Marine propulsion systems are complex and require regular attention to ensure long-lasting performance. Proper upkeep and the ability to recognize early signs of potential issues can greatly extend the life of any marine drive mechanism. This guide serves as an essential resource for understanding the key aspects of maintaining these systems, providing a foundation for addressing common challenges encountered on the water.

Understanding the Essentials of Maintenance is crucial for any vessel owner. This section explores fundamental practices, from regular inspections to preventive measures, aimed at preserving the drive’s condition and efficiency. By delving into these topics, you will gain the knowledge to identify symptoms of wear and tear before they develop into serious complications.

Additionally, this guide includes step-by-step troubleshooting techniques designed to empower users to address various technical issues independently. Whether it’s simple upkeep or more involved repairs, these methods offer insights into each stage of the process, helping to restore functionality with minimal downtime and cost.

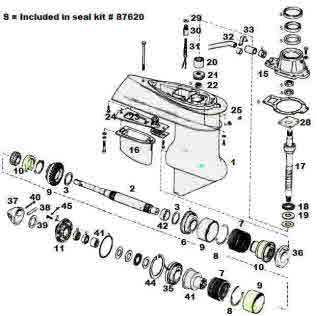

Understanding the OMC Cobra Outdrive System

The propulsion mechanism in marine vessels plays a critical role in delivering power from the engine to the water, allowing efficient movement and control. This system combines various components that work together to transfer torque, enabling smooth navigation and stability. Knowing the key functions and parts involved in this setup can enhance your comprehension of how these systems operate and facilitate troubleshooting when necessary.

In essence, this mechanism includes an assembly of gears, shafts, and propellers that translate engine force into forward or reverse motion. By converting rotational energy to thrust, this configuration provides the vessel with responsive handling and adaptability, which is especially important in varying water conditions.

Recognizing common elements within the structure, like the drive shaft, propeller, and gear housing, can help you identify where issues might arise. These components endure significant stress, and their alignment and condition are essential for optimal performance. With regular checks and a basic understanding of how these parts work together, the system’s reliability and efficiency can be maintained effectively.

Common Issues with Cobra Outdrive

This section explores typical malfunctions that may arise in marine propulsion systems, addressing frequent points of wear and operational challenges. Recognizing these issues early on helps prevent further complications and supports smoother sailing experiences.

Symptoms of Wear and Tear

Over time, various components are subject to natural deterioration due to frequent use and exposure to harsh marine environments. Key indicators can help identify when parts are nearing the end of their service life.

- Strange Noises: Grinding or whining sounds often signal friction between metal parts, which can stem from inadequate lubrication or worn gears.

- Shifting Problems: Difficulty shifting can indicate mechanical misalignments or issues within the control cables.

- Overheating: High temperatures may result from inadequate cooling or water intake blockages, affecting overall performance.

Inspection Points for Consistent Operation

Regular checks help ensure that all essential components are funct

Maintenance Tips for Long-Term Use

Regular care and inspection are essential for ensuring the longevity and reliable performance of your marine system. By adopting a few preventative maintenance practices, you can help minimize wear, prevent damage, and ensure that your equipment runs smoothly over time.

Lubricate Moving Parts: Apply suitable lubricants to all moving components to reduce friction, prevent rust, and enhance the performance of each part. Regular lubrication helps maintain the smooth operation of mechanical sections and extends the life of the entire system.

Inspect Seals and Gaskets: Regularly check seals and gaskets for wear, as these elements prevent water intrusion. Replace any compromised seals promptly to avoid potential damage and ensure waterproofing integrity.

Flush After Every Use: After each outing, flush the system with fresh water to remove salt, sand, and other residues. This prevents corrosion and helps keep internal parts clean and

Signs of Outdrive Malfunction

Recognizing symptoms of mechanical issues in marine propulsion systems is essential for timely intervention and ensuring a smooth boating experience. Identifying these signs early can prevent more significant problems and costly repairs.

Unusual Sounds

One of the most noticeable indicators of malfunction is the presence of abnormal noises. Listen for:

- Grinding: A harsh, metallic sound, often indicating worn gears or misalignment.

- Rattling: A loose part or component may cause a repetitive rattling sound, especially at low speeds.

- Whining: A high-pitched whine might point to issues with bearings or inadequate lubrication.

Performance Changes

Sudden shifts in performance are another common symptom of mechanical issues. Be mindful of:

- Loss of Power: Reduced thrust or speed can indicate internal wear or damage.

DIY Troubleshooting Techniques

Effective troubleshooting of marine propulsion systems can be simplified with a structured approach. By understanding common issues and systematically testing each component, enthusiasts can often resolve problems on their own, saving time and resources.

- Check Connections: Begin by examining electrical connections, fuel lines, and hoses for loose or corroded parts. A simple visual inspection often reveals problems that can be fixed immediately.

- Identify Symptoms: Listen for unusual noises or note any unusual vibrations. These signs often hint at specific mechanical issues, helping narrow down possible causes.

- Inspect for Wear: Regularly check for wear and tear on moving parts. Components such as seals, bearings, and gaskets are subject to degradation and may need replacement over time.

- Test Fuel System: If there are power issues, verify the fuel system for any blockages, leaks, or contamination. Replacing fuel filters and cleaning injectors can significantly improve performance.

-

Essential Tools for Repairs

When undertaking maintenance or restoration tasks, having the right instruments at your disposal is crucial for achieving effective results. A well-equipped workspace not only streamlines the process but also enhances safety and efficiency. Below is a list of indispensable tools that every technician should consider having on hand for various tasks.

- Socket Set: A comprehensive set of sockets in various sizes is essential for loosening and tightening bolts and nuts.

- Wrenches: Adjustable and fixed wrenches allow for gripping and turning fasteners effectively.

- Screwdrivers: A range of flathead and Phillips screwdrivers is necessary for handling different types of screws.

- Torque Wrench: This tool is critical for applying a specific torque to fasteners, ensuring proper tightness without damage.

- Pliers: Needle-nose and standard pliers are useful for gripping, twisting, and cutting wire.

- Multimeter: Essential for testing electrical components, this device measures voltage, current, and resistance.

- Work Light: Adequate illumination is important for visibility in tight or dimly lit spaces.

In addition to the tools listed, having a well-organized toolbox can greatly enhance your efficiency and make the repair process smoother. By ensuring that you have these essential instruments readily available, you can tackle maintenance tasks with confidence.

Replacing Key Components Safely

Ensuring the safe replacement of vital elements in your marine propulsion system is crucial for maintaining optimal performance and longevity. Proper procedures and precautions can prevent accidents and damage during the process.

Before starting any replacement, it is essential to gather the necessary tools and materials. Here are some recommended steps to follow:

- Gather Tools and Materials:

- Wrenches and sockets

- Safety goggles and gloves

- Replacement parts

- Cleaning supplies

- Prepare the Work Area:

- Ensure the environment is well-lit and organized.

- Remove any unnecessary items to avoid clutter.

- Disconnect Power Sources:

- Turn off all electrical systems.

- Disconnect the battery to prevent accidental starts.

- Follow Manufacturer Guidelines:

- Consult specifications for each component.

- Use recommended replacement parts to ensure compatibility.

- Handle Components with Care:

- Support heavy parts securely during removal and installation.

- Avoid damaging seals or gaskets.

- Test the System:

- Once all components are replaced, conduct a thorough inspection.

- Reconnect the power and test for proper functionality before taking to water.

By adhering to these safety measures, you can effectively manage the replacement of critical parts, ensuring a reliable and efficient operation for your vessel.

Lubrication and Fluids Guide

Proper maintenance of marine propulsion systems requires a thorough understanding of the various lubricants and fluids essential for optimal performance. Ensuring that each component is adequately serviced with the correct substances not only enhances functionality but also extends the lifespan of the entire system.

It is crucial to utilize high-quality lubricants specifically designed for marine applications. These products are formulated to withstand harsh conditions, including exposure to water and varying temperatures. Regular checks and timely replacements of these fluids will help prevent wear and tear on critical parts.

Moreover, following the manufacturer’s recommendations regarding fluid specifications is vital. This includes adhering to the prescribed intervals for oil changes and ensuring the use of suitable gear oils. Regular monitoring of fluid levels will also contribute to maintaining peak operational efficiency.

In summary, a well-planned lubrication routine, combined with the appropriate fluid types, is key to achieving reliable performance and longevity in marine propulsion systems.

Electrical System Checks and Repairs

Ensuring the functionality of the electrical system is crucial for optimal performance and safety. This section focuses on systematic evaluations and solutions for common issues that may arise within the electrical framework of your vessel. By conducting thorough inspections and applying the appropriate fixes, you can enhance the reliability of the onboard systems.

Initial Inspection should begin with a visual assessment of all wiring and connections. Look for any signs of corrosion, fraying, or loose terminals that could lead to poor conductivity or failures. Ensure that all connections are secure and free of moisture.

Testing Components involves using a multimeter to check voltage levels and continuity throughout the circuit. Verify that each component functions correctly and that there are no unexpected drops in voltage that might indicate a fault. Pay particular attention to the battery and its terminals, as these are often the source of electrical issues.

Resolving Issues may require replacing damaged components or re-establishing connections. Always use parts that are rated for marine environments to ensure durability and performance. If the problem persists after basic troubleshooting, consider consulting a professional technician to conduct more in-depth diagnostics.

Regular maintenance of the electrical system will not only prolong the lifespan of the components but also enhance the safety and enjoyment of your boating experience. Keeping the system in peak condition is essential for a trouble-free operation.

Winterizing the Cobra Outdrive

Preparing your marine propulsion system for the colder months is essential to ensure its longevity and reliable performance. Proper seasonal maintenance helps protect against potential damage caused by freezing temperatures and moisture accumulation.

The following steps outline the necessary actions to effectively safeguard your unit during the winter season:

Step Action Description 1 Flush the System Run fresh water through the system to remove any salt, dirt, or debris. 2 Drain Fluids Completely drain the gear oil and replace it with new oil to prevent contamination. 3 Winterizing Solution Inject antifreeze into the system to protect internal components from freezing. 4 Inspect Components Check all seals, gaskets, and hoses for wear or damage that may require attention. 5 Cover and Store Use a protective cover to shield the unit from the elements during storage. By following these steps, you can ensure that your propulsion system remains in optimal condition and is ready for use when the warmer weather returns.