Understanding the functionality and upkeep of mobile power systems is essential for any traveler. Regular attention ensures that these essential components operate efficiently, providing the necessary energy for various appliances during journeys. Proper care not only enhances performance but also extends the lifespan of the equipment.

Common issues can arise from wear and tear, improper usage, or environmental factors. Familiarity with troubleshooting techniques and preventive measures can empower users to address minor complications swiftly. A comprehensive approach to maintenance allows for smoother travels and reduced downtime.

Resources outlining procedures and best practices are invaluable for users seeking to enhance their knowledge and skills. These guides offer detailed insights into various aspects of the system, equipping individuals with the confidence to manage challenges independently. Adopting a proactive stance in managing these power systems significantly contributes to a positive travel experience.

Understanding frequent complications and their solutions is essential for ensuring optimal performance of your power system. Below are some typical problems encountered and practical suggestions for addressing them.

-

Starting Problems:

- Check the fuel level to ensure sufficient supply.

- Inspect the battery connections for corrosion or looseness.

- Verify the operation of the ignition switch and safety mechanisms.

-

Overheating:

- Ensure proper ventilation around the unit.

- Clean or replace air filters to improve airflow.

- Monitor the coolant levels and inspect for leaks.

-

Noise Issues:

- Check for loose parts or components that may need tightening.

- Inspect for worn bearings that might require replacement.

- Evaluate the overall condition of the muffler and exhaust system.

-

Electrical Failures:

- Examine wiring for signs of damage or fraying.

- Test circuit breakers and fuses for proper functionality.

- Ensure that all electrical connections are secure and free of corrosion.

Addressing these common challenges promptly can significantly enhance the reliability and longevity of your power equipment. Regular maintenance and vigilant monitoring are key to preventing issues from escalating.

Essential Tools for Generator Repair

Having the right equipment is crucial for effectively addressing issues that may arise during maintenance tasks. This section highlights the fundamental instruments needed for troubleshooting and fixing power sources, ensuring optimal functionality and longevity.

| Tool | Purpose |

|---|---|

| Multimeter | Used for measuring voltage, current, and resistance, allowing diagnostics of electrical circuits. |

| Wrenches | Essential for loosening or tightening bolts and nuts, facilitating access to internal components. |

| Screwdrivers | Required for removing screws to access various sections of the unit. |

| Pliers | Helpful for gripping, twisting, and cutting wires, ensuring safe handling of electrical connections. |

| Oil Filter Wrench | Designed to assist in replacing oil filters, maintaining engine performance. |

| Socket Set | Provides various sizes for different bolts, enabling quick and efficient assembly or disassembly. |

| Flashlight | Illuminates dark areas, making it easier to work in confined spaces. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficiency of your mobile energy source. Following a systematic approach will help you maintain optimal performance and prevent unexpected breakdowns.

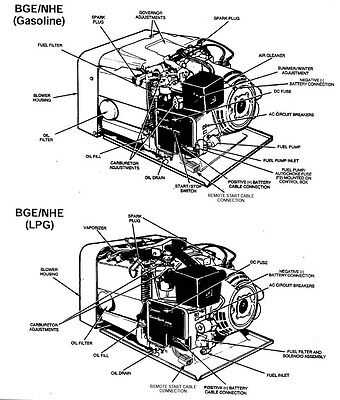

- Inspection: Start with a thorough visual examination of the unit. Look for any signs of wear, leaks, or damage.

- Cleaning: Remove dirt and debris from external surfaces. Ensure that air intake areas are clear to promote proper airflow.

- Fluid Check: Regularly check and top off fluids, including oil and coolant, according to the specifications outlined by the manufacturer.

- Filter Replacement: Change the air and fuel filters as recommended to ensure efficient operation. Dirty filters can hinder performance.

- Battery Maintenance: Inspect the battery connections for corrosion and ensure the terminals are clean. Test the battery charge regularly.

Following these steps will contribute significantly to the reliable functioning of your equipment. Always refer to specific guidelines for detailed information regarding frequency and techniques.

Electrical System Diagnostics Explained

Understanding the intricacies of an electrical system is crucial for identifying issues that may arise during operation. This segment delves into the methodologies used to assess and troubleshoot the functionality of various components, ensuring optimal performance and reliability.

Effective diagnostics begin with a thorough examination of the system’s components, including wiring, connectors, and circuit boards. By utilizing specialized tools and techniques, technicians can detect irregularities that may disrupt normal operations.

The process typically involves measuring voltage levels, checking continuity, and inspecting for any signs of wear or damage. Identifying symptoms early can prevent more severe failures, ultimately saving time and resources during maintenance tasks.

Moreover, a comprehensive understanding of schematics and circuitry enhances the ability to pinpoint specific malfunctions. This knowledge is essential for implementing appropriate solutions and restoring functionality efficiently.

Fuel System Cleaning Techniques

Maintaining a clean fuel system is essential for optimal performance and longevity of equipment. Various methods can be employed to ensure the fuel system remains free from contaminants, improving efficiency and preventing potential issues.

Routine Cleaning Practices

- Regularly inspect fuel filters and replace them as needed to ensure smooth flow.

- Utilize fuel additives designed to clean injectors and combustion chambers.

- Drain and replace old fuel periodically to prevent the buildup of sediment.

Advanced Cleaning Methods

- Perform a deep cleaning using specialized equipment to flush out the entire fuel system.

- Employ ultrasonic cleaning techniques for fuel injectors to remove stubborn deposits.

- Consider professional cleaning services for comprehensive maintenance.

Replacing Generator Components Safely

Ensuring the proper functioning of your power supply unit requires careful attention to component replacement. Adopting safe practices during the process can prevent accidents and prolong the lifespan of the equipment. Understanding the necessary precautions and the correct procedures is essential for successful maintenance.

Safety Precautions

Before commencing any replacement task, it is crucial to follow several safety measures:

- Always disconnect the power source to avoid electric shocks.

- Utilize appropriate personal protective equipment (PPE) such as gloves and goggles.

- Work in a well-ventilated area to prevent the accumulation of harmful fumes.

Replacement Process Overview

The following steps outline a systematic approach to component substitution:

| Step | Description |

|---|---|

| 1 | Turn off and disconnect the unit from the power supply. |

| 2 | Remove the access panel using a suitable tool. |

| 3 | Identify the faulty component for replacement. |

| 4 | Carefully disconnect any wires or connectors attached to the part. |

| 5 | Install the new component, ensuring all connections are secure. |

| 6 | Replace the access panel and reconnect to the power source. |

By adhering to these guidelines, individuals can successfully replace components while minimizing risks associated with the maintenance process.

Oil Changes and Filter Replacements

Regular maintenance is crucial for ensuring the longevity and efficiency of your equipment. One of the essential tasks in this process involves replacing the lubricant and filters at specified intervals. Properly executed changes not only enhance performance but also minimize wear and tear on internal components.

Importance of Lubricant Quality

The choice of lubricant plays a significant role in the functionality of the system. High-quality oil reduces friction and heat, contributing to a smoother operation. Always refer to the specifications to select the appropriate type for your machinery.

Steps for Filter Replacement

Changing the filter is a straightforward task that can prevent contaminants from entering the system. Start by turning off the unit and allowing it to cool. Remove the old filter carefully and install the new one, ensuring a secure fit. It is advisable to check for leaks after the replacement.

Starting System Troubleshooting Methods

This section outlines essential strategies for diagnosing issues within the ignition framework of your power unit. Identifying and addressing faults in this area can enhance overall functionality and ensure reliable operation.

Begin by examining the power source, ensuring that connections are secure and that the battery is fully charged. A weak or depleted battery can lead to insufficient power supply, causing starting difficulties.

Next, inspect the ignition switch and wiring for any signs of wear or damage. Faulty components may interrupt the current flow, preventing the system from engaging properly.

Additionally, assess the starter motor’s condition. A malfunctioning starter can result in a lack of response when attempting to initiate the unit. Testing the motor with a multimeter can help verify its operational integrity.

Lastly, evaluate safety mechanisms that may inhibit starting. Certain models include features that prevent operation under unsafe conditions, which could be mistakenly perceived as an ignition issue.

Noise Reduction Strategies for Generators

Reducing sound levels is essential for improving the comfort of users and minimizing disturbance to surrounding environments. Various techniques can effectively minimize operational noise, enhancing overall performance and user experience.

Soundproofing Techniques

Implementing soundproofing materials can significantly decrease noise transmission. Utilizing acoustic panels or insulation within the enclosure helps absorb sound waves, preventing them from escaping. Additionally, placing sound-dampening mats underneath can further minimize vibrations that contribute to unwanted noise.

Operational Adjustments

Modifying operational practices can also play a crucial role in noise management. Ensuring regular maintenance and timely servicing can reduce excessive sound caused by wear and tear. Moreover, adjusting the load levels to optimal ranges allows for smoother operation, which inherently results in quieter functioning.

Regular Maintenance Schedule Recommendations

Establishing a consistent upkeep routine is essential for ensuring optimal performance and longevity of your equipment. Adhering to a well-defined schedule not only prevents unexpected failures but also enhances efficiency, allowing for smoother operation during usage.

Daily Inspections: Before operation, conduct a visual examination to check for any leaks, damage, or unusual noises. This proactive approach can help identify potential issues early.

Weekly Tasks: Clean external components and ensure air vents are free of debris. Checking fluid levels is crucial; top up oil, coolant, and fuel as necessary to maintain proper functionality.

Monthly Maintenance: Inspect filters and replace them if dirty. Additionally, tighten all connections and inspect belts for wear. A thorough examination of the electrical system will help prevent future complications.

Seasonal Service: At the start of each season, perform a comprehensive check. This should include testing the starting system, reviewing the battery condition, and ensuring all safety features are operational. Regular servicing not only extends the lifespan but also guarantees reliability during critical times.

Finding Replacement Parts and Resources

Locating suitable components and support materials is essential for maintaining your equipment’s efficiency and longevity. Whether you are dealing with minor issues or significant malfunctions, having access to the right resources can significantly simplify the process. This section outlines effective strategies for sourcing quality parts and reliable assistance.

Online Marketplaces and Retailers

Numerous online platforms specialize in selling components for various machinery. These websites often provide extensive catalogs, allowing users to search by specifications or equipment types. Utilizing customer reviews and ratings can also help in selecting trustworthy vendors.

Local Suppliers and Service Centers

Visiting nearby suppliers or service centers can yield valuable insights. Many local businesses offer personalized advice and may carry specific items in stock. Establishing a relationship with these providers can lead to better deals and quicker access to necessary parts.