The maintenance of off-road vehicles is essential for ensuring optimal performance and longevity. Proper care can significantly enhance the driving experience, making adventures more enjoyable and safe. Understanding the intricacies of these machines allows owners to troubleshoot issues effectively and perform necessary upkeep.

Familiarity with the various components and systems is crucial. Knowledge of how to address common problems and carry out routine checks can save time and resources. This section aims to provide comprehensive insights into the care and servicing of rugged automobiles.

Additionally, adopting a methodical approach to maintenance not only prevents potential breakdowns but also fosters a deeper connection with the vehicle. Engaging in hands-on work can empower enthusiasts to take control of their automotive journeys.

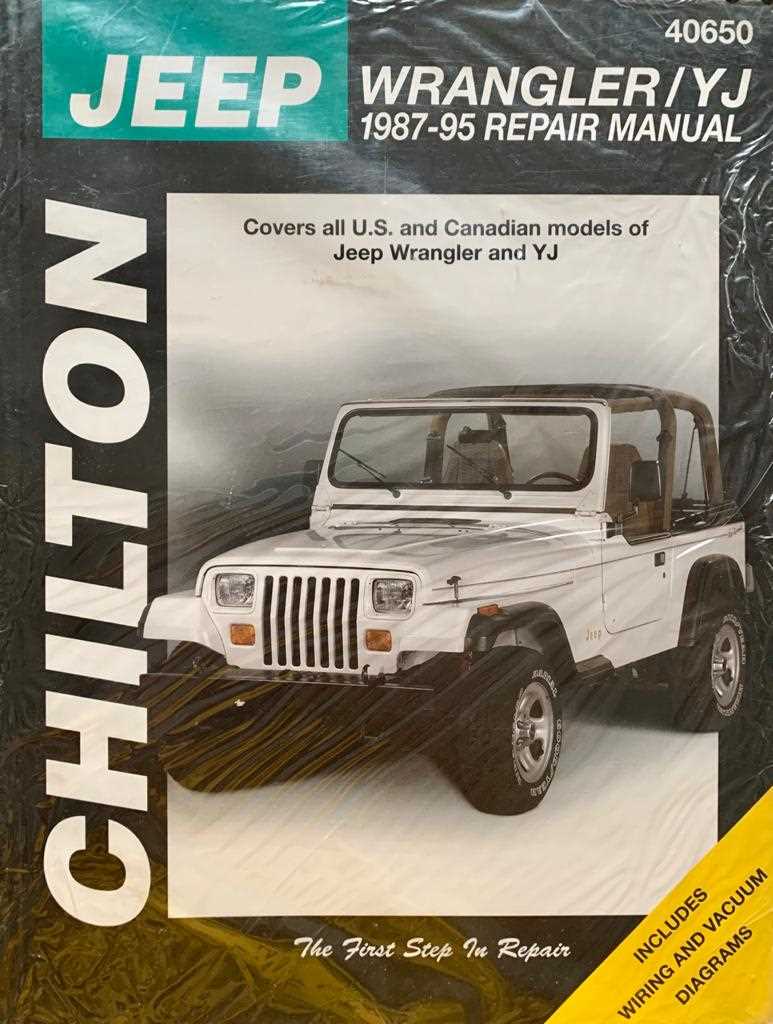

Jeep YJ Overview and Specifications

This section provides a comprehensive look at a classic off-road vehicle, highlighting its design, features, and key technical details that contribute to its popularity among enthusiasts.

Design and Structure: The vehicle boasts a rugged and distinctive appearance, characterized by its angular lines and robust build. Its compact size enhances maneuverability, making it ideal for both urban and off-road environments.

Engine and Performance: Under the hood, a powerful engine delivers impressive torque, enabling excellent performance on various terrains. The drivetrain is engineered for durability and reliability, ensuring a smooth driving experience even in challenging conditions.

Interior Features: The cabin combines functionality with comfort, offering essential controls within easy reach. Ample storage space and adaptable seating arrangements cater to both daily use and adventurous outings.

Specifications Summary: Key specifications include the vehicle’s dimensions, weight, and fuel efficiency, which make it a versatile choice for both everyday drivers and off-road adventurers.

Essential Tools for Maintenance

Proper upkeep of your vehicle requires a selection of indispensable instruments. These tools ensure that routine checks and repairs can be performed efficiently, enhancing the longevity and performance of your automobile.

Among the most vital items is a comprehensive set of wrenches and sockets, allowing for easy access to various fasteners. A sturdy jack and jack stands are essential for safely lifting the vehicle during maintenance tasks. Additionally, screwdrivers in multiple sizes and types are crucial for tackling different components.

For tasks involving fluids, a fluid transfer pump and an assortment of funnels will facilitate smooth operations. A quality diagnostic tool can help identify issues quickly, saving time and effort. Finally, a reliable set of pliers, along with a torque wrench, ensures that connections are secure and adhere to proper specifications.

Common Issues and Troubleshooting

Addressing typical challenges in vehicle maintenance can significantly enhance performance and longevity. By identifying frequent problems, owners can take proactive steps to mitigate potential breakdowns.

Frequent Problems

- Electrical system failures

- Overheating engine

- Transmission slipping

- Suspension wear

Troubleshooting Steps

- Check battery connections and charge level.

- Inspect coolant levels and radiator for leaks.

- Examine transmission fluid levels and quality.

- Assess suspension components for wear or damage.

Engine Repair and Maintenance Tips

Ensuring the longevity and efficiency of your vehicle’s power unit requires regular attention and proper care. By following essential practices, you can maintain optimal performance and prevent potential issues from escalating into costly repairs.

Regular Inspection and Cleaning

Frequent checks of the engine components are vital. Look for signs of wear, leaks, or corrosion. Keeping the engine bay clean not only helps in identifying problems early but also contributes to better airflow and overall efficiency.

Fluid Levels and Quality

Maintaining the right levels of essential fluids, such as oil and coolant, is crucial for engine health. Regularly check the condition of these fluids, replacing them as necessary to ensure smooth operation and prevent overheating or damage.

Transmission System Insights

The transmission system plays a crucial role in vehicle performance, facilitating the transfer of power from the engine to the wheels. Understanding its components and functionality is essential for optimizing driving experience and ensuring longevity.

Types of Transmission: There are primarily two types of systems: manual and automatic. Each type offers distinct advantages, with the former providing greater control and the latter ensuring ease of use.

Common Issues: Regular maintenance is vital to prevent problems such as slipping gears or unusual noises. Identifying symptoms early can help mitigate costly repairs.

Fluid Management: The quality and level of transmission fluid are critical for smooth operation. It is important to follow guidelines for fluid changes to maintain optimal performance.

Upgrades and Modifications: Enthusiasts often explore enhancements to improve efficiency or power output. However, modifications should be approached carefully to avoid compromising system integrity.

Suspension and Steering Adjustments

This section focuses on the necessary modifications and calibrations to enhance the ride quality and handling performance of your vehicle. Proper alignment and suspension settings are crucial for ensuring optimal control and comfort during driving.

Understanding Suspension Settings

Adjusting the suspension involves fine-tuning components such as springs, shocks, and struts to achieve the desired height and firmness. These adjustments can significantly impact how the vehicle responds to different terrains.

Steering Calibration

Steering adjustments ensure that the wheel alignment is accurate, which is essential for safe maneuvering. Misalignment can lead to uneven tire wear and affect overall handling.

| Adjustment Type | Recommended Procedure | Frequency |

|---|---|---|

| Spring Tension | Measure and adjust using a spring compressor. | Every 10,000 miles |

| Shock Absorber Replacement | Inspect for leaks; replace if necessary. | Every 30,000 miles |

| Wheel Alignment | Use alignment tools to check camber and toe settings. | Every 6 months |

Brake System Inspection Procedures

The assessment of the braking mechanism is crucial for ensuring vehicle safety and performance. Regular checks help identify potential issues before they escalate, promoting efficient functionality and reliability on the road.

Begin by examining the brake pads and shoes for wear. Inspect for uneven thickness and any signs of cracking or damage. If the pads are worn down to the indicators, replacement is necessary.

Next, evaluate the rotors and drums. Look for scoring, grooves, or discoloration, which may indicate overheating. Measuring the thickness with calipers ensures they are within manufacturer specifications.

Inspect the brake fluid level and condition. The fluid should be clear and free of contaminants. If it appears dark or contains debris, it may need to be flushed and replaced.

Examine the brake lines for leaks or signs of wear. Cracks or corrosion can compromise the system’s integrity, necessitating immediate replacement of affected sections.

Finally, test the brake pedal’s firmness. A spongy feel may indicate air in the lines or a malfunctioning master cylinder. Ensure all components are functioning smoothly for optimal braking performance.

Electrical System Diagnostics

This section focuses on the essential techniques for evaluating the electrical components of your vehicle. Understanding the functionality of these elements is crucial for identifying potential issues and ensuring optimal performance.

Key areas to examine include:

- Battery health and connections

- Fuses and relays

- Wiring integrity and grounds

- Sensor functionality

- Control modules and their communication

Begin the diagnostic process by following these steps:

- Inspect the battery for corrosion and secure connections.

- Check fuses for continuity and replace any blown units.

- Examine wiring for signs of wear, fraying, or damage.

- Test sensors using a multimeter to ensure they are functioning correctly.

- Utilize diagnostic tools to read error codes from control modules.

By systematically addressing each of these areas, you can effectively diagnose and troubleshoot electrical issues, ensuring a reliable operation of your vehicle.

Body and Frame Restoration Techniques

Restoring the structure and chassis of a vehicle involves meticulous attention to detail and a thorough understanding of various methods. This process not only enhances the aesthetic appeal but also ensures the integrity and safety of the automobile.

Assessment of Damage is the first step in any restoration project. Carefully inspecting the body and frame for rust, dents, and misalignments allows for an accurate evaluation of the necessary repairs. Utilizing specialized tools can help identify hidden issues that may not be immediately visible.

Next, Rust Treatment is crucial in preserving the longevity of the structure. Removing rust through sanding, grinding, or chemical treatments can prevent further deterioration. Afterward, applying protective coatings is essential to shield the metal from future corrosion.

For Frame Straightening, using hydraulic equipment or frame jigs can realign bent sections. This technique restores the vehicle’s original geometry, improving handling and stability. Ensuring precise measurements during this phase is vital to achieve optimal results.

Welding and Fabrication play significant roles in the restoration process. When sections of the body or frame are too damaged, new metal may need to be fabricated and welded into place. Employing proper welding techniques is essential for structural integrity and aesthetics.

Finally, Finishing Touches such as painting and sealing contribute to the overall look and protection of the vehicle. Selecting high-quality materials ensures a durable and visually appealing finish that will withstand the test of time.

Wiring Diagram and Layout

This section provides a comprehensive overview of the electrical schematics and configurations used in the vehicle. Understanding the layout is crucial for troubleshooting and making modifications to the electrical system effectively.

Overview of Electrical Components

The electrical system consists of various components, including switches, sensors, and wiring harnesses, each playing a vital role in the functionality of the vehicle. Familiarizing oneself with these elements will aid in identifying potential issues and implementing efficient solutions.

Connection Points and Circuits

Clear identification of connection points and circuits is essential for accurate repairs and upgrades. Properly following the layout ensures that all components function harmoniously, minimizing the risk of electrical failures. Attention to detail in this aspect can greatly enhance the vehicle’s performance and reliability.

Upgrades and Modifications for Performance

Enhancing the capabilities of your off-road vehicle involves a range of improvements that can significantly boost its overall performance. From engine modifications to suspension upgrades, these changes not only elevate driving experience but also improve handling and efficiency.

Consider implementing the following upgrades to maximize your vehicle’s potential:

| Upgrade Type | Description |

|---|---|

| Engine Tuning | Optimizing the engine’s performance through remapping or chip tuning to increase horsepower and torque. |

| Exhaust System | Installing a high-performance exhaust system for better airflow and a more aggressive sound. |

| Suspension Lift | Raising the suspension to improve ground clearance, allowing for better obstacle navigation. |

| Tires | Upgrading to all-terrain tires for enhanced grip and stability on various surfaces. |

| Braking System | Enhancing the braking system with performance brake pads and rotors for improved stopping power. |

These modifications not only increase performance but also add to the durability and reliability of your vehicle in challenging environments.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is crucial for both personal well-being and the integrity of the vehicle. Proper precautions help prevent accidents and injuries, allowing for a more efficient and effective process.

General Safety Measures

- Wear appropriate personal protective equipment (PPE), such as gloves and safety goggles.

- Work in a well-ventilated area to avoid inhaling harmful fumes.

- Keep a first aid kit nearby in case of minor injuries.

- Ensure that tools and equipment are in good condition and properly stored.

Handling Fluids and Chemicals

- Always read labels and safety data sheets for any chemicals used.

- Dispose of fluids according to local regulations to minimize environmental impact.

- Use absorbent materials to clean up spills immediately to prevent slips.

- Avoid mixing different substances unless specified, as this can cause dangerous reactions.