Maintaining essential lifting machinery is crucial for ensuring operational efficiency and safety in various industrial settings. Understanding the intricacies of these devices not only extends their lifespan but also minimizes the risk of unexpected breakdowns. This section serves as a foundational resource for individuals seeking to enhance their knowledge of maintenance practices.

Through systematic guidance, users will explore the essential components, common issues, and effective solutions associated with these machines. Emphasis will be placed on troubleshooting techniques and preventive measures, enabling operators to identify and address potential problems before they escalate.

Furthermore, this guide aims to empower users with the confidence and skills necessary for effective upkeep. By familiarizing oneself with the mechanics and nuances of these tools, operators can ensure optimal performance and reliability, ultimately contributing to a more productive work environment.

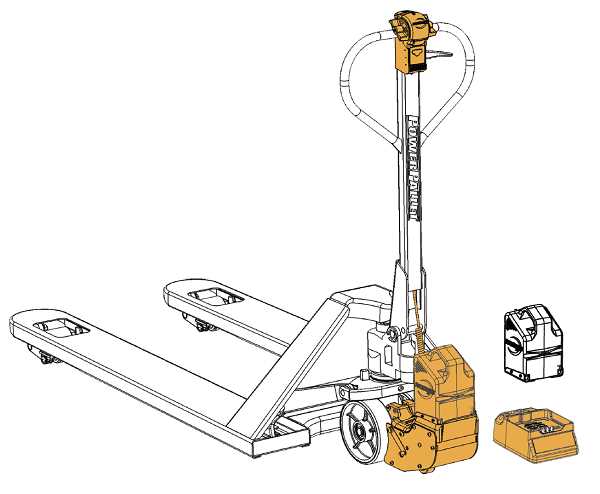

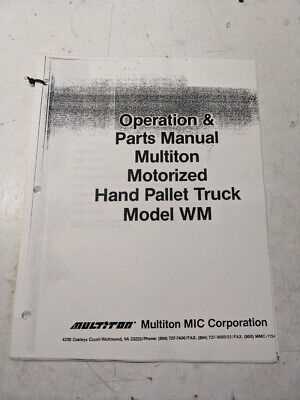

Overview of Multiton Pallet Jacks

This section provides an insight into a specialized equipment category designed for the efficient handling and transport of heavy loads in various industrial settings. Understanding the mechanics, design, and operational principles of this equipment is essential for ensuring optimal performance and longevity.

Design and Functionality

These devices typically feature a robust structure that can accommodate significant weight, making them invaluable in warehouses and manufacturing environments. The design incorporates ergonomics, allowing operators to maneuver loads with minimal physical strain, enhancing productivity and safety.

Applications and Benefits

Commonly used in logistics and supply chain operations, this equipment enhances workflow by facilitating the swift movement of goods. The ability to streamline processes not only boosts efficiency but also reduces the risk of damage to products, ultimately leading to cost savings and improved operational outcomes. Regular maintenance and understanding the operational features are crucial for maximizing the benefits of these tools.

Common Issues with Pallet Jacks

In the world of material handling, several challenges can arise that impact the functionality and efficiency of equipment used for transporting heavy loads. Understanding these common problems can help users maintain their tools effectively and ensure smooth operations.

Hydraulic Problems: One frequent issue is related to the hydraulic system, where leaks or malfunctions can lead to a lack of lifting capability. Users may notice that the equipment struggles to elevate loads, indicating a need for inspection.

Worn Wheels: Another common concern is the wear and tear of wheels. Over time, the wheels may become damaged or flattened, causing difficulty in maneuverability. Regular checks can help identify this issue before it affects performance.

Steering Difficulties: Steering mechanisms can also experience problems, such as stiffness or resistance. This can result from debris accumulation or internal wear, making it essential to keep the steering system clean and well-lubricated.

Frame Integrity: The structure itself may face issues, such as bends or cracks from heavy use. Inspecting the frame regularly ensures that it remains sturdy and safe for continued operation.

Addressing these common issues promptly can extend the lifespan of the equipment and enhance overall productivity in handling materials.

Essential Tools for Repairing Equipment

Having the right instruments is crucial for effective maintenance and servicing of machinery. A well-equipped toolkit not only streamlines the process but also enhances the overall quality of work. Understanding which tools are necessary can significantly impact efficiency and outcomes.

Basic Hand Tools

Hand tools form the foundation of any maintenance operation. Wrenches, screwdrivers, and pliers are indispensable for assembly and disassembly tasks. Each tool serves a specific function, allowing for precise adjustments and repairs. For instance, a good set of torque wrenches is essential for ensuring proper tension on bolts and screws, which helps prevent future issues.

Power Tools and Diagnostic Equipment

In addition to hand tools, power tools play a vital role in expediting tasks. Tools such as drills and impact wrenches can save significant time during maintenance. Furthermore, diagnostic equipment, including multimeters and pressure gauges, allows technicians to identify issues quickly and accurately. Investing in quality power tools and diagnostic devices can lead to a more efficient and effective maintenance process.

Step-by-Step Repair Process

Maintaining equipment functionality requires a systematic approach to addressing issues that may arise. This section outlines a detailed procedure for troubleshooting and fixing common problems encountered with lifting devices, ensuring optimal performance and safety.

Begin by gathering the necessary tools and materials, including wrenches, screwdrivers, and replacement parts. This preparation is crucial for an efficient workflow. Next, carefully assess the unit to identify symptoms of malfunction, such as unusual noises or decreased lifting capacity.

Once you have pinpointed the issue, disassemble the relevant components with caution, taking care to document each step. This will aid in reassembly and ensure that no parts are misplaced. Inspect each part for wear or damage, replacing any faulty components as needed.

After replacement, clean all areas of the device to remove debris or contaminants that could affect performance. Reassemble the unit according to your earlier documentation, ensuring that each part is secured properly. Finally, conduct a thorough test to confirm that the equipment operates smoothly and efficiently.

By following this structured method, you can effectively restore functionality and extend the lifespan of your lifting equipment.

Maintenance Tips for Longevity

Regular upkeep is essential to extend the lifespan of any equipment. By following a few straightforward practices, operators can ensure optimal performance and reduce the likelihood of breakdowns. These tips aim to highlight key areas of focus for effective maintenance.

| Tip | Description |

|---|---|

| Daily Inspections | Check for visible signs of wear and tear to identify potential issues early. |

| Proper Lubrication | Apply appropriate lubricants to moving parts to minimize friction and enhance efficiency. |

| Battery Care | Ensure batteries are charged regularly and maintain clean terminals for better performance. |

| Cleanliness | Keep the equipment free from debris and dirt to prevent damage and ensure smooth operation. |

| Professional Servicing | Schedule periodic check-ups with qualified technicians to address any underlying issues. |

Diagnosing Mechanical Failures

Identifying issues within lifting equipment is crucial for ensuring optimal performance and safety. A systematic approach to troubleshooting can help pinpoint the root causes of malfunctions, enabling timely solutions. This section outlines key strategies for diagnosing mechanical problems effectively.

Common Symptoms of Mechanical Issues

- Unusual noises during operation

- Difficulty in lifting or lowering loads

- Uneven movement or instability

- Fluid leaks in hydraulic components

- Signs of wear on wheels and forks

Steps for Effective Diagnosis

- Observe the equipment during operation to note any irregularities.

- Check for visible signs of damage or wear on all moving parts.

- Inspect hydraulic fluid levels and conditions.

- Test the controls and mechanisms for responsiveness.

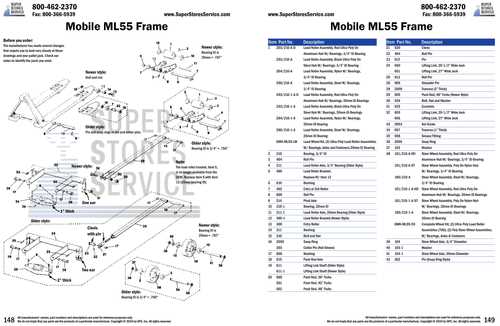

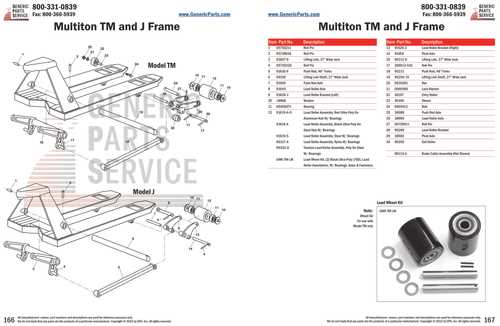

- Consult the manufacturer’s guidelines for specific troubleshooting tips.

By following these steps and recognizing common symptoms, operators can effectively address mechanical failures and maintain equipment reliability.

Electrical Components and Troubleshooting

This section focuses on the various electrical elements involved in the operation of lifting equipment and offers guidance on diagnosing and resolving common issues. Understanding these components is essential for maintaining optimal performance and ensuring safety during usage.

Key Electrical Components

Among the critical elements are batteries, motors, and control circuits. The battery serves as the power source, providing energy to operate the entire system. Motors convert electrical energy into mechanical motion, enabling movement and lifting actions. Additionally, control circuits regulate the flow of electricity and manage the equipment’s functionality.

Troubleshooting Common Issues

When issues arise, it’s important to systematically check each component. Begin by inspecting the battery for proper charge levels and connections. A dead or improperly connected battery can lead to malfunction. Next, examine the motor for signs of wear or overheating, as these can affect performance. Finally, review the control circuits for any loose wires or damaged connections, which can disrupt electrical flow and lead to operational failures.

Hydraulic System Maintenance Procedures

Proper upkeep of the hydraulic system is essential for ensuring optimal performance and longevity of equipment. Regular maintenance helps prevent malfunctions, reduces wear and tear, and enhances efficiency. By following systematic procedures, users can identify potential issues early and maintain smooth operation.

Routine Inspection

Conducting regular inspections is vital for detecting any signs of wear, leakage, or damage. During these evaluations, pay close attention to connections, hoses, and the hydraulic fluid level. An effective inspection routine includes the following steps:

| Inspection Step | Description |

|---|---|

| Visual Check | Look for any visible leaks or damage to hoses and fittings. |

| Fluid Level | Ensure that the hydraulic fluid is at the recommended level for optimal performance. |

| Pressure Test | Test the system pressure to confirm it is within the specified range. |

Fluid Replacement

Replacing the hydraulic fluid is crucial for maintaining system efficiency. Contaminated fluid can lead to reduced performance and potential system failure. Follow these steps for effective fluid replacement:

| Procedure Step | Details |

|---|---|

| Drain Old Fluid | Carefully drain the existing hydraulic fluid into a suitable container. |

| Filter Change | Replace the hydraulic filter to ensure proper filtration of the new fluid. |

| Add New Fluid | Fill the system with the recommended hydraulic fluid type. |

Replacing Worn-out Parts

Maintaining optimal performance of handling equipment requires timely substitution of deteriorated components. Over time, regular usage can lead to wear that affects functionality, safety, and efficiency. This section outlines the steps and considerations involved in replacing these essential elements to ensure seamless operation.

Before beginning the replacement process, it is crucial to identify which parts are compromised. Common indicators of wear include unusual noises, difficulty in maneuvering, or uneven lifting. Conduct a thorough inspection to determine which components need attention.

| Part | Signs of Wear | Replacement Tips |

|---|---|---|

| Wheels | Flat spots, cracks, or excessive noise | Ensure you select the correct size and type; lubricate before installation. |

| Hydraulic Cylinder | Leaks, sluggish operation | Check for compatible replacement parts; ensure proper sealing during installation. |

| Handles | Cracks, loosening | Use appropriate tools for a secure fit; consider ergonomic options for comfort. |

Once the worn components are identified and sourced, follow the manufacturer’s guidelines for replacement. Taking the time to ensure each part is correctly installed will extend the lifespan of the equipment and maintain its operational integrity.

Safety Precautions During Repairs

When conducting maintenance on equipment, it is essential to prioritize safety to prevent accidents and ensure a secure working environment. Adhering to specific guidelines can significantly reduce the risk of injury while enhancing overall efficiency during the process.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes gloves to protect hands from sharp edges and chemical exposure, safety glasses to shield eyes from debris, and steel-toed boots to guard feet against heavy items. Ensure that all equipment is in good condition and fits properly.

Work Area Organization

Maintaining a tidy workspace is vital for safety. Keep tools and components organized to minimize hazards. Remove any unnecessary clutter that could pose a tripping risk. Additionally, ensure that the area is well-ventilated, especially when working with solvents or other potentially harmful substances.

By following these precautions, one can significantly mitigate risks associated with maintenance tasks, promoting a safer and more productive atmosphere.

Understanding Manufacturer Guidelines

When working with any type of equipment, it is crucial to familiarize yourself with the recommendations provided by the producer. These guidelines serve as a roadmap for ensuring optimal performance and longevity of the machinery. Following these instructions not only enhances operational efficiency but also minimizes the risk of malfunctions.

Importance of Adherence

Strict compliance with the manufacturer’s directives can prevent a variety of issues, from minor inconveniences to major breakdowns. By understanding the specific requirements outlined, operators can make informed decisions about maintenance practices, usage limitations, and necessary inspections.

Key Components of Guidelines

Manufacturer instructions typically include critical information regarding operational procedures, safety precautions, and recommended maintenance schedules. Familiarity with these elements ensures that users can effectively manage their equipment and address any concerns that may arise in a timely manner.

When to Seek Professional Help

Recognizing when to call in an expert can significantly impact the longevity and functionality of your equipment. While some issues may appear manageable, others could lead to more serious problems if not addressed properly. Understanding the signs that indicate professional assistance is required is crucial for maintaining operational efficiency.

Persistent Issues: If you encounter recurring malfunctions that don’t resolve with basic troubleshooting, it’s time to consult a specialist. Ongoing problems often suggest underlying issues that require advanced knowledge and tools.

Unusual Noises or Behavior: Any strange sounds or erratic movements can indicate potential mechanical failures. These symptoms may point to deeper complications that should not be ignored, as they could escalate into more significant damage.

Safety Concerns: If the equipment poses a risk to user safety, seeking expert help is essential. Malfunctions that compromise safety should be addressed immediately to prevent accidents or injuries.

Lack of Knowledge: If you’re unsure how to diagnose or fix a specific problem, it’s best to involve a professional. Attempting repairs without proper understanding can lead to further complications.

By being aware of these indicators, you can ensure your machinery remains in optimal condition, safeguarding both your investment and the safety of your workplace.