For anyone who relies on equipment to maintain a consistent environment, understanding how to perform basic upkeep and diagnose common issues can be essential. With frequent use, components can sometimes experience wear, leading to reduced performance. Addressing these aspects can help keep the unit running efficiently, ensuring reliability even in demanding conditions.

Our detailed guide provides insights into routine maintenance practices, along with methods for recognizing and resolving common technical challenges. From identifying potential causes of operational interruptions to replacing specific parts, this guide aims to make complex steps clear and approachable. By developing a deeper familiarity with the inner workings of your equipment, you can extend its lifespan and improve its functionality.

Whether you are new to equipment care or looking to refine your skills, this guide offers essential information, step-by-step gu

Reddy Heater Repair Guide

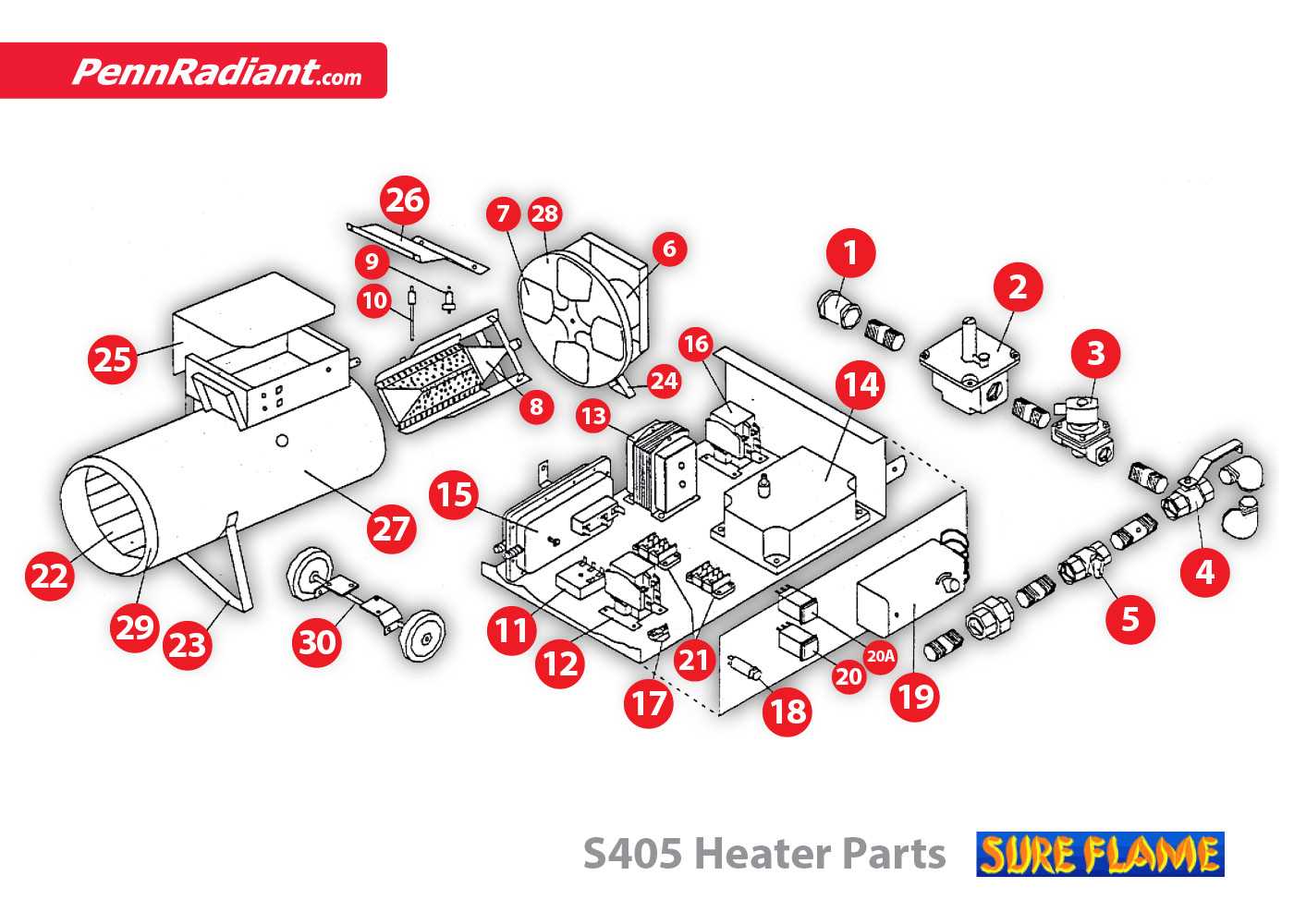

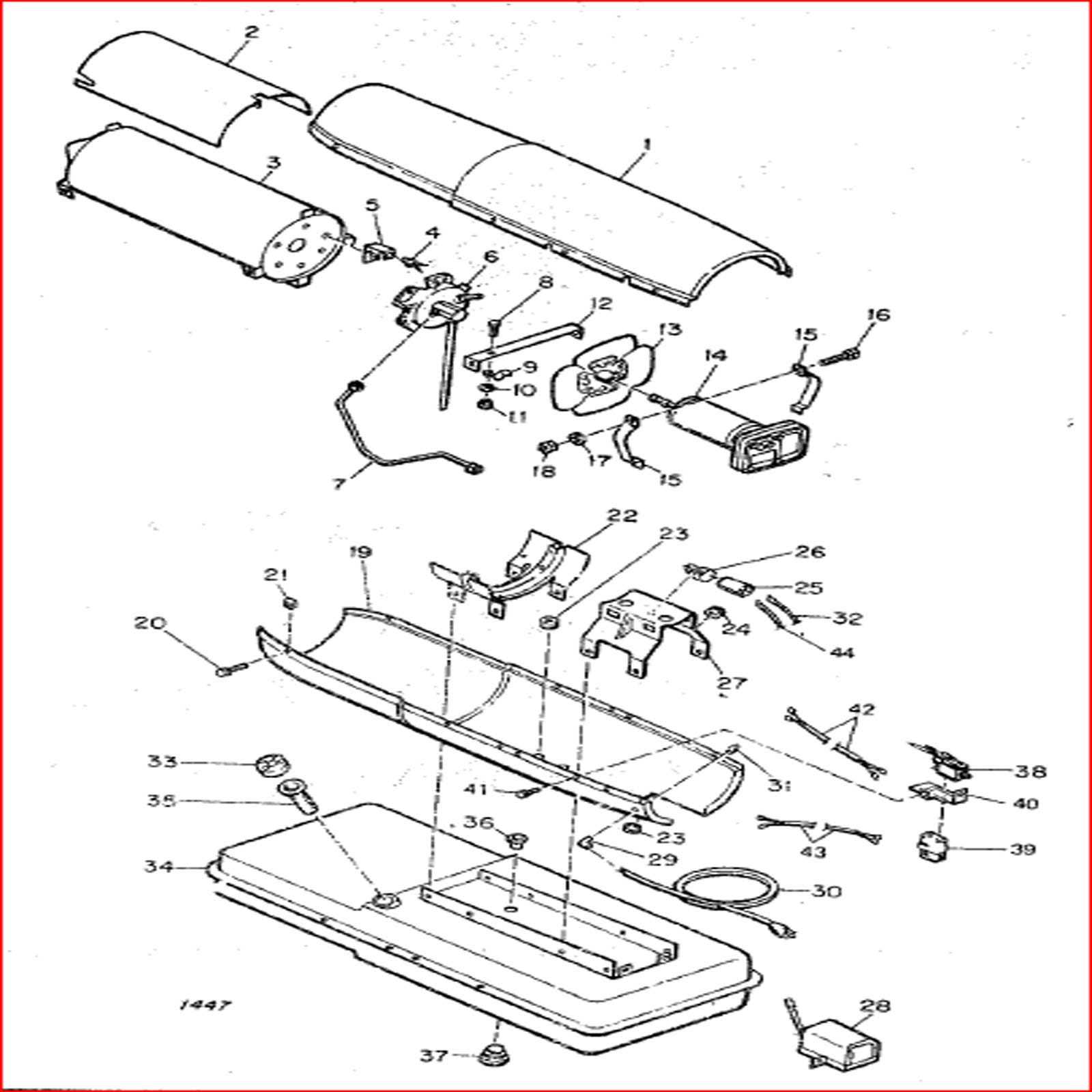

Many devices designed for producing warmth can experience common issues over time, impacting efficiency and functionality. This section provides guidance on identifying potential problem areas and offers insights into straightforward troubleshooting steps to restore effective operation. With a bit of care and regular maintenance, these units can often continue serving reliably for years.

Common Issues and Solutions

When a unit is not functioning optimally, several common challenges may arise. Frequent obstacles include a weak ignition system, inconsistent warmth production, and airflow blockages. Ensuring components are clean and in proper condition is vital. Periodic examination of essential parts like filters, igniters, and connections can often reveal the source of the problem and facilitate a quick resolution.

E

Understanding Common Heater Problems

Proper maintenance and troubleshooting are essential for ensuring that devices used for warming spaces operate efficiently. Identifying and addressing frequent issues promptly can help in restoring smooth functionality, improving safety, and extending the equipment’s lifespan. Below, we explore some of the most typical challenges that may arise, along with helpful tips on recognizing and handling each scenario.

| Issue | Symptoms | Possible Solution | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ignition Failure | Device fails to start or shuts down shortly after turning on | Check for blocked or malfunctioning ignition components; ensure fuel supply is adequate and uninterrupted. |

| Task | Frequency | Method |

|---|---|---|

| Inspect Filters | Monthly | Visual check for dirt accumulation |

| Clean Filters | Every 1-3 Months | Wash with mild soap and water, or replace if necessary |

| Check for Damage | Monthly | Look for tears or deformities |

| Replace Filters | Every 6-12 Months | Use high-quality replacements to ensure efficiency |

Implementing these practices will significantly improve air quality and prolong the lifespan of the system. Always follow manufacturer recommendations for specific care instructions related to filtration components.

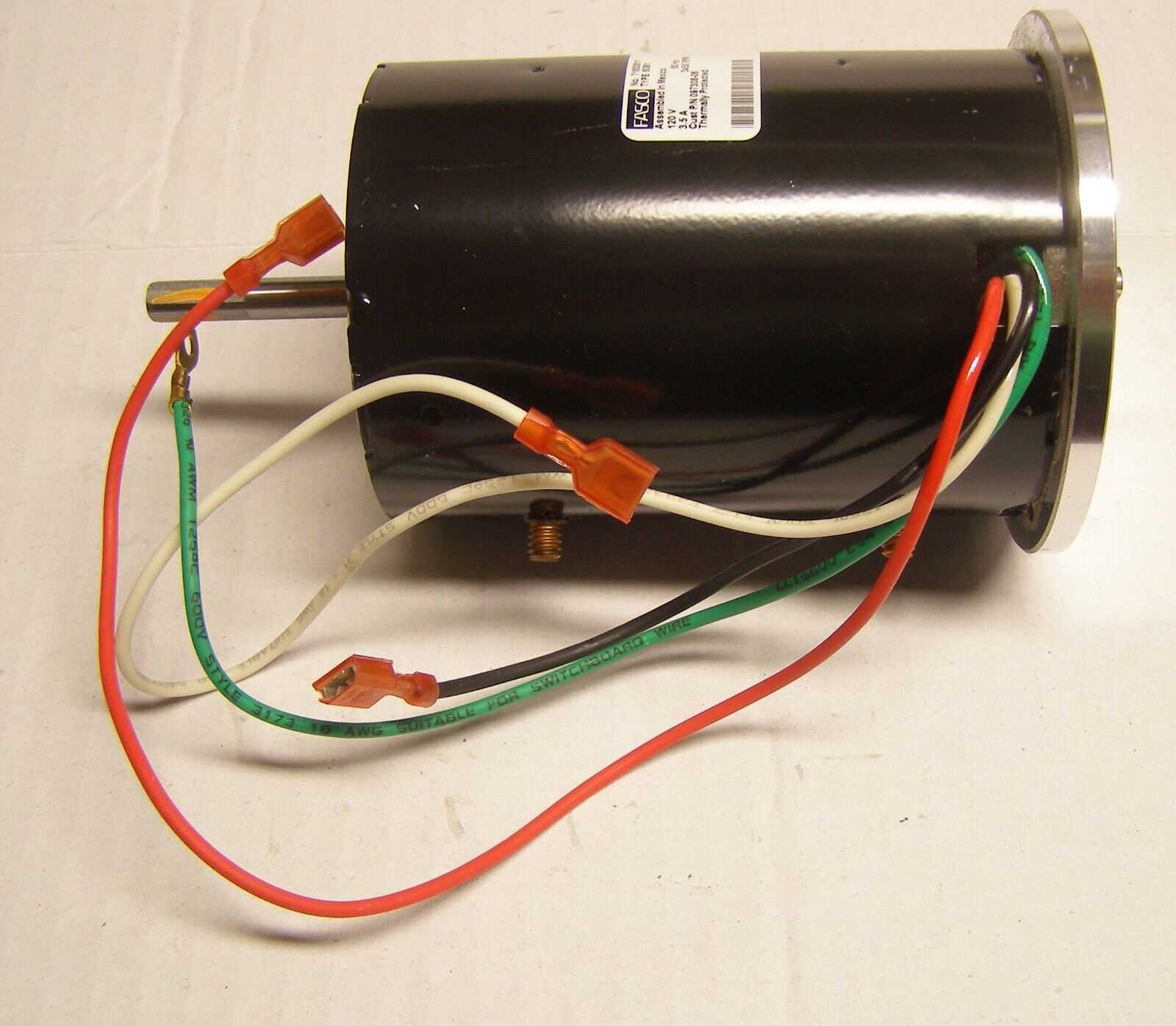

Fixing Electrical Connection Problems

Addressing issues with electrical connections is crucial for ensuring the safe and efficient operation of any device. These problems can lead to malfunctions, reduced performance, or even hazards. Identifying the root cause of connectivity issues and implementing effective solutions can help restore functionality and prevent future complications.

Common Symptoms of Connection Issues

Users may notice various signs indicating potential connectivity problems. Flickering lights, intermittent operation, or complete power loss are often the first indications. Additionally, unusual sounds or odors may accompany these symptoms, suggesting underlying electrical faults. Recognizing these warning signs early can aid in timely intervention.

Troubleshooting Steps

To resolve connection issues, begin by inspecting the wiring for any visible damage or loose connections. Ensure that all terminals are secure and free of corrosion. Using a multimeter, check for continuity and voltage at critical junctions. If problems persist, consider replacing faulty components. Always prioritize safety by disconnecting power before conducting any repairs.

Adjusting Fuel Pressure Settings

Properly configuring the fuel pressure is essential for optimal performance of your appliance. Adjustments may be necessary to ensure that the system operates efficiently and reliably. This process involves a few straightforward steps that can enhance the overall functionality and longevity of the unit.

Before beginning the adjustment, it is important to gather the necessary tools:

- Pressure gauge

- Screwdriver set

- Wrench

- Owner’s documentation for reference

Follow these steps to adjust the fuel pressure settings:

- Turn off the appliance and disconnect it from the power source.

- Locate the pressure adjustment mechanism, typically found near the fuel supply line.

- Attach the pressure gauge to the designated port to measure the current fuel pressure.

- Use the appropriate tool to turn the adjustment screw clockwise to increase pressure or counterclockwise to decrease it.

- Monitor the gauge while making adjustments to achieve the desired pressure level.

- Once the correct setting is reached, securely tighten the adjustment screw to prevent it from shifting.

- Reattach the pressure gauge and check for any leaks in the fuel line.

- Reconnect the power source and turn on the system to ensure it operates smoothly.

Regular monitoring and adjustments of the fuel pressure can lead to improved efficiency and performance, reducing the likelihood of potential issues in the future.

Dealing with Overheating Concerns

Overheating is a common issue that can affect the functionality and safety of various heating appliances. Understanding the potential causes and solutions is essential for maintaining optimal performance and preventing hazards.

Common Causes of Excessive Heat

- Blocked airflow due to dirt or debris accumulation.

- Faulty components, such as thermostats or sensors, that fail to regulate temperature effectively.

- Electrical issues, including loose connections or damaged wiring.

- Overuse or operating beyond recommended limits.

Preventative Measures

- Regularly clean and inspect the unit to ensure unobstructed airflow.

- Monitor the temperature settings to avoid excessive operation.

- Conduct routine maintenance checks to identify and replace malfunctioning parts.

- Consult a professional for complex electrical repairs or if overheating persists.

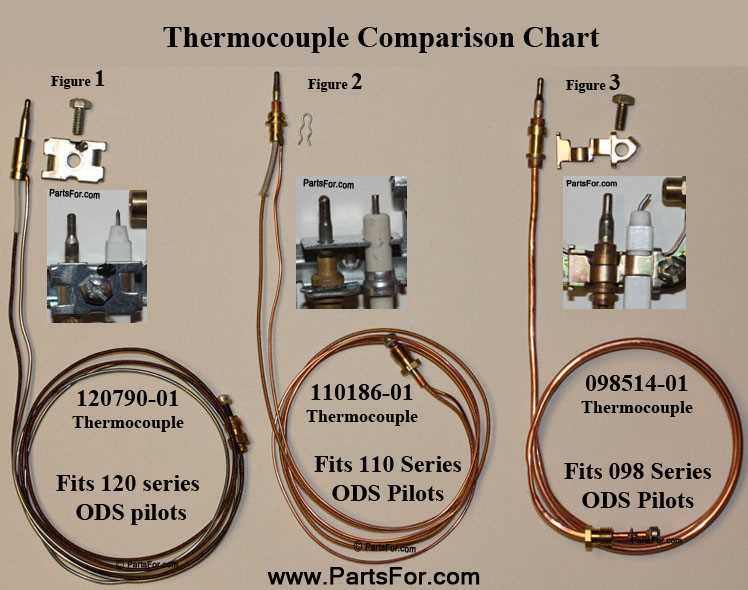

Troubleshooting Temperature Control Systems

Effectively managing temperature regulation is crucial for optimal performance. Issues within these systems can lead to inconsistent operations, requiring systematic evaluation to identify and resolve underlying problems.

To begin diagnosing issues, consider the following common factors:

- Sensor Malfunction: Ensure that the temperature sensors are functioning correctly. Inaccurate readings can disrupt the entire system.

- Electrical Connections: Inspect all wiring and connections for signs of damage or corrosion. Loose or faulty connections may impede functionality.

- Calibration Issues: Verify that the control system is properly calibrated. Miscalibrated devices can produce unreliable temperature settings.

- Software Glitches: Examine the software interface for errors. Updates or resets may be necessary to restore proper operation.

Once potential issues are identified, follow these steps for a structured approach:

- Begin by inspecting the control panel for error codes or indicators.

- Test each sensor individually to confirm accurate readings.

- Check all electrical connections for stability and integrity.

- Consult the technical specifications to ensure compliance with operational standards.

By methodically addressing these areas, you can enhance the performance of temperature regulation systems and ensure a reliable and efficient operation.

Inspecting Fuel Lines and Tanks

Examining the pathways and reservoirs that transport and store fuel is crucial for ensuring optimal performance and safety. Regular checks can help identify potential issues before they escalate into major problems.

Begin your inspection by following these essential steps:

- Visual Inspection: Examine all visible fuel conduits and tanks for signs of wear or damage. Look for cracks, leaks, or corrosion.

- Check Connections: Ensure that all fittings and joints are secure. Loose connections can lead to fuel leaks.

- Inspect for Blockages: Ensure that fuel lines are clear and free from obstructions. Debris can impede fuel flow, leading to performance issues.

- Evaluate Tank Condition: Assess the integrity of the storage tanks. Check for rust or any signs of deterioration that could compromise fuel quality.

- Smell for Leaks: Be aware of any unusual odors, as they can indicate fuel leaks that require immediate attention.

After completing the inspection, take appropriate actions based on your findings. Replace any damaged parts and clean the lines as necessary to maintain efficiency and safety.

Safety Tips for Heater Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. This section provides essential guidelines to follow when working on heating devices, promoting a secure and effective working environment.

Preparation Before Starting

- Read the device’s documentation thoroughly to understand its components and functionality.

- Gather all necessary tools and materials to avoid interruptions during the process.

- Ensure the work area is clean and free from any flammable materials.

Protective Measures

- Always wear appropriate personal protective equipment, such as gloves and safety glasses.

- Turn off the power supply to the unit before starting any work to prevent electrical hazards.

- Keep a fire extinguisher nearby in case of emergency situations.

Following these precautions will help create a safer atmosphere while conducting necessary adjustments or fixes.