When it comes to ensuring optimal performance of specialized equipment, understanding the intricacies of upkeep is essential. This section delves into the nuances of enhancing longevity and functionality, providing essential insights for both novice users and seasoned professionals alike. By familiarizing oneself with key techniques and best practices, individuals can navigate the challenges that arise during operation.

Every piece of machinery has its own set of complexities, and knowing how to address common issues can prevent minor problems from escalating. This guide aims to equip users with the knowledge needed to tackle various challenges effectively. Emphasizing proactive measures and informed decision-making, it serves as a vital resource for maintaining equipment efficiency.

With a focus on detailed procedures and practical advice, readers will discover valuable tips that streamline the process of maintaining their machinery. The information presented here encourages a hands-on approach, empowering individuals to take charge of their equipment’s care. Ultimately, this will lead to enhanced performance and reliability over time.

Overview of Ge Triton XL

The Ge Triton XL represents a significant advancement in the realm of modern appliances, designed to enhance efficiency and functionality in various settings. This equipment embodies a fusion of innovative technology and user-centric features, making it a preferred choice for many households and professional environments.

Engineered for performance, this model offers a range of capabilities that cater to diverse needs. Its robust construction ensures durability, while intuitive controls allow for seamless operation. Users can expect not only reliability but also an improved experience that streamlines daily tasks.

With a focus on energy efficiency, the device minimizes consumption without compromising on effectiveness. The integration of smart features allows for convenient monitoring and adjustments, promoting a sustainable approach to usage. Overall, the Ge Triton XL stands out as a reliable solution for anyone seeking to elevate their appliance experience.

Common Issues with Ge Triton XL

Users often encounter several frequent challenges when utilizing this specific model. Understanding these common problems can help in identifying solutions and enhancing the overall performance of the appliance. Below, we outline some of the prevalent issues faced by owners.

Performance Problems

One of the most reported concerns involves inefficiencies in operation. This can manifest as poor cleaning results or unexpected noise during cycles. Such issues may stem from various factors, including blockages or wear and tear on internal components.

Maintenance Challenges

Another area where users face difficulties is in the upkeep of the unit. Regular maintenance is essential to ensure longevity and optimal functioning. Neglecting this aspect can lead to more severe malfunctions over time.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Poor Cleaning | Blockages, worn parts | Inspect and clean filters; replace damaged components |

| Excessive Noise | Loose parts, motor issues | Tighten components; check motor functionality |

| Water Leakage | Seal damage, loose connections | Inspect seals; tighten or replace connections |

| Electrical Failures | Wiring issues, faulty components | Check wiring; consult a technician for repairs |

Tools Required for Repairs

When embarking on maintenance tasks, having the right equipment is essential for achieving optimal results. Proper tools not only enhance efficiency but also ensure that every component is addressed with precision. Understanding the necessary implements can significantly streamline the process, allowing for a smoother experience.

Essential Hand Tools

A variety of hand tools is vital for any upkeep endeavor. Items such as screwdrivers, wrenches, and pliers form the foundation of your toolkit, enabling you to tackle most common adjustments with ease. Additionally, a reliable set of pliers and adjustable wrenches will provide the flexibility needed for diverse tasks.

Power Tools and Accessories

For more complex issues, power tools can greatly enhance your capability. Drills and saws, along with appropriate bits and blades, are indispensable for cutting and fastening. Furthermore, having access to sanders and grinders will aid in achieving a polished finish on various surfaces.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to addressing common issues with your equipment, ensuring a systematic approach to troubleshooting and maintenance. By following these detailed instructions, you can effectively restore functionality and extend the lifespan of your device.

Identifying the Issue

Before proceeding with any adjustments, it is essential to pinpoint the specific problem. Start by examining the symptoms closely. Listen for unusual sounds, check for visible damage, and note any irregular behavior during operation. Documenting these observations will facilitate a more focused approach in the subsequent steps.

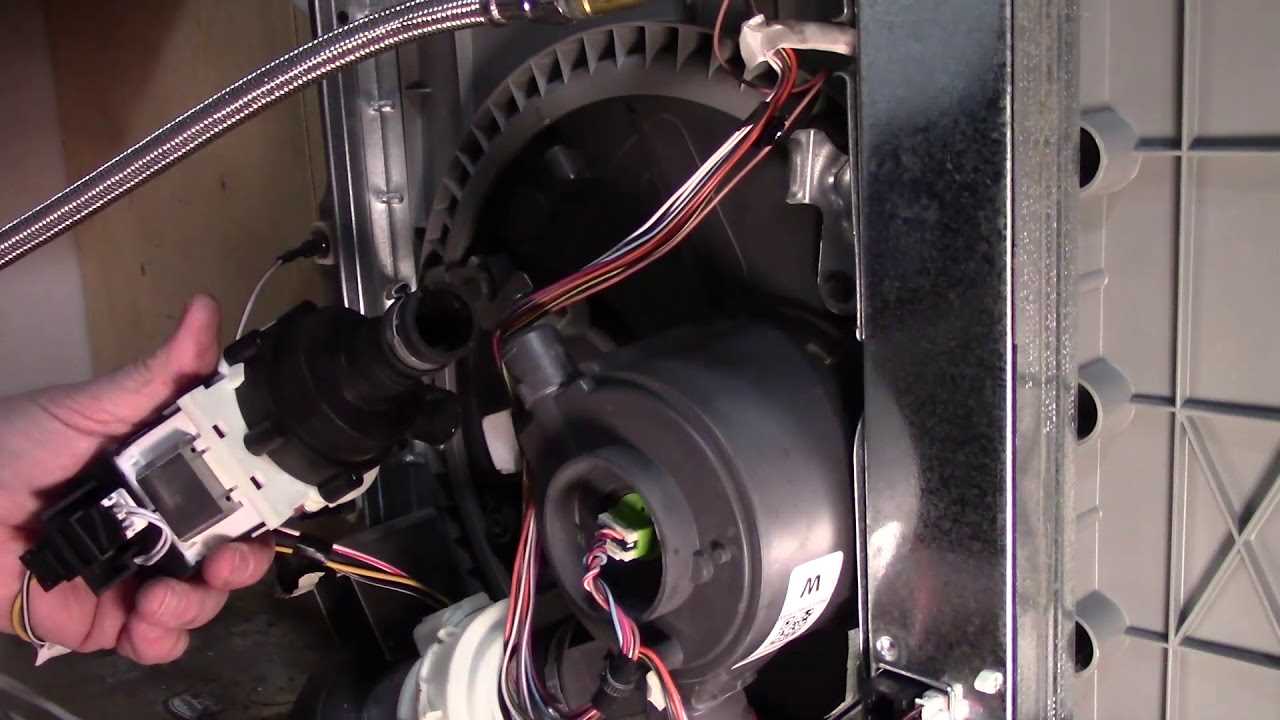

Executing the Fix

Once the issue is identified, gather the necessary tools and components. Begin by disconnecting the device from any power sources to ensure safety. Follow the outlined procedures to disassemble relevant sections carefully. Replace faulty parts as needed, making sure to reassemble the unit securely. After completing the process, reconnect the power and conduct a thorough test to confirm that the problem has been resolved.

Remember: Regular maintenance checks can prevent many common issues, keeping your equipment in optimal condition for longer.

Understanding Electrical Components

Electrical components play a crucial role in the functioning of various devices and systems. These elements work together to ensure that electrical energy is efficiently converted into usable power, allowing for the operation of machinery and the performance of tasks. Understanding the intricacies of these components is essential for troubleshooting issues and optimizing performance.

Key Elements of Electrical Systems

At the core of any electrical system are components such as resistors, capacitors, and inductors. Resistors limit the flow of electric current, while capacitors store and release energy as needed. Inductors create magnetic fields when current flows through them, which can influence the behavior of the circuit. Each of these parts has distinct functions and characteristics that contribute to the overall efficiency of the system.

Importance of Proper Wiring and Connections

Proper wiring and connections are vital for maintaining the integrity of electrical systems. Loose connections can lead to increased resistance, overheating, and ultimately failure of the component. Ensuring that all wires are securely attached and free of corrosion is critical for optimal performance. Regular inspections and maintenance can help identify potential issues before they escalate, safeguarding the entire system.

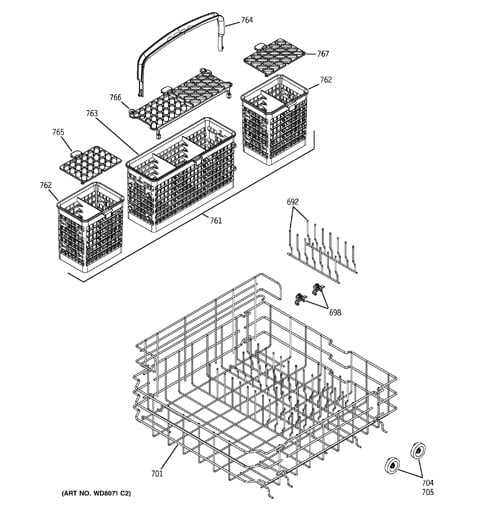

Replacing Essential Parts

Maintaining optimal performance of your equipment often requires the careful substitution of critical components. Understanding which parts are vital for functionality can enhance longevity and efficiency. This section will guide you through the process of identifying and exchanging these indispensable elements.

1. Identifying Key Components: Begin by recognizing the parts that are crucial for the smooth operation of your device. These may include the motor, battery, and essential seals. A thorough examination will help pinpoint any components that show signs of wear or malfunction.

2. Gathering Necessary Tools: Before starting the replacement process, ensure you have the right tools on hand. A well-equipped toolkit typically includes screwdrivers, pliers, and specialized instruments designed for component handling.

3. Step-by-Step Replacement: Carefully follow a sequence to remove the faulty part. This usually involves disconnecting power sources, unscrewing covers, and gently extracting the component. Replace it with the new part, ensuring a secure fit.

4. Testing Functionality: After installation, it’s crucial to test the equipment to verify that the new part is functioning correctly. Observe any changes in performance and listen for unusual sounds, which may indicate further issues.

In conclusion, replacing vital components is essential for maintaining efficiency and extending the lifespan of your machinery. By following the outlined steps and paying attention to detail, you can ensure that your device operates at its best.

Troubleshooting Techniques for Users

When encountering issues with your device, it’s essential to adopt systematic approaches to identify and resolve the underlying problems. Effective troubleshooting not only saves time but also enhances the overall user experience by ensuring optimal functionality.

Start with Basic Checks: Before delving into complex solutions, verify that all connections are secure and components are properly installed. Simple steps like checking power sources and cables can often eliminate common issues.

Utilize Diagnostic Tools: Many devices come equipped with built-in diagnostics. Familiarizing yourself with these features can provide valuable insights into potential malfunctions. Consult the specifications for guidance on accessing these tools.

Review User Documentation: Even if you are familiar with the product, revisiting the documentation can uncover overlooked details. Troubleshooting sections often outline common problems and their solutions, providing a quick reference during times of need.

Experiment with Settings: Adjusting configurations can sometimes resolve functionality issues. Explore various settings to see if changes lead to improved performance. Remember to document any alterations made, allowing for easy restoration if necessary.

Seek Online Resources: Community forums and dedicated websites can be invaluable. Engaging with other users who have faced similar challenges can yield practical advice and solutions. Don’t hesitate to share your experience and ask for guidance.

Perform a System Reset: If problems persist, consider restoring the device to its original settings. This step can often clear up software-related issues but be sure to back up any important data beforehand.

By implementing these techniques, users can effectively navigate challenges, enhancing both their understanding and enjoyment of the device.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment requires consistent attention and proper care. Regular maintenance not only enhances performance but also prevents potential issues before they arise. Here are some essential practices to keep your device in optimal condition.

Regular Inspection

- Perform frequent checks for wear and tear.

- Look for loose connections or components that may need tightening.

- Inspect seals and gaskets for any signs of damage or degradation.

Cleaning Procedures

- Clean the exterior surfaces to remove dirt and debris.

- Use appropriate cleaning solutions that won’t damage sensitive components.

- Ensure that all vents and filters are free of obstructions to promote airflow.

By adhering to these practices, you can significantly increase the lifespan of your equipment and maintain its efficiency over time.

Safety Precautions During Repairs

Ensuring safety is paramount when conducting maintenance tasks. Proper precautions can prevent accidents and ensure a secure working environment. Understanding potential hazards and following guidelines can significantly reduce risks associated with the process.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes safety goggles, gloves, and sturdy footwear to shield against injuries. Additionally, wearing masks can protect against harmful dust or fumes generated during the work.

Work Area Considerations

Maintaining a clean and organized workspace is crucial. Remove any unnecessary tools or materials that could lead to tripping or accidents. Ensure adequate ventilation, especially when dealing with chemicals or substances that may emit fumes, to safeguard your health.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process when you know where to look. There are several reliable sources that cater specifically to individuals seeking high-quality parts to maintain or enhance the functionality of their devices.

One of the most effective avenues is the manufacturer’s official website, which often provides a dedicated section for ordering spare components. This ensures that you receive authentic items designed to fit seamlessly with your equipment.

Online marketplaces are another excellent option. Websites such as eBay and Amazon typically feature a vast selection of parts, often at competitive prices. Be sure to check seller ratings and reviews to guarantee quality.

Additionally, specialty retailers that focus on your specific type of equipment can offer valuable expertise and a range of options. These stores often have knowledgeable staff who can assist you in finding the exact parts you need.

Finally, consider reaching out to local repair shops or forums. Often, these communities can provide insights into where to source parts, or they may have surplus components available for purchase.