This section provides a comprehensive overview of how to effectively address common issues encountered with outdoor cutting equipment. Understanding the functionality and potential problems of these tools is essential for maintaining optimal performance and longevity.

By following a structured approach to troubleshooting, users can quickly identify the source of any malfunction. This guide emphasizes practical solutions and preventive measures to ensure that your outdoor gear remains in peak condition.

Whether you’re dealing with starting difficulties, inconsistent operation, or other challenges, this resource aims to empower users with the knowledge needed for successful upkeep. With the right techniques and insights, maintaining your equipment can be a straightforward and rewarding experience.

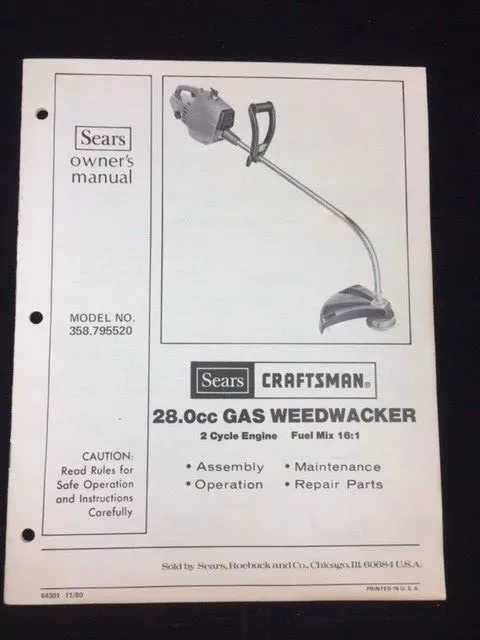

Craftsman Weed Wacker Repair Manual

This section provides essential guidance for maintaining and troubleshooting a popular gardening tool. Understanding the common issues that may arise can significantly enhance performance and extend the lifespan of the device.

Basic Maintenance: Regular upkeep is crucial. Ensure that the engine is clean and that all components are lubricated appropriately. This not only prevents wear but also ensures efficient operation.

Troubleshooting Common Issues: If the machine fails to start, check the fuel supply and ignition components. Often, a simple adjustment can resolve performance issues. Additionally, examining the cutting mechanism for damage can prevent further complications.

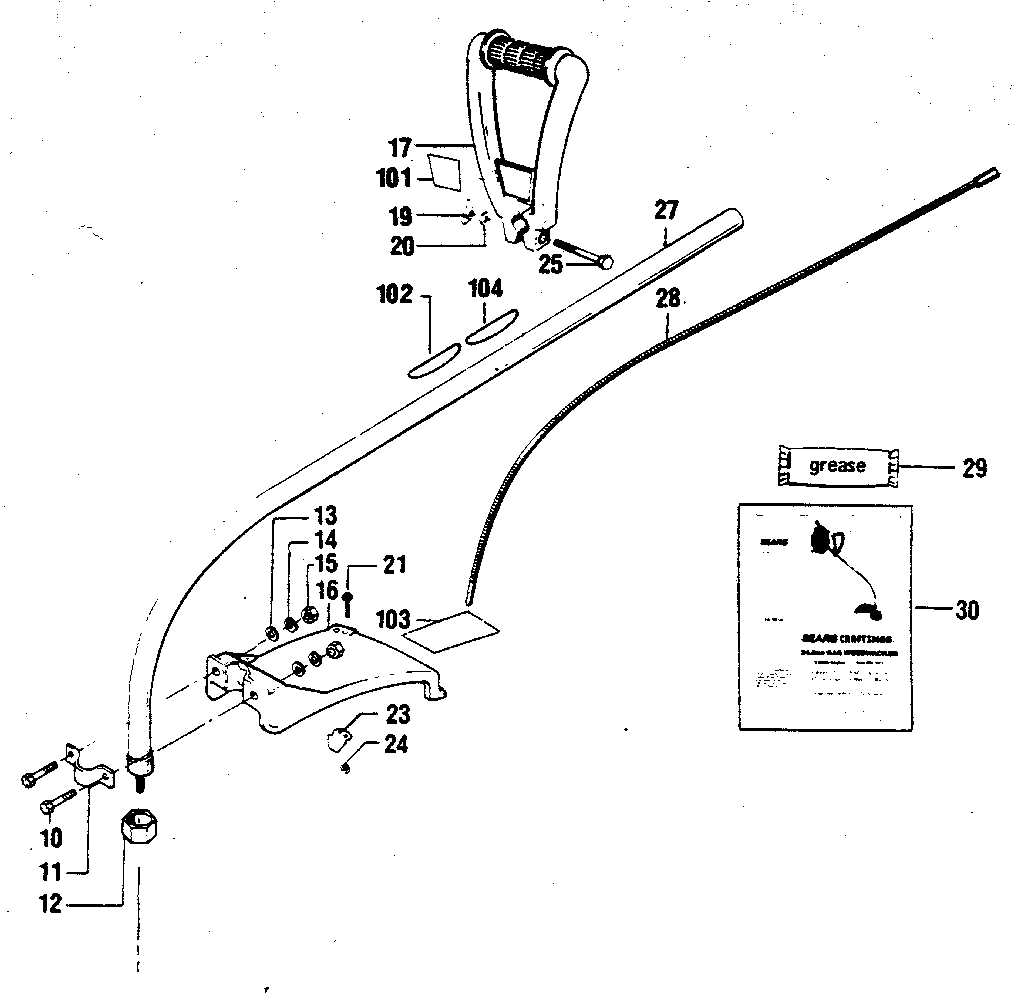

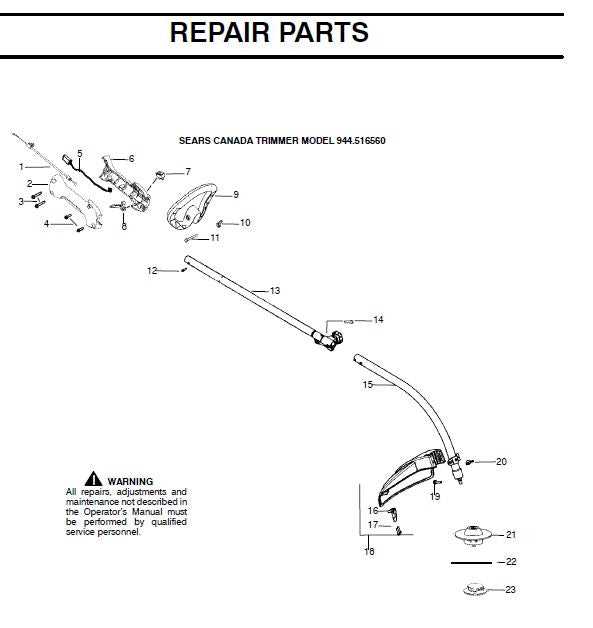

Parts Replacement: Knowing when to replace worn parts is vital for optimal functionality. Regularly inspect the line and spool, as these components are prone to wear. Utilizing high-quality replacements will enhance durability and efficiency.

Common Issues with Weed Wackers

Maintaining garden trimming tools can present various challenges. Users often encounter specific malfunctions that hinder performance. Understanding these common problems is essential for effective troubleshooting and restoration of functionality.

Frequent Problems

- Starting Difficulties: Many users struggle to start their devices due to fuel issues, spark plug failures, or air filter blockages.

- Power Loss: A noticeable decrease in power may arise from clogged lines or worn components.

- Excessive Vibration: Tools may vibrate more than usual, often due to unbalanced cutting elements or loose parts.

- Overheating: Operating at high temperatures can lead to engine failure, commonly caused by insufficient cooling or excessive load.

Preventive Measures

- Regularly check and replace filters to ensure proper airflow.

- Maintain fuel quality and replace spark plugs as needed.

- Inspect cutting elements for damage and balance.

- Allow the machine to cool down during extended use.

Essential Tools for Weed Wacker Repair

When it comes to maintaining your outdoor cutting equipment, having the right instruments is crucial for efficient and effective service. Various implements facilitate the troubleshooting and enhancement of these machines, ensuring optimal performance.

1. Screwdrivers: A set of screwdrivers, both flathead and Phillips, is essential for loosening and tightening fasteners. These tools are versatile and used in numerous applications, making them indispensable.

2. Pliers: Needle-nose and standard pliers help in gripping, bending, and cutting wires or components. Their precision allows for detailed work, especially in tight spaces.

3. Socket Set: A complete socket set is vital for handling bolts and nuts of various sizes. It enables easy access to hard-to-reach areas and speeds up the assembly and disassembly process.

4. Fuel Container: A sturdy container is necessary for safely storing and transporting fuel. This ensures that you have a proper supply when needed, preventing delays during your tasks.

5. Cleaning Tools: Brushes and cloths are important for removing debris and residue from various parts of the equipment. Keeping the components clean prolongs the life of the machine and enhances its efficiency.

By equipping yourself with these essential instruments, you can effectively manage and enhance the performance of your outdoor cutting machinery, ensuring a smooth operation for years to come.

Identifying Engine Troubles

Understanding engine issues is essential for maintaining optimal performance in outdoor power equipment. Various symptoms may indicate that the engine is not functioning properly, and recognizing these signs early can prevent further damage.

One common indicator is difficulty starting the engine. If the unit fails to ignite or requires multiple attempts, it may signal a problem with the fuel system or ignition components. Additionally, unusual noises such as knocking or sputtering can suggest internal mechanical issues that need attention.

Another aspect to consider is a decrease in power output. If the device struggles to perform tasks it once handled easily, it could be due to worn parts or blockages within the fuel delivery system. Regular inspection of these components is crucial for early detection of potential problems.

Monitoring fuel consumption can also provide insights into engine health. Excessive use of fuel may point to inefficient combustion or other underlying concerns. Keeping track of these factors can aid in diagnosing and addressing issues before they escalate.

Fixing Starter Mechanism Problems

Addressing issues with the starting system is essential for ensuring smooth operation of your equipment. Common challenges often arise from wear and tear, improper assembly, or debris interference. Understanding the components involved can greatly enhance your troubleshooting efforts and help restore functionality.

Identifying Common Issues

Start by examining the pull cord and its attachment. If the cord does not retract or is frayed, it may need replacement. Additionally, check for obstructions in the housing that could impede movement. Loose screws or components can also contribute to malfunction, so ensure everything is securely fastened.

Steps for Resolution

Begin by removing the starter cover to access the mechanism. Clean any dirt or debris, as this can hinder performance. If the spring is damaged or not engaging properly, consider replacing it. Reassemble the components carefully, ensuring all parts are aligned correctly. Test the system multiple times to confirm that it operates smoothly and reliably.

Replacing Trimmer Line Effectively

Changing the cutting line on a trimming tool is a straightforward yet essential task to maintain optimal performance. A properly replaced line ensures efficient cutting and prevents unnecessary wear on the equipment. This section provides a clear guide to facilitate this process.

Before starting, gather all necessary materials, including the correct type of line and any required tools. Begin by disconnecting the device from any power source for safety. Next, access the spool by following the specific method for your model. Most spools can be easily removed by unscrewing or pressing a release tab.

Once you have access to the spool, remove any remaining line. Take the new line and measure out the required length, typically specified in your device’s specifications. Feed the line through the spool’s eyelets and wind it tightly, ensuring it is evenly distributed to prevent tangling.

After winding, secure the line in place according to the manufacturer’s instructions. Reassemble the spool onto the trimmer, ensuring it clicks or locks into place securely. Finally, reconnect the power source and perform a test run to verify that the line operates smoothly and effectively.

Understanding Carburetor Maintenance

Proper upkeep of the fuel delivery component is crucial for optimal performance and longevity of outdoor equipment. This essential part ensures that the correct air-fuel mixture reaches the engine, affecting its efficiency and reliability. Regular attention to this element can prevent common issues, enhancing overall functionality.

Signs of Poor Functioning

Recognizing symptoms of inadequate performance can help in timely interventions. Common indicators include difficulty starting, irregular idling, or sudden stalling during operation. Observing these signs early can save time and reduce the risk of further complications.

Maintenance Tips

To maintain this vital component effectively, periodic cleaning and inspection are recommended. Disassembling the unit and using appropriate cleaning agents can remove build-up and debris. Ensuring that all components are intact and functional will contribute significantly to the equipment’s performance.

Troubleshooting Spark Plug Issues

Identifying and resolving problems related to the ignition component is essential for maintaining optimal performance in small engines. This section outlines common signs of malfunction and practical steps to address them effectively.

One of the primary indicators of a faulty ignition component is difficulty starting the engine. If the device fails to start or runs inconsistently, checking the ignition element is crucial. Ensure it is clean and free from carbon buildup, as debris can hinder its function.

Another common issue is poor performance during operation. If the engine sputters or loses power while in use, inspect the ignition component for wear or damage. Replacing it may be necessary if signs of deterioration are present.

Additionally, if excessive fuel consumption occurs, it can indicate that the ignition component is not firing correctly. Assessing the gap and ensuring it meets manufacturer specifications can often resolve this issue. Regular maintenance checks will help prevent these complications and extend the life of the engine.

Air Filter Cleaning Tips

Maintaining the air filtration system of your outdoor equipment is crucial for optimal performance. A clean filter ensures that the engine receives the right amount of air, which can enhance efficiency and prolong the lifespan of the machinery.

Regular Inspection

Check the air filter regularly for dirt and debris. It’s advisable to inspect it before each use, especially in dusty environments. If you notice excessive buildup, it’s time for a thorough cleaning or replacement.

Cleaning Process

To clean the filter, gently tap it to remove loose particles. For deeper cleaning, rinse it with warm water and a mild detergent. Allow it to dry completely before reinstalling. Ensure it fits snugly back in place to maintain optimal airflow. Always refer to specific guidelines for your equipment to ensure proper care.

Fuel Line and Tank Checks

Ensuring the integrity of the fuel delivery system is crucial for the optimal functioning of your equipment. This section outlines the essential steps for inspecting the fuel pathways and storage container, which can significantly impact performance and reliability.

Start by examining the fuel lines for any signs of wear, cracks, or leaks. Any damage can lead to fuel loss or contamination, which affects the overall operation. Next, check the tank for proper sealing and cleanliness. A clean tank prevents impurities from entering the fuel system, ensuring smooth operation.

| Check | Inspection Method | Notes |

|---|---|---|

| Fuel Lines | Visually inspect for cracks or leaks | Replace if damaged |

| Fuel Tank | Check for proper sealing | Clean if necessary |

| Fuel Filter | Inspect for clogs | Replace if dirty |

Regular checks and maintenance of these components can prevent performance issues and prolong the lifespan of your equipment.

Adjusting the Throttle Settings

Proper adjustment of throttle controls is essential for optimal performance of your trimming device. Ensuring the throttle operates smoothly can enhance efficiency and prolong the life of the equipment. This section outlines the steps to achieve the ideal settings for your device.

Understanding Throttle Mechanics

The throttle mechanism regulates the engine’s power output. A well-tuned throttle allows for responsive acceleration and steady operation. Key components include:

- Throttle cable

- Control lever

- Carburetor settings

Steps for Adjustment

- Begin by locating the throttle cable connected to the control lever.

- Check for any wear or damage; replace if necessary.

- Loosen the adjustment screw to allow for cable repositioning.

- Pull the cable to increase tension or release it for decreased tension.

- Tighten the adjustment screw to secure the desired position.

- Test the throttle response by operating the control lever.

- Make further adjustments as needed until smooth operation is achieved.

Regularly checking and adjusting these settings can significantly improve the functionality and reliability of your equipment, ensuring it meets your trimming needs effectively.