Maintaining optimal functionality in complex vehicle systems is essential for ensuring longevity and reliability. This segment focuses on essential procedures and insights for enhancing performance and addressing common issues associated with intricate components responsible for power distribution. Through systematic approaches, enthusiasts and professionals alike can achieve significant improvements.

Understanding the mechanisms and nuances of these systems can prevent costly failures and enhance overall vehicle performance. This guide aims to equip readers with the knowledge necessary to tackle a variety of challenges, from diagnosing issues to implementing effective solutions. By delving into this subject, one can gain a deeper appreciation for the engineering behind these vital systems.

Whether you are a seasoned technician or a curious DIYer, this resource will serve as a valuable asset. The information provided will illuminate best practices, troubleshooting techniques, and maintenance strategies, fostering a proactive mindset when dealing with vehicle components. Embrace the journey of exploration and mastery in this critical aspect of automotive care.

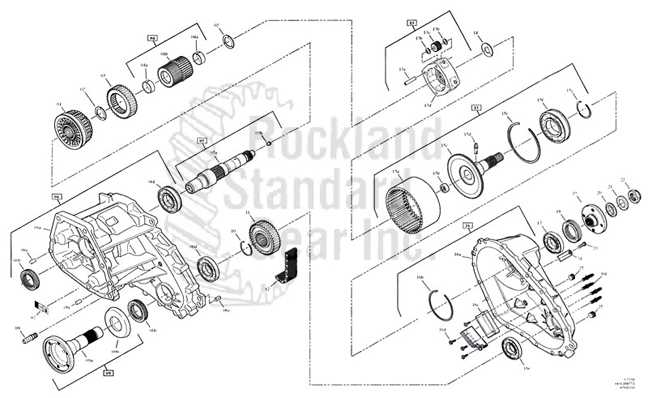

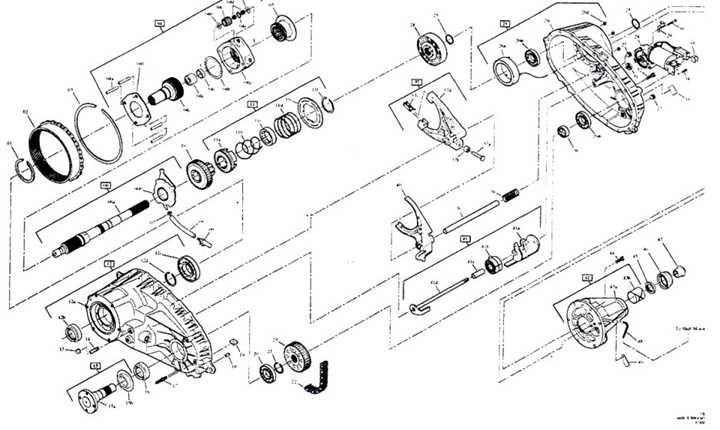

Borg Warner Transfer Case Overview

This section provides an insight into a critical component of many four-wheel-drive systems, designed to manage the distribution of power between the front and rear axles. Understanding its functionality is essential for those seeking to enhance the performance and reliability of their vehicles.

Functionality and Design

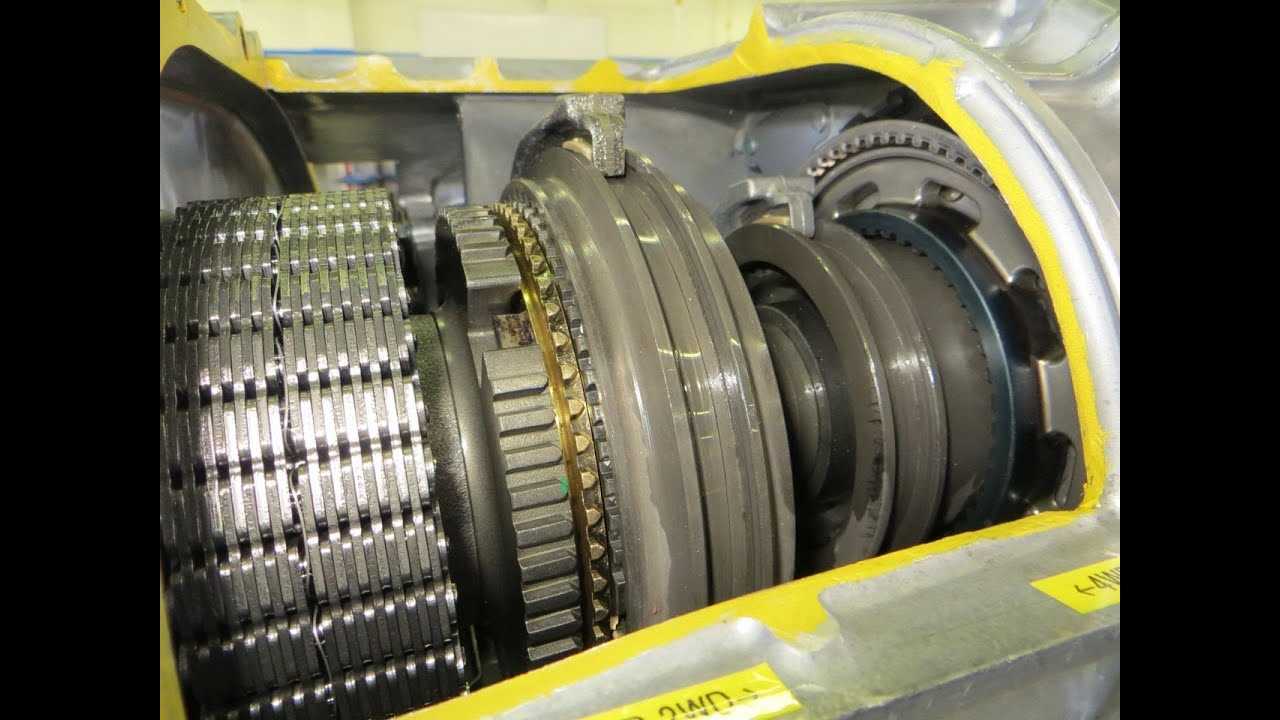

The unit plays a vital role in ensuring effective traction by controlling the torque split between axles. This mechanism allows vehicles to adapt to various terrains, providing stability and control during challenging driving conditions. Its engineering often features advanced materials and technologies to withstand significant stress and wear.

Common Issues and Solutions

While generally robust, this assembly can encounter certain challenges over time, such as fluid leaks or gear wear. Regular maintenance and timely intervention are crucial to prevent minor issues from escalating into major failures. Utilizing a systematic approach to diagnosis and corrective actions can greatly enhance the longevity of this component.

Common Issues in Transfer Cases

Understanding the typical challenges encountered in multi-gear systems is essential for maintaining optimal vehicle performance. Various components can wear out or become misaligned, leading to potential malfunctions. Identifying these issues early can prevent more significant complications down the road.

Frequent Problems

- Fluid Leaks: One of the most prevalent concerns, often caused by worn seals or gaskets.

- Overheating: Excessive heat can result from low fluid levels or blocked cooling passages, affecting efficiency.

- Noise: Unusual sounds, such as grinding or clunking, may indicate internal damage or insufficient lubrication.

- Shifting Issues: Difficulty in changing gears can stem from worn components or a malfunctioning actuator.

Signs of Malfunction

- Fluid discoloration or burnt smell.

- Vibration during operation.

- Warning lights illuminated on the dashboard.

- Inconsistent performance when engaging different driving modes.

Regular inspections and prompt attention to these symptoms can greatly enhance the longevity and reliability of the system, ensuring smooth operation under various driving conditions.

Tools Required for Repair Work

Having the right equipment is crucial for performing maintenance and restoration tasks effectively. Utilizing appropriate instruments ensures precision and enhances the overall efficiency of the process. A well-equipped workspace not only simplifies the job but also promotes safety and quality results.

Essential Hand Tools: A selection of wrenches, sockets, and screwdrivers is fundamental for disassembly and assembly tasks. Pliers and hammers are also necessary for gripping and adjusting components as needed.

Power Tools: An electric drill can expedite the removal of stubborn fasteners, while a torque wrench is vital for applying the correct force to bolts. These tools significantly reduce manual effort and improve accuracy.

Measuring Instruments: Calipers and micrometers are essential for ensuring precise measurements. Accurate dimensions are critical in maintaining proper functionality and compatibility of parts.

Safety Gear: Protective eyewear, gloves, and appropriate clothing should be worn to safeguard against potential hazards during the work process. Safety should always be a priority in any hands-on task.

Equipping yourself with these essential tools will greatly enhance your capability to undertake complex tasks effectively and safely.

Step-by-Step Disassembly Process

This section outlines a systematic approach to dismantling the unit, ensuring all components are removed carefully and methodically. Following these steps will help maintain the integrity of parts for future assembly or replacement.

Preparation and Tools

Before starting, gather all necessary tools, including wrenches, screwdrivers, and a clean workspace. Ensure you have containers to organize screws and small parts to avoid misplacement during the process. Preparation is key to a smooth disassembly.

Disassembly Steps

Begin by disconnecting the unit from its mounting. Remove any external attachments that may hinder access. Next, proceed to take off the outer casing, using the appropriate tools to avoid damaging the surface. Carefully document the arrangement of components as they are removed, which will assist in reassembly later. As you continue, be attentive to seals and gaskets, as these may require replacement during reassembly.

Inspecting Components for Damage

Thorough examination of mechanical parts is crucial for ensuring optimal functionality and longevity of the system. Identifying wear, fractures, or irregularities can prevent further issues and costly repairs. This section outlines key areas to focus on during inspection, along with recommended practices for assessing the condition of each component.

Key Areas to Examine

- Seals and Gaskets: Check for signs of leaks or deterioration, which can compromise the integrity of the assembly.

- Shafts: Look for scratches, bends, or wear marks that may indicate misalignment or excessive use.

- Bearings: Listen for unusual noises while rotating; roughness or binding can signal the need for replacement.

- Housing: Inspect for cracks or distortions that could affect alignment or lead to component failure.

Inspection Techniques

- Perform a visual assessment to spot obvious damage or irregularities.

- Utilize calipers or micrometers to measure critical dimensions and tolerances.

- Conduct a functional test to ensure each part operates smoothly within the assembly.

- Document any findings to track the condition of components over time.

Cleaning and Preparing Parts

Ensuring optimal functionality of components requires thorough cleaning and preparation. This process is crucial to eliminate contaminants that can impair performance and longevity. Proper attention to detail in this phase can significantly enhance the overall efficiency of the assembly.

Initial Cleaning Steps

Begin by removing any visible dirt or grease using a suitable solvent. A soft brush can assist in loosening stubborn debris without damaging the surfaces. For intricate areas, consider using compressed air to dislodge particles that may be trapped. Once the exterior is clean, inspect for any signs of wear or damage that may require further attention.

Surface Treatment

After the initial cleaning, proceed to treat surfaces to promote better adhesion and prevent future corrosion. Use a fine abrasive pad or sandpaper to lightly scuff the surfaces, ensuring they are smooth yet textured enough for effective bonding. Rinse thoroughly to remove any residue and allow components to dry completely before proceeding with reassembly.

Reassembly Techniques and Tips

Successfully putting components back together requires a systematic approach and attention to detail. Whether you’re dealing with gears, housing, or various fittings, understanding the reassembly process can significantly enhance the longevity and performance of the unit.

Preparation and Organization

Before starting, ensure all parts are clean and free from debris. Organizing components by size and type can save time and reduce the risk of errors. Using labeled containers for small pieces can also facilitate a smoother workflow.

Step-by-Step Assembly

Following a methodical sequence during reassembly is crucial. Begin with the larger components, ensuring they fit snugly and securely. Using the appropriate tools can prevent damage and ensure a proper fit. After securing each part, double-check the alignment before moving on to the next step to maintain accuracy throughout the process.

Fluid Types and Specifications

This section discusses the various liquid substances essential for the optimal functioning of drivetrain components. Understanding the specific types and their characteristics is crucial for maintaining performance and longevity.

Recommended Fluids

For proper operation, it is vital to utilize fluids that meet the required standards. The recommended types often include synthetic blends and high-performance lubricants, each designed to withstand specific temperature ranges and provide optimal protection against wear.

Specifications and Standards

When selecting fluids, always refer to the manufacturer’s specifications. Important factors include viscosity ratings and performance certifications. Using the correct formulations ensures effective lubrication, minimizing the risk of component failure.

Troubleshooting Common Problems

This section focuses on identifying and addressing frequent issues encountered in a specific mechanical system. Understanding these challenges can enhance performance and prolong the lifespan of the equipment.

1. Unusual Noises

Experiencing strange sounds during operation is a common sign of underlying issues. These noises may indicate wear and tear on components or improper lubrication. Regularly inspecting and maintaining the system can help prevent such occurrences.

2. Fluid Leaks

Leaks can lead to serious complications if not addressed promptly. Checking for signs of fluid escaping from joints or seals is essential. If detected, it’s crucial to locate the source and replace any damaged parts to ensure proper functioning.

Note: Always consult a professional if you are unsure about diagnosing or fixing any problems. Taking action early can save time and resources in the long run.

Upgrading Components for Performance

Enhancing the efficiency and responsiveness of your vehicle’s drivetrain can lead to significant improvements in performance. By focusing on specific parts, you can achieve better handling, increased torque, and improved overall dynamics. This section will explore key areas where upgrades can yield notable benefits.

Key Areas for Enhancement

One of the most impactful upgrades involves the modification of the gear set. By selecting a higher ratio, you can improve acceleration while maintaining power delivery. Additionally, replacing standard bearings with high-performance alternatives can reduce friction and enhance durability, allowing for smoother operation under increased loads.

Improving Fluid Dynamics

Upgrading to a more advanced lubrication system can also contribute to better performance. Utilizing synthetic fluids can provide superior heat resistance and reduced viscosity, leading to improved flow rates. This not only enhances lubrication but also helps in maintaining optimal operating temperatures during demanding conditions.

Preventive Maintenance Guidelines

Regular upkeep is essential for ensuring optimal performance and longevity of your vehicle’s drivetrain components. By implementing systematic practices, you can significantly reduce the risk of unexpected failures and enhance reliability.

Routine Inspections: Periodically examine all related elements for signs of wear or damage. Look for fluid leaks, unusual noises, and any visible abnormalities that could indicate underlying issues.

Fluid Checks: Maintaining the appropriate level and quality of lubricants is crucial. Regularly inspect and replace fluids according to the manufacturer’s recommendations to prevent overheating and reduce friction.

Component Lubrication: Ensure that all moving parts are adequately lubricated. Applying the right type of grease or oil helps to minimize wear and tear, allowing for smoother operation.

Adjustments and Alignments: Ensure that all assemblies are properly aligned and adjusted. Misalignment can lead to excessive stress on components, resulting in premature failure.

Timely Replacements: Replace worn or damaged components as soon as they are identified. Proactive replacement can prevent more extensive damage and costly repairs in the future.

By adhering to these preventive guidelines, you can enhance the durability and performance of your vehicle’s systems, ensuring a safer and more enjoyable driving experience.

Resources for Further Learning

Expanding your knowledge in automotive systems can significantly enhance your skills and understanding. Whether you are a novice or an experienced technician, numerous resources are available to help you deepen your expertise. These tools can range from online courses to detailed literature that covers various aspects of automotive technology.

Books and Publications

Reading comprehensive texts dedicated to vehicle mechanisms can provide invaluable insights. Look for specialized books that cover the intricacies of different vehicle components, focusing on diagnostics and maintenance techniques. Industry journals also offer updates on the latest technologies and practices.

Online Courses and Tutorials

Many platforms offer structured courses aimed at automotive enthusiasts. Websites like Coursera and Udemy provide video tutorials and hands-on projects that can be beneficial. Additionally, forums and discussion boards are excellent for engaging with a community of like-minded individuals who share their knowledge and experiences.

Finding Professional Repair Services

When dealing with complex mechanical systems, locating qualified professionals for assistance is essential. These experts possess the necessary skills and tools to address various issues that may arise within your equipment. Ensuring the right expertise not only enhances performance but also extends the lifespan of your components.

To begin your search, consider reaching out to local automotive service centers that specialize in drivetrain components. Many of these establishments offer comprehensive evaluations and diagnostics to determine the root cause of any malfunctions. Additionally, online platforms can be a valuable resource, allowing you to read reviews and compare service offerings.

Another option is to consult forums or communities dedicated to enthusiasts of similar systems. Members often share recommendations for reputable technicians who have demonstrated exceptional knowledge and service quality. This grassroots approach can provide insights that are not readily available through traditional advertising.

Always remember to inquire about the experience level of the service provider and their familiarity with your specific type of machinery. This will ensure that you receive high-quality care tailored to your needs. A well-informed choice can lead to significant improvements in functionality and reliability.