In the world of compact all-terrain vehicles, ensuring optimal performance and longevity is essential for an enjoyable experience. Regular upkeep not only enhances functionality but also prevents unforeseen issues that could arise during use. This section aims to provide valuable insights into the care and adjustment of such vehicles, ensuring they remain in peak condition for adventure.

Understanding the intricacies of these machines can empower owners to tackle common challenges effectively. By familiarizing yourself with essential techniques and practices, you can take control of maintenance tasks that are crucial for sustained performance. This guidance will cover various aspects of upkeep, ensuring that users can confidently navigate the demands of their vehicle.

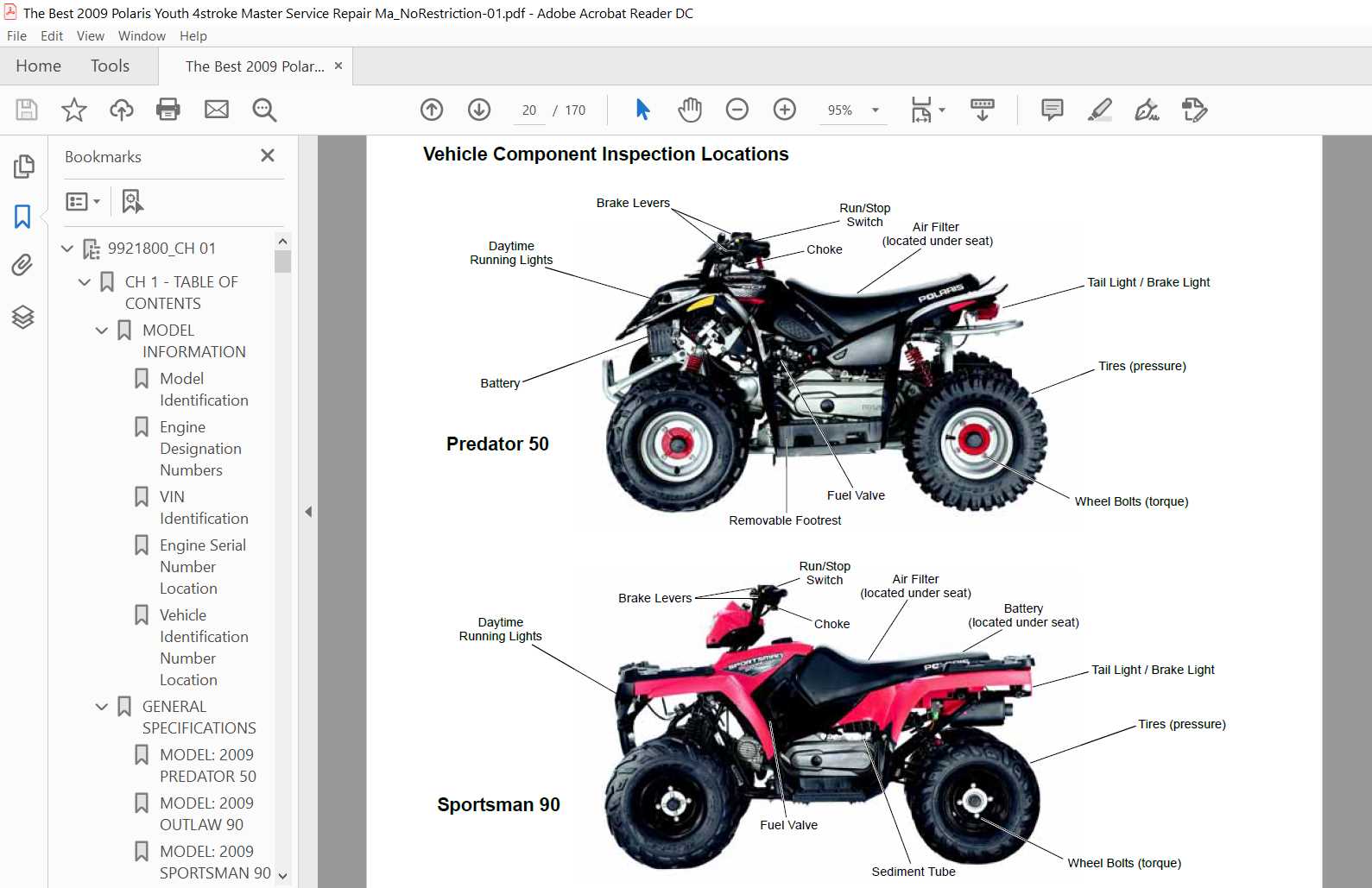

This section offers insights into a compact recreational vehicle designed for younger riders. It emphasizes the importance of maintenance and understanding the various components that contribute to the vehicle’s performance and safety.

Key Features of the Vehicle

- Compact design for easy handling

- Powerful engine suited for various terrains

- Lightweight structure enhancing maneuverability

Importance of Regular Maintenance

Consistent upkeep is vital to ensure longevity and optimal performance. Regular checks can prevent unexpected breakdowns and enhance safety during use.

- Enhances overall performance

- Prevents costly repairs

- Ensures rider safety

Common Issues and Troubleshooting

- Starting difficulties

- Unusual noises during operation

- Handling issues on uneven surfaces

Essential Tools for Maintenance

Having the right tools is crucial for effective upkeep. Below is a list of commonly used tools:

- Wrenches and sockets

- Screwdrivers of various sizes

- Lubricants and cleaning supplies

Safety Precautions

Before performing any maintenance, it’s essential to take safety measures to avoid accidents:

- Wear appropriate protective gear

- Ensure the vehicle is stable

- Work in a well-ventilated area

Conclusion

Understanding the fundamental aspects of this compact vehicle, along with its care, can significantly enhance the riding experience. A proactive approach to maintenance ensures both safety and enjoyment.

Common Issues with Polaris Predator 50

When it comes to small off-road vehicles, users may encounter several typical challenges that affect performance and reliability. Understanding these common problems can help owners troubleshoot effectively and maintain their machines in optimal condition.

Engine Performance Issues: One frequent concern is related to engine efficiency. Riders often experience difficulty in starting or inconsistent power delivery, which may stem from fuel supply problems or electrical system faults.

Braking System Malfunctions: Another area that often requires attention is the braking system. Users may notice reduced stopping power or strange noises, indicating potential wear or issues within the brake components that should be assessed promptly.

Tire Wear and Handling: The condition of tires plays a crucial role in overall handling and safety. Uneven wear patterns can lead to poor traction and stability, necessitating regular inspection and maintenance to ensure a smooth ride.

Transmission Troubles: Lastly, transmission-related difficulties can arise, impacting gear shifting and responsiveness. This may be caused by worn components or inadequate lubrication, highlighting the importance of routine checks and servicing.

Tools Needed for Repairs

When it comes to maintaining your vehicle, having the right equipment is essential for ensuring efficient and effective work. A well-equipped toolkit not only simplifies tasks but also enhances safety during the process. Here, we outline the necessary implements that will aid in your maintenance efforts.

Essential Tools

Various implements are required for different tasks. Below is a list of the most crucial tools that will assist you in various maintenance activities.

| Tool | Purpose |

|---|---|

| Wrench Set | For loosening and tightening bolts and nuts. |

| Screwdriver Set | To drive screws into place and remove them as needed. |

| Pliers | Useful for gripping and bending materials. |

| Jack | To lift the vehicle for access to the undercarriage. |

| Torque Wrench | To ensure proper tightening of fasteners to avoid damage. |

Safety Equipment

In addition to the tools mentioned, safety gear is also critical to prevent injuries. Always make sure to use protective eyewear, gloves, and a mask when necessary to ensure a safe working environment.

Step-by-Step Maintenance Guide

Proper upkeep of your vehicle is essential for ensuring its longevity and optimal performance. This guide provides a comprehensive approach to routine care, enabling you to keep your machine in excellent condition.

Follow these steps for effective maintenance:

- Regular Inspections:

- Check the tire pressure and tread depth.

- Inspect the brakes for wear and functionality.

- Examine fluid levels, including oil and coolant.

- Cleaning:

- Wash the exterior to remove dirt and debris.

- Clean the air filter to ensure proper airflow.

- Wipe down surfaces to prevent corrosion.

- Lubrication:

- Apply lubricant to moving parts such as chains and joints.

- Check and grease wheel bearings as needed.

- Battery Maintenance:

- Inspect battery terminals for corrosion.

- Ensure connections are tight and secure.

- Charge the battery regularly to prevent depletion.

- Scheduled Servicing:

- Follow manufacturer recommendations for interval servicing.

- Replace worn or damaged parts promptly.

By adhering to this maintenance routine, you will enhance the reliability and safety of your vehicle, ensuring it remains ready for any adventure.

How to Troubleshoot Electrical Problems

Electrical issues can often be challenging to identify, but with a systematic approach, you can pinpoint the root cause. Understanding the common signs of electrical malfunctions and knowing how to methodically investigate each component is crucial for effective resolution.

Identifying Symptoms

Start by observing any unusual behavior in the equipment. Look for signs such as flickering lights, unexpected shutdowns, or failure to start. These symptoms can indicate underlying electrical faults that require immediate attention.

Checking Connections and Components

Inspect all wiring and connectors for any visible damage, corrosion, or loose fittings. A secure and intact connection is vital for proper functionality. Ensure that all cables are correctly seated and that no frayed wires are present. Testing individual components with a multimeter can also help determine their operational status and isolate the issue.

Replacing the Air Filter

Maintaining optimal engine performance requires regular attention to the air filtration system. A clean air filter ensures that the engine receives the proper amount of air, which is essential for efficient combustion and overall functionality.

Steps to Change the Air Filter:

First, locate the air filter housing. This is typically found near the engine and may be secured with screws or clips. Carefully remove these fasteners to access the filter.

Next, gently take out the old filter. Inspect it for dirt and debris, which can restrict airflow. If it appears dirty, it is crucial to replace it with a new filter that matches the specifications of your engine.

Once the new filter is in place, reassemble the housing by securing it with the previously removed screws or clips. Ensure everything is tightly fastened to prevent any air leaks.

Finally, run the engine for a short period to check for any unusual noises or issues. Regularly changing the air filter will enhance performance and extend the life of the engine.

Adjusting the Carburetor Settings

Proper tuning of the fuel delivery system is essential for optimal performance and efficiency. Adjusting the settings ensures the engine receives the correct air-fuel mixture, contributing to smooth operation and longevity.

Here are the steps to effectively adjust the settings:

- Gather necessary tools, including a screwdriver and a tachometer.

- Start the engine and allow it to warm up to operating temperature.

- Locate the adjustment screws on the carburetor.

Follow these guidelines for adjustments:

- Idle Speed: Adjust the idle speed screw until the engine idles smoothly.

- Air-Fuel Mixture: Turn the mixture screw to achieve a steady RPM while monitoring engine response.

- Final Check: Test drive the vehicle to ensure responsiveness and make further adjustments if necessary.

Regular maintenance of the fuel delivery system not only improves performance but also enhances fuel efficiency.

Oil Change Procedure Explained

Changing the lubricating fluid in your vehicle is a crucial maintenance task that ensures optimal performance and longevity. This process involves removing the old oil and replacing it with fresh, clean fluid, which helps keep the engine components running smoothly and reduces wear.

Preparation Steps

Before starting the procedure, gather all necessary tools and materials. You will need a suitable oil filter, the correct type of lubricant, a wrench, and an oil catch pan. Make sure the engine is cool to prevent burns, and park the vehicle on a level surface for safety.

Procedure

Begin by locating the drain plug underneath the engine and position the catch pan beneath it. Carefully unscrew the drain plug and allow the used oil to flow into the pan. Once drained, replace the plug securely. Next, remove the old filter using the wrench and install a new one. Finally, refill the engine with the new oil through the designated opening, ensuring you use the correct amount as specified in the guidelines.

Regular oil changes are essential for maintaining engine health. They help prevent sludge buildup and ensure that moving parts remain well-lubricated.

Checking and Replacing the Battery

This section provides essential guidance for assessing and swapping out the power source of your vehicle. Regular maintenance of the battery ensures optimal performance and longevity, preventing unexpected breakdowns during use.

Inspecting the Battery Condition

Before proceeding with any replacements, it is crucial to evaluate the current state of the battery. Look for signs of corrosion, leaks, or physical damage. A thorough inspection helps determine whether a replacement is necessary or if cleaning and recharging will suffice.

Steps for Replacement

When it becomes evident that a new battery is required, follow these steps to ensure a safe and effective replacement:

| Step | Description |

|---|---|

| 1 | Turn off the vehicle and disconnect the negative terminal first to prevent electrical shorts. |

| 2 | Remove the positive terminal, followed by any securing mechanisms holding the battery in place. |

| 3 | Carefully lift out the old battery, ensuring no spills occur. |

| 4 | Place the new battery in position and secure it, connecting the positive terminal first. |

| 5 | Reconnect the negative terminal and ensure all connections are tight. |

Following these steps will help maintain your vehicle’s reliability and efficiency.

Inspecting the Brake System

Regular assessment of the braking components is crucial for ensuring safety and optimal performance. This process involves checking various elements that contribute to the overall functionality of the braking system.

Key Components to Examine

- Brake Pads: Inspect for wear and tear, ensuring they maintain sufficient thickness.

- Brake Fluid: Check the fluid level and quality, replacing it if it appears contaminated.

- Brake Lines: Look for any signs of leaks, cracks, or damage that could compromise braking efficiency.

- Disc and Drum Condition: Examine for grooves, warping, or other forms of deterioration.

Inspection Procedure

- Start by safely elevating the vehicle to access the brake components.

- Remove the wheels if necessary to gain a clearer view of the brake assembly.

- Carefully assess each part, noting any issues that require attention or replacement.

- Reassemble components and test the braking system to ensure proper function.

Repairing the Suspension Components

The suspension system plays a crucial role in ensuring a smooth and stable ride. Proper maintenance of these elements is essential for optimal performance. Addressing any issues promptly can enhance the overall handling and comfort of the vehicle.

Identifying Common Issues

Before proceeding with maintenance, it’s important to recognize potential problems. Common symptoms include:

- Unusual noises during operation

- Uneven tire wear

- Difficulty in steering

- Excessive bouncing or swaying

Steps for Maintenance

Follow these general steps to maintain the suspension system effectively:

- Inspect all components for wear and damage.

- Clean any dirt or debris from the joints and moving parts.

- Replace worn-out parts as necessary, ensuring to use quality replacements.

- Lubricate the necessary joints to ensure smooth movement.

- Test the system after maintenance to confirm proper functionality.

Handling Tire Maintenance and Replacement

Proper care and timely replacement of tires are crucial for ensuring safety and optimal performance. Regularly inspecting tire condition and maintaining the correct pressure can significantly extend their lifespan and enhance handling capabilities.

Routine Inspections

Performing regular checks for wear, damage, and inflation levels is essential. Look for signs of uneven wear, punctures, or cracks that may compromise performance. Maintaining the recommended air pressure not only improves fuel efficiency but also ensures better traction and stability on the road.

Replacement Guidelines

When it’s time for new tires, select ones that suit the vehicle’s specifications and intended use. Proper installation and alignment are critical for maintaining balance and safety. Consider consulting a professional for installation to ensure that all aspects are addressed effectively.

When to Seek Professional Help

Identifying when to call in an expert can be crucial for maintaining optimal performance and safety. Some situations require specialized knowledge and tools that go beyond basic troubleshooting. Recognizing these instances can save time and prevent further complications.

Signs of Complex Issues

Unusual noises, persistent malfunctions, or visible damage are often indicators that professional intervention is necessary. If basic checks do not resolve the problem, it may signal deeper mechanical concerns that require thorough examination.

Safety Considerations

Any situation that poses a risk to safety should be taken seriously. If operation seems dangerous or if there is uncertainty about handling repairs, seeking assistance from a qualified technician is advisable. Their expertise can ensure that both the equipment and the user remain safe.