Proper maintenance of your cleaning device is essential for ensuring optimal performance and longevity. Whether you’re tackling tough stains on your driveway or refreshing your patio, understanding how to troubleshoot and care for your machine can make all the difference. This section provides valuable insights into common issues and solutions, helping you keep your equipment running smoothly.

From identifying potential problems to implementing effective fixes, you’ll find comprehensive guidance tailored to your needs. Emphasizing the importance of routine checks and servicing, this resource aims to empower users with the knowledge required to maximize the efficiency of their cleaning tool.

By familiarizing yourself with the inner workings and common challenges associated with your device, you can avoid unnecessary downtime and costly repairs. This manual is designed to serve as a practical companion, offering step-by-step instructions and essential tips to enhance your cleaning experience.

Understanding Ryobi Pressure Washers

This section delves into the intricacies of high-performance cleaning devices designed for residential and commercial use. These tools harness the power of water to eliminate dirt and grime effectively, making them essential for various outdoor tasks.

Key Features

Modern cleaning units boast several essential attributes, such as adjustable pressure settings, ergonomic designs, and energy-efficient motors. These innovations enhance user experience and ensure optimal performance, allowing for tailored cleaning solutions across different surfaces.

Maintenance Considerations

Proper upkeep is vital for longevity and efficiency. Regular inspections of components, such as hoses and nozzles, can prevent potential issues. Additionally, keeping the unit clean and following operational guidelines can significantly extend its lifespan.

Common Issues with Pressure Washers

In the realm of cleaning equipment, various challenges can arise that hinder optimal functionality. Understanding these prevalent problems is crucial for effective maintenance and restoration of performance.

Frequent Problems

- Low Water Flow: Insufficient water output can stem from clogged filters or hoses, leading to diminished cleaning capability.

- Inconsistent Pressure: Variations in water pressure may result from pump malfunctions or air leaks in the system.

- Unusual Noises: Strange sounds during operation often indicate issues with internal components or wear and tear.

Maintenance Tips

- Regularly check and clean filters to ensure unobstructed water flow.

- Inspect hoses for leaks or cracks that could affect performance.

- Follow manufacturer guidelines for servicing to prolong equipment life.

Tools Needed for Repairs

When addressing issues with your equipment, having the right instruments is essential for effective troubleshooting and maintenance. The proper tools not only facilitate the repair process but also help prevent potential damage to components.

Here is a list of essential tools to consider:

- Socket Set: Various sizes for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips for different types of screws.

- Pliers: Useful for gripping and twisting wires or small parts.

- Wrenches: Adjustable wrenches can help with nuts and fittings.

- Multimeter: For checking electrical connections and diagnosing issues.

- Torque Wrench: Ensures proper tension on bolts to avoid over-tightening.

- Cleaning Supplies: Brushes and cloths for maintaining cleanliness of components.

- Safety Gear: Gloves and goggles to protect yourself during repairs.

Equipped with these tools, you will be better prepared to tackle any challenges that arise while maintaining your equipment.

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to identifying and resolving common issues encountered with cleaning equipment. By following these steps, users can effectively diagnose problems and implement solutions to restore optimal functionality.

1. Identify the Issue: Begin by determining the nature of the problem. Common symptoms include lack of power, reduced flow, or unusual noises. Observing these signs can help narrow down potential causes.

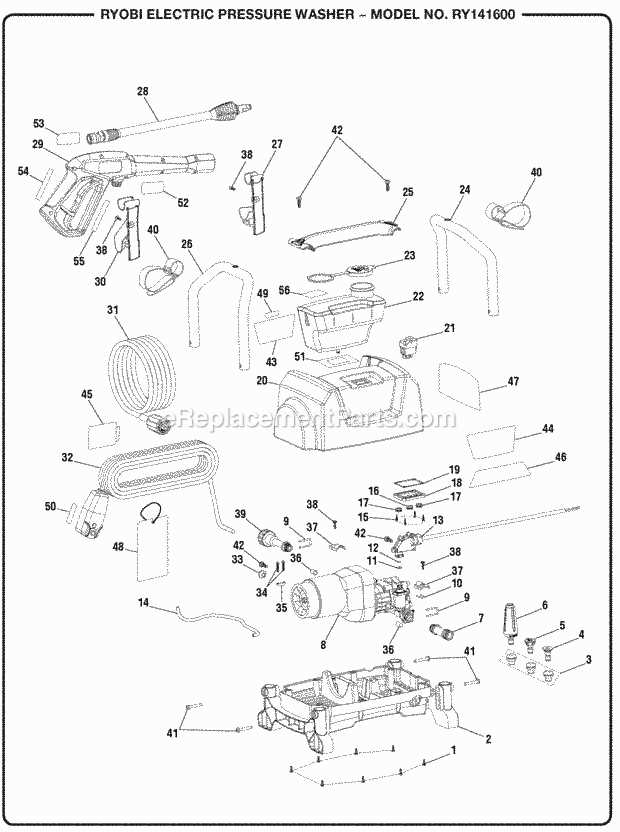

2. Check Connections: Ensure that all connections are secure and free from obstructions. Inspect hoses, nozzles, and fittings for any signs of damage or blockages that could impede performance.

3. Inspect Power Supply: Verify that the unit is receiving power. Check the electrical outlet, extension cords, and any fuses or circuit breakers that may affect operation. If using a battery, ensure it is charged and properly installed.

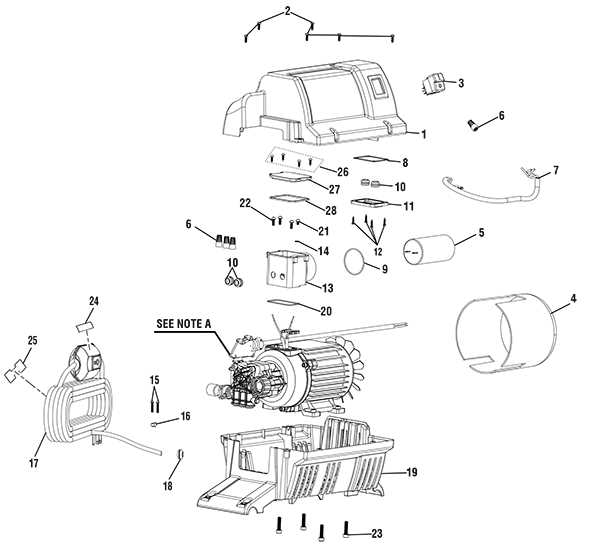

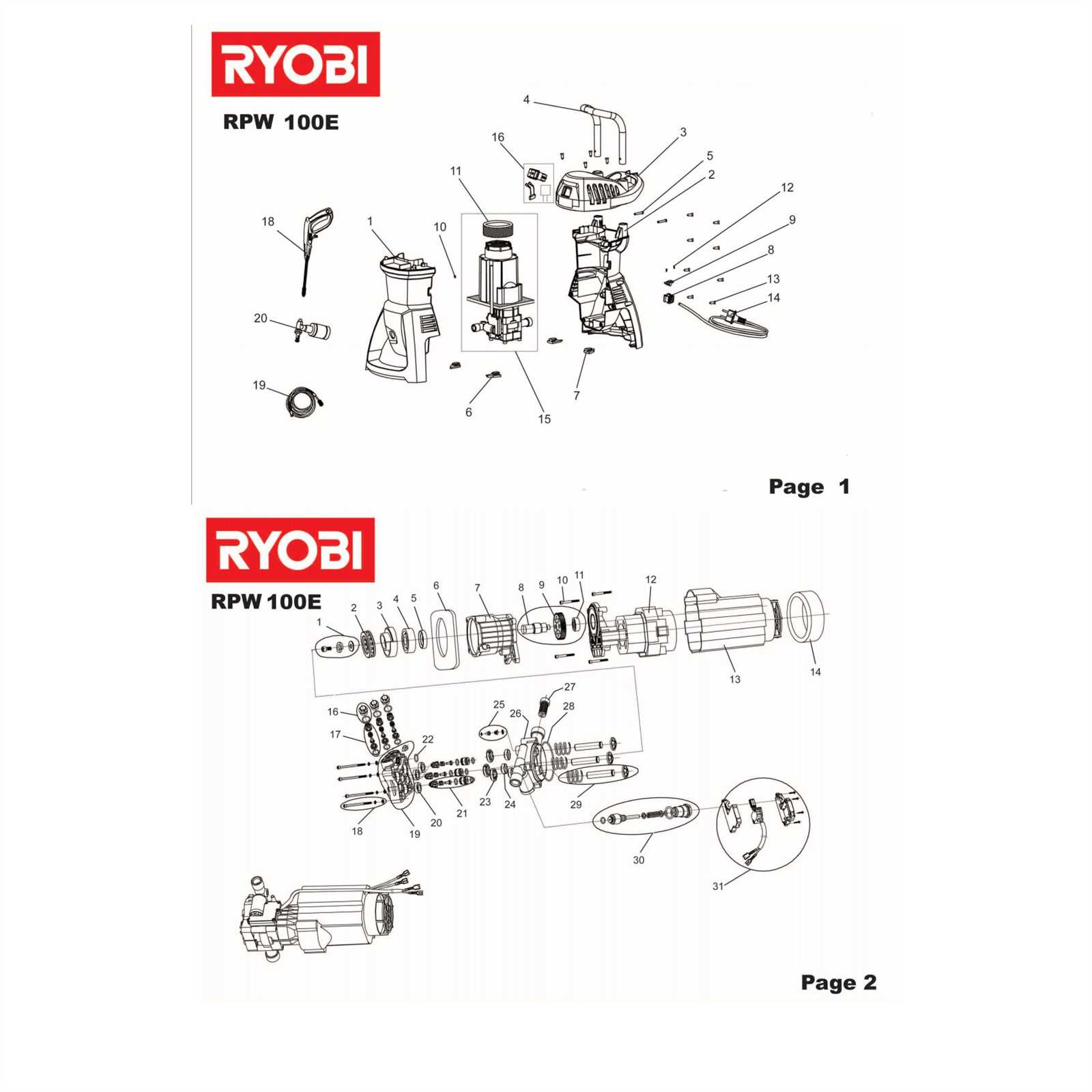

4. Examine Internal Components: Open the housing to check internal parts for wear or damage. Pay close attention to seals, valves, and pumps, as these can affect overall performance if not functioning correctly.

5. Perform a Test Run: After addressing any identified issues, conduct a test run to evaluate whether the problem has been resolved. Monitor performance and listen for any unusual sounds during operation.

6. Seek Professional Assistance: If problems persist despite troubleshooting efforts, consider consulting a professional technician. They can provide advanced diagnostics and repairs that may require specialized knowledge or tools.

Replacing the Pressure Hose

When maintaining your cleaning equipment, it may become necessary to change the connecting line that delivers fluid under force. This task can significantly enhance the performance of your machine, ensuring effective operation during use.

Before starting the process, ensure that your device is disconnected from any power source to prevent accidents. Carefully examine the existing line for any signs of wear or damage, such as cracks or leaks. If such issues are found, it’s time to proceed with the replacement.

To replace the line, begin by loosening the fittings at both ends. Use an appropriate tool to avoid damaging the connectors. Once the fittings are detached, remove the old line from the device. Take note of the length and diameter to ensure the new component matches correctly.

After acquiring the new line, attach it to the connections, making sure to tighten the fittings securely. It’s essential to verify that there are no obstructions and that the alignment is correct. Once everything is in place, reconnect the power source and perform a test run to ensure proper functionality.

Tip: Regularly inspect your equipment to catch potential issues early, ensuring a longer lifespan and better performance during use.

Maintaining the Pump System

Proper upkeep of the water pumping mechanism is essential for ensuring optimal performance and longevity. Regular attention to this component helps prevent issues that can arise from wear and tear, leading to enhanced efficiency and reduced downtime.

Regular Inspection: Consistent examination of the pumping unit for any signs of leaks or wear is crucial. Look for any visible cracks or loose fittings that may affect functionality.

Cleaning: Keeping the system clean from debris and contaminants is vital. Regularly remove any buildup that could hinder performance, especially around intake and output areas.

Lubrication: Ensure that moving parts are adequately lubricated according to the manufacturer’s specifications. This practice minimizes friction and extends the lifespan of the components.

Water Quality: Using clean, treated water can significantly impact the overall health of the pumping system. Avoid using water with high mineral content or impurities, as these can lead to clogs and operational issues.

By following these maintenance practices, users can ensure their water pumping mechanism remains efficient and reliable over time.

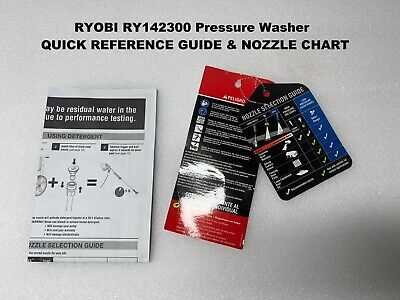

Cleaning the Nozzle and Filters

Maintaining optimal performance of your cleaning device requires regular attention to its components, particularly the nozzle and filtration system. These parts can accumulate debris and contaminants, hindering efficiency and effectiveness during use. Routine cleaning ensures that water flow remains unobstructed and helps extend the lifespan of your equipment.

Steps for Cleaning the Nozzle

Begin by detaching the nozzle from the unit, following the manufacturer’s guidelines. Rinse it thoroughly under running water to remove loose dirt and buildup. For stubborn residue, a soft brush can be employed to gently scrub the surfaces. After cleaning, inspect the nozzle for any signs of damage or wear, and reattach it securely once dry.

Cleaning the Filters

Next, focus on the filters, which play a crucial role in maintaining proper operation. Remove the filter components and rinse them with water to eliminate dirt particles. If necessary, soak them in a mild cleaning solution for deeper cleaning. Ensure that the filters are completely dry before reinserting them into the system to prevent any moisture-related issues.

Electrical Components Inspection

Examining the electrical elements of a cleaning device is crucial for ensuring optimal performance and longevity. A thorough inspection can help identify potential issues that may lead to malfunctions or inefficiencies. This section outlines the key components to focus on during the evaluation process.

Key Components to Inspect

When assessing electrical parts, consider the following components:

| Component | Inspection Method | Signs of Damage |

|---|---|---|

| Circuit Board | Visual inspection for burnt traces or corrosion | Discoloration, cracks, or missing components |

| Wiring | Check for fraying or exposed conductors | Wear, cuts, or melting |

| Connectors | Ensure tight connections and check for rust | Loose fittings or discoloration |

| Switches | Test functionality with a multimeter | Unresponsive or intermittent operation |

Maintenance Tips

Regular maintenance of electrical components not only prolongs the lifespan of the equipment but also enhances safety. Always ensure connections are secure, clean, and free from corrosion to prevent unexpected failures.

Handling Fuel System Problems

Issues related to the fuel system can significantly affect the operation of outdoor equipment. Identifying and addressing these challenges is crucial for maintaining optimal performance and ensuring longevity. This section provides essential insights into common problems and their solutions.

Common symptoms of fuel system difficulties include:

- Engine not starting

- Irregular or unstable performance

- Excessive fuel consumption

- Fuel leaks or odors

To effectively manage these issues, consider the following steps:

- Inspect Fuel Lines: Check for cracks, leaks, or blockages that may restrict flow.

- Examine the Fuel Filter: A clogged filter can hinder fuel delivery. Replace it if necessary.

- Assess Fuel Quality: Ensure that the fuel used is fresh and free of contaminants. Old or contaminated fuel can cause starting problems.

- Check the Fuel Pump: Test the pump’s operation and replace it if it fails to deliver fuel adequately.

Regular maintenance of the fuel system can prevent many issues. Ensure to clean and replace components as recommended to keep your equipment functioning smoothly.

Winterization and Storage Tips

Proper preparation for colder months is essential to ensure your cleaning device remains in optimal condition. Taking the time to winterize and store your equipment effectively can prevent damage and extend its lifespan.

Draining Fluids: Before storing your unit, it’s crucial to remove any remaining liquids. This step helps prevent freezing and potential cracks in the internal components. Make sure to run the machine briefly to expel water from the system.

Cleaning the Exterior: A thorough cleaning of the outer surfaces not only improves appearance but also prevents corrosion. Use a gentle detergent and soft cloth to wipe away any grime, ensuring all parts are clean and dry before storage.

Choosing a Storage Location: Store your device in a dry, climate-controlled environment. Avoid areas with extreme temperatures or humidity, as these conditions can lead to deterioration. Keeping the unit elevated on a shelf can further protect it from moisture.

Protective Cover: Consider using a protective cover to shield your equipment from dust and debris. This simple measure can help maintain its condition and make it ready for use when the season changes.

When to Seek Professional Help

Determining the right moment to consult an expert can save time, effort, and potential further damage. While many issues can be addressed through basic troubleshooting and maintenance, some situations warrant professional intervention to ensure safety and effectiveness.

Signs Indicating Professional Assistance is Needed

- Persistent Issues: If problems persist despite following standard guidelines.

- Unusual Sounds: Any strange noises that deviate from normal operation can signal deeper issues.

- Leaks: Visible leaks from the unit may indicate serious mechanical failures.

- Power Problems: Difficulty starting or inconsistent power output should prompt a professional evaluation.

Benefits of Professional Services

- Expert Knowledge: Professionals have specialized training and experience to diagnose complex problems accurately.

- Proper Tools: They possess the necessary tools and equipment for effective troubleshooting and fixes.

- Time Efficiency: Relying on an expert can expedite the resolution process, saving you time in the long run.

- Warranty Protection: Utilizing professional services may help maintain warranty coverage for the equipment.