In the realm of mechanical devices, understanding the intricacies of their operation and potential issues is crucial for optimal performance. Whether you’re a seasoned technician or a novice enthusiast, having access to detailed guidelines can significantly enhance your ability to address challenges effectively. This section aims to provide essential insights into the upkeep and troubleshooting of specific equipment.

Regular maintenance not only extends the lifespan of your machinery but also ensures safety and reliability during operation. By familiarizing yourself with various components and their functions, you can diagnose problems promptly and implement suitable solutions. This guide encompasses a wealth of knowledge, offering practical advice and expert tips to navigate common difficulties encountered in the field.

Equipped with the right information, users can take proactive measures to maintain their equipment, minimizing downtime and maximizing efficiency. Through careful attention to detail and adherence to best practices, individuals can empower themselves to tackle any obstacles that may arise, ensuring their machinery continues to perform at its best.

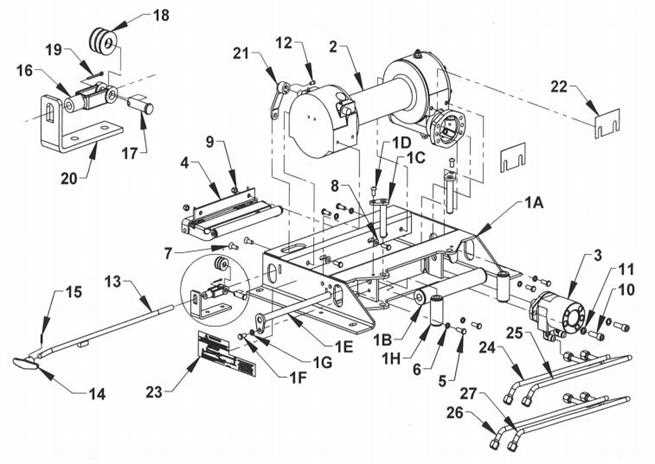

Thorough examination of the various parts involved in the lifting mechanism is essential for ensuring optimal performance and longevity. By identifying wear, damage, or misalignment, one can effectively maintain the device and prevent unexpected failures during operation.

Key Parts to Examine

During the inspection process, focus on several critical components. Regular checks will help in early detection of issues that could lead to serious complications.

| Component | What to Look For |

|---|---|

| Drum | Check for cracks, warping, or surface corrosion. |

| Gearbox | Listen for unusual noises and inspect for oil leaks. |

| Cable | Look for frays, kinks, or any signs of wear. |

| Brake System | Ensure proper engagement and check for any signs of overheating. |

| Power Source | Verify connections and check for any signs of corrosion. |

Maintenance Tips

Regular maintenance can significantly extend the life of the components. Clean all parts thoroughly and lubricate moving elements as recommended. Additionally, follow a scheduled inspection routine to catch potential issues early.

Replacing Worn-Out Parts

Over time, components in mechanical devices can deteriorate, impacting their performance and reliability. It is essential to regularly assess these elements to ensure optimal functioning. By identifying and substituting aged or damaged components, you can extend the lifespan of your equipment and maintain its efficiency.

Assessing Condition: Before beginning the replacement process, carefully inspect all relevant parts for signs of wear, such as cracks, corrosion, or abnormal movement. This thorough evaluation will help determine which elements require immediate attention.

Choosing Replacement Components: Selecting high-quality replacements is crucial. Opt for parts that match the original specifications to guarantee compatibility and performance. Research reputable suppliers and consider consulting experts if necessary.

Installation Process: When installing new components, follow the manufacturer’s guidelines to ensure proper fitting and functionality. Use appropriate tools to avoid damaging the surrounding areas. After installation, perform a comprehensive test to confirm that the system operates smoothly and efficiently.

Regular maintenance, including the timely replacement of worn parts, is vital for sustaining the performance and safety of your mechanical equipment.

Lubrication and Maintenance Tips

Proper upkeep is essential for ensuring the longevity and smooth operation of your equipment. Regular attention to lubrication and maintenance can prevent wear and tear, enhance performance, and reduce the risk of mechanical failure.

Regular Lubrication: Applying the right lubricant at appropriate intervals is crucial. Use high-quality grease or oil, depending on the manufacturer’s specifications. Pay particular attention to gears, bearings, and any moving parts that require smooth operation. Over-lubrication can be as detrimental as under-lubrication, so be mindful of the amount used.

Inspection: Frequent checks can identify potential issues before they escalate. Look for signs of wear, corrosion, or damage to components. Ensure that seals are intact and that there are no leaks. Addressing minor problems early can save time and costs later.

Cleaning: Keeping the unit free of debris and dirt is essential for optimal functionality. Regularly clean all external surfaces and inspect internal components during maintenance sessions. Use a soft brush or cloth to avoid scratching delicate parts.

Storage: If the machinery is not in use for extended periods, store it in a dry and sheltered location. Protect it from environmental factors that could lead to rust or other forms of deterioration. Consider covering it with a breathable tarp to prevent moisture accumulation.

Follow Guidelines: Always refer to the provided instructions for specific maintenance routines. Each device may have unique requirements that are vital for its operation. Adhering to these guidelines ensures your equipment remains in top condition.

Reassembly Techniques for Efficiency

Efficient reassembly of mechanical components is crucial for maintaining optimal performance and longevity. Employing effective strategies during this process can significantly reduce downtime and enhance functionality. Understanding the best practices for putting parts back together not only simplifies the task but also ensures that all elements work harmoniously.

One of the key techniques involves organizing components systematically. Using labeled containers or trays to keep screws, bolts, and small parts separate can save valuable time. This approach minimizes the risk of losing items and allows for quick access when needed. Additionally, creating a step-by-step guide or checklist tailored to the specific assembly process can help streamline efforts and maintain focus.

Another valuable method is to leverage appropriate tools designed for efficiency. Utilizing torque wrenches and screwdrivers that fit precisely can prevent damage to components and ensure that everything is tightened correctly. Regularly inspecting tools for wear can also play a significant role in achieving successful outcomes.

Finally, incorporating a collaborative approach by involving multiple individuals can lead to improved results. Having an extra pair of hands can facilitate more complex tasks, and sharing insights and techniques among team members can foster a better understanding of the reassembly process. This collective effort not only speeds up the task but also contributes to a higher level of quality in the final product.

Testing Winch Functionality

Ensuring the optimal performance of your pulling device is crucial for effective operation. This section outlines the necessary steps to assess the functionality of your equipment, allowing you to identify potential issues before they become significant problems.

Begin by inspecting the unit for any visible damage or wear. Look for frayed cables, corroded terminals, or loose connections that may hinder performance. Once visual checks are complete, perform an operational test. Connect the power source and activate the system to observe its response. Listen for unusual noises and monitor the speed at which it operates. A smooth and steady operation indicates good functionality, while any irregularities should be noted for further evaluation.

If the initial tests do not reveal any issues, conduct a load test. Attach a weight that is within the device’s rated capacity and observe how it handles the load. The equipment should lift or pull the weight without straining or exhibiting sluggish behavior. If the mechanism struggles, consider examining the internal components for further troubleshooting.

Regularly testing your device not only ensures reliability but also extends its lifespan. By following these assessment steps, you can maintain optimal performance and address any concerns promptly.

Troubleshooting Electrical Problems

Identifying and resolving issues related to electrical systems can be a complex task. This section aims to provide essential guidance for diagnosing common malfunctions that may arise in these mechanisms. Understanding the typical symptoms and underlying causes is crucial for effective troubleshooting.

Identifying Symptoms

Before delving into solutions, it is important to recognize the signs of electrical failure. Common indicators include inconsistent power supply, unusual noises during operation, and failure to activate. Monitoring these symptoms can lead to a quicker diagnosis and targeted repairs.

Testing and Solutions

Once symptoms are identified, utilize a multimeter to check voltage levels and continuity. Ensure all connections are secure and free of corrosion. If voltage is absent, inspect the power source and wiring for damage. In cases of intermittent issues, consider the possibility of a faulty relay or switch. Replace any compromised components to restore functionality. Regular maintenance and inspections can prevent many common electrical problems from occurring.

Safety Precautions During Repairs

Ensuring a secure working environment is crucial when conducting maintenance on heavy machinery. Proper precautions not only protect the individual performing the task but also safeguard the equipment and surrounding personnel. Adhering to guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Utilizing the appropriate personal protective gear is essential. Always wear safety goggles to shield your eyes from flying debris and gloves to protect your hands from sharp objects and chemicals. Additionally, consider using steel-toed boots to prevent foot injuries from heavy components.

Workspace Organization

Maintaining a tidy and organized workspace is vital for safe operations. Ensure that tools are easily accessible and that the area is free from clutter. Proper lighting is also necessary to clearly see the components you are working on, reducing the chance of mishaps.

Where to Find Replacement Parts

Locating suitable components for maintenance and upgrades can significantly enhance the longevity and functionality of your equipment. Understanding where to source these essential elements is key to efficient repairs and seamless operation.

Authorized Dealers and Distributors

One of the most reliable sources for replacement components is authorized dealers. These vendors offer original parts that guarantee compatibility and quality. To find a local distributor, consider the following:

- Visit the official website of the manufacturer.

- Contact customer service for a list of authorized sellers.

- Check online directories or forums dedicated to equipment enthusiasts.

Online Retailers and Marketplaces

The internet provides a plethora of options for purchasing spare parts. Numerous online platforms specialize in selling components for various types of machinery. Here are some tips to navigate this space:

- Utilize search engines to find reputable online retailers.

- Read customer reviews to assess the reliability of the seller.

- Compare prices across multiple websites to ensure the best deal.