Maintaining and troubleshooting household laundry devices can often be a challenging task for many users. Understanding the common issues that arise and knowing how to address them is essential for ensuring the longevity and efficiency of your appliances. This section provides insights into typical problems encountered and offers helpful suggestions for resolving them.

Identifying Symptoms is the first step toward effective solutions. Users may experience a variety of malfunctions, ranging from unusual noises to improper functioning. By carefully observing and documenting these symptoms, one can streamline the troubleshooting process and focus on specific areas that require attention.

Once the symptoms are recognized, exploring potential causes becomes crucial. This may include checking for blockages, ensuring proper settings, or inspecting electrical connections. Armed with this knowledge, users can take proactive measures to address issues and maintain optimal performance.

When addressing issues with household appliances, having the right instruments can make the process smoother and more efficient. The following list outlines essential items that can aid in troubleshooting and fixing common problems effectively.

Essential Tools

- Screwdrivers (both flathead and Phillips)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and standard)

- Multimeter for electrical diagnostics

- Tape measure for precise measurements

Safety Equipment

- Safety goggles to protect eyes

- Work gloves to ensure hand safety

- Non-slip footwear for stability

Having these tools on hand not only prepares you for various tasks but also enhances safety and efficiency during the process.

Troubleshooting Water Drain Problems

Addressing drainage issues can be essential for ensuring optimal performance of your appliance. When water fails to exit the drum properly, it can lead to unwanted residue and operational difficulties. Identifying the root causes of such problems is key to restoring functionality.

Common Causes of Drainage Issues

Several factors may contribute to poor water drainage. Blocked hoses, clogged filters, or malfunctioning pumps are among the primary culprits. Regular maintenance checks can help identify these issues before they escalate into significant malfunctions.

Steps to Resolve Drainage Problems

Begin by inspecting the drainage hose for kinks or obstructions. Ensure it is properly positioned and free of debris. Next, examine the filter for any blockages that might prevent efficient water flow. If these components are clear, testing the pump’s functionality may be necessary to confirm it operates as intended.

Fixing Spin Cycle Malfunctions

Addressing issues during the spinning phase of laundry cycles is essential for achieving optimal results. Various factors can lead to problems during this stage, and understanding these can help you troubleshoot effectively.

Common reasons for spin cycle issues include:

- Unbalanced Load: Overloading or unevenly distributing items can prevent proper spinning.

- Drainage Problems: Blockages in the drainage system can hinder effective water removal.

- Faulty Motor: A malfunctioning motor may not provide the necessary power to initiate the spin.

- Worn Belts: Belts that are worn or damaged may fail to transfer the motor’s power to the drum.

To resolve these malfunctions, consider the following steps:

- Check the load balance and redistribute items if necessary.

- Inspect the drainage system for any obstructions and clean as needed.

- Examine the motor for any signs of wear or damage.

- Replace worn or damaged belts to restore proper function.

By following these guidelines, you can effectively troubleshoot and address issues during the spinning phase, ensuring your laundry processes run smoothly.

Addressing Power Supply Issues

Ensuring a reliable power source is crucial for the proper functioning of any household appliance. When electrical problems arise, it is essential to identify the root cause to restore the appliance to its optimal performance. This section will guide you through common power-related challenges and their solutions.

Identifying Electrical Problems

Before proceeding with repairs, it is important to assess the electrical supply. Here are some common signs of power issues:

- No response when attempting to start the device

- Intermittent operation or sudden shutdowns

- Tripped circuit breakers or blown fuses

Troubleshooting Steps

Follow these steps to diagnose and potentially resolve power supply issues:

- Check the power cord for any visible damage.

- Ensure that the outlet is functioning by testing it with another device.

- Inspect circuit breakers or fuses for any signs of failure.

- Examine the connection between the appliance and the power source for any loose wires.

By systematically evaluating these aspects, you can often pinpoint the issue and take appropriate corrective action to ensure reliable operation.

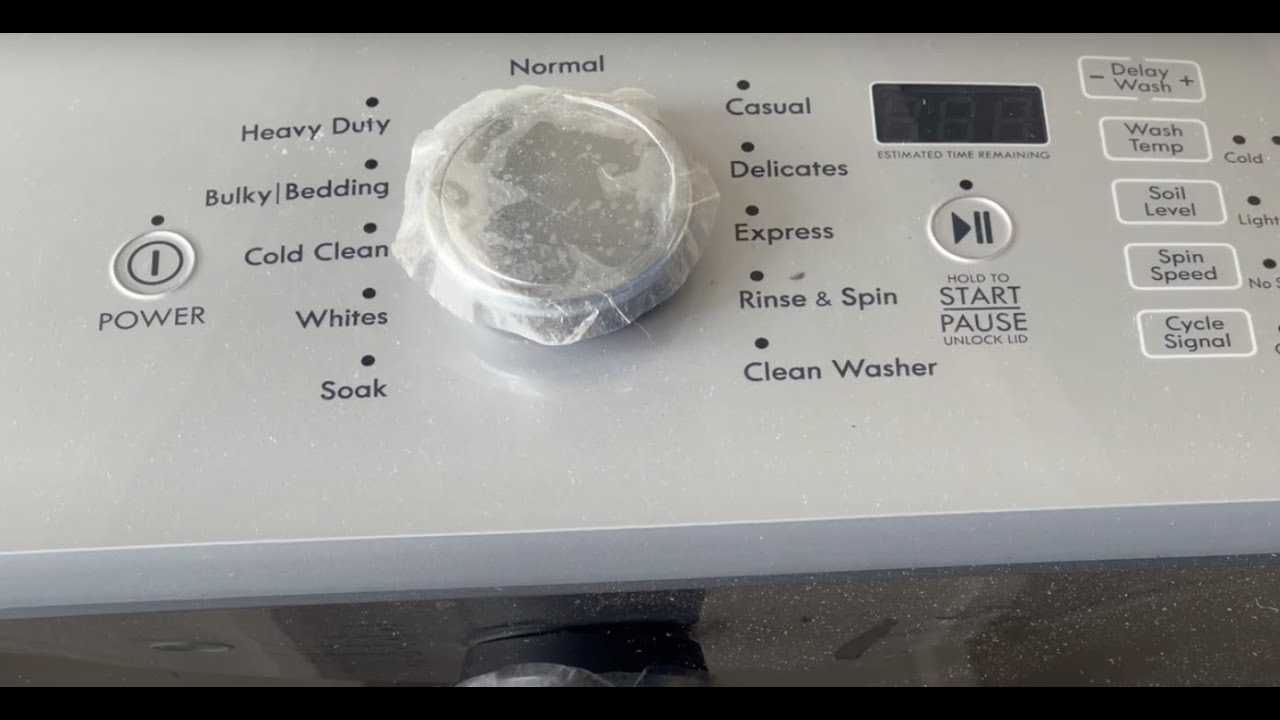

Inspecting the Door Mechanism

Ensuring proper function of the entry point mechanism is crucial for the overall performance of the appliance. Regular checks can help identify issues early, preventing more significant problems down the line.

Visual Examination

- Inspect the exterior for signs of wear or damage.

- Check the hinges for rust or corrosion that may hinder movement.

- Ensure that the locking mechanism engages smoothly.

Functional Testing

- Open and close the entry point multiple times to assess ease of use.

- Listen for any unusual noises during operation that could indicate malfunction.

- Test the locking function to ensure it secures properly when closed.

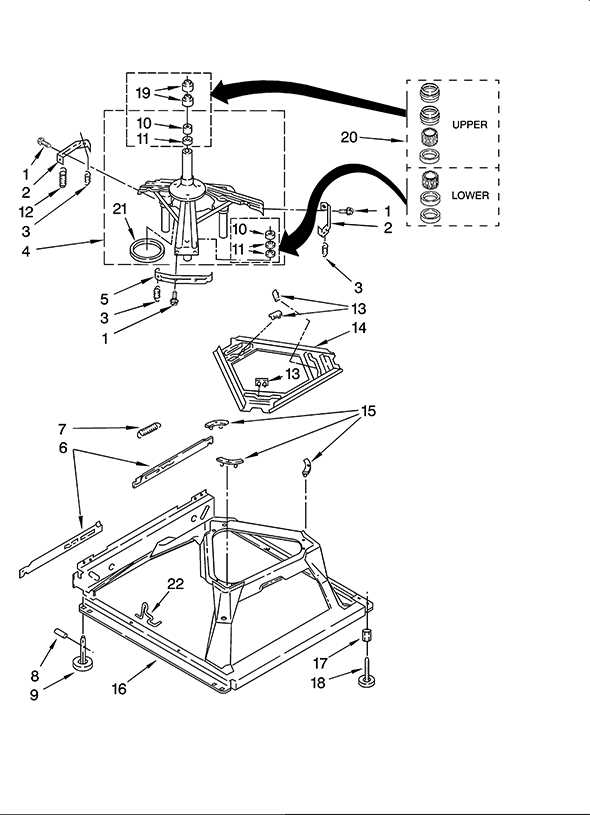

Replacing the Agitator Assembly

When addressing issues related to the agitation function of your laundry appliance, it may become necessary to replace the component responsible for this crucial task. This process can restore optimal performance and enhance the efficiency of the unit.

Tools and Materials Needed

Before beginning the replacement, gather the following tools: a socket set, screwdrivers, and a replacement agitator assembly. Ensuring you have all materials at hand will streamline the process.

Steps to Follow

Start by disconnecting the power supply and water connections for safety. Next, remove the top panel and access the inner workings. Detach the old assembly by unscrewing it carefully, then position the new component in place and secure it. Reassemble the panels, reconnect everything, and test the unit to confirm the successful installation.

Cleaning the Filter and Hoses

Maintaining the cleanliness of the filter and hoses is essential for optimal performance of your appliance. Regularly inspecting and cleaning these components can prevent clogs and enhance efficiency, ensuring your device operates smoothly.

Steps to Clean the Filter

- Turn off the appliance and unplug it for safety.

- Locate the filter, usually found at the bottom front of the unit.

- Remove the filter by twisting or pulling it out gently.

- Rinse the filter under warm water to eliminate any debris.

- Inspect the filter for damage and replace it if necessary.

- Reinsert the filter securely back into its housing.

Cleaning the Hoses

- Disconnect the hoses from the appliance and the water supply.

- Check for any visible blockages or buildup inside the hoses.

- Use a long brush or a flexible cleaning tool to clear any obstructions.

- Rinse the hoses thoroughly with clean water to remove any remaining residues.

- Reconnect the hoses and ensure they are tightly secured to avoid leaks.

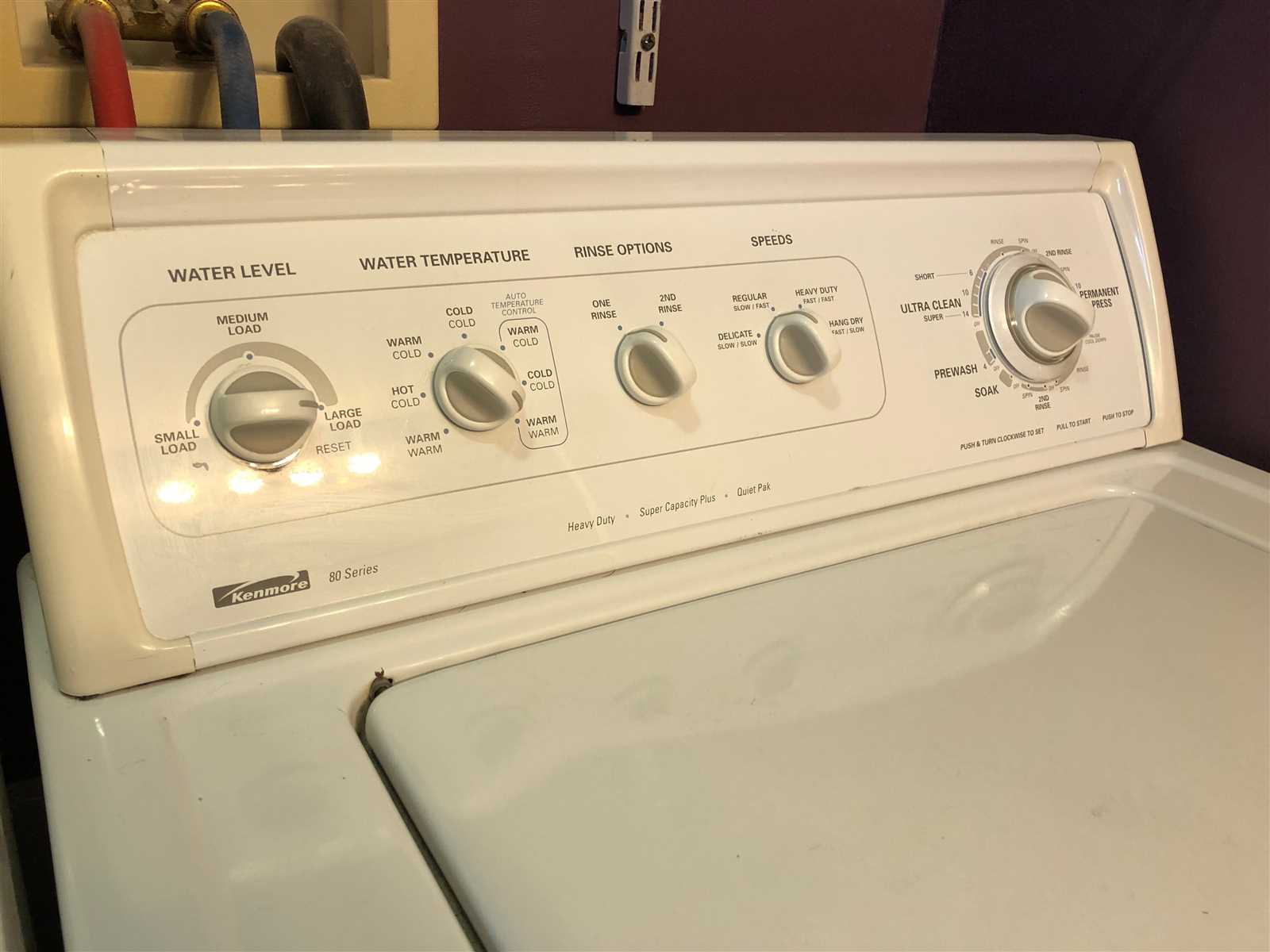

Adjusting the Water Level Switch

Ensuring proper functionality of the water level control is essential for optimal performance of your appliance. Adjusting this component can help maintain the desired water levels during operation, improving efficiency and preventing potential issues.

Follow these steps to modify the water level switch:

- Unplug the appliance to ensure safety before beginning any adjustments.

- Locate the water level switch, typically found near the control panel.

- Inspect the tubing connected to the switch for any blockages or kinks that could affect performance.

- Use a screwdriver to gently loosen the screws securing the switch in place.

- Adjust the height of the switch according to your preferences by repositioning it carefully.

- Tighten the screws to secure the switch in its new position.

- Reconnect any tubing that was detached during the adjustment.

- Plug in the appliance and run a test cycle to verify that the water levels are now functioning correctly.

Regular maintenance of this component is recommended to ensure long-term reliability and efficiency of the appliance.

Dealing with Unusual Noises

Experiencing unexpected sounds during operation can be concerning. Identifying the source of these disturbances is crucial to ensuring the longevity and efficiency of your appliance. This section aims to provide insights into common noises and potential causes, helping you troubleshoot effectively.

Grinding or Rattling Sounds: These noises may indicate that objects are trapped within the drum or that components are loose. Check for any foreign items that might be causing interference. It’s important to remove these to prevent damage.

Banging or Thumping: Such sounds often arise from an unbalanced load. Ensure that items are evenly distributed in the drum. If the issue persists, it may be worth examining the suspension system for wear or damage.

Hissing or Whining: These noises can suggest issues with the motor or pump. Listen carefully to determine if the sound is coming from these areas, and consider inspecting the relevant components for blockages or mechanical failure.

Understanding and addressing these unusual sounds promptly can help maintain optimal performance and extend the lifespan of your appliance.

Conducting Regular Maintenance Tips

Maintaining your laundry appliance is essential for optimal performance and longevity. By implementing a consistent maintenance routine, you can prevent common issues, enhance efficiency, and ensure that your unit operates smoothly. Here are some practical tips to keep your device in top shape.

Routine Cleaning

Regular cleaning of various components is crucial. Focus on areas that accumulate lint and debris, such as filters and dispensers. A clean environment helps in avoiding clogs and ensures that your unit runs efficiently.

Inspecting Hoses and Connections

Check hoses and connections frequently for signs of wear or leaks. Replacing damaged hoses promptly can prevent potential water damage and enhance the overall safety of your appliance.

| Task | Frequency |

|---|---|

| Clean lint filters | After every use |

| Check hoses | Monthly |

| Inspect drum for debris | Every 3 months |

| Run a cleaning cycle | Monthly |

When to Call a Professional

Understanding when to seek expert assistance can save time and prevent further complications. Certain issues may seem manageable, but they require specialized knowledge and tools to address effectively.

- If you encounter persistent leaks despite your attempts to fix them.

- When strange noises occur during operation that are out of the ordinary.

- If the unit fails to start or complete its cycle after troubleshooting.

- When there are electrical issues, such as blown fuses or tripped breakers.

- If you notice unusual smells, indicating possible electrical problems.

In these situations, it is advisable to contact a qualified technician who can diagnose and resolve the problem safely and efficiently.