In the world of agricultural equipment, ensuring optimal functionality is essential for productivity and efficiency. A well-structured guide serves as a cornerstone for enthusiasts and professionals alike, offering insights into the nuances of upkeep and troubleshooting.

Understanding the intricacies of machinery is crucial for anyone involved in the farming sector. A detailed reference can empower operators to address common issues and implement best practices, ultimately leading to enhanced performance and longevity.

Whether you are a seasoned expert or a novice, detailed resources provide the ultimate pathway to mastering the art of machinery care. With the right information at hand, you can delve into effective techniques that will keep your equipment running smoothly through various challenges.

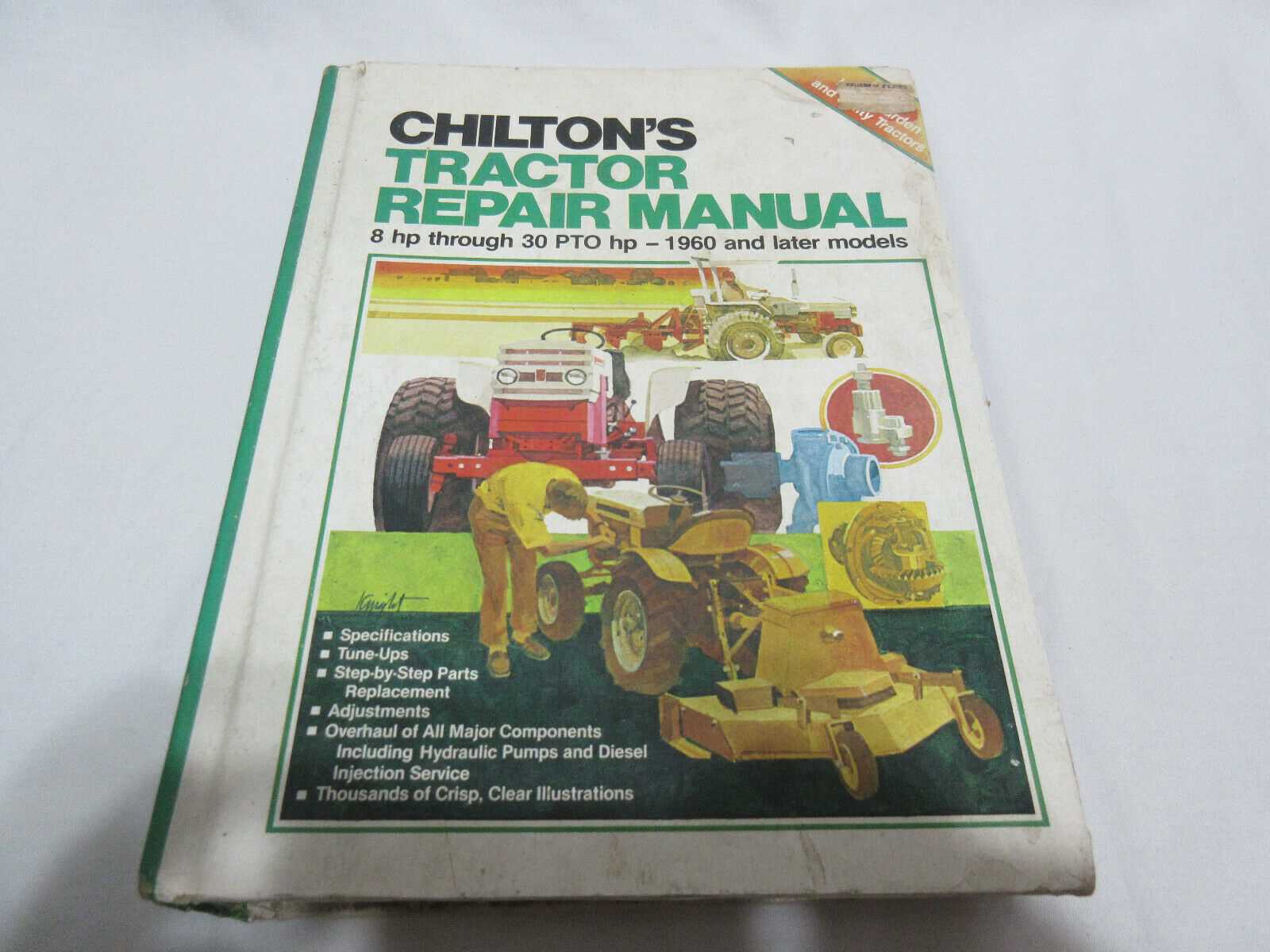

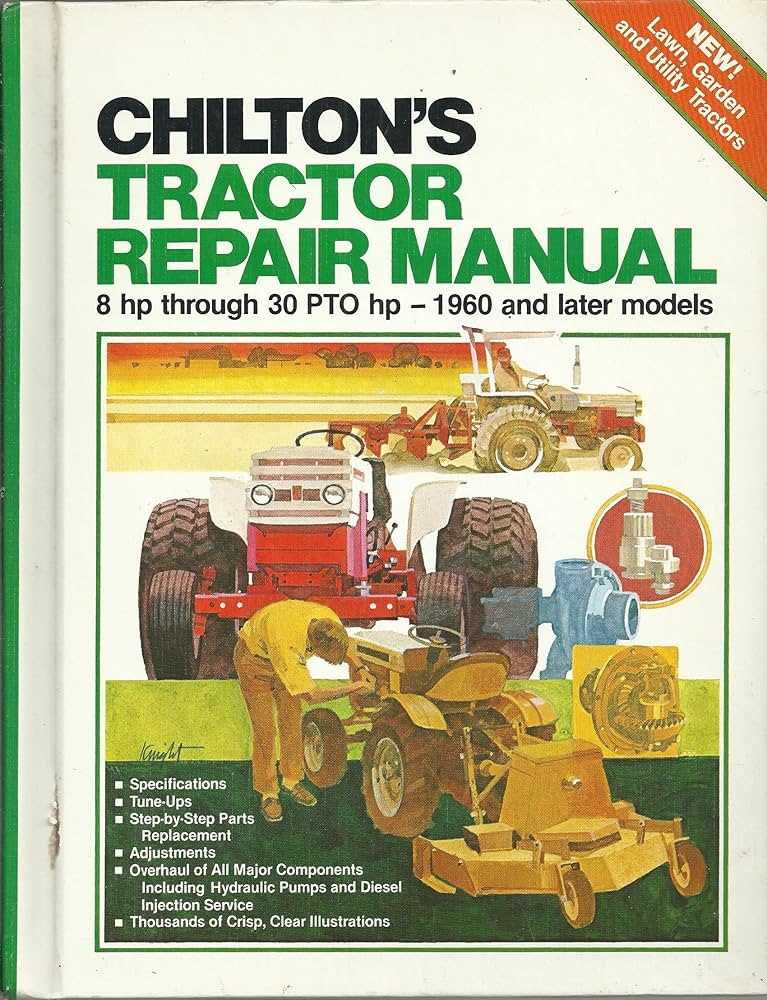

Overview of Chilton Tractor Manuals

This section provides a comprehensive look at specialized literature designed to assist users in the upkeep and maintenance of heavy machinery. These resources serve as invaluable tools for both novice and seasoned operators, offering detailed insights into various operational procedures and troubleshooting techniques.

Key Features

- Step-by-step instructions for common tasks

- Detailed diagrams and illustrations for clarity

- Maintenance schedules to ensure optimal performance

- Tips for diagnosing issues effectively

- Safety precautions and guidelines

Benefits of Using These Resources

- Enhanced understanding of machinery functions

- Cost savings through self-service maintenance

- Increased equipment longevity and reliability

- Empowerment through knowledge of technical aspects

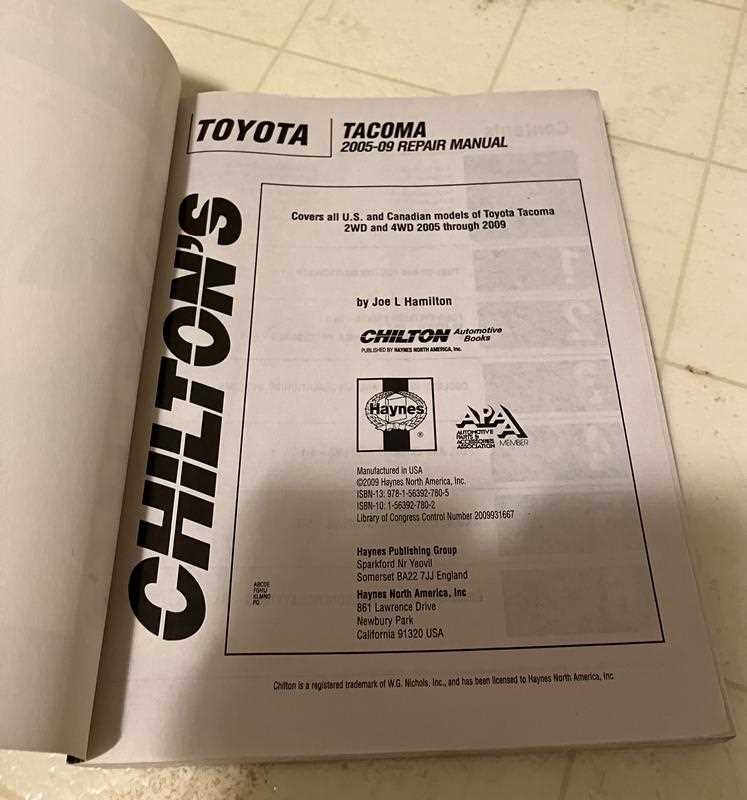

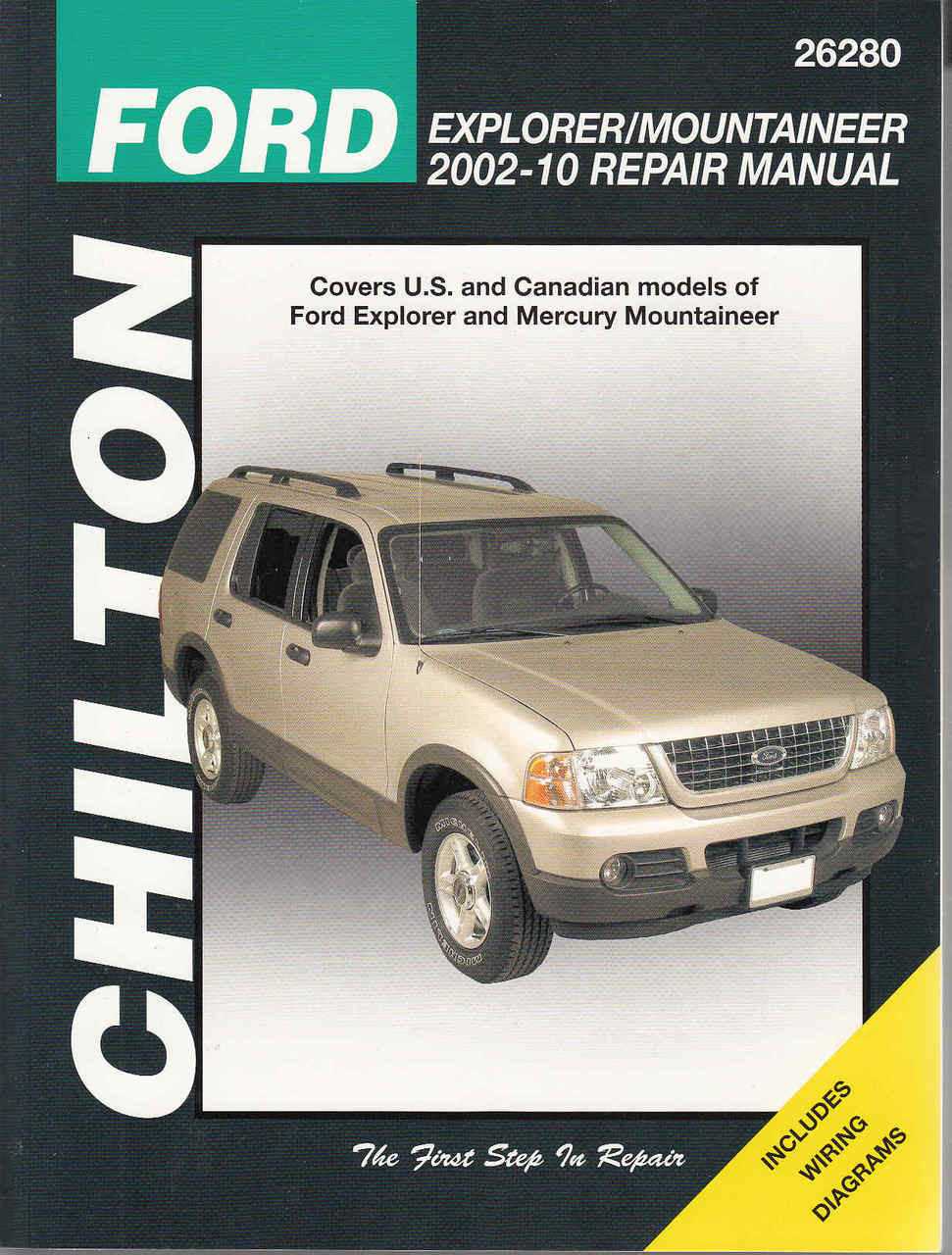

Key Features of Chilton Manuals

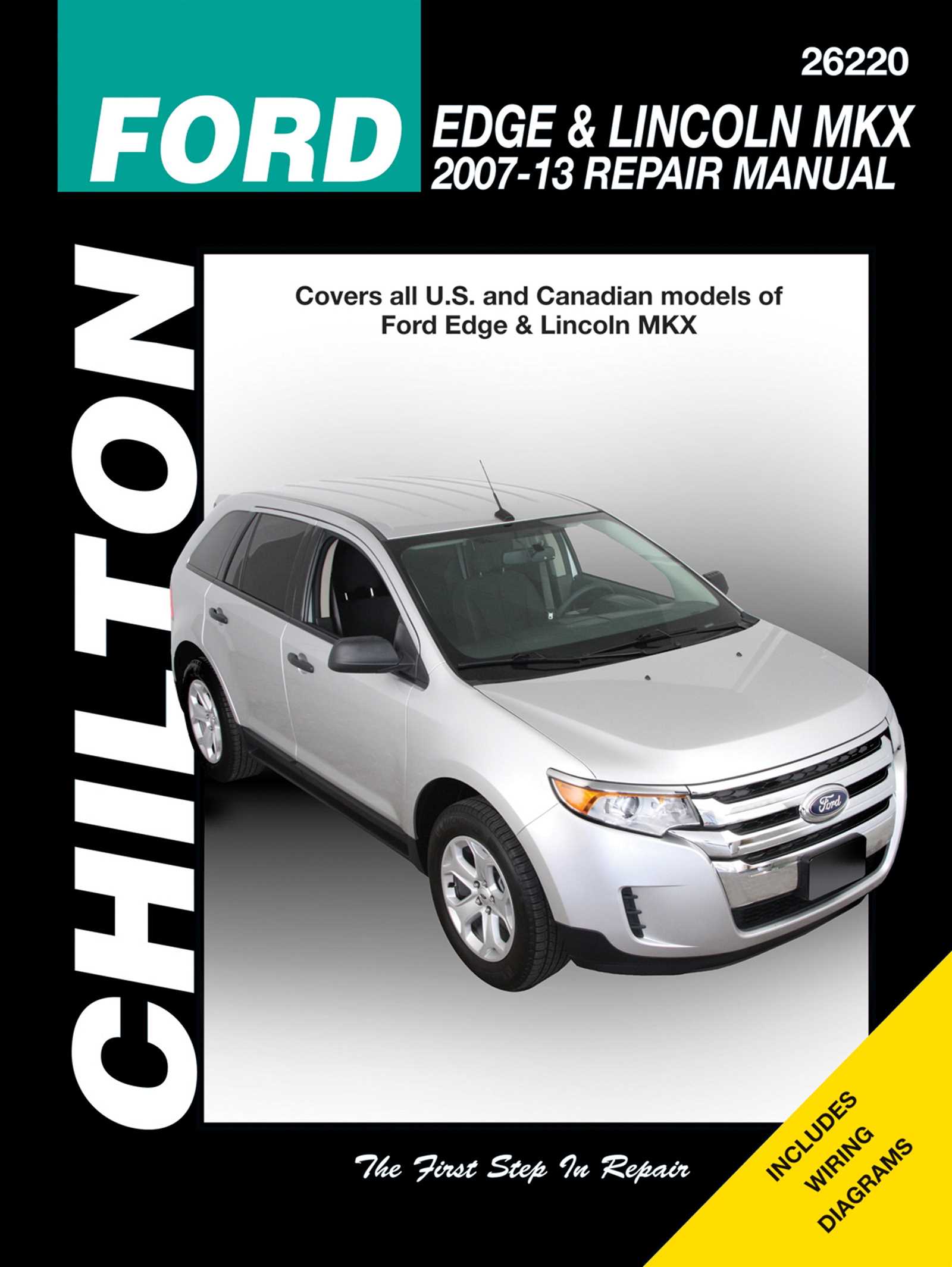

The comprehensive guides available for automotive maintenance and troubleshooting are renowned for their detailed content and user-friendly approach. These resources cater to both novices and seasoned mechanics, ensuring a broad audience can benefit from the wealth of information provided.

Extensive Coverage

One of the standout attributes of these guides is their thorough coverage of a wide range of vehicles. From classic models to the latest releases, each publication is designed to address specific needs, offering insights into various systems and components. This ensures that users have access to relevant information regardless of the age or type of their vehicle.

User-Friendly Layout

Another notable feature is the organized structure of the content. The logical arrangement allows readers to quickly locate necessary sections, whether they are seeking troubleshooting tips, maintenance schedules, or repair procedures. Clear illustrations and step-by-step instructions enhance understanding, making complex tasks more approachable.

In summary, these guides serve as invaluable resources for anyone looking to maintain or restore their vehicles, providing clarity and expertise that empower users to take on automotive challenges with confidence.

Benefits of Using Repair Manuals

Utilizing comprehensive guides for maintenance and troubleshooting offers numerous advantages for both novice and experienced users. These resources serve as valuable references that enhance understanding, facilitate effective problem-solving, and ultimately promote the longevity of equipment.

| Advantage | Description |

|---|---|

| Increased Knowledge | Accessing detailed instructions helps users grasp the mechanics and functionality of their machinery, empowering them to make informed decisions. |

| Time Efficiency | Step-by-step directions streamline the troubleshooting process, allowing individuals to quickly identify and resolve issues without unnecessary delays. |

| Cost Savings | Understanding how to perform maintenance tasks reduces reliance on professional services, leading to significant financial savings over time. |

| Safety Assurance | Guides often include safety precautions and best practices, helping users avoid accidents and ensure safe operation during maintenance. |

| Accessibility | These resources are widely available, making it easy for users to obtain the information they need whenever they require assistance. |

Common Repairs for Chilton Tractors

Maintaining agricultural machinery is essential for optimal performance and longevity. Various issues can arise due to wear and tear, environmental factors, or operational mishaps. Understanding the frequent maintenance tasks can help ensure that equipment remains in peak condition, ultimately enhancing productivity.

Engine Issues

One of the most prevalent concerns involves engine functionality. Regular checks of components such as spark plugs, filters, and belts are crucial. Replacing worn-out parts can prevent larger issues and improve efficiency. It’s also important to monitor oil levels and change it as needed to keep the engine running smoothly.

Hydraulic System Maintenance

The hydraulic system is vital for many operations. Leaks can lead to decreased performance and safety hazards. Regular inspections of hoses and connections, along with fluid level checks, can mitigate these risks. Addressing any signs of wear promptly can save time and resources in the long run.

How to Navigate the Manual

Understanding the structure of your guide is essential for efficient troubleshooting and maintenance. This resource is designed to provide step-by-step assistance, enabling you to quickly locate the information you need. Familiarizing yourself with the layout will enhance your ability to address various tasks with confidence.

Sections and Index

The first step in using this guide is to explore the table of contents. This section outlines the major categories, helping you identify where to find specific topics. Additionally, an index at the back of the book offers a comprehensive list of keywords, making it easy to search for particular issues or components.

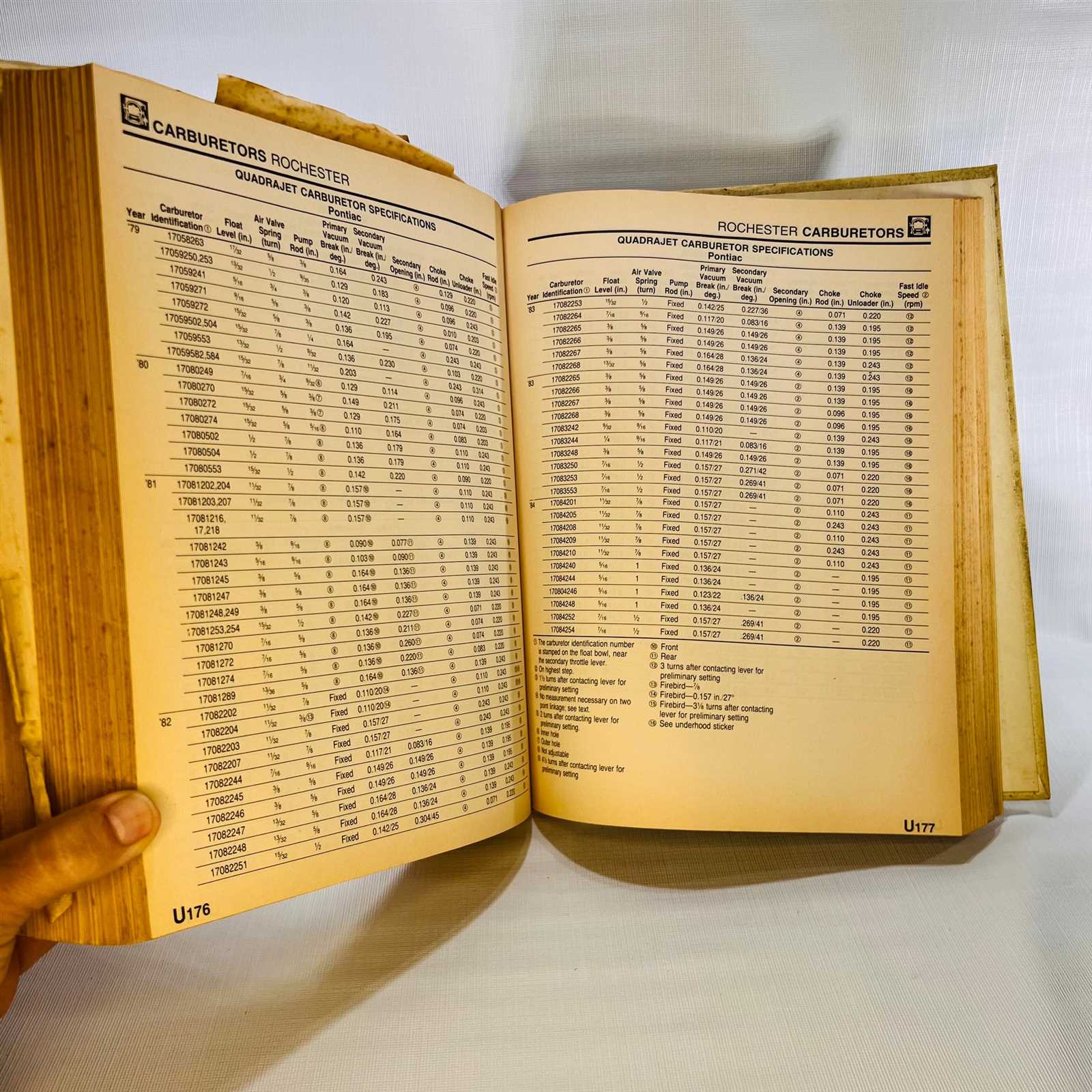

Using Diagrams and Illustrations

Visual aids play a crucial role in understanding complex concepts. Throughout the guide, you’ll find diagrams and illustrations that clarify instructions. Pay attention to these visuals, as they can significantly enhance your comprehension of the procedures outlined in the text. Refer to these graphics frequently to ensure you’re following the steps accurately.

Tools Needed for Tractor Repair

Effective maintenance of machinery requires a well-equipped workshop. Understanding the necessary implements ensures efficient work and can significantly reduce downtime. This section outlines essential instruments that facilitate the process of upkeep and troubleshooting.

Essential Instruments

When engaging in maintenance tasks, having the right tools on hand is crucial. Here is a list of fundamental implements commonly required:

| Tool | Purpose |

|---|---|

| Wrenches | For loosening and tightening bolts and nuts. |

| Screwdrivers | Used for fastening and loosening screws. |

| Socket Set | Essential for working with various sizes of fasteners. |

| Pliers | Helpful for gripping, bending, and cutting wire or other materials. |

| Jack Stands | Provide support when lifting heavy machinery. |

Specialized Equipment

In addition to basic tools, specialized equipment may be required for certain tasks. This can include diagnostic devices and safety gear, which enhance both efficiency and safety during maintenance operations.

Maintaining Your Tractor Effectively

Proper upkeep of your agricultural machinery is essential for optimal performance and longevity. Regular attention to various components not only enhances efficiency but also prevents costly breakdowns. Adopting a systematic approach to maintenance can significantly extend the lifespan of your equipment.

Key areas to focus on include the engine, transmission, and hydraulic systems. Each of these parts requires specific care to ensure smooth operation. By following a routine maintenance schedule, you can identify issues early and address them promptly.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace engine oil to ensure proper lubrication and efficiency. |

| Filter Replacement | Every 200 hours | Change air and fuel filters to maintain optimal performance. |

| Fluid Levels Check | Weekly | Inspect coolant, hydraulic fluid, and transmission fluid levels. |

| Tire Inspection | Monthly | Check for proper inflation and tread wear to ensure stability. |

| Belt and Hose Check | Every 500 hours | Look for wear and tear, replacing as necessary to prevent failure. |

By adhering to these guidelines and maintaining a proactive mindset, you can ensure your machinery remains in excellent working condition, ready to tackle any task efficiently.

Safety Precautions During Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. This involves adhering to established protocols and using appropriate protective gear. Understanding potential hazards can significantly reduce risks associated with mechanical work.

First and foremost, ensure that the workspace is clean and organized. A clutter-free environment minimizes the chances of slips and falls, which are common in busy areas. Additionally, be aware of your surroundings and any moving parts that may pose a threat.

Protective equipment is vital for personal safety. Always wear safety goggles to shield your eyes from debris, and consider gloves to protect your hands from sharp edges and chemicals. Sturdy footwear can also prevent injuries from heavy objects.

It is also important to familiarize yourself with the tools and equipment being used. Improper handling can lead to accidents, so read all instructions carefully. If you are unsure about any procedure, seek guidance rather than taking unnecessary risks.

Finally, maintain clear communication with anyone involved in the project. Ensure that everyone is aware of the tasks at hand and any potential hazards. By fostering a culture of safety, you create a more secure environment for all participants.

Understanding Tractor Parts and Systems

Comprehending the various components and their interactions within agricultural machinery is crucial for effective operation and maintenance. Each element plays a vital role, contributing to the overall functionality and efficiency of the equipment. This knowledge empowers operators to identify issues, perform necessary adjustments, and enhance performance.

Every piece of machinery consists of numerous systems that work in harmony. From the engine that provides power to the transmission that regulates movement, understanding these systems is essential for optimal performance. Below is a breakdown of key components and their functions:

| Component | Function |

|---|---|

| Engine | Converts fuel into mechanical energy to power the machine. |

| Transmission | Transfers power from the engine to the wheels, controlling speed and torque. |

| Hydraulic System | Facilitates lifting and moving implements using fluid pressure. |

| Electrical System | Supplies power for starting, lighting, and operating various components. |

| Cooling System | Maintains optimal engine temperature to prevent overheating. |

| Fuel System | Delivers fuel to the engine, ensuring efficient combustion. |

Familiarity with these essential parts allows users to address potential challenges and prolong the lifespan of their equipment. A well-informed operator is better equipped to ensure the reliability and efficiency of their machinery.

Resources for Additional Support

When faced with mechanical challenges, having access to various sources of assistance can significantly enhance your troubleshooting capabilities. Whether you’re a novice or an experienced individual, tapping into diverse resources can provide valuable insights, technical advice, and community support.

Online Forums and Communities

Engaging with online platforms dedicated to enthusiasts and professionals can yield practical knowledge and shared experiences. These forums often feature discussions on common issues, tips for maintenance, and innovative solutions. Participating in these communities allows users to ask questions and receive guidance from fellow members who may have faced similar challenges.

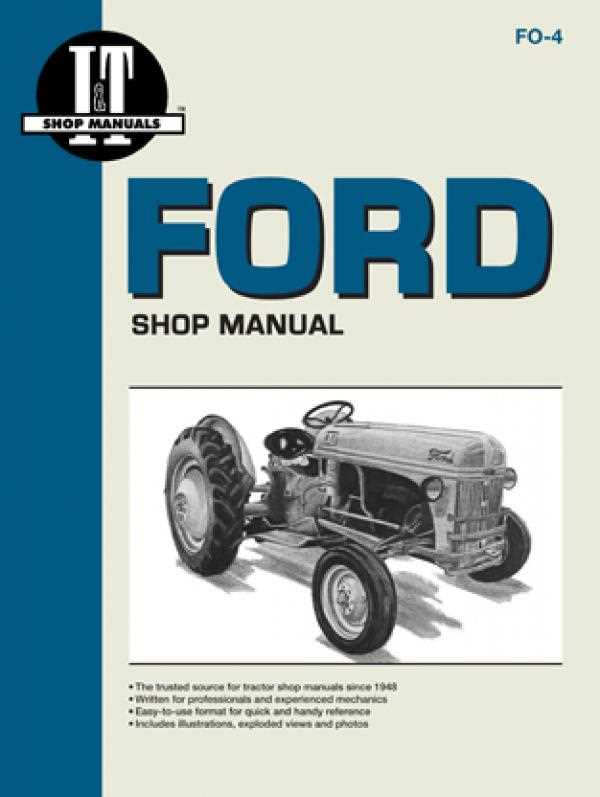

Technical Literature and Guides

In addition to digital resources, printed literature remains a reliable option for those seeking detailed information. Technical guides, reference books, and instructional literature can offer in-depth insights into specific systems and components. Exploring these materials can deepen your understanding and provide step-by-step instructions for various tasks.