Every two-wheeled vehicle requires attention to ensure optimal performance and longevity. This section provides essential information and insights into the upkeep of your scooter, focusing on various aspects of its functionality and components.

Understanding how to care for your ride can enhance your experience and prevent unexpected issues. By following straightforward guidelines, you can tackle common challenges, keep your machine in top condition, and enjoy a smooth journey.

Whether you’re a seasoned enthusiast or a novice rider, this resource is designed to empower you with the knowledge needed to maintain your vehicle effectively. Get ready to dive into the world of scooter care and make the most out of your riding experience.

When maintaining or fixing a two-wheeled vehicle, having the right instruments at hand is crucial for achieving efficient results. The following section outlines the fundamental equipment required to ensure smooth operation and longevity of the vehicle. By understanding the necessary tools, owners can tackle various tasks with confidence and skill.

| Tool | Purpose |

|---|---|

| Wrench Set | For tightening or loosening nuts and bolts |

| Screwdriver Set | For adjusting screws in various components |

| Socket Set | For removing or securing larger fasteners |

| Torque Wrench | To apply a specific torque to fasteners |

| Pliers | For gripping, twisting, or cutting wires |

| Multimeter | For diagnosing electrical issues |

| Oil Filter Wrench | To facilitate oil changes |

| Cleaning Supplies | For keeping components free of dirt and debris |

Common Issues and Solutions

This section addresses frequent challenges faced by users and offers practical solutions to enhance the experience with their vehicles. Understanding these common problems can help in maintaining optimal performance and longevity.

One prevalent issue is difficulty in starting the engine, often caused by a drained battery or faulty connections. Ensuring the battery is fully charged and all connections are secure can typically resolve this matter.

Another common concern is irregular engine performance, which may stem from a clogged fuel filter or dirty spark plug. Regular inspection and replacement of these components can significantly improve functionality.

Furthermore, brake responsiveness can diminish over time due to worn pads or low fluid levels. Regular checks and timely replacements can ensure safety and reliability during operation.

Lastly, tire pressure often goes unnoticed but is crucial for handling and efficiency. Maintaining the correct pressure as per manufacturer guidelines can prevent wear and enhance ride quality.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your two-wheeled vehicle. This guide will outline a systematic approach to maintain your machine effectively, helping you identify and address key areas that require attention.

Essential Tasks

- Check and change the oil regularly.

- Inspect the brakes for wear and functionality.

- Monitor tire pressure and tread condition.

- Clean or replace the air filter as needed.

- Examine the battery for corrosion and charge levels.

Detailed Process

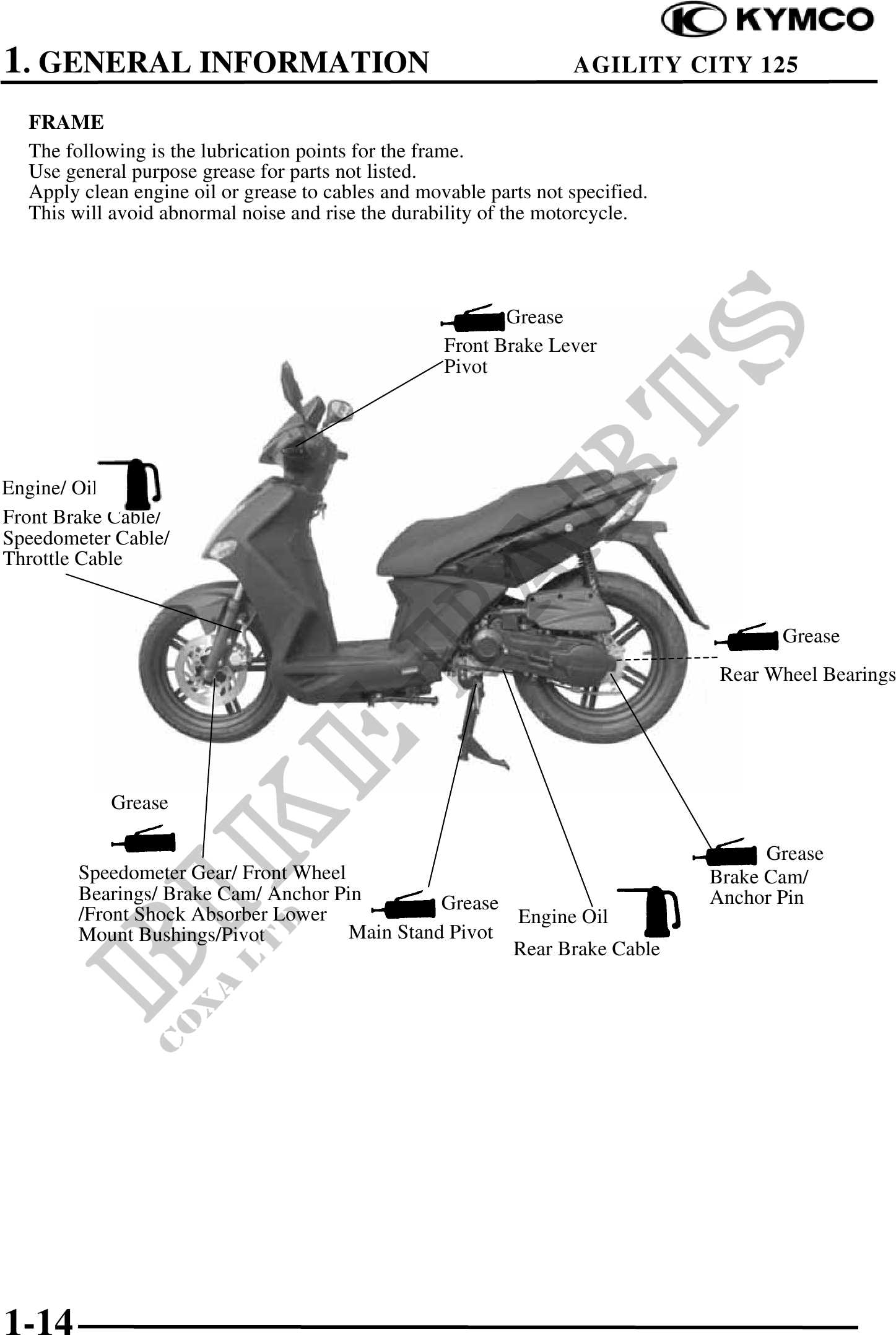

- Oil Change: Begin by warming up the engine for a few minutes. This allows the oil to flow more freely. Turn off the engine and place a drain pan under the oil pan. Remove the drain plug and let the oil drain completely. Replace the drain plug and add new oil according to specifications.

- Brake Inspection: Lift the vehicle to inspect the brake pads and discs. Look for any signs of wear or damage. If the pads are worn beyond the recommended thickness, replace them immediately.

- Tire Maintenance: Use a pressure gauge to check tire inflation. Inflate to the recommended pressure if necessary. Inspect the tread for any signs of uneven wear or damage and replace tires as needed.

- Air Filter Care: Remove the air filter and clean it with compressed air. If it is excessively dirty or damaged, replace it to ensure optimal airflow.

- Battery Check: Disconnect the battery and inspect the terminals for corrosion. Clean any buildup and ensure a secure connection before reconnecting.

Understanding the Electrical System

The electrical system is a critical component that powers various functionalities within a vehicle. It encompasses a range of elements, including wiring, connectors, and electronic devices, all working together to ensure optimal performance and reliability.

Key Components

- Battery: Stores electrical energy and provides power for starting and running the engine.

- Alternator: Charges the battery while the engine is running and supplies power to electrical systems.

- Wiring Harness: A collection of wires that connect various electrical components.

- Fuses: Protect electrical circuits from overload by breaking the connection when necessary.

- Starter Motor: Engages the engine when the ignition is activated.

Common Issues

- Battery Failure: A dead or weak battery can prevent the vehicle from starting.

- Electrical Shorts: Damaged wiring can lead to short circuits, causing malfunctioning components.

- Corroded Connectors: Poor connections can result in intermittent electrical issues.

- Faulty Alternator: An inefficient alternator can lead to battery drain and reduced power to electrical systems.

Engine Troubleshooting Techniques

Addressing engine issues requires a systematic approach to identify and resolve common problems. Understanding the underlying causes of malfunctions can significantly enhance performance and reliability.

1. Visual Inspection: Begin by conducting a thorough visual examination of the engine components. Look for any signs of wear, leaks, or loose connections. Ensure that all hoses and cables are intact and securely fastened.

2. Diagnostic Tools: Utilize diagnostic equipment to assess the engine’s performance. Tools such as multimeters and pressure gauges can provide valuable data regarding electrical systems and compression levels.

3. Fuel System Evaluation: Check the fuel delivery system, including the tank, lines, and filter. Blockages or contaminants can lead to poor engine function. Clean or replace components as necessary.

4. Ignition System Checks: Examine the ignition system, ensuring that spark plugs are clean and properly gapped. Faulty ignition components can cause misfires and reduced efficiency.

5. Regular Maintenance: Implement a routine maintenance schedule to keep the engine in optimal condition. Regular oil changes, air filter replacements, and fluid checks can prevent many issues from arising.

By applying these techniques, one can effectively troubleshoot engine concerns, ensuring a smoother and more efficient operation.

Brake System Inspection Procedures

Ensuring the proper functionality of the braking mechanism is crucial for safe operation. Regular assessments help identify potential issues, allowing for timely maintenance and enhancing overall performance. This section outlines essential steps for conducting a thorough evaluation of the braking components.

The inspection process involves examining various parts of the braking system, including the pads, discs, and hydraulic components. It is important to follow systematic procedures to ensure that all elements are checked for wear, damage, or fluid leaks.

| Inspection Step | Description |

|---|---|

| Visual Inspection | Check brake pads and discs for wear or damage. Look for uneven surfaces or excessive wear. |

| Fluid Level Check | Inspect brake fluid reservoir for proper levels. Top up if necessary and check for any leaks. |

| Brake Lever Function | Test the brake lever for smooth operation. Ensure it engages and disengages the brakes properly. |

| Brake Performance Test | Conduct a test ride to assess braking effectiveness. Listen for unusual noises during application. |

Following these procedures will help maintain the reliability of the braking system, ensuring a safe riding experience. Regular inspections are a key part of effective vehicle care and contribute to optimal functionality.

Cleaning and Lubrication Tips

Maintaining the cleanliness and proper lubrication of your vehicle is essential for ensuring its longevity and optimal performance. Regular upkeep not only enhances the efficiency of the engine but also prevents potential wear and tear on vital components. This section outlines effective strategies to keep your ride in top shape.

Routine Cleaning

It is important to regularly remove dirt and debris from the exterior and mechanical parts. Use a mild detergent mixed with water to gently scrub surfaces, paying special attention to areas prone to grime accumulation. Rinse thoroughly and dry to prevent rust and corrosion. Make sure to inspect the air filter as well, ensuring it is free from dust to facilitate proper airflow.

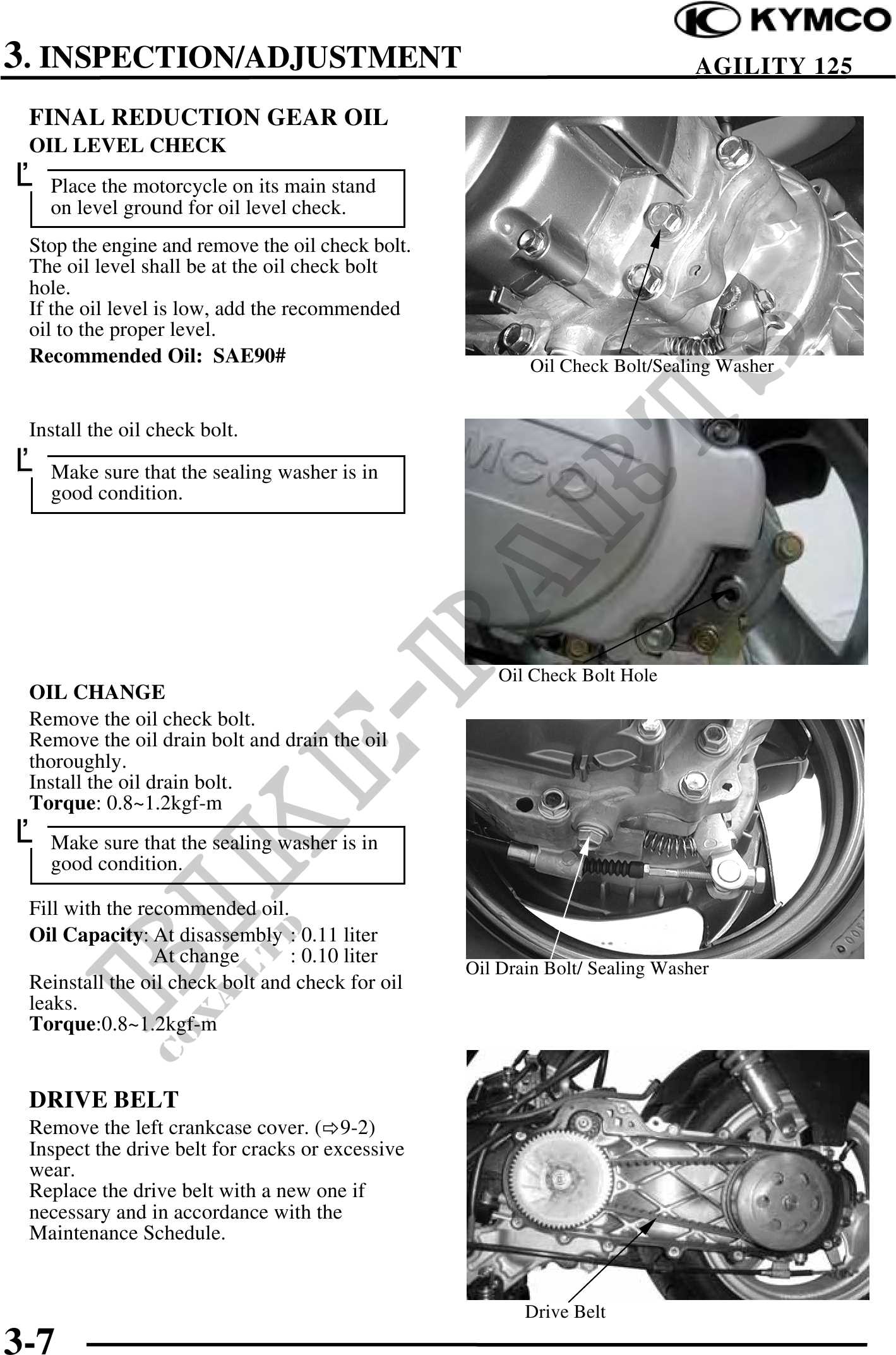

Effective Lubrication Practices

Applying the right lubricants to moving parts is crucial for reducing friction and enhancing performance. Focus on key areas such as the chain, cables, and pivot points. Utilize a quality lubricant recommended for your specific model. Ensure to wipe away excess grease to avoid attracting dirt. Regularly check fluid levels in the brakes and transmission systems, replenishing as needed for smooth operation.

Replacing Tires and Wheels

Maintaining optimal performance and safety of your vehicle involves regular checks and timely replacement of tires and wheels. This section provides essential guidance on how to properly execute these replacements, ensuring your ride remains smooth and secure on the road.

Tools and Equipment Needed

Before starting the replacement process, gather the necessary tools to facilitate the task. Here’s a list of items you’ll require:

| Tool | Description |

|---|---|

| Jack | Used to lift the vehicle for easy access to wheels. |

| Lug Wrench | Essential for loosening and tightening lug nuts. |

| Tire Pressure Gauge | Helps to check the pressure of the new tires. |

| Replacement Tires | New tires suitable for your specific model. |

Steps for Replacement

Follow these steps to ensure a successful tire and wheel change:

- Secure the vehicle on a flat surface and engage the parking brake.

- Use the jack to lift the vehicle off the ground.

- Remove the lug nuts using the lug wrench and take off the old tire.

- Align the new tire with the wheel hub and securely attach it using the lug nuts.

- Lower the vehicle and check the tire pressure before driving.

Preparing for Seasonal Changes

As the seasons shift, it’s essential to adapt your vehicle to ensure optimal performance and longevity. This involves a series of important checks and adjustments that cater to the specific challenges posed by different weather conditions.

During the transition from one season to another, take the time to inspect vital components. Focus on aspects such as fluid levels, tire conditions, and battery health. These factors can greatly influence how well your vehicle operates, particularly in extreme temperatures.

| Season | Recommended Checks |

|---|---|

| Spring | Inspect tires for wear, check brakes, and clean the exterior. |

| Summer | Ensure coolant levels are adequate, check air conditioning, and verify tire pressure. |

| Autumn | Examine lighting systems, prepare for rain by checking brakes, and inspect wiper blades. |

| Winter | Test battery performance, use winter tires, and check antifreeze levels. |

By following these guidelines, you can enhance the reliability and safety of your vehicle throughout the year, ensuring it remains in prime condition no matter the weather.

Safety Precautions During Repairs

When undertaking maintenance on your vehicle, adhering to safety measures is essential to ensure a secure working environment. Proper precautions help prevent accidents and injuries, allowing you to focus on the task at hand without unnecessary risks.

Personal Protective Equipment

Utilizing appropriate protective gear is crucial. Always wear gloves to shield your hands from sharp edges and hazardous materials. Additionally, goggles should be worn to protect your eyes from debris and chemicals. A well-fitting mask can also be beneficial in preventing inhalation of harmful fumes.

Workspace Organization

A clutter-free workspace is vital for safety. Ensure that your tools and materials are organized and easily accessible. This not only improves efficiency but also reduces the risk of tripping or misplacing items, which can lead to accidents during the process.