Steering Mechanism: Rotate the steering wheel while observing the re

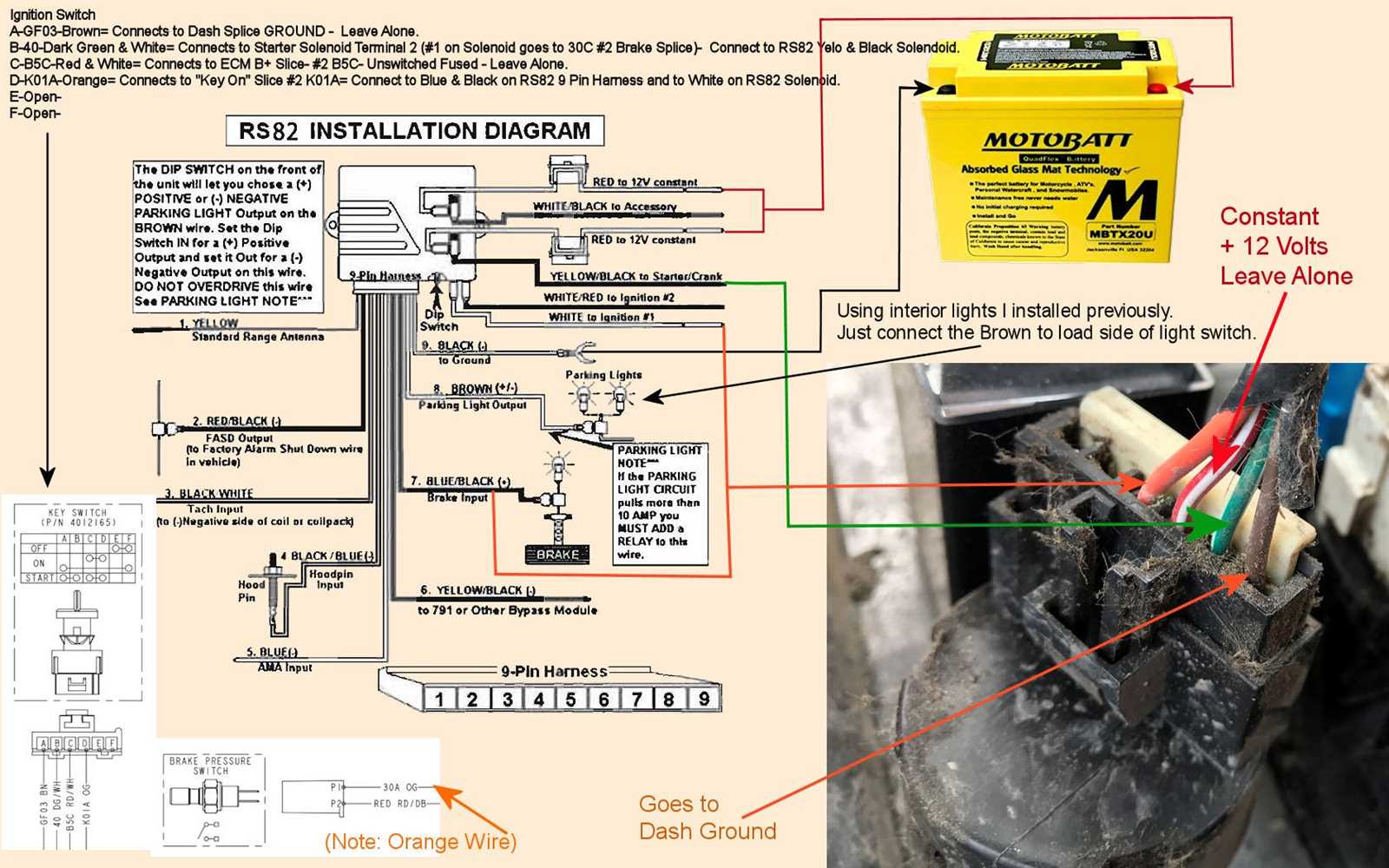

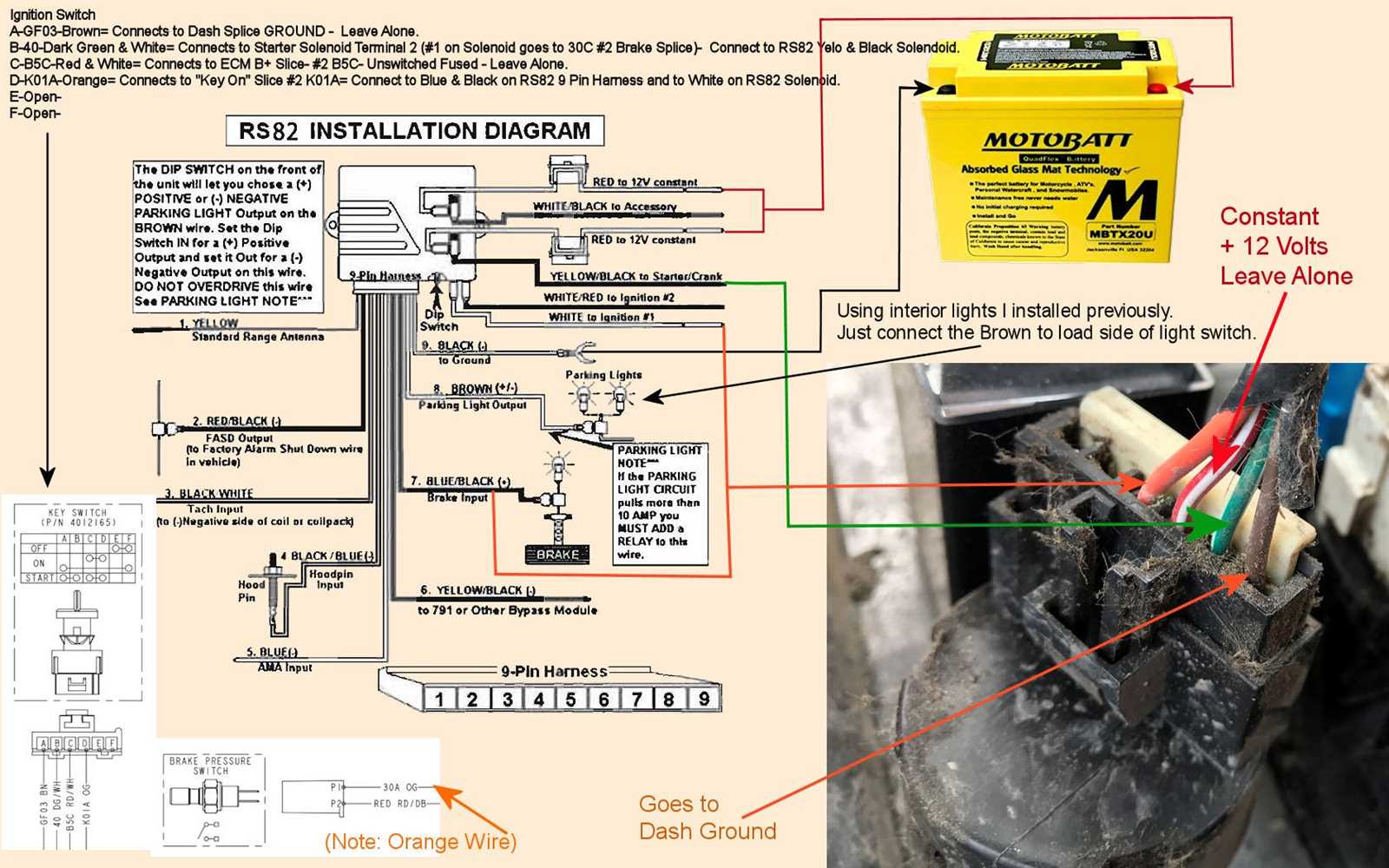

Fixing Common Electrical Issues

Electrical problems in utility vehicles can often disrupt performance, leading to inconvenient breakdowns. Identifying these issues early and following a systematic approach can help prevent more serious malfunctions. In this section, we’ll explore some of the recurring electrical challenges and offer solutions to troubleshoot effectively.

Inspecting Battery Connections and Voltage

A frequent cause of electrical troubles stems from the battery. Loose or corroded connections can impede proper power flow, affecting the entire system. Start by checking the battery terminals and cleaning any visible corrosion. After securing all connections, test the battery voltage to confirm it meets the standard range. If voltage levels are below specification, charging or replacement may be necessary.

Testing Fuses and Relays

Another source of electrical failures is faulty fuses or relays. Inspect the fuse box to locate any blown fuses, which often appear blackened or broken. Replace defective fuses with ones of the same amperage rating to prevent potential damage to the system. Similarly, malfunctioning relays can disrupt

Maintenance Tips for the Cooling System

Ensuring the proper functioning of the cooling system is crucial for the longevity and performance of your vehicle. Regular upkeep can prevent overheating and maintain optimal engine temperature. Here are essential strategies to keep your cooling system in top shape.

Regular Inspections

Frequent checks can help identify potential issues before they escalate. Inspect hoses, clamps, and connections for wear and tear. Look for leaks around the radiator and engine block, as even minor leaks can affect overall performance.

Fluid Levels and Quality

Maintaining the right coolant level is essential for effective heat transfer. Regularly check the coolant reservoir and ensure it is filled to the appropriate level. Additionally, monitor the condition of the coolant; it should be free of debris and discoloration. If the coolant appears rusty or contaminated, consider flushing the system and replacing it with fresh fluid.

| Maintenance Task |

Frequency |

| Inspect hoses and clamps |

Every 500 miles |

| Check coolant level |

Monthly |

| Flush cooling system |

Every 2 years |

| Inspect radiator for leaks |

Before each riding season |

Brake System Troubleshooting and Repairs

The braking system is crucial for the safe operation of any off-road vehicle. When issues arise, it is essential to accurately diagnose and address them to ensure optimal performance and rider safety. This section covers common problems, diagnostic steps, and solutions to effectively resolve brake-related concerns.

Common Issues and Symptoms

Braking problems can manifest in various ways, including decreased responsiveness, unusual noises, or fluid leaks. Identifying the specific symptoms is the first step toward effective resolution. Below is a table listing typical brake issues along with their potential causes and recommended actions:

| Issue |

Possible Causes |

Recommended Actions |

| Spongy brake pedal |

Air in the brake lines, low fluid levels |

Bleed the brakes, check and refill fluid |

| Noisy brakes |

Worn pads, debris between pads and rotor |

Inspect pads, clean or replace as necessary |

| Leaking fluid |

Damaged lines or seals |

Inspect and replace damaged components |

| Reduced braking power |

Worn pads or rotors, malfunctioning calipers |

Replace pads and rotors, service calipers |

Preventive Measures

Regular maintenance is key to preventing brake issues. Routine inspections, timely replacement of worn components, and proper fluid checks will enhance the lifespan of the braking system and improve overall vehicle safety.

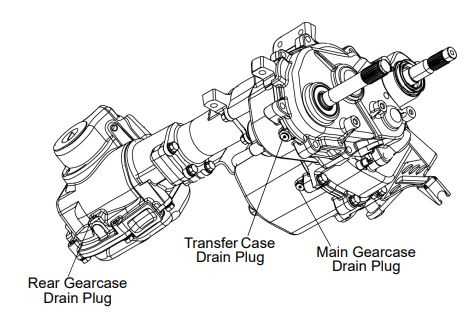

Lubrication and Fluid Replacement Essentials

Proper maintenance of an off-road vehicle is crucial for optimal performance and longevity. One of the key aspects of this maintenance involves ensuring that all moving parts are adequately lubricated and that the various fluids are replaced at regular intervals. This not only helps in preventing wear and tear but also enhances the overall efficiency of the machine.

Importance of Regular Lubrication

Lubrication plays a vital role in minimizing friction between components, thus reducing the risk of overheating and damage. Using the right type of lubricant for different parts of the vehicle ensures smooth operation and extends the lifespan of critical components. Always refer to the manufacturer’s recommendations to select appropriate lubricants.

Fluid Replacement Guidelines

Routine fluid replacement is essential to maintain the functionality of various systems such as the engine, transmission, and brakes. It is recommended to check the fluid levels regularly and replace them as needed. Utilizing clean, high-quality fluids will improve the reliability and performance of your vehicle.

Battery Care and Charging Procedures

Proper maintenance of the energy source is essential for optimal performance and longevity. Regular attention to charging practices and overall upkeep can prevent unexpected failures and enhance the reliability of your vehicle.

Follow these guidelines to ensure effective management of the power supply:

| Procedure |

Details |

| Inspection |

Check for corrosion on terminals and ensure that connections are tight and free of debris. |

| Charging |

Use a compatible charger and follow the manufacturer’s instructions for charging cycles to prevent overcharging. |

| Maintenance |

Regularly clean the battery terminals and ensure fluid levels are adequate if applicable. |

| Storage |

When not in use, store the energy source in a cool, dry place and disconnect it from the vehicle to minimize discharge. |

| Testing |

Periodically test the voltage and overall health of the battery to determine if replacement is necessary. |

Adhering to these practices will significantly extend the lifespan of the energy unit and ensure your vehicle operates reliably when needed.

How to Replace CV Boots and Axles

Replacing constant velocity (CV) boots and axles is a crucial maintenance task for ensuring optimal performance and longevity of your off-road vehicle. Over time, these components can wear out or become damaged, leading to potential issues with handling and drivetrain function. This guide will walk you through the necessary steps to efficiently perform this replacement.

Before starting, make sure you have the following tools and materials:

- Socket set

- Wrenches

- CV boot clamps

- Grease

- Jack and jack stands

- Safety goggles

- Protective gloves

- Preparation: Begin by safely lifting the vehicle with a jack and securing it with jack stands. This will provide adequate space to work on the suspension and drivetrain components.

- Remove the Wheel: Take off the wheel corresponding to the axle you are replacing. Use a lug wrench to loosen the lug nuts before lifting the vehicle.

- Detach the Axle: Locate the CV axle nut and remove it using the appropriate socket. Then, disconnect any other components that may be obstructing the axle’s removal.

- Replace the CV Boot: If you are only replacing the boot, slide the old boot off the axle and discard it. Clean the axle thoroughly and apply fresh grease before sliding on the new boot. Secure it with clamps.

- Install the New Axle: If you are replacing the entire axle, carefully position the new axle into the hub and tighten the axle nut securely. Ensure that all connections are properly reattached.

- Reassemble: Replace the wheel and lower the vehicle. Tighten the lug nuts in a crisscross pattern to ensure even pressure.

- Final Checks: Once everything is reassembled, check for any unusual noises or movements during a test drive to confirm the successful installation.

Regularly checking and replacing CV boots and axles will help maintain the integrity and performance of your vehicle, allowing for a safer and more enjoyable ride.

Fuel System Cleaning and Adjustment

Maintaining the integrity of the fuel system is essential for optimal performance and longevity of your vehicle. Regular cleaning and adjustment ensure that fuel flows smoothly, preventing clogs and inefficiencies that can lead to engine issues.

Cleaning the Fuel System: Begin by removing any dirt or debris from the fuel lines and components. Use a suitable cleaning solution to flush the system, ensuring that all residues are eliminated. Pay special attention to the fuel injectors, as they can become obstructed over time, affecting fuel atomization and overall engine performance.

Adjustment Procedures: Once the cleaning is complete, inspect the fuel pressure regulator and adjust it to the manufacturer’s specifications. This ensures that the fuel is delivered at the correct pressure, optimizing combustion. Additionally, check for any leaks in the system and replace worn seals or gaskets as necessary to maintain a tight seal.

Final Checks: After cleaning and adjustment, run the engine to verify that it operates smoothly. Listen for any irregular sounds and monitor performance to confirm that the adjustments have had a positive effect. Regular maintenance of the fuel system not only enhances performance but also contributes to better fuel efficiency.

Troubleshooting Ignition Problems

Encountering issues with the starting system can be frustrating, yet understanding common ignition challenges can aid in diagnosing the problem effectively. This section outlines typical symptoms and potential solutions to restore functionality and ensure a smooth operation.

Identifying Symptoms

Common indicators of ignition troubles include difficulty starting the engine, intermittent failure to ignite, or unexpected shutdowns during operation. Observing these signs may point to issues within the electrical components or fuel delivery systems.

Potential Solutions

Begin by checking the battery voltage and connections to ensure they are secure and fully charged. A weak or dead battery often leads to ignition failure. Next, inspect the ignition coil and spark plugs for wear and damage; replacing faulty components can resolve many ignition issues. Additionally, verify that the fuel system is delivering the correct mixture to the engine, as fuel starvation can mimic ignition problems.