Understanding the intricacies of all-terrain vehicle upkeep is essential for enthusiasts and operators alike. This section provides valuable insights into the necessary steps for ensuring optimal performance and longevity of your vehicle. By delving into various components and their functionalities, readers can equip themselves with the knowledge needed to tackle common issues effectively.

From routine inspections to troubleshooting potential faults, having a thorough grasp of maintenance practices can significantly enhance your riding experience. The following information will highlight critical procedures and guidelines, empowering users to maintain their vehicle in peak condition. A proactive approach not only prevents future complications but also fosters a deeper connection with the machine.

Whether you are a seasoned rider or a newcomer, this guide serves as a vital resource for navigating the complexities of your all-terrain vehicle. Emphasizing the importance of hands-on understanding, it encourages users to engage with their equipment, ensuring every journey is both safe and enjoyable.

2002 Polaris Sportsman 700 Overview

This section provides an in-depth look at a specific model of all-terrain vehicle, highlighting its key features and capabilities. Designed for both recreational and utility purposes, this vehicle combines rugged performance with user-friendly controls, making it suitable for a variety of terrains and tasks.

Key Features

The vehicle boasts a powerful engine that ensures robust acceleration and reliable performance. Its advanced suspension system allows for smooth handling over rough landscapes, providing riders with comfort and stability. Additionally, a well-designed cargo capacity enhances its utility for transporting equipment and supplies.

Performance and Handling

With its exceptional traction and maneuverability, this model excels in various conditions, from muddy trails to rocky paths. The integration of cutting-edge technology further enhances the overall driving experience, ensuring responsive handling and efficient power management. Riders can enjoy both speed and control, making it a preferred choice for enthusiasts and workers alike.

Key Specifications and Features

This section highlights the essential characteristics and functionalities of the all-terrain vehicle, providing insights into its design and capabilities.

General Specifications

- Engine Type: Four-stroke, single-cylinder

- Displacement: 695 cc

- Cooling System: Liquid-cooled

- Transmission: Automatic with high and low range

- Drive System: 4×4 with selectable options

Performance Features

- Power Output: Approximately 50 horsepower

- Top Speed: Around 65 mph

- Fuel Capacity: 5.5 gallons

- Weight: Approximately 600 lbs

- Towing Capacity: Up to 1,500 lbs

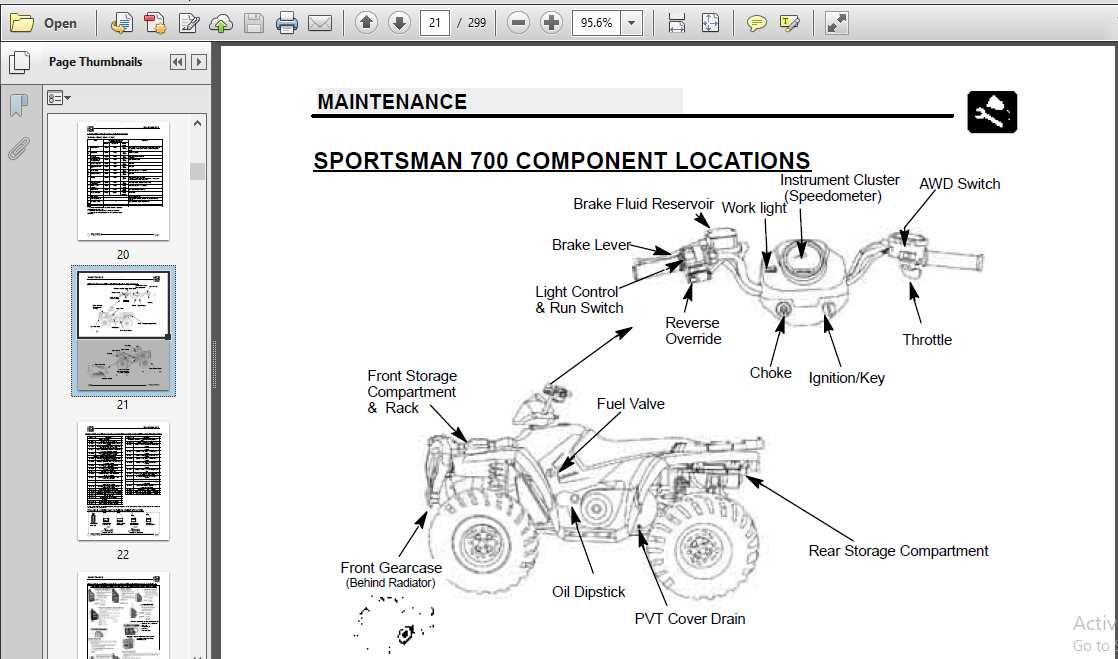

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your all-terrain vehicle. By following a consistent maintenance schedule, you can enhance its reliability and performance, making each ride more enjoyable. These guidelines will help you keep your machine in top condition.

Routine Inspections: Conduct frequent checks of critical components such as the engine, brakes, and tires. Ensure that all fluid levels are adequate and that there are no visible signs of wear or damage. This proactive approach can prevent minor issues from escalating into significant repairs.

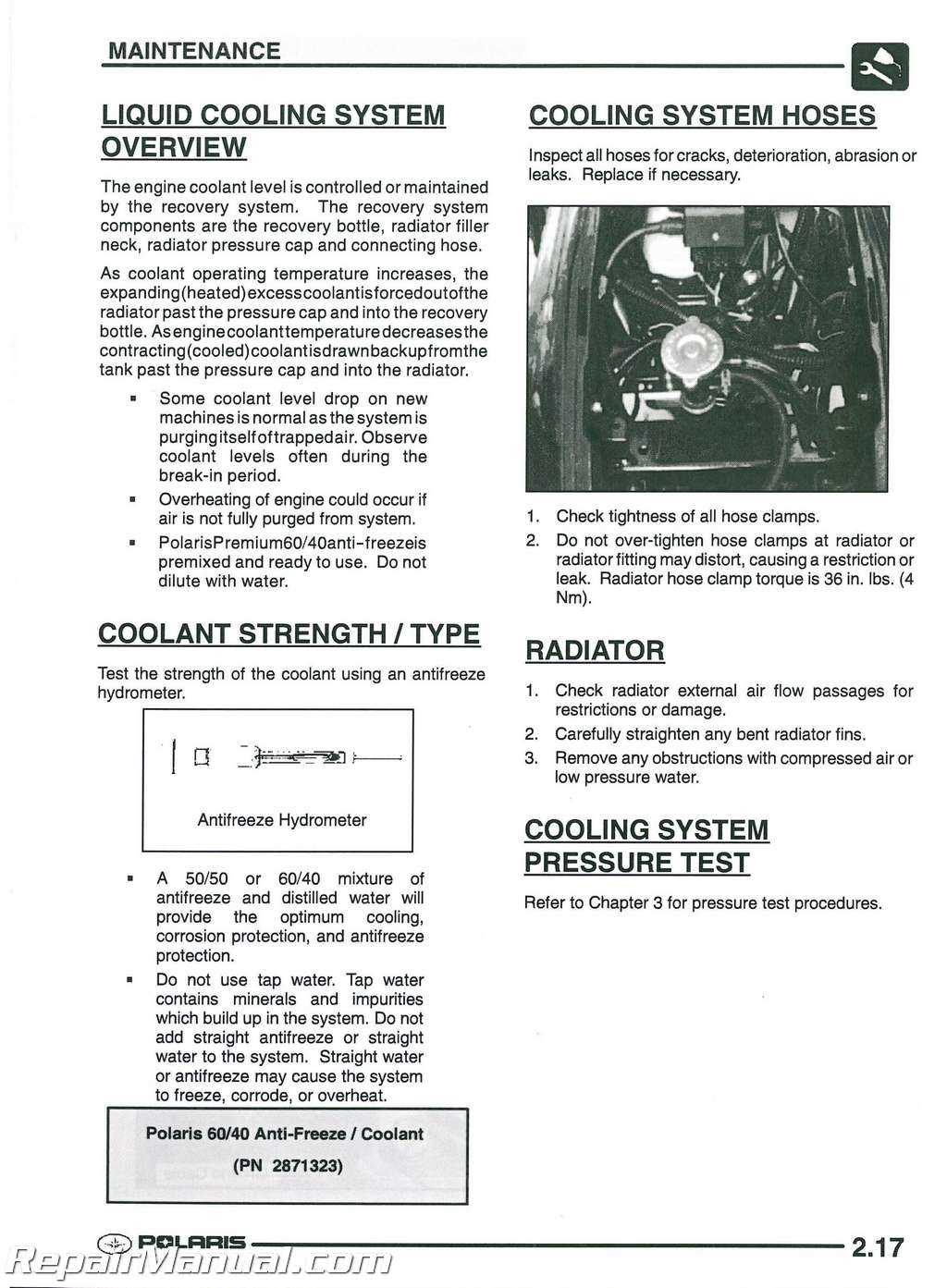

Fluid Changes: Regularly replace engine oil, coolant, and other fluids as recommended. Fresh fluids promote optimal operation and protect vital parts from corrosion and wear. Pay attention to the manufacturer’s guidelines regarding service intervals.

Air Filter Maintenance: Keep the air filter clean and replace it when necessary to ensure proper airflow. A clean filter enhances engine performance and fuel efficiency while reducing emissions.

Tire Care: Monitor tire pressure regularly and inspect for any signs of damage or uneven wear. Proper tire maintenance not only improves traction but also contributes to a smoother ride.

Battery Check: Inspect the battery terminals for corrosion and ensure that connections are secure. A well-maintained battery is crucial for reliable starts and overall electrical system performance.

By adhering to these maintenance practices, you can significantly extend the lifespan of your vehicle while ensuring it operates at its best. Remember, an ounce of prevention is worth a pound of cure.

Common Issues and Troubleshooting Tips

This section focuses on frequently encountered problems and effective strategies for resolving them in all-terrain vehicles. Understanding typical issues can significantly enhance the ownership experience and maintain optimal performance.

Owners often report various challenges that can arise during operation. Addressing these concerns promptly can prevent more severe complications down the line. Below are some common problems and their corresponding troubleshooting steps:

| Issue | Possible Causes | Troubleshooting Steps |

|---|---|---|

| Engine won’t start | Dead battery, faulty starter, or fuel supply issues | Check battery voltage, inspect starter connections, and ensure fuel is reaching the engine. |

| Poor acceleration | Clogged air filter or fuel injector problems | Replace or clean the air filter, and check the fuel injector for blockages. |

| Overheating | Low coolant level or radiator issues | Inspect coolant levels, and check for leaks or obstructions in the radiator. |

| Noisy operation | Worn belts or loose components | Examine belts for wear and adjust any loose parts to reduce noise. |

Electrical System and Wiring Insights

The electrical system of an all-terrain vehicle plays a crucial role in its overall performance and reliability. Understanding the wiring components and their interconnections can significantly enhance troubleshooting and maintenance efforts. Proper functioning of the electrical network ensures that all systems, from ignition to lighting, operate seamlessly.

Wiring Configuration is essential for efficient electrical flow. It typically includes various cables, connectors, and circuit elements that must be correctly installed to avoid failures. Each component should be inspected regularly to ensure there are no frayed wires or loose connections that could lead to short circuits.

Battery Management is another vital aspect. A well-maintained battery provides the necessary power for starting the engine and supporting various electrical accessories. Regularly checking the battery terminals for corrosion and ensuring a secure fit can prevent unexpected breakdowns.

Fuse Systems serve as protective measures within the electrical network. These components help prevent damage to wiring by breaking the circuit in case of overload. Familiarizing oneself with the location and specifications of fuses can aid in quick replacements during troubleshooting.

By focusing on these aspects, one can ensure the electrical system remains robust, enhancing the longevity and reliability of the vehicle.

Engine Components and Repair Procedures

This section focuses on the essential elements of the engine and the necessary steps for maintaining and fixing them. Understanding the various components is crucial for ensuring optimal performance and longevity.

The engine comprises multiple parts that work in unison to facilitate efficient operation. These components include the cylinder head, piston, crankshaft, and camshaft, each playing a vital role in the overall functionality of the engine.

| Component | Function |

|---|---|

| Cylinder Head | Encloses the combustion chamber and houses valves. |

| Piston | Moves up and down in the cylinder, creating power strokes. |

| Crankshaft | Converts linear motion of the piston into rotational motion. |

| Camshaft | Controls the timing of valve openings and closings. |

To ensure these parts function correctly, regular inspections and maintenance procedures are essential. This may include checking for wear and tear, replacing worn components, and ensuring proper lubrication.

Following the outlined procedures can help prevent significant issues and extend the lifespan of the engine, ultimately leading to a smoother and more reliable operation.

Transmission and Drive Train Details

This section provides an overview of the essential components involved in the power transfer system of all-terrain vehicles. Understanding these elements is crucial for optimal performance and longevity.

The transmission and drive train are integral to ensuring efficient power delivery from the engine to the wheels. Key components include:

- Transmission System: Responsible for managing gear ratios, it allows the vehicle to operate effectively across various terrains.

- Drive Shaft: This component transmits power from the transmission to the wheels, enabling motion.

- Differential: Ensures proper wheel rotation, especially when turning, allowing for better handling and stability.

- Axles: These are crucial for connecting the wheels to the drive train, bearing the weight of the vehicle while allowing for rotation.

Regular maintenance of these components is vital to prevent wear and tear. Here are some recommended practices:

- Check fluid levels regularly to ensure smooth operation.

- Inspect for leaks or damages in the drive components.

- Lubricate moving parts as specified in the guidelines to reduce friction.

- Monitor for unusual noises or performance issues during operation.

By adhering to these practices and understanding the components involved, users can enhance the vehicle’s performance and reliability on various terrains.

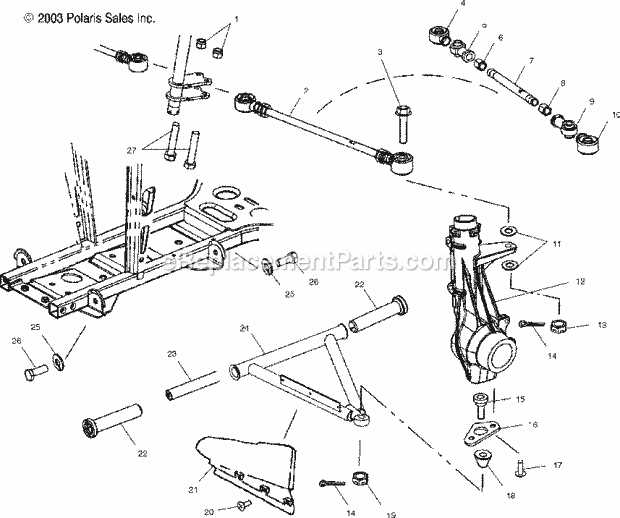

Suspension System Adjustments and Care

The suspension system of an all-terrain vehicle plays a crucial role in ensuring a smooth and controlled ride. Regular maintenance and proper adjustments are essential to enhance performance and extend the lifespan of the components involved. This section covers essential practices for maintaining and fine-tuning the suspension system.

Regular Inspection

To maintain optimal functionality, frequent inspections of the suspension components are necessary. Look for the following:

- Signs of wear or damage on shocks and struts

- Check bushings for cracks or deterioration

- Examine springs for deformation or breakage

Adjusting the Suspension

Proper adjustments can significantly improve ride quality and handling. Follow these steps for effective modifications:

- Determine the vehicle’s intended use (e.g., recreational, utility).

- Adjust the preload on the shocks based on load conditions.

- Fine-tune compression and rebound settings for specific terrain types.

By adhering to these guidelines, users can ensure their suspension system remains in peak condition, contributing to a safer and more enjoyable riding experience.

Brake System Inspection and Repair

Ensuring the optimal functionality of the braking mechanism is crucial for vehicle safety and performance. Regular assessments can help identify issues early, preventing more severe damage and ensuring reliable stopping power. This section outlines essential procedures for evaluating and servicing the braking components effectively.

Inspection Procedures

Begin by visually examining the brake pads, rotors, and fluid levels. Check for signs of wear or contamination, as these factors can significantly impact performance. Ensure that all components are free of leaks and damage.

Common Issues and Solutions

Several typical problems may arise within the braking system. Here are some of the most frequent concerns and their recommended solutions:

| Issue | Symptoms | Solution |

|---|---|---|

| Worn Brake Pads | Squeaking noise, reduced stopping power | Replace with new pads |

| Fluid Leak | Spongy brake feel, warning light | Inspect hoses and connections; repair or replace |

| Overheating Rotors | Brake fade, unusual smells | Allow cooling, inspect for damage, replace if necessary |

Fuel System Maintenance and Optimization

Maintaining and enhancing the fuel system is crucial for ensuring optimal performance and efficiency of your vehicle. Proper care of this system can prevent issues such as poor fuel economy, rough idling, and starting difficulties. Regular checks and adjustments can significantly extend the life of the components involved.

Begin by inspecting the fuel lines for any signs of wear or leaks. Ensuring that all connections are tight and secure will help prevent fuel loss and maintain pressure. Clean fuel injectors periodically to remove any deposits that may hinder their performance. This can be achieved through specialized cleaning solutions or by using fuel additives designed for this purpose.

Furthermore, it is essential to monitor the fuel filter. A clogged filter can restrict flow, leading to reduced engine efficiency. Replacing the filter according to the manufacturer’s recommendations is a simple yet effective maintenance step. Lastly, always use high-quality fuel to prevent contamination and ensure that the system operates smoothly.

Accessory Installation and Upgrades

Enhancing your vehicle with various accessories can significantly improve its functionality and overall performance. Upgrades can range from basic additions like racks and storage solutions to advanced enhancements that boost engine efficiency and riding comfort. Proper installation ensures that each component works seamlessly with the existing systems, offering both convenience and improved performance.

Common Accessory Options

There are numerous options available for upgrading your vehicle. Here are some popular choices:

| Accessory | Benefits |

|---|---|

| Winch | Assists with towing and pulling heavy loads. |

| Plow | Facilitates snow removal and landscaping tasks. |

| Storage Box | Provides additional space for tools and gear. |

| Upgraded Tires | Enhances traction and stability on various terrains. |

Installation Tips

When installing accessories, it’s essential to follow the manufacturer’s instructions for best results. Here are some general tips:

- Gather all necessary tools and components before starting.

- Ensure that the vehicle is parked on a flat surface and is stable.

- Check compatibility of the accessory with your vehicle model.

- Consult with professionals if unsure about the installation process.

Safety Precautions and Best Practices

Ensuring safety during maintenance and operation is essential for any vehicle. Proper precautions help prevent accidents and extend the life of the equipment. Familiarizing oneself with guidelines and best practices contributes to a safer environment for both the user and the machinery.

Before starting any work, always wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. These items protect against potential hazards such as sharp components or harmful chemicals.

It is crucial to work in a well-ventilated area to avoid inhaling fumes or dust. Additionally, keep the workspace organized and free from clutter to minimize the risk of trips and falls. Ensure all tools are in good condition and appropriate for the tasks at hand.

When handling the vehicle, always refer to the manufacturer’s guidelines for specific safety instructions. This includes securing the vehicle on a stable surface and using proper lifting techniques if necessary. Never attempt to service a vehicle that is running or in gear.

By following these precautions and adopting good practices, users can significantly reduce the likelihood of accidents and ensure a more efficient and enjoyable experience.

Resources for Further Assistance

When tackling maintenance and troubleshooting tasks for your all-terrain vehicle, various resources can provide valuable insights and support. Whether you’re a seasoned mechanic or a novice enthusiast, accessing the right information can enhance your understanding and skillset.

Here are some helpful sources to consider:

- Online Forums: Engage with communities where fellow owners share experiences, solutions, and tips.

- Video Tutorials: Platforms like YouTube offer step-by-step guides for common procedures and repairs.

- Official Websites: Manufacturer sites often feature technical bulletins, parts diagrams, and FAQs.

- Local Dealerships: Authorized service centers can provide professional advice and service options.

- Books and Guides: Comprehensive literature covering various models can serve as handy references.

Utilizing these resources can significantly ease the process of maintenance and problem-solving, ensuring a smoother experience with your vehicle.