When working with outdoor power tools, maintaining their performance and longevity is essential. Proper upkeep and addressing potential issues early can save both time and effort, ensuring that your equipment runs smoothly and reliably.

Understanding the Key Components is crucial to keeping everything in optimal condition. Familiarity with various parts and their functions enables users to tackle issues effectively. Knowing what to look for can help prevent small problems from escalating, preserving the efficiency of your tool.

Regular care and attention to each component can significantly extend the life of your equipment. From cleaning to part replacements, every step in maintaining these tools contributes to their reliable operation. Following a structured approach to maintenance and addressing minor issues promptly can make a world of difference in performance.

Overview of MS Model Chainsaw

This powerful and reliable chainsaw model is designed for both occasional tasks and more demanding woodcutting projects. Built to deliver consistent performance, it combines durability with efficiency, making it a popular choice among users who require a tool that handles a variety of environments and conditions effectively.

Key aspects of this chainsaw model include:

- Engine Power: Crafted for an optimal balance between power and weight, ensuring ease of use while delivering effective cutting force.

- Design: Ergonomic handle placement and anti-vibration features help reduce user fatigue, promoting safe and comfortable operation.

- Durability: Constructed with high-quality materials and a robust build, this tool withstands regular wear and tear, allowing for extended use.

- Maintenance Accessibility: E

Common Issues with the MS 250 Model

Over time, this chainsaw model may encounter a few typical challenges that users often report. Awareness of these common concerns can help identify signs of wear or misalignment and ensure smoother, longer-lasting performance.

- Starting Difficulties: Users sometimes experience trouble starting, particularly if the engine hasn’t been maintained regularly or if fuel has been left unused for a long period.

- Idle Problems: Issues with idling may cause the saw to stall, often due to an unclean carburetor or air filter, affecting the machine’s smooth operation.

- Chain Tension: Frequent loosening of the chain during use can occur, typically requiring regular checks and adjustments to maintain cutting efficiency and safety.

- Power Loss: A drop in power can result from clogged fuel lines, old spark plugs, or debris

Tools Needed for Effective Repair

Having the right tools is essential to achieve a smooth and efficient maintenance process. By preparing properly, you can ensure each task is completed accurately and safely, reducing downtime and improving the longevity of your equipment.

Basic Tools

Start with fundamental tools that are necessary for most mechanical tasks. These will include a range of wrenches, screwdrivers, and pliers to tackle various parts and components. Additionally, a sturdy set of Allen keys and adjustable pliers will help manage more specific adjustments.

Specialized Tools

For more precise work, a few specialized items will be needed. Torque wrenches, for instance, are essential for ensuring bolts are secured to the correct tension, while a compression tester can be beneficial for assessing the internal pressure in certain parts. A spark plug wrench, meanwhile, is a valuable tool for removing

Step-by-Step Disassembly Guide

This section provides a straightforward approach to carefully dismantling the equipment, offering guidance on each phase of the process. The goal is to help users disassemble the parts efficiently while maintaining the integrity of each component. Following these instructions allows for secure handling, reducing any risk of damage and preparing each piece for inspection, cleaning, or further maintenance.

Start by gathering all necessary tools, such as screwdrivers and pliers, and place them within reach to streamline the process. Having a clean workspace also ensures that small components do not get lost. Pay close attention to each part’s position as you go, taking notes or photos if needed to make reassembly easier later.

Begin by removing the main housing screws, working carefully to keep each one organized by its position. Once the exterior is separated, identify and gradually disconnect any internal components. Take extra care with delicate parts to avoid applying excess force, ensuring each piece is handled properly and set aside in an orderly fashion.

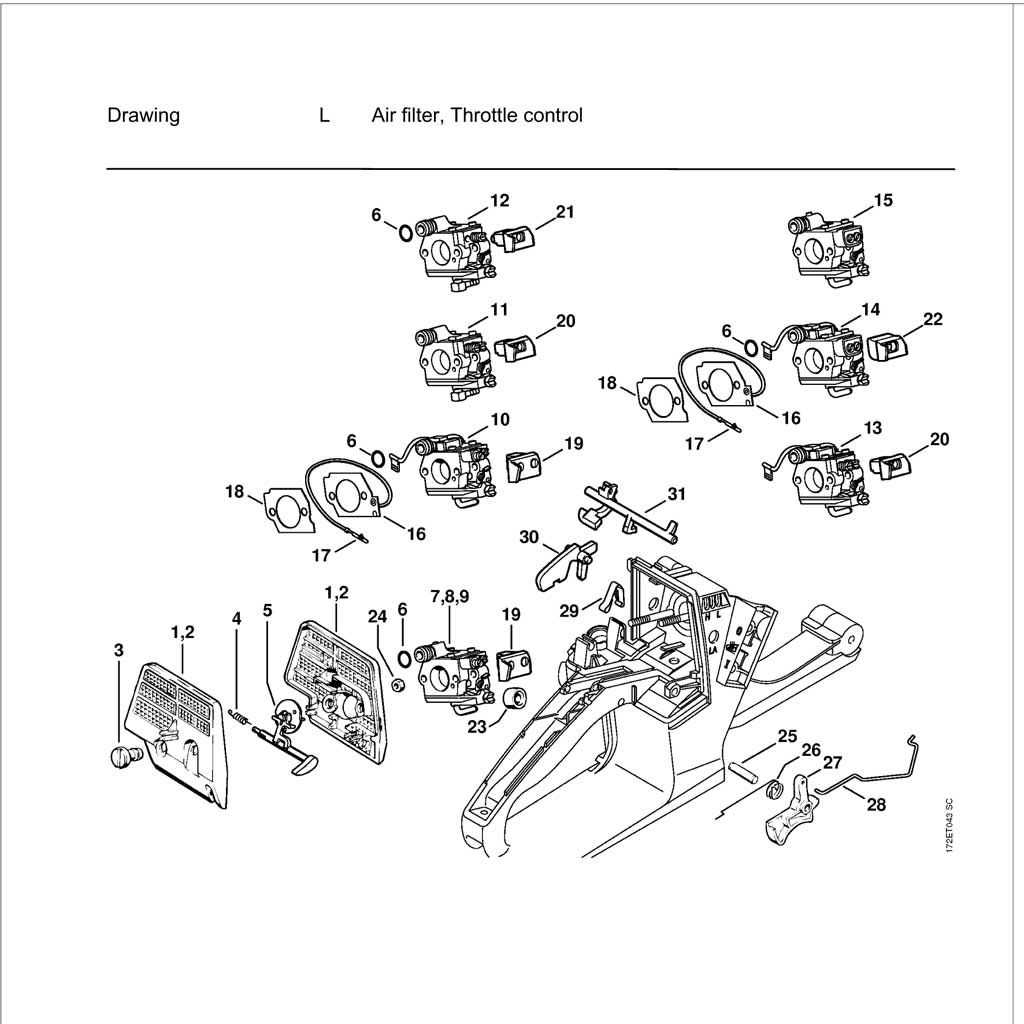

Inspecting and Cleaning the Carburetor

The carburetor plays a vital role in engine performance, ensuring a balanced fuel and air mix. Regular inspection and cleaning of this component are essential for maintaining optimal function and avoiding common issues caused by residue buildup.

To examine and clean the carburetor, begin by ensuring all necessary tools and a clean workspace are ready. Pay close attention to each section for any signs of wear or blockage.

Step Description 1. Access the Carburetor Remove the air filter cover to gain access to the carburetor. Be cautious with screws and small parts. 2. Inspect Components Check the carburetor’s parts, including jets, diaphragms, and gaskets, for Replacing the Air Filter and Spark Plug

Maintaining optimal performance in your chainsaw requires regular attention to key components such as the air filter and spark plug. These elements play a crucial role in ensuring efficient engine operation and longevity. In this section, we will explore the steps necessary to effectively replace these parts, enhancing your equipment’s functionality.

Steps for Air Filter Replacement

Begin by removing the cover that protects the air filter. This often involves loosening screws or latches. Once the cover is off, carefully take out the old filter and inspect the area for any debris. Clean the housing to ensure proper airflow, then insert the new filter, making sure it fits snugly before reattaching the cover.

Installing a New Spark Plug

Next, locate the spark plug, which is typically found on the side of the engine. Use a spark plug wrench to unscrew the old plug, taking care not to damage the surrounding components. Before installing the new plug, check the gap with a gauge to ensure proper spacing. Finally, thread the new spark plug in by hand, then tighten it securely with the wrench, being cautious not to over-torque.

Chain Maintenance and Sharpening Tips

Proper upkeep of your cutting tool’s chain is essential for optimal performance and longevity. Regular maintenance not only enhances efficiency but also ensures safety during operation. Here, we will explore effective practices for maintaining and sharpening your chain, ensuring it remains in peak condition.

Regular Inspection

Frequent checks are vital for identifying wear and tear. Look out for the following signs:

- Visible damage or cracks on the chain links.

- Signs of rust or corrosion.

- Uneven wear on the cutting edges.

Sharpening Techniques

Maintaining sharpness is crucial for effective cutting. Follow these steps for optimal results:

- Use a quality sharpening file designed for your chain type.

- Follow the manufacturer’s specifications for angle and depth.

- Make even strokes, ensuring consistent pressure throughout.

- Check the tension after sharpening to maintain efficiency.

By adhering to these maintenance and sharpening guidelines, you can extend the life of your cutting tool’s chain, ensuring it performs at its best for all your tasks.

Adjusting the Chainsaw’s Idle Speed

Properly setting the idle speed of your power saw is crucial for optimal performance and safety. This process ensures that the tool runs smoothly when not in active use, preventing stalling and facilitating easier handling during operation.

To achieve the correct idle speed, locate the appropriate adjustment screws, which are usually found on the carburetor. Start the engine and allow it to warm up to its normal operating temperature before making any adjustments. This ensures that the settings you apply reflect how the tool will behave during actual use.

Next, turn the idle adjustment screw clockwise to increase the speed, or counterclockwise to decrease it. Pay close attention to the engine’s response; the ideal setting allows the chainsaw to idle without stalling while maintaining a steady sound. After fine-tuning, test the tool by revving the engine and observing its behavior. A well-adjusted idle speed contributes to enhanced efficiency and prolongs the lifespan of the equipment.

Fixing Fuel and Oil Leaks

Addressing issues related to fluid leaks is crucial for maintaining optimal performance and safety in your equipment. Identifying the source of these leaks can prevent further damage and ensure that the machinery operates efficiently.

Common Causes of fuel and oil leaks often include damaged seals, worn-out gaskets, or loose connections. Inspecting these components regularly can help you catch problems early before they escalate.

To resolve leaks, start by cleaning the affected area thoroughly to identify the precise source. Once located, assess whether the part needs replacement or simply tightening. If replacing, ensure you use compatible components that meet specifications for a secure fit. After any repairs, test the machinery to confirm that leaks have been eliminated and everything functions smoothly.

Regular maintenance, including checking for wear and tear, can significantly reduce the risk of leaks in the future. Establishing a routine inspection schedule will help prolong the life of your equipment and enhance its reliability.

Checking and Replacing the Ignition Coil

The ignition coil is a vital component in the operation of a gas-powered tool, providing the necessary spark for ignition. Regular inspection and, if needed, replacement of this part can ensure optimal performance and reliability.

To check the condition of the ignition coil, follow these steps:

Step Description 1 Disconnect the power source to ensure safety during inspection. 2 Remove the cover to access the ignition coil. 3 Inspect the coil for any visible damage or corrosion. 4 Test the coil with a multimeter to ensure it operates within the specified resistance range. If the ignition coil is found to be faulty, replacing it is straightforward. Simply follow these steps:

Step Description 1 Acquire a compatible ignition coil for your specific model. 2 Disconnect the old coil’s wires and remove it from its mounting. 3 Install the new coil, ensuring proper alignment and secure connections. 4 Reassemble any covers and reconnect the power source. Following these procedures will help maintain the efficiency and longevity of your equipment.

Cleaning and Lubricating the Engine Parts

Maintaining optimal performance of engine components is crucial for longevity and efficiency. Regular cleaning and lubrication not only enhance functionality but also prevent wear and tear, ensuring the machine operates smoothly.

Importance of Regular Maintenance

Routine care of the engine parts helps in identifying any potential issues before they escalate. A clean engine runs cooler and reduces the risk of overheating, while proper lubrication minimizes friction and wear. Ignoring these practices can lead to significant damage and costly repairs.

Steps for Effective Cleaning

Begin by disconnecting the power source and removing any debris from the exterior. Use a soft brush to gently clear dust and dirt from various components. Afterward, apply a suitable cleaning solution to remove grease and grime. For lubrication, choose high-quality oil that meets the specifications of the engine. Apply it to moving parts, ensuring that all contact surfaces are adequately coated.

Remember: Always consult the manufacturer’s guidelines for specific recommendations on cleaning agents and lubricants to avoid damaging any parts.

Reassembling the Chainsaw Safely

Properly reassembling a cutting tool is crucial for ensuring its efficiency and safety during operation. Adhering to specific guidelines and best practices will help prevent accidents and ensure optimal performance.

Follow these essential steps to reassemble your chainsaw securely:

- Ensure all components are clean and free from debris before starting the assembly.

- Carefully review the user guidelines to familiarize yourself with the assembly process.

- Organize all parts and tools in a designated workspace to avoid confusion.

While reassembling, keep these safety tips in mind:

- Wear protective gloves to prevent cuts and scrapes.

- Always work in a well-lit area to enhance visibility.

- Double-check that all parts fit correctly and are secured tightly.

- Be mindful of sharp edges and moving parts throughout the process.

After reassembly, conduct a thorough inspection to ensure everything is properly aligned and functioning before using the tool.

Maintenance Tips for

Regular upkeep of your equipment is essential for optimal performance and longevity. By implementing a few straightforward practices, you can enhance the efficiency of your tool and prevent potential issues. Proper care not only ensures smooth operation but also extends the lifespan of your machinery.

Maintenance Task Frequency Description Inspect the Chain Before each use Check for wear and ensure proper tension. A well-maintained chain reduces the risk of accidents. Clean Air Filter Every 10 hours of use Remove debris and clean the filter to promote efficient airflow and optimal engine performance. Check Spark Plug Every 20 hours of use Inspect for damage and replace if necessary to ensure reliable ignition and performance. Lubricate Moving Parts Weekly Apply lubricant to all moving components to reduce friction and wear. Examine Fuel System Monthly Check for leaks or clogs in the fuel lines and clean the fuel filter to maintain flow efficiency.