooth operation.

- Inspect and replace the air filter periodically to maintain airflow and efficiency.

- Monitor coolant levels and replace coolant as necessary to prevent overheating.

- Examine spark plugs for wear and replace them according to the service schedule.

- Keep the fuel system clean by using quality fuel and occasional fuel system cleaners.

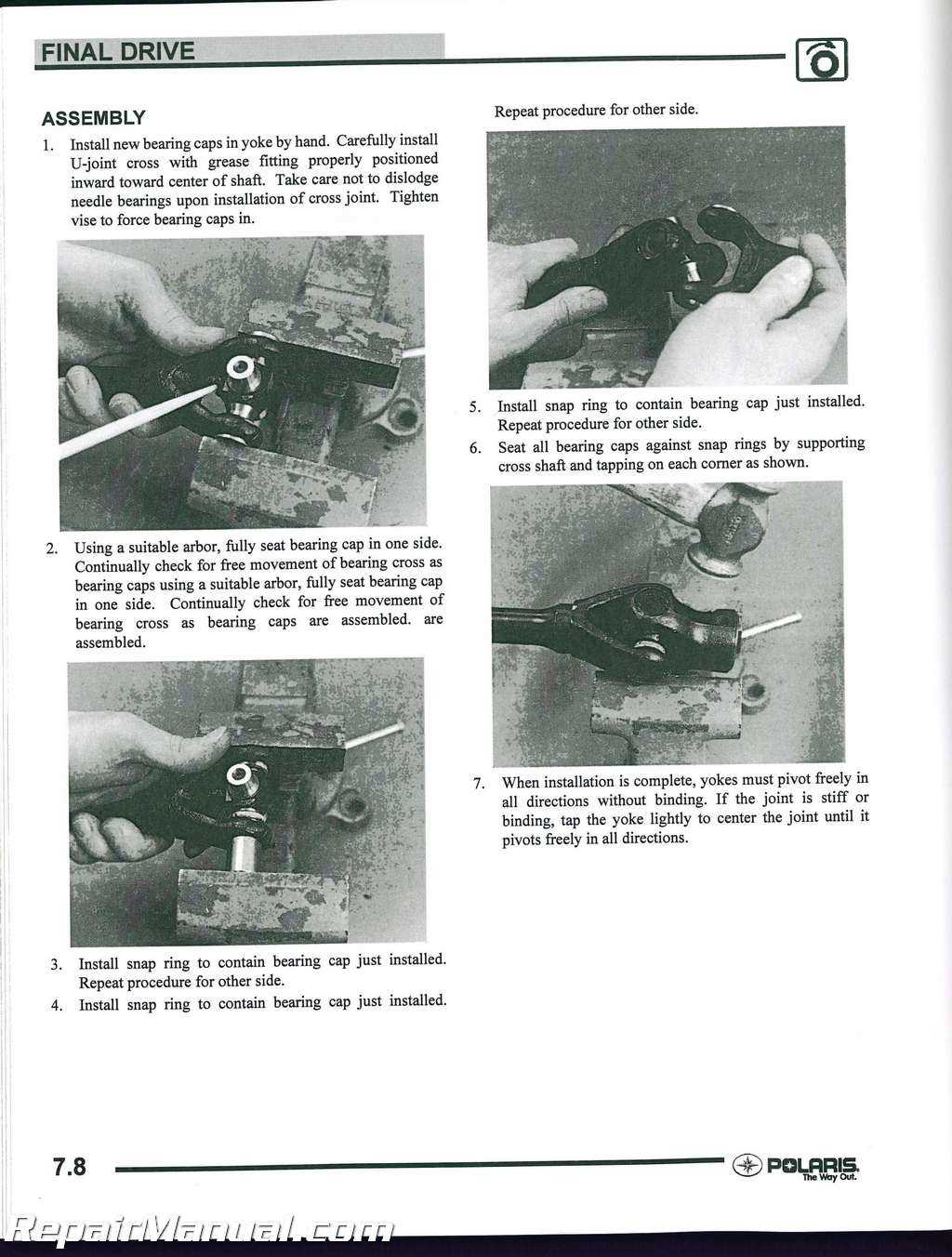

Transmission and Drive System Insights

The transmission and drive system of an all-terrain vehicle play a crucial role in its performance and overall functionality. Understanding these components is essential for ensuring optimal operation and longevity of the machine. This section delves into the intricacies of how power is transferred from the engine to the wheels, enhancing both efficiency and control.

Transmission Mechanism: The transmission serves as the intermediary between the engine and the drive system, allowing the operator to adjust speed and torque as needed. Typically, these systems utilize a series of gears and clutches that work together to provide smooth acceleration and deceleration. Familiarity with the different types of transmission–such as automatic and manual–can aid in recognizing their respective advantages and maintenance requirements.

Drive Components: The drive system encompasses various elements, including the drive shafts, differentials, and axles. Each of these components contributes to the overall handling and traction of the vehicle. Regular inspection of these parts is vital to prevent wear and ensure that power is efficiently transmitted to the wheels.

Maintenance Practices: To prolong the life of the transmission and drive system, routine maintenance is essential. This includes checking fluid levels, replacing filters, and inspecting for leaks or damage. Adhering to a regular maintenance schedule can prevent costly repairs and enhance the vehicle’s reliability on rugged terrain.

In summary, gaining insights into the transmission and drive system is vital for any operator. By understanding how these components function and how to care for them, one can significantly improve the performance and durability of the vehicle.

Electrical System Troubleshooting

Diagnosing issues within the electrical system of an all-terrain vehicle requires a systematic approach to ensure proper functionality. Understanding the components and their interconnections is essential for effective resolution of problems. This section provides guidance on identifying common electrical faults and the methods to address them.

Start by examining the battery condition, ensuring it is charged and securely connected. Corroded terminals can impede performance, so clean them if necessary. Utilize a multimeter to check voltage levels; a healthy battery should read around 12.6 volts when fully charged.

Next, inspect the wiring harness for any visible damage, such as fraying or disconnections. Look for loose or broken connectors that may disrupt the circuit. Pay attention to ground connections, as poor grounding can lead to erratic behavior of electrical components.

If the lighting or instrumentation shows signs of malfunction, verify the associated fuses. Replace any blown fuses and test the affected components again. Additionally, check the switches and relays, ensuring they operate correctly without sticking or short-circuiting.

Finally, if the issue persists, consider using diagnostic tools to analyze the system further. Such tools can reveal error codes that provide insights into specific malfunctions, aiding in targeted troubleshooting efforts.

Suspension and Steering Adjustments

This section covers the essential modifications and settings for the suspension and steering systems to enhance performance and handling. Proper adjustments can lead to improved stability, comfort, and control, ensuring a more enjoyable experience during operation.

Key areas to focus on include:

- Suspension Settings:

- Adjusting the preload to match the weight of the rider and cargo.

- Tuning compression and rebound damping for optimal ride quality.

- Checking for wear and proper alignment of suspension components.

- Steering Adjustments:

- Aligning the handlebars to ensure straight tracking.

- Adjusting the steering sensitivity for better maneuverability.

- Inspecting tie rods and joints for any signs of damage or looseness.

Regular checks and adjustments of these systems will not only extend the lifespan of components but also contribute to safer and more responsive handling. Always consult the specific guidelines for detailed procedures and specifications.

Braking System Overview

The braking system is a crucial component of any vehicle, ensuring safety and control during operation. It functions by converting kinetic energy into thermal energy through friction, allowing the machine to slow down or come to a complete stop. Understanding its mechanisms and components is essential for maintaining optimal performance and enhancing safety.

Components of the Braking System

A typical braking system comprises several key parts, including brake pads, rotors, calipers, and hydraulic lines. Each element plays a vital role in the overall functionality. The brake pads create friction against the rotors, while the calipers house the pads and apply the necessary pressure. Hydraulic lines facilitate fluid movement, enabling effective force transfer throughout the system.

Maintenance and Troubleshooting

Bodywork and Frame Repair Techniques

This section focuses on the methods and strategies for restoring and enhancing the exterior and structural components of off-road vehicles. Effective bodywork and frame techniques are essential for maintaining the durability and aesthetics of these machines, ensuring they perform optimally in various conditions.

When addressing issues related to the body and frame, it is crucial to identify the specific damage and choose appropriate repair methods. The following table outlines common repair techniques and their applications:

| Technique | Description | Application |

|---|---|---|

| Plastic Welding | A process that involves melting plastic components to bond them together. | Used for cracks or breaks in plastic body panels. |

| Frame Straightening | Aligning bent or misaligned frame sections to restore original geometry. | Essential for maintaining handling and stability. |

| Painting | Applying protective and aesthetic coatings to body surfaces. | Used to protect against corrosion and enhance appearance. |

| Body Fillers | Material used to fill dents and imperfections before painting. | Helps achieve a smooth surface finish. |

| Rust Treatment | Techniques to remove and prevent rust on metal components. | Critical for longevity and safety of metal frames. |

Implementing these techniques can significantly improve the performance and longevity of vehicles, allowing them to withstand the rigors of off-road adventures while maintaining a polished look.

Fluid Types and Change Intervals

Maintaining optimal performance of your vehicle involves understanding the various types of fluids required and their respective change intervals. Proper fluid management ensures longevity and efficiency, preventing potential issues that may arise from neglect.

There are several key fluids to monitor, each with specific properties and recommended service timelines. Below is a table summarizing these fluids, their types, and suggested intervals for replacement.

| Fluid Type | Recommended Fluid | Change Interval |

|---|---|---|

| Engine Oil | Synthetic or Conventional Oil | Every 1,500 miles or annually |

| Transmission Fluid | ATF Type | Every 3,000 to 5,000 miles |

| Cooling System Fluid | Antifreeze/Coolant | Every 2 years or 24,000 miles |

| Brake Fluid | DOT 3 or DOT 4 | Every 2 years |

| Fuel Stabilizer | Fuel Additive | As needed, especially before long storage |

Regular checks and timely changes of these fluids contribute significantly to the vehicle’s performance and reliability. Always refer to manufacturer recommendations for specific guidelines.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance on vehicles is crucial to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and enhance the overall experience of servicing machinery.

- Wear Appropriate Gear: Always use personal protective equipment such as gloves, goggles, and sturdy footwear to shield against potential hazards.

- Work in a Well-Ventilated Area: Ensure that the workspace is adequately ventilated to avoid inhalation of harmful fumes or dust.

- Disconnect the Battery: Before starting any maintenance, disconnect the battery to prevent electrical shocks or accidental starts.

Implementing these precautions not only safeguards the individual performing the task but also helps in maintaining the integrity of the equipment. Always be mindful of your surroundings and the tools you are using.

- Use Tools Correctly: Familiarize yourself with the tools required for the job and use them as intended to avoid injuries.

- Keep the Workspace Organized: A tidy environment minimizes the risk of accidents caused by tripping over tools or parts.

- Read Documentation: Consult any available guidelines or manuals before proceeding to ensure proper procedures are followed.

By following these safety measures, individuals can create a safer and more effective environment for conducting maintenance tasks.

Resources for Parts and Manuals

Finding reliable resources for components and documentation is essential for maintaining and restoring any vehicle. These materials provide critical information for troubleshooting, assembly, and sourcing parts. Utilizing both online and offline resources can enhance the repair process and ensure that you have the correct information at hand.

Online Retailers: Numerous websites specialize in aftermarket and original components, making it easier to find what you need. These platforms often provide detailed descriptions and compatibility information, ensuring that you select the right items for your machine.

Manufacturer Websites: The official site of the brand offers a wealth of resources, including parts catalogs, instructional guides, and technical specifications. Visiting these pages can help you verify parts numbers and access detailed schematics.

Community Forums: Engaging with fellow enthusiasts through online forums can be incredibly beneficial. These communities often share tips, experiences, and even downloadable resources, enhancing your understanding and ability to perform repairs.

Local Dealerships: Establishing a relationship with nearby dealerships can be invaluable. They can provide authentic parts and personalized advice tailored to your specific model, along with access to service bulletins and updates.

Library Resources: Don’t overlook public libraries, which may have physical copies of service guides or access to online databases containing useful manuals. This can be a cost-effective way to find detailed information.

Utilizing a combination of these resources can streamline the repair process and ensure that your vehicle remains in optimal condition.