In this guide, we focus on the essentials of maintaining high-performance machinery with an emphasis on longevity and optimal function. By following systematic steps, you’ll gain valuable insight into efficient upkeep and troubleshooting methods that ensure continued reliability and strength.

Each section provides detailed information on essential procedures, from regular checks to more intricate adjustments. Understanding these techniques can significantly enhance operational stability, reduce the need for frequent repairs, and improve overall productivity.

Throughout this guide, key practices and expert recommendations are covered, empowering you to perform each task effectively and with confidence. This approach not only aids in preventing potential breakdowns but also extends the working life of critical components.

Deutz 2011 Engine Guide for Maintenance

This section provides a comprehensive overview for handling upkeep and addressing potential issues with a specific model of industrial engine. Offering clear and systematic instructions, this guide ensures that users can approach each maintenance task with confidence, regardless of technical experience.

Essential Upkeep Practices

Regular inspection and maintenance are crucial to keep an engine functioning smoothly and extending its lifespan. This part of the guide highlights essential tasks, including routine checks, cleaning methods, and preventive care tips, allowing for early detection of minor issues before they develop into significant problems.

Troubleshooting Common Issues

For users encountering unexpected engine performance issues, this section covers the most frequent concerns and practical solutions. Whether it’s irregular noise, power fluctuations, or temperature inconsistencies, detailed troubleshooting tips and recommended actions will help identify and resolve these challenges effectively.

Understanding Key Engine Components

The effectiveness of an engine relies heavily on the harmonious function of its individual parts. This section provides an overview of the essential elements within the engine, exploring their roles in maintaining consistent operation. Familiarity with each part’s purpose enhances insight into how the entire system works as a unified mechanism.

| Component | Description |

|---|---|

| Cylinder Block | The foundation of the engine, housing crucial parts like the cylinders, crankshaft, and connecting rods. It provides structural support and stability for the engine’s internal movements. |

| Piston | Responsible for transforming energy generated by fuel combustion into mechanical motion, allowing the crankshaft to rotate and create power. |

| Fuel Injector | Precisely delivers fuel to the combustion chamber, ensuring optimal fuel-to-air ratio and efficient combustion process. |

| Oil Pump | Maintains the circulation of lubrication oil through engine components, reducing friction and preventing overheating. |

| Crankshaft | Transforms the reciprocating motion of the pistons into rotational motion, ultimately powering the equipment’s functions. |

| Cooling System | Prevents the engine from overheating by circulating coolant through the system, maintaining an optimal operating temperature. |

Common Issues in Deutz 2011 Engines

Engines in this category are known for durability, yet they may develop specific operational issues over time. Recognizing these early can prevent extended downtimes and costly repairs, as addressing minor problems early helps maintain consistent performance. This section explores several prevalent complications and provides insights into their potential causes and symptoms.

Fuel System Challenges

One frequently observed issue involves the fuel system, where blockages or wear in fuel lines or injectors can lead to diminished engine efficiency. Symptoms might include rough idling or difficulty in starting, often caused by fuel contamination or injector wear. Routine inspection of fuel filters and injectors can mitigate these effects.

Cooling System Concerns

Overheating can be a recurrent problem in high-demand environments, often stemming from insufficient coolant levels, radiator clogs, or water pump wear. Indicators of an overheating issue include a rise in temperature during operation or sudden shutdowns. Regular coolant checks and radiator cleaning can reduce the likelihood of these concerns.

How to Diagnose Engine Problems

Diagnosing issues in an engine requires a careful and systematic approach to identify potential malfunctions. Understanding the key symptoms and tracing them back to their sources can help avoid extensive repairs and ensure smoother operation. This guide provides essential steps and methods to recognize and interpret common engine troubles efficiently.

Identifying Common Symptoms

Engine issues often present recognizable symptoms, including unusual noises, loss of power, or excessive exhaust emissions. Observing these signs early and noting any changes in the engine’s behavior is crucial. Documenting details such as engine sounds, temperature changes, or fuel consumption patterns can assist in isolating the cause.

Diagnostic Tools and Techniques

Using diagnostic tools can simplify troubleshooting and provide valuable insights. Devices such as pressure gauges, scanners, and thermometers help assess various engine parameters. By comparing these readings against standard values, it is possible to pinpoint abnormal areas that require further inspection.

| Symptom | Possible Cause | Diagnostic Approach |

|---|---|---|

| Excessive Smoke | Faulty fuel system or air filter | Inspect fuel lines and air intake; check for clogs or leaks |

| Engine Overheating | Cooling system malfunction | Check coolant levels and radiator function |

| Loss of Power | Compression or fuel delivery issues | Measure compression and examine fuel injectors |

Essential Tools for Deutz 2011 Repairs

Effective upkeep and servicing of engines require specific tools that ensure precision and safety. Utilizing the right instruments not only simplifies the task but also contributes to the longevity of the machine. Below is a comprehensive list of essential equipment for maintenance tasks, aimed at achieving both efficiency and reliability.

Hand Tools

- Socket Set: Facilitates handling various bolt sizes, allowing for quick adjustments.

- Torque Wrench: Ensures that components are tightened to the recommended level, preventing issues from under- or over-tightening.

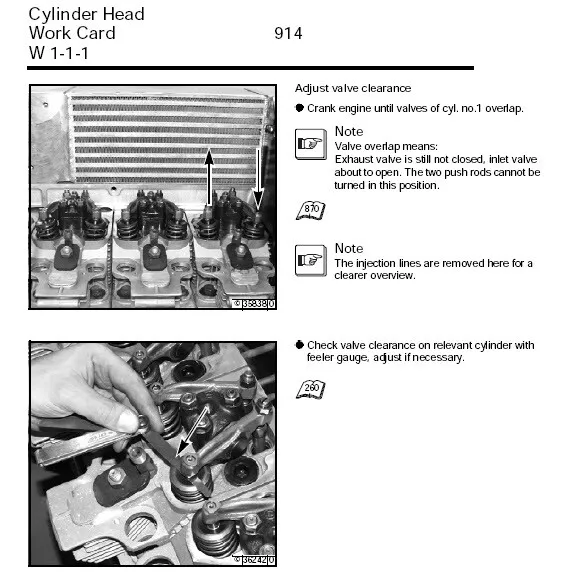

- Feeler Gauges: Assists in measuring precise gaps and spaces within the mechanism.

- Screwdrivers and Hex Keys: Essential for reaching hard-to-access areas and small components.

Diagnostic and Testing Equipment

- Compression Tester: Verifies engine compression, highlighting potential wear in critical parts.

- Multimeter: Measures electrical values to ensure accurate function and detect issues in electrical circuits.

- Oil Pressure Gauge: Confirms appropriate oil flow, preventing damage from insufficient lubrication.

Using the right set of tools streamlines the maintenance process and enhances the precision of each task, ultimately leading to a more reliable and efficient engine.

Replacing Worn Parts Efficiently

Maintaining optimal performance in machinery requires the timely substitution of deteriorated components. This practice not only enhances functionality but also prolongs the lifespan of the entire system. Identifying which parts require attention and implementing effective strategies for replacement can lead to significant improvements in operational efficiency.

Identifying Deteriorated Components

Regular inspections are crucial for detecting signs of wear. Look for abnormal noises, vibrations, or performance issues that may indicate a failing part. Keeping a detailed log of maintenance activities can help pinpoint recurring problems and prioritize replacements.

Efficient Replacement Strategies

When replacing components, always opt for high-quality alternatives that match or exceed the specifications of the original parts. Additionally, employing proper tools and techniques will streamline the process, reducing downtime and enhancing safety. Training personnel in best practices for replacement can further ensure efficient operations.

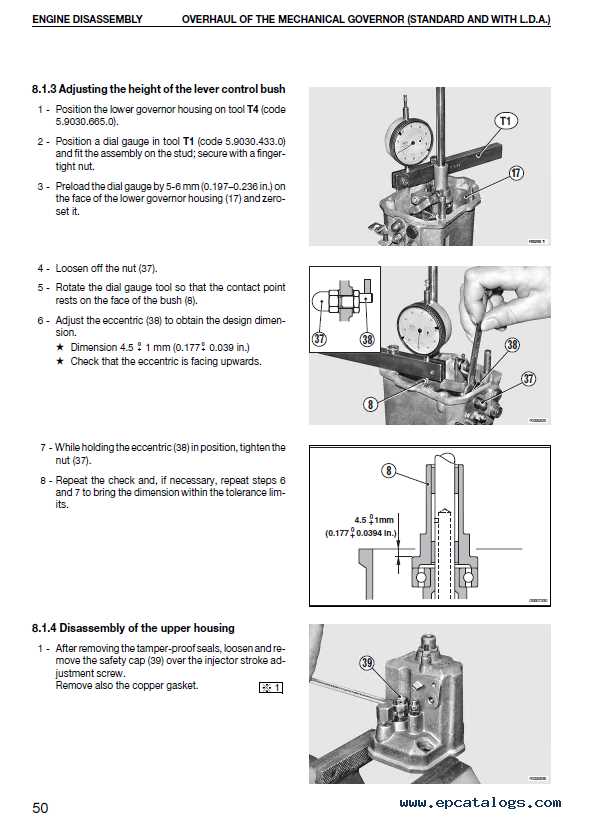

Step-by-Step Engine Disassembly Guide

This section provides a comprehensive overview of the process involved in dismantling an engine. Understanding the systematic approach to disassembly is crucial for effective maintenance and troubleshooting. Following a detailed guide ensures that each component is handled correctly, minimizing the risk of damage and facilitating efficient reassembly.

Preparation for Disassembly

Before starting the disassembly, gather all necessary tools and equipment. Ensure that the workspace is clean and organized. Disconnect the power source and remove any external accessories that may hinder access to the engine components. It is essential to document the configuration and orientation of parts for easier reassembly later.

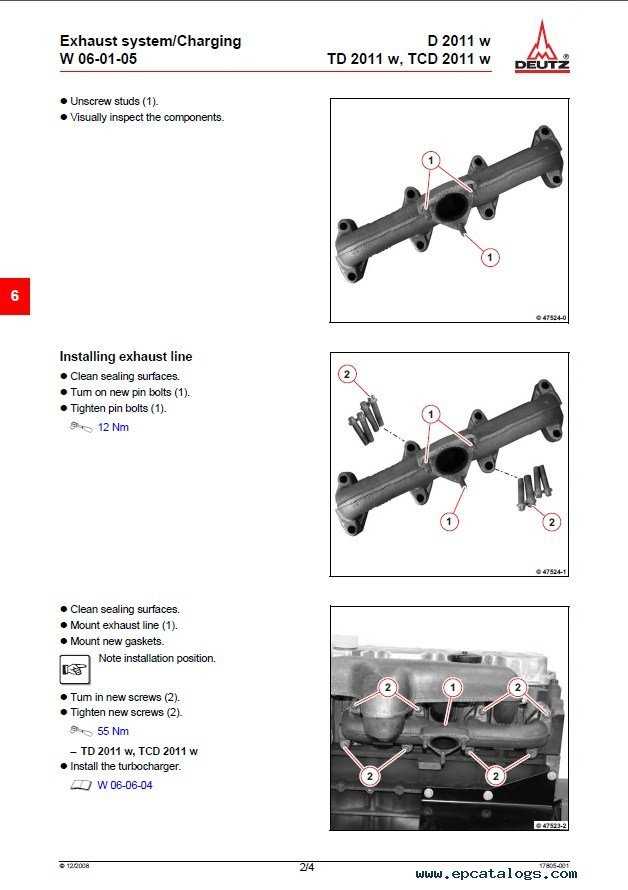

Disassembly Steps

Begin with the removal of the outer casing and protective covers. Gradually proceed to take off individual components such as the intake manifold, exhaust system, and valve covers. Carefully label and store each part in a designated area. Pay close attention to any bolts or fasteners, as their size and type may vary. Following this methodical approach will enhance the efficiency of the disassembly process.

Cleaning and Maintaining Engine Components

Regular upkeep of engine parts is crucial for optimal performance and longevity. Proper cleaning and maintenance routines help prevent the accumulation of dirt, grime, and other contaminants that can hinder efficiency and lead to premature wear. Implementing systematic practices ensures that each component functions effectively and extends the life of the engine.

Essential Cleaning Techniques

Employing the right cleaning methods is vital for preserving engine components. Here are some recommended techniques:

| Component | Cleaning Method | Frequency |

|---|---|---|

| Air Filter | Remove and gently wash with soap and water | Every 3 months |

| Fuel Injector | Use a specialized cleaner or solvent | Every 6 months |

| Cooling System | Flush with a coolant flush solution | Annually |

Maintenance Practices

In addition to cleaning, regular inspections and preventive measures are essential for maintaining engine components. Check for signs of wear and tear, replace filters as needed, and ensure that all connections are secure. Consistent maintenance not only improves performance but also reduces the risk of unexpected failures.

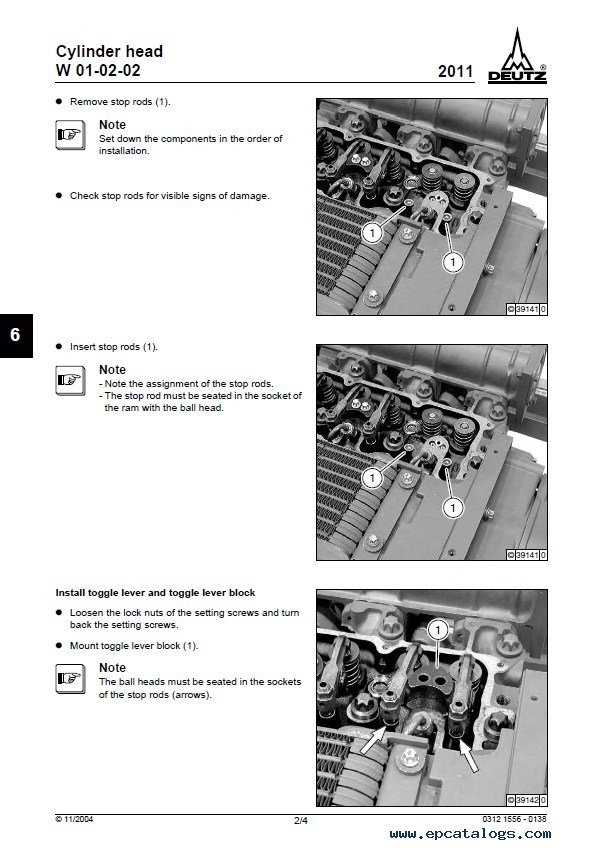

Reassembly Tips for Deutz 2011 Engines

When putting together the components of an engine, attention to detail and proper techniques are crucial for ensuring optimal performance and longevity. This section provides valuable insights and strategies to facilitate the successful reassembly of your engine.

Preparation and Organization

Before beginning the reassembly process, it is essential to gather all necessary tools and components. Organize parts systematically, labeling each one to prevent confusion. Create a clean workspace to minimize the risk of contamination and damage to delicate components.

Step-by-Step Approach

Follow a structured, step-by-step approach during reassembly. Refer to diagrams or previous notes to ensure all components are fitted correctly. Pay special attention to torque specifications for bolts and nuts, as improper torque can lead to mechanical failure. Finally, perform a thorough inspection of the assembled unit before reinstallation to confirm everything is in place and functioning as intended.

Lubrication and Fluids Recommendations

Proper maintenance of equipment involves utilizing the right lubricants and fluids to ensure optimal performance and longevity. Selecting appropriate substances plays a crucial role in preventing wear and tear, enhancing efficiency, and promoting smooth operation.

When it comes to lubrication, consider the following types:

- Engine Oil: A high-quality engine oil is essential for reducing friction and protecting engine components.

- Transmission Fluid: This fluid is vital for smooth gear shifting and maintaining the health of the transmission system.

- Hydraulic Oil: Used in hydraulic systems, it ensures efficient power transfer and operation.

In addition to lubricants, ensure that all fluids meet the manufacturer’s specifications. Regularly check the levels and quality of:

- Coolant: Prevents overheating and protects against corrosion.

- Brake Fluid: Essential for effective braking performance.

- Power Steering Fluid: Ensures smooth steering functionality.

Regular monitoring and timely replacement of these fluids will contribute significantly to the reliability and performance of the equipment, ultimately leading to reduced downtime and repair costs.

Troubleshooting Electrical System Failures

Addressing issues within an electrical system can be challenging, yet it is essential for ensuring optimal performance and reliability. A systematic approach can help identify and resolve common malfunctions that may arise, leading to improved functionality.

Begin by conducting a thorough visual inspection of all components, including wiring, connectors, and fuses. Look for signs of wear, corrosion, or loose connections, as these can often be the root cause of electrical problems. Next, utilize a multimeter to check voltage levels at various points in the circuit. This will help pinpoint areas where power loss may occur.

If the system incorporates relays or switches, test these components for proper operation. A malfunctioning relay can disrupt the flow of electricity and lead to system failures. Additionally, reviewing the system’s schematic can provide valuable insights into potential problem areas and assist in tracing electrical pathways.

For more complex issues, consider isolating individual sections of the electrical system. This can help narrow down the source of the problem and allow for more focused troubleshooting efforts. Keeping a detailed log of any findings and corrective actions taken can also facilitate future maintenance and repairs.

Cooling System Maintenance Procedures

Proper upkeep of the cooling system is essential for optimal engine performance and longevity. This section outlines the essential steps involved in maintaining the cooling system, ensuring efficient operation and preventing potential overheating issues.

Regular Inspection

Conducting frequent inspections of the cooling system components is vital. Check the radiator for any signs of leaks or damage, and ensure that the hoses are free from cracks or wear. Additionally, verify that the coolant level is within the recommended range and that there are no visible obstructions in the airflow pathways.

Coolant Replacement

Replacing the coolant at regular intervals helps maintain its effectiveness in regulating engine temperature. It is recommended to use a high-quality coolant that meets the specifications for your engine. Before adding new coolant, flush the system to remove any contaminants. This process ensures that the engine operates at its optimal temperature and reduces the risk of corrosion.

Final Testing After Engine Repairs

After completing modifications or service on an engine, it’s essential to conduct thorough assessments to ensure optimal functionality and performance. This phase is crucial for identifying any potential issues that may have arisen during the maintenance process, allowing for immediate resolution before the engine is returned to operation.

Conducting Performance Evaluations

Performance evaluations should include a series of tests to assess various parameters such as power output, fuel efficiency, and operational stability. Monitoring engine vibrations and listening for any unusual noises can also provide insights into the internal condition of the engine. Utilizing diagnostic tools can help pinpoint any anomalies that require attention.

Safety Checks and Final Adjustments

Prior to finalizing the process, it is vital to perform safety checks to verify that all components are securely installed and functioning as intended. Adjusting settings to the manufacturer’s specifications can significantly enhance reliability. Ensuring that all safety features are operational will provide peace of mind when the engine is put back into service.