This section serves as a comprehensive resource for individuals seeking to enhance their knowledge about the upkeep and troubleshooting of off-road utility vehicles. Whether for recreational use or work-related tasks, understanding the intricacies of these machines is essential for optimal performance.

By exploring various techniques and methods, users will gain insights into common issues and their solutions. Emphasizing the importance of regular checks, this guide aims to empower owners to effectively address potential challenges, ensuring their vehicles remain in peak condition.

Through detailed explanations and step-by-step instructions, readers can delve into the fundamental aspects of vehicle maintenance. This knowledge not only prolongs the lifespan of the machine but also enhances safety and reliability during operation.

Overview of Polaris Ranger 500

This section provides an insightful look into a versatile all-terrain vehicle designed for various outdoor tasks. Known for its robust performance and adaptability, it is a popular choice among enthusiasts and professionals alike. This vehicle combines power with functionality, making it suitable for both recreational activities and demanding work environments.

Key Features

Among its standout characteristics, this model boasts an impressive engine, advanced suspension system, and spacious cargo capacity. The thoughtful design enhances maneuverability and comfort, allowing users to tackle challenging terrains effortlessly.

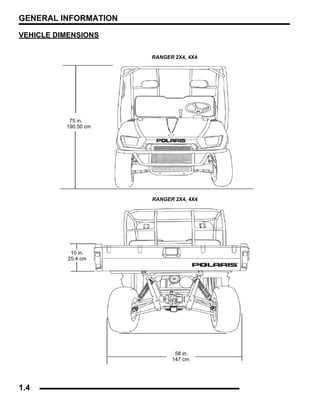

Specifications

| Feature | Details |

|---|---|

| Engine Type | Single-cylinder, liquid-cooled |

| Horsepower | Various options available |

| Transmission | Automatic with selectable 2WD/4WD |

| Cargo Capacity | Up to 1,000 lbs |

| Seating Capacity | Two to four passengers |

Common Issues and Troubleshooting Tips

This section focuses on frequent problems encountered with utility vehicles and provides effective strategies for resolving them. Understanding typical challenges can enhance the maintenance experience and extend the lifespan of the equipment.

Electrical Problems

Electrical issues are among the most prevalent concerns, often manifesting as difficulty starting or inconsistent power delivery. Inspecting the battery connections and ensuring they are clean and secure can often resolve these issues. Additionally, checking fuses and relays for damage or malfunction is crucial for maintaining proper functionality.

Engine Performance

Suboptimal engine performance can stem from various factors, including fuel quality and air intake restrictions. Regularly changing the fuel filter and inspecting the air filter for debris can improve efficiency. If the engine exhibits unusual noises or vibrations, it is advisable to conduct a thorough examination of the spark plugs and ignition system for potential wear or damage.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your vehicle. A well-structured maintenance plan not only enhances performance but also minimizes the risk of unforeseen issues.

To achieve optimal functionality, adhere to the following recommended tasks:

- Check and change the engine oil at regular intervals.

- Inspect the air filter and replace it if necessary to ensure proper airflow.

- Examine the brake system and adjust or replace components as needed.

- Inspect tire pressure and tread depth; rotate tires to promote even wear.

- Test the battery’s charge and clean terminals to prevent corrosion.

In addition, keep an eye on the following seasonal tasks:

- Before winter, prepare the vehicle by checking antifreeze levels and inspecting the heating system.

- During spring, inspect the suspension components and ensure all lights are functioning.

- Regularly clean the exterior and undercarriage to remove dirt and debris that can cause wear.

Adhering to this schedule will help maintain your vehicle’s performance and reliability over time.

Essential Tools for Repairs

When undertaking maintenance tasks on all-terrain vehicles, having the right equipment is crucial for ensuring efficiency and effectiveness. Proper tools not only facilitate the process but also help prevent damage to components during servicing.

| Tool | Description |

|---|---|

| Socket Set | Ideal for loosening and tightening bolts of various sizes, ensuring a secure fit. |

| Wrench Set | Provides leverage for turning fasteners, useful for components in tight spaces. |

| Screwdrivers | Essential for accessing panels and securing parts with screws of different types. |

| Pliers | Helpful for gripping and twisting wires or holding small components during installation. |

| Torque Wrench | Ensures that fasteners are tightened to the correct specifications, preventing over-tightening. |

| Diagnostic Tool | Used for identifying issues within the system, allowing for precise troubleshooting. |

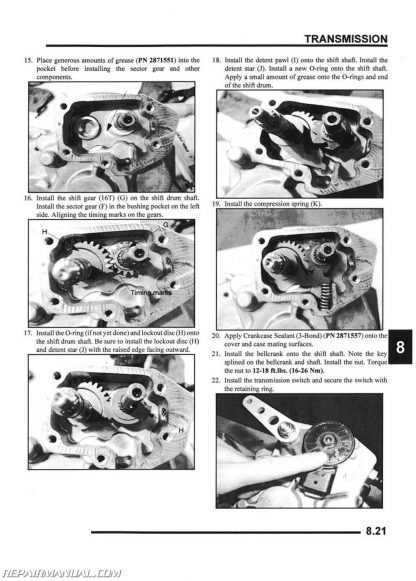

Step-by-Step Repair Processes

This section outlines a systematic approach to troubleshooting and fixing various issues that may arise in utility vehicles. Following these organized steps ensures that problems are identified accurately and addressed efficiently, leading to improved performance and longevity of the vehicle.

Identification of Issues

Begin by assessing the symptoms displayed by the vehicle. Carefully document any unusual sounds, performance drops, or visual signs of wear. This initial observation phase is crucial for understanding the underlying problems.

Repair Procedures

Once issues are identified, follow these structured procedures to resolve them:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement parts based on the identified issue. |

| 2 | Disconnect the vehicle’s power source to ensure safety during maintenance. |

| 3 | Access the affected area by removing any panels or covers as needed. |

| 4 | Inspect components thoroughly for damage or malfunction, replacing parts as necessary. |

| 5 | Reassemble the vehicle, ensuring all connections are secure and components are correctly positioned. |

| 6 | Reconnect the power source and perform a test run to verify the effectiveness of the repairs. |

Following these steps diligently will lead to successful maintenance outcomes and enhance the overall reliability of the vehicle.

Electrical System Diagnostics and Fixes

This section delves into troubleshooting techniques and solutions for common electrical issues encountered in off-road vehicles. Understanding the components and their interactions is crucial for effective diagnostics and resolution of problems.

Common Issues and Symptoms

- Inconsistent starting behavior

- Dim or flickering lights

- Malfunctioning gauges

- Loss of power to accessories

Diagnostic Steps

- Inspect all connections for corrosion or looseness.

- Test the battery voltage and load capacity.

- Examine fuses and relays for integrity.

- Utilize a multimeter to check for continuity in wiring.

- Verify the function of the alternator and regulator.

Following these steps can help identify the root cause of electrical malfunctions, enabling efficient repairs and restoring optimal function.

Engine Components and Replacement Guide

This section provides an overview of essential elements within the engine and outlines the process for their replacement. Understanding these components is crucial for maintaining optimal performance and longevity.

Key parts include the cylinder head, piston, and crankshaft, each playing a vital role in engine functionality. Regular inspection of these elements can prevent potential issues and ensure smooth operation.

When replacing components, it is important to follow manufacturer specifications. Ensure that all necessary tools are available and take care to maintain cleanliness to avoid contamination during the process.

For a successful replacement, refer to the torque specifications and procedures specific to each component. After installation, perform thorough checks to confirm proper functionality and alignment.

Importance of Regular Oil Changes

Maintaining optimal performance and longevity of any engine is essential for its overall efficiency. One crucial aspect of this maintenance is the timely replacement of lubrication fluid. Regularly changing this vital substance ensures that the internal components remain well-lubricated, reducing friction and wear.

Frequent oil changes not only help in maintaining the engine’s health but also improve fuel efficiency. As the lubricant ages, it can become contaminated with dirt, debris, and other particles, leading to decreased performance. By replacing it at regular intervals, the engine operates more smoothly and efficiently.

Moreover, adhering to a consistent oil change schedule can prevent costly repairs down the line. A well-lubricated engine is less prone to overheating and damage, extending its lifespan and saving the owner from unexpected expenses. Regular maintenance ultimately contributes to a reliable and enjoyable driving experience.

Upgrading Parts for Enhanced Performance

Improving the functionality of your all-terrain vehicle can significantly elevate your riding experience. Upgrading specific components not only boosts power and efficiency but also enhances durability and handling. Here are some popular modifications to consider for optimizing performance.

Key Components for Upgrade

- Engine Tuning: Adjusting fuel and air mixture can lead to improved horsepower.

- Suspension Enhancements: Upgrading shocks and springs provides better stability on rugged terrain.

- Exhaust System: Installing a high-performance exhaust can enhance airflow, resulting in increased power.

- Wheels and Tires: Selecting the right set can improve traction and handling, crucial for off-road conditions.

Benefits of Upgrading

- Increased acceleration and top speed.

- Improved handling and cornering stability.

- Enhanced overall reliability and longevity of parts.

- Better fuel efficiency, reducing operating costs.

By carefully selecting which components to upgrade, owners can create a customized vehicle that meets their specific needs and enhances overall performance on various terrains.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is essential for both personal safety and effective outcomes. Adopting appropriate measures can prevent accidents and injuries, safeguarding both the individual and the equipment.

Personal Protective Equipment

Wearing suitable personal protective gear is crucial. This includes gloves to prevent cuts, goggles to protect eyes from debris, and sturdy footwear to shield feet from heavy objects. Such precautions significantly reduce the risk of harm.

Work Area Organization

Maintaining a tidy workspace is vital for minimizing hazards. Clear any unnecessary items, keep tools organized, and ensure adequate lighting. A well-ordered environment promotes focus and helps avoid accidents during maintenance tasks.