Effective maintenance of aquatic propulsion systems is crucial for optimal performance and longevity. These guides serve as invaluable resources, providing detailed instructions on troubleshooting, upkeep, and component replacement. A well-structured manual ensures users can confidently navigate the complexities of their equipment.

In the realm of aquatic technology, familiarizing oneself with these instructional documents empowers enthusiasts to take proactive steps in managing their devices. Whether addressing common issues or implementing routine service, having access to comprehensive references can significantly enhance the user experience.

Utilizing these resources not only facilitates efficient operations but also fosters a deeper understanding of the underlying mechanics. With clarity and precision, individuals can tackle various challenges, ensuring their systems remain reliable on the water.

When it comes to watercraft propulsion systems, several challenges can arise, affecting performance and efficiency. Understanding these common complications can help users maintain optimal functionality and prolong the lifespan of their devices.

- Power Failure: One of the most frequent issues is a complete loss of power, often caused by dead batteries or faulty connections.

- Overheating: Continuous operation can lead to excessive heat, resulting in damage to the internal components if not addressed promptly.

- Unresponsive Controls: Sometimes, the control systems may become unresponsive due to electrical faults or wear over time.

- Unusual Noises: Grinding or clicking sounds can indicate mechanical issues that require immediate attention.

- Corrosion: Exposure to water and elements can lead to rust and corrosion, negatively impacting performance.

By being aware of these common issues, users can take proactive steps to diagnose and resolve problems, ensuring reliable performance on the water.

Essential Tools for Repairs

When it comes to maintaining and fixing aquatic propulsion devices, having the right equipment is crucial for achieving effective outcomes. Proper tools not only simplify the process but also enhance the quality of the work performed. This section outlines the fundamental instruments needed for efficient service.

Basic Hand Tools

Among the most vital tools are hand-held implements. A screwdriver set is necessary for loosening or tightening screws that secure various components. Additionally, pliers can assist in gripping, twisting, and cutting wires or other materials. A wrench set is also essential for handling nuts and bolts, ensuring all connections are secure.

Specialized Equipment

In addition to standard hand tools, specialized devices can greatly aid in specific tasks. A multimeter is indispensable for measuring electrical currents and diagnosing potential issues within the system. Furthermore, a heat gun or soldering iron may be required for any modifications involving wiring or plastic components. Having these tools at hand will streamline the maintenance process and lead to successful outcomes.

Step-by-Step Repair Procedures

This section provides a comprehensive approach to addressing common issues encountered in electric propulsion systems. Following a systematic methodology ensures that each aspect is carefully evaluated, leading to efficient troubleshooting and resolution of problems.

Gather Necessary Tools

Before commencing any work, it is essential to assemble all required instruments. A well-organized workspace enhances productivity and safety. Basic tools typically include:

- Screwdrivers: Both flathead and Phillips types.

- Wrenches: Adjustable and socket varieties.

- Multimeter: For checking voltage and continuity.

- Plier set: Including needle-nose and cutting pliers.

Follow Systematic Troubleshooting Steps

Begin with a thorough inspection of all components. Check connections, look for signs of wear, and ensure everything is securely fastened. Use the multimeter to test electrical systems, ensuring power reaches the necessary parts. Document findings for reference.

After identifying the issue, proceed with the disassembly of components as needed. Take care to remember the order of assembly, as this will facilitate smoother reassembly later. Replace any faulty parts and recheck connections before reassembling the unit.

Preventative Maintenance Tips

Regular upkeep is essential for extending the lifespan of your aquatic propulsion device and ensuring its optimal performance. By adhering to a few simple practices, you can prevent issues before they arise, ultimately saving time and resources in the long run.

Here are some effective strategies for maintaining your equipment:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Inspect Electrical Connections | Monthly | Check for corrosion or loose wires to ensure reliable operation. |

| Clean Components | After Each Use | Remove debris and salt buildup to prevent damage and ensure efficiency. |

| Check Battery Levels | Weekly | Monitor the charge to avoid performance issues during use. |

| Test Safety Features | Before Every Use | Ensure all safety mechanisms are functioning correctly for user protection. |

| Inspect Propeller | Monthly | Look for signs of wear or damage that could affect functionality. |

Understanding Electrical Components

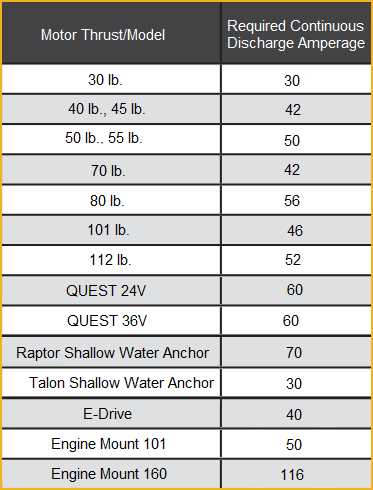

Grasping the intricacies of electrical components is essential for effective maintenance and enhancement of aquatic propulsion systems. Each part plays a crucial role in the overall functionality, requiring knowledge of how they interact to ensure optimal performance.

Key Elements in Electrical Systems

Several vital elements contribute to the operation of electrical systems. Familiarity with these components is fundamental for troubleshooting and upgrades:

- Resistors: Control current flow and voltage levels.

- Capacitors: Store and release electrical energy.

- Diodes: Allow current to flow in one direction only.

- Transistors: Act as switches or amplifiers in circuits.

- Batteries: Provide the necessary power supply for operation.

Importance of Proper Functionality

Ensuring that all components function correctly is critical for reliability. Regular checks and understanding the role of each part can prevent unexpected failures. Consider the following tips:

- Regularly inspect connections for signs of corrosion or wear.

- Test components individually to verify functionality.

- Replace faulty parts promptly to avoid system malfunctions.

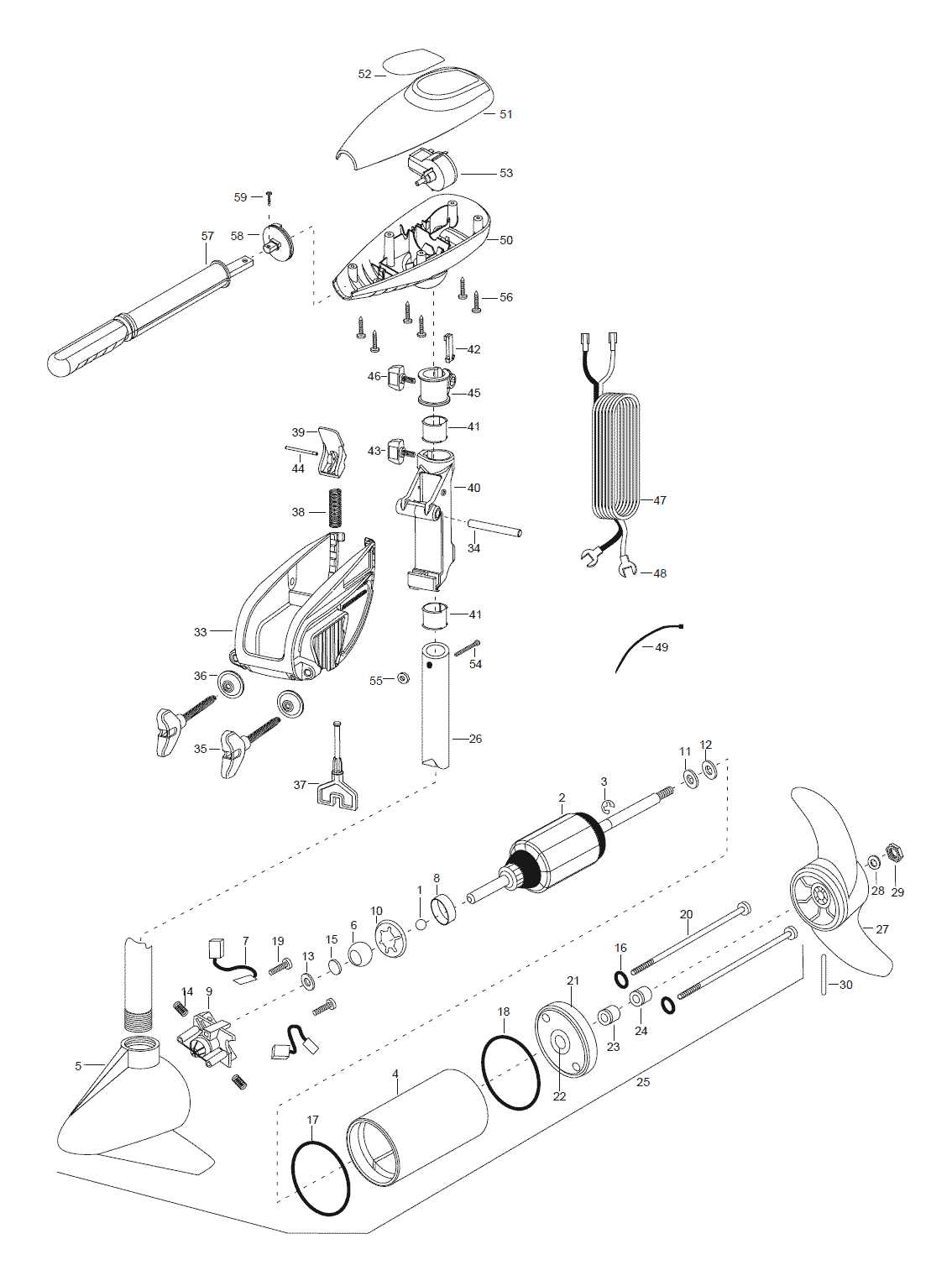

Replacing Worn Out Parts

Maintaining the functionality of aquatic propulsion devices requires periodic updates of various components. Over time, certain elements may wear down, leading to decreased efficiency and performance. Addressing these worn-out components is crucial for ensuring a smooth experience on the water.

Identifying which parts need replacement is the first step in the process. Here are some common components that may require attention:

- Batteries: Over time, the capacity of batteries can diminish, leading to shorter operational times.

- Propellers: Scrapes and bends can impair performance and maneuverability.

- Wiring: Frayed or corroded wires can lead to electrical issues and should be replaced promptly.

- Connectors: Loose or damaged connectors can disrupt the flow of power and should be checked regularly.

Once you have identified the worn parts, it’s essential to acquire suitable replacements. Follow these guidelines for a successful replacement:

- Consult the specifications of your device to find compatible parts.

- Gather necessary tools, such as wrenches and screwdrivers, before beginning the process.

- Carefully remove the old components, ensuring that you don’t damage surrounding areas.

- Install the new parts according to the manufacturer’s instructions, ensuring secure connections.

By proactively replacing worn components, you can enhance the performance and longevity of your aquatic propulsion system.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance on aquatic propulsion devices is paramount. Adhering to specific safety measures not only protects the individual conducting the work but also safeguards the equipment from potential damage. Awareness of potential hazards and the implementation of preventive actions create a safer workspace.

Before beginning any tasks, it is essential to disconnect the power source to prevent accidental activation. Wearing appropriate protective gear, such as gloves and goggles, helps mitigate the risk of injury. Moreover, maintaining a clutter-free workspace can prevent accidents and allow for easier access to tools and components. Always follow the manufacturer’s guidelines for safe handling of materials and tools to ensure a smooth and secure operation.

Resources for Troubleshooting Problems

When facing challenges with your aquatic propulsion device, having access to the right resources is essential for effective diagnostics and solutions. A variety of guides, websites, and community forums offer valuable information that can assist in identifying issues and implementing fixes.

Online Communities and Forums

Participating in online groups can provide insights from fellow enthusiasts. Here are some popular platforms:

- Reddit: Subreddits dedicated to boating and fishing often contain threads on common issues.

- Facebook Groups: Many user-created groups focus on specific brands and models, allowing for shared experiences.

- Dedicated Forums: Websites like iBoats and The Hull Truth feature sections specifically for discussing propulsion devices.

Instructional Videos and Tutorials

Visual aids can be particularly helpful for troubleshooting. Consider the following sources:

- YouTube: Channels dedicated to marine equipment frequently post tutorials and troubleshooting videos.

- Manufacturer Websites: Some manufacturers offer video content showcasing common repairs and maintenance techniques.

- Online Courses: Platforms like Udemy may provide comprehensive courses focused on aquatic devices and their upkeep.

Upgrading Your Trolling Motor

Enhancing the performance of your aquatic propulsion device can significantly improve your overall experience on the water. Upgrades may involve various components that can boost efficiency, extend battery life, or enhance maneuverability. Understanding the possibilities for enhancement can help you make informed decisions for a more enjoyable outing.

Choosing the Right Enhancements

When considering upgrades, it’s essential to evaluate the specific aspects you wish to improve. Whether you are looking for increased speed, better handling in rough waters, or extended operational time, there are various components to explore. Options may include advanced propellers, upgraded control systems, or improved power sources.

Installation and Compatibility

Before proceeding with any enhancements, ensure that the selected parts are compatible with your existing setup. Proper installation is crucial for optimal performance, so following manufacturer guidelines or consulting with a professional can help avoid common pitfalls. With the right upgrades, you can significantly enhance your vessel’s capabilities.

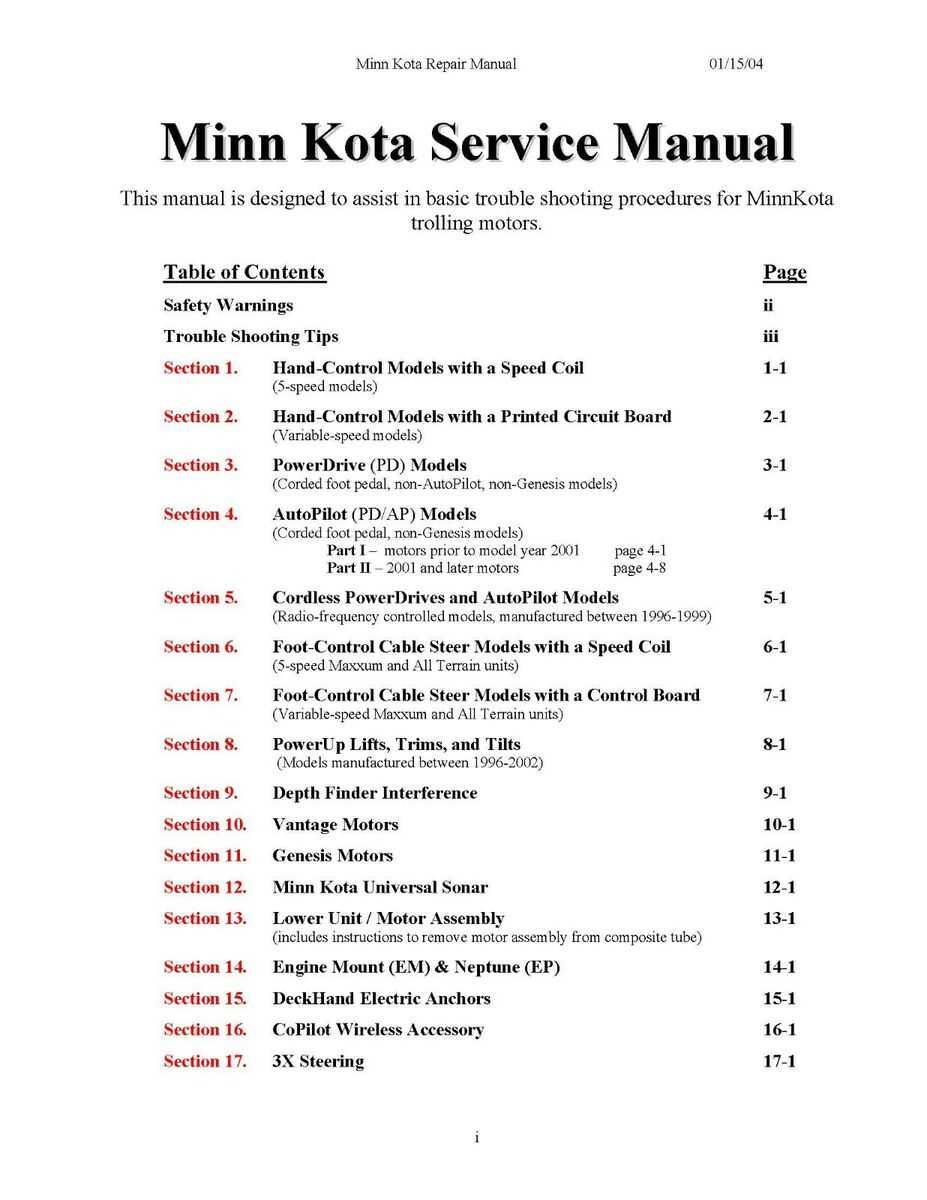

Where to Find Repair Manuals

Locating comprehensive guides for maintenance and troubleshooting can significantly enhance your experience with aquatic propulsion devices. These resources not only provide valuable insights but also ensure optimal performance and longevity of your equipment.

Several avenues can be explored to acquire these essential documents:

- Official Websites: Many manufacturers offer downloadable versions of their guides directly on their official platforms. This ensures you receive the most accurate and up-to-date information.

- Online Retailers: Websites that specialize in marine supplies often stock printed or digital copies of guides for various devices. They may also provide user reviews to assist in your selection.

- Forums and Community Groups: Online communities dedicated to aquatic enthusiasts frequently share resources, including guides. Engaging with fellow users can lead to discovering valuable documents.

- Local Repair Shops: Visiting nearby service centers can yield not only expert advice but also access to printed guides or recommendations for sourcing them.

By utilizing these resources, you can effectively find the necessary documents to ensure the proper functioning of your aquatic propulsion equipment.