Maintaining off-road vehicles is essential for ensuring optimal performance and longevity. Understanding the intricacies of your machine can help prevent common issues and enhance your overall experience. This section delves into the critical aspects of upkeep, offering insights and tips for effective care.

Whether you’re a seasoned enthusiast or a newcomer to the world of outdoor adventures, knowing how to address various challenges is vital. With a focus on practical advice, this guide provides a comprehensive approach to keeping your vehicle in top condition. From routine checks to advanced troubleshooting, the information here is designed to empower you in your maintenance journey.

Discovering effective solutions is a key part of vehicle ownership. By familiarizing yourself with essential techniques and tools, you can tackle issues confidently. The following sections will outline step-by-step processes, common pitfalls, and best practices to ensure your machine remains reliable and ready for any adventure.

Overview of Massimo 700

This section provides a comprehensive examination of a versatile utility vehicle known for its robustness and efficiency in various terrains. With an emphasis on performance and durability, this model is designed to meet the needs of both recreational users and those requiring reliable transportation for work-related tasks.

Key Features

The vehicle boasts a powerful engine that ensures optimal performance, enabling it to tackle challenging landscapes effortlessly. Enhanced suspension systems contribute to a smooth ride, while user-friendly controls facilitate ease of operation. Additionally, ample cargo space is available, making it suitable for transporting tools and equipment.

Applications

This robust vehicle is ideal for a variety of applications, including farming, hunting, and outdoor recreation. Its capability to handle heavy loads and navigate difficult conditions makes it a preferred choice among enthusiasts and professionals alike, ensuring reliability in every endeavor.

Common Issues and Solutions

This section explores frequent challenges encountered with utility vehicles and provides effective solutions to address them. Understanding these common problems can greatly enhance the performance and longevity of your equipment.

Electrical Failures

One of the primary issues users face involves electrical components. Symptoms may include failure to start or intermittent power loss. Solution: Check all connections and fuses. Ensure the battery is fully charged and inspect wiring for any signs of damage.

Engine Overheating

Overheating can lead to severe damage if not addressed promptly. This problem may arise from coolant leaks or a malfunctioning thermostat. Solution: Regularly inspect the cooling system, top up coolant levels, and replace any faulty components.

Maintenance Guidelines for Longevity

Ensuring the extended lifespan of your vehicle requires consistent care and attention. Regular upkeep not only enhances performance but also prevents unexpected failures, saving time and resources in the long run.

First, conduct routine inspections of key components, such as the engine, brakes, and electrical systems. Look for signs of wear or damage and address any issues promptly to prevent further complications.

Additionally, maintaining proper fluid levels is crucial. Regularly check and replace oil, coolant, and other essential fluids according to the manufacturer’s recommendations. This practice helps to keep the engine and other systems functioning smoothly.

Cleaning and lubricating moving parts will also contribute to overall efficiency. Remove dirt and debris from various areas and apply appropriate lubricants to prevent rust and wear.

Finally, adhere to a structured maintenance schedule. Keeping track of service intervals for oil changes, filter replacements, and other essential tasks will ensure that your vehicle remains in peak condition for years to come.

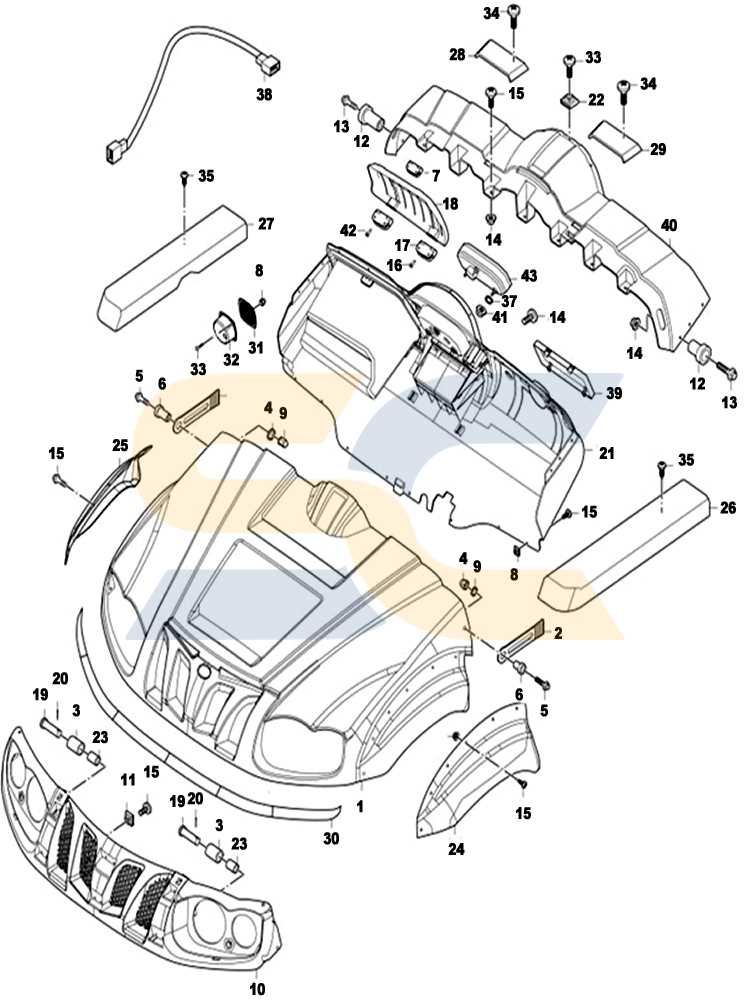

Parts Replacement and Upgrades

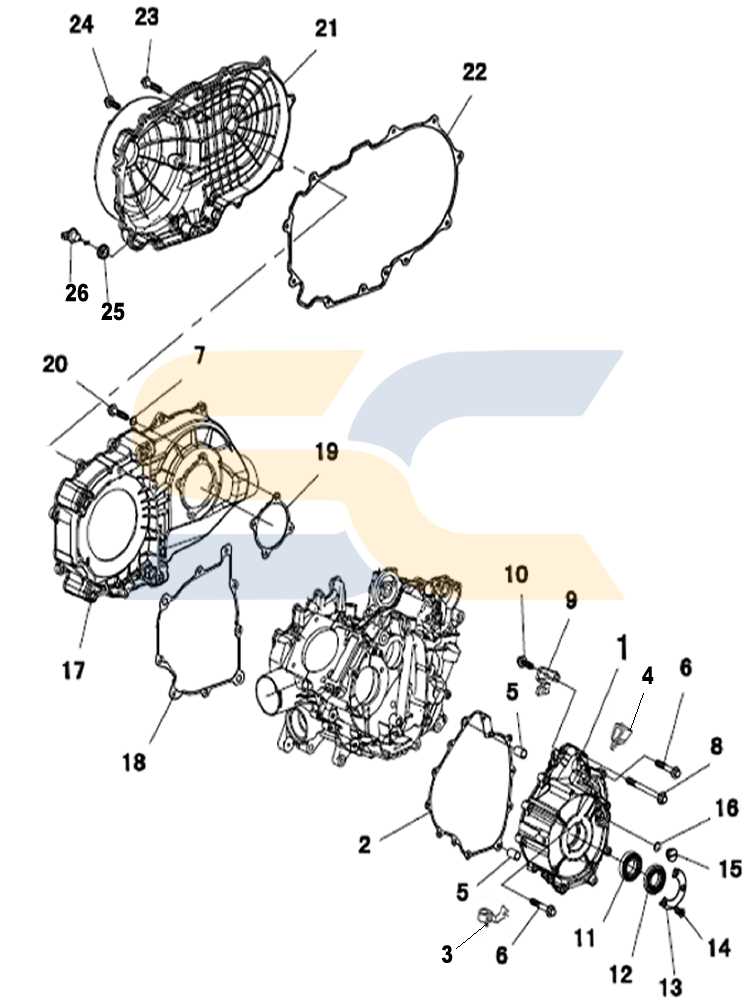

Maintaining optimal performance in your vehicle often requires timely replacement and enhancements of key components. Understanding the right timing and methods for these upgrades can significantly enhance both functionality and longevity.

When considering component substitution, it’s crucial to identify the parts that are most prone to wear and tear. Regularly inspecting engine components, transmission systems, and suspension elements can help in determining when replacements are necessary. Investing in high-quality alternatives can lead to improved efficiency and reliability.

In addition to basic replacements, upgrading certain systems can provide enhanced performance. For example, installing a more advanced exhaust system or upgrading the fuel injectors can lead to increased horsepower and torque. These modifications not only improve performance but also contribute to a better overall driving experience.

Lastly, always consult with a qualified technician or refer to reputable sources for guidance on compatible upgrades and replacements. This ensures that any modifications align with the specifications of your vehicle, maintaining safety and reliability.

Electrical System Troubleshooting

This section focuses on identifying and resolving issues within the electrical framework of your vehicle. Understanding how various components interact is crucial for effective diagnostics and repair.

Common Electrical Issues

- Battery Problems: Check for loose connections, corrosion, or a weak charge.

- Wiring Issues: Inspect for frayed wires or damaged insulation that may cause shorts.

- Fuse Failures: A blown fuse can disrupt electrical flow, leading to malfunctioning systems.

- Sensor Malfunctions: Faulty sensors may give inaccurate readings, impacting performance.

Troubleshooting Steps

- Begin with a visual inspection of the battery and connections.

- Utilize a multimeter to check voltage and continuity in the wiring.

- Replace any blown fuses and observe if the issue persists.

- Test sensors with appropriate diagnostic tools to ensure they are functioning correctly.

By following these guidelines, you can systematically identify and rectify electrical issues, ensuring optimal functionality of your vehicle.

Engine Performance Enhancements

Improving the efficiency and power output of an engine involves various techniques and modifications that can significantly enhance overall performance. These enhancements focus on optimizing airflow, fuel delivery, and engine management systems, resulting in a more responsive and powerful machine.

Air Intake Modifications

One of the primary methods to boost engine performance is upgrading the air intake system. By installing a high-performance air filter and larger intake ducts, the engine can breathe more freely. This increased airflow allows for a better fuel-air mixture, promoting combustion efficiency and improving throttle response.

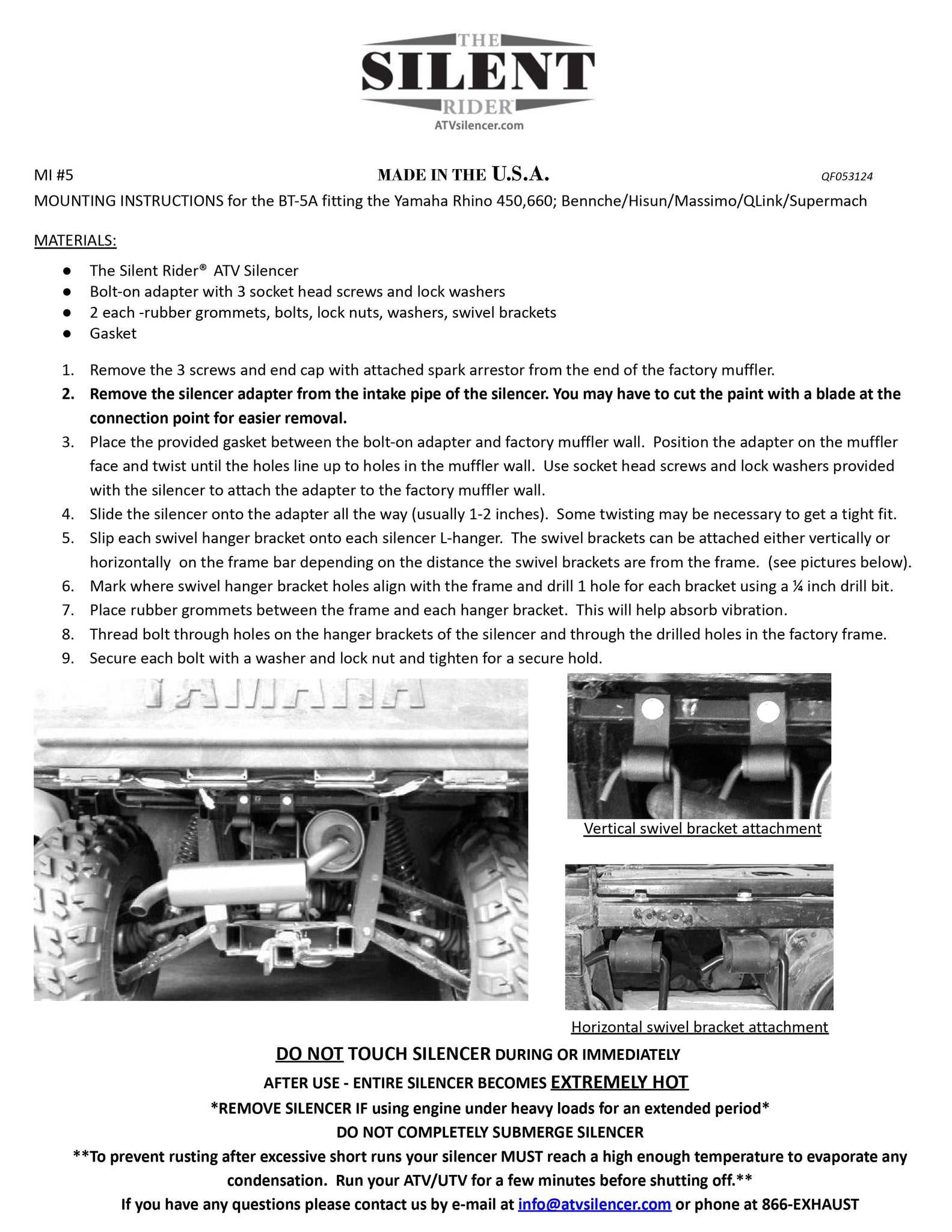

Exhaust System Upgrades

Enhancing the exhaust system is equally vital for maximizing performance. Replacing the stock exhaust with a high-flow system reduces back pressure, allowing exhaust gases to exit more efficiently. This modification not only increases horsepower but also contributes to a more aggressive engine sound, adding to the overall experience.

Combining these enhancements can lead to a remarkable transformation in engine dynamics. By focusing on both air intake and exhaust flow, enthusiasts can achieve a balance that maximizes power while maintaining reliability and efficiency.

Hydraulic System Maintenance Tips

Regular upkeep of hydraulic systems is essential for optimal performance and longevity. Proper care not only ensures efficiency but also prevents costly breakdowns and extends the lifespan of components. Following a few key practices can significantly enhance system reliability.

1. Routine Fluid Checks: Regularly inspect hydraulic fluid levels and quality. Low levels can lead to inadequate lubrication, while contaminated fluid can damage internal components. Always replace fluids according to the manufacturer’s recommendations.

2. Inspect Hoses and Connections: Examine hoses for any signs of wear, cracks, or leaks. Tighten connections to prevent fluid loss and maintain pressure. Replacing damaged hoses promptly can avert serious issues.

3. Monitor Temperature: Keep an eye on operating temperatures. Overheating can cause fluid breakdown and lead to system failures. If temperatures consistently exceed recommended levels, investigate potential causes and make necessary adjustments.

4. Clean Filters Regularly: Dirty filters can restrict fluid flow and reduce system efficiency. Regularly cleaning or replacing filters ensures that contaminants do not enter the system, thereby protecting vital components.

5. Check for Air Bubbles: Air trapped in the hydraulic fluid can cause erratic system behavior. Bleed the system as needed to remove any air bubbles and ensure smooth operation.

Implementing these practices will contribute to a well-functioning hydraulic system, enhancing overall performance and reliability.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is paramount for both personal well-being and the longevity of the equipment. Proper precautions can prevent accidents and injuries, creating a secure environment for the process. This section outlines essential guidelines to follow before and during service procedures.

General Guidelines

Always wear appropriate personal protective equipment (PPE) such as gloves, goggles, and closed-toe shoes. Familiarize yourself with the tools and components you will be working with to avoid mishaps. Ensure that the work area is clean and organized, minimizing distractions and potential hazards.

Electrical Safety

When dealing with electrical components, always disconnect the power source before beginning any work. Use insulated tools to reduce the risk of electrical shock. It is advisable to verify that the equipment is properly grounded to prevent static discharge and other electrical issues.

| Precaution | Description |

|---|---|

| Wear PPE | Use gloves, goggles, and appropriate footwear to protect against injuries. |

| Disconnect Power | Always turn off and unplug the equipment before starting any tasks. |

| Use Insulated Tools | Utilize tools designed to minimize the risk of electrical shock. |

| Keep Work Area Clean | Maintain an organized workspace to avoid accidents and distractions. |

Tools Needed for Repair Tasks

Successfully addressing issues with machinery requires a selection of essential instruments. Having the right equipment on hand can streamline the process and enhance efficiency, allowing for a smoother workflow when tackling various challenges. Understanding the necessary tools is crucial for effective maintenance and troubleshooting.

Basic Hand Tools

Starting with fundamental implements, items such as wrenches, pliers, and screwdrivers are indispensable. These tools are vital for loosening or tightening components, ensuring that parts fit securely. Investing in high-quality hand tools will not only improve performance but also provide durability for future tasks.

Diagnostic Equipment

In addition to hand tools, having diagnostic devices can significantly aid in identifying underlying issues. Multimeters, pressure gauges, and scanners are examples of equipment that assist in analyzing the condition of various systems. Utilizing these instruments enables a more precise assessment, facilitating timely interventions.

Understanding the User Manual

Every guide serves as a crucial resource for users, offering essential insights into the operation and maintenance of their equipment. This section highlights the importance of comprehending the instructions provided, ensuring that users can effectively utilize their devices and troubleshoot common issues.

Key Features: Familiarity with the layout and structure of the document is vital. Most guides include sections on setup, usage tips, safety precautions, and troubleshooting advice. Understanding these elements allows users to navigate the content efficiently.

Safety Information: A comprehensive guide emphasizes safety protocols, which are essential for preventing accidents and ensuring proper functionality. Users should prioritize reading these sections to safeguard their equipment and themselves.

Maintenance Tips: Regular upkeep is often outlined in the documentation, providing users with methods to extend the lifespan of their devices. Following these recommendations can lead to improved performance and reliability.

Conclusion: Grasping the content of the guide not only enhances the user experience but also empowers individuals to resolve issues independently, fostering confidence in their operational abilities.

Recommended Service Intervals

Regular maintenance is essential to ensure optimal performance and longevity of your vehicle. Adhering to specific timelines for service can prevent potential issues and keep components functioning efficiently. Establishing a routine schedule helps in identifying wear and tear early, thereby avoiding costly repairs.

It is advisable to conduct a thorough inspection every 50 hours of operation. During this check, focus on fluid levels, tire pressure, and any visible signs of wear. Additionally, an extensive service should be performed at every 200 hours, which includes changing oils, filters, and examining critical systems for integrity.

For long-term care, a comprehensive evaluation should take place annually. This should encompass all aspects of the machinery, ensuring all parts are in top condition. Following these intervals will significantly enhance the reliability and safety of your vehicle.

FAQs About Massimo 700 Repairs

This section addresses common inquiries related to troubleshooting and maintenance of the vehicle in question. Understanding frequent issues and solutions can significantly aid users in managing their machines effectively.

What are some common problems faced by users?

Users often report difficulties with starting, electrical malfunctions, and engine performance. Recognizing these issues early can lead to timely interventions and prevent further complications.

How can I troubleshoot electrical issues?

To diagnose electrical concerns, check the battery connections, inspect fuses, and ensure all wiring is intact. If the problem persists, consider consulting a professional for detailed analysis.