For those who rely on powerful outdoor equipment, understanding the intricacies of maintenance is crucial for ensuring longevity and optimal performance. This section delves into essential techniques and insights aimed at empowering users to effectively manage their machinery. By familiarizing oneself with the operational nuances, one can significantly enhance the durability and reliability of their tools.

Effective upkeep not only prolongs the life of the device but also enhances safety and efficiency during use. In this guide, readers will discover a variety of troubleshooting tips, routine maintenance practices, and common issues that may arise. Each aspect is designed to provide practical solutions that can be implemented easily, even by those with limited technical experience.

Furthermore, this resource emphasizes the importance of using the correct techniques and tools, which can make all the difference in addressing any mechanical challenges. With a focus on clarity and accessibility, users will be better equipped to tackle potential problems, ensuring that their outdoor machinery remains in top condition.

Understanding the Husqvarna 460 Rancher

The machine in question is designed for robust performance, appealing to both amateur enthusiasts and seasoned professionals alike. Its power and versatility make it an essential tool for a variety of outdoor tasks, from cutting firewood to handling larger forestry jobs.

Featuring a well-balanced design, this tool offers ease of handling, allowing users to work efficiently for extended periods. The innovative engineering behind its engine ensures optimal fuel consumption while maintaining impressive cutting speed. This combination not only enhances productivity but also contributes to a more environmentally friendly operation.

Regular maintenance is crucial for preserving the longevity and effectiveness of this equipment. Understanding its components and functionality can significantly impact performance and reliability. With proper care, users can expect consistent results and a satisfying experience every time they engage in their outdoor projects.

In summary, mastering the features and upkeep of this powerful tool empowers users to tackle a range of tasks with confidence, making it a worthwhile investment for anyone involved in outdoor work.

Key Features of the Chainsaw

This section explores the essential attributes that define a high-performance cutting tool, focusing on aspects that enhance usability, efficiency, and durability. Understanding these features can help users select the right equipment for their needs, ensuring a reliable and effective experience in various cutting tasks.

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a robust power unit that delivers impressive cutting force, allowing for swift and efficient operation. |

| Lightweight Design | The ergonomic and lightweight structure facilitates ease of handling, reducing fatigue during extended use. |

| Automatic Oiling System | This feature ensures that the bar and chain receive consistent lubrication, promoting longevity and optimal performance. |

| Easy Start Technology | Innovative starting mechanisms simplify ignition, making it easier for users to get started quickly. |

| Safety Features | Incorporates multiple safety mechanisms such as chain brakes and throttle locks to enhance user protection during operation. |

| Vibration Reduction | Advanced vibration dampening systems minimize user fatigue and improve comfort, enabling longer periods of use. |

Common Issues Faced by Users

When operating outdoor power equipment, users often encounter a variety of challenges that can affect performance and reliability. Understanding these common problems is essential for maintaining optimal functionality and ensuring longevity of the equipment.

- Starting Difficulties: Many users report issues with initiating the engine, often caused by fuel-related problems, stale gasoline, or improper starting techniques.

- Chain Tension Problems: Maintaining the correct chain tension is crucial. An improperly tensioned chain can lead to excessive wear or even derailment during operation.

- Fuel System Blockages: Clogs in the fuel lines or filters can hinder the flow of fuel, resulting in inconsistent performance or stalling.

- Overheating: Users may experience overheating due to inadequate lubrication, clogged cooling fins, or prolonged use without breaks.

- Vibration Issues: Excessive vibration can be a sign of unbalanced components, leading to user discomfort and potential damage to the equipment.

Addressing these common concerns not only enhances the user experience but also extends the lifespan of the equipment.

Essential Tools for Repair

When it comes to maintaining outdoor power equipment, having the right instruments is crucial for effective service and longevity. A well-equipped toolkit not only simplifies the task but also ensures safety and efficiency during the process.

- Wrenches: Various sizes are necessary for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are essential for handling different screws.

- Socket Set: A complete socket set is ideal for quick and secure fastening.

- Pliers: Useful for gripping, twisting, and cutting wire or small components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications.

Additionally, some specialty tools can enhance the overall efficiency of the work:

- Chain Breaker: Essential for repairing or replacing chains.

- Feeler Gauges: Used for measuring gaps or clearances accurately.

- Multimeter: Helps diagnose electrical issues effectively.

Equipping yourself with these essential instruments will facilitate smoother maintenance and ensure that your equipment remains in optimal working condition.

Step-by-Step Maintenance Guide

Proper upkeep of your equipment is essential for its longevity and optimal performance. This guide outlines a systematic approach to maintaining your device, ensuring it operates efficiently and reliably for years to come.

Essential Maintenance Steps

- Check and Clean the Air Filter

- Remove the air filter cover.

- Take out the filter and clean it with soap and water.

- Allow it to dry completely before reinserting.

- Inspect the Spark Plug

- Remove the spark plug using a wrench.

- Check for wear and replace if necessary.

- Ensure the gap is set to the manufacturer’s specifications.

- Sharpen the Chain

- Secure the chain in a vise.

- Use a file to sharpen each tooth, maintaining the correct angle.

- Check for any damage and replace if needed.

Additional Tips for Longevity

- Regularly check and tighten all screws and bolts.

- Store the equipment in a dry, protected area when not in use.

- Use appropriate fuel and oil to avoid engine issues.

Following these maintenance steps will help ensure your equipment remains in excellent working condition and ready for any task. Regular checks and timely repairs will contribute significantly to its performance and lifespan.

Troubleshooting Engine Problems

When faced with engine issues, a systematic approach can help identify the root cause of the malfunction. Understanding common symptoms and their potential triggers allows for effective diagnosis and resolution. Regular maintenance can also prevent many problems from arising in the first place.

Start by examining the fuel system. Ensure that the fuel is fresh and free from contaminants, as stale or dirty fuel can lead to poor performance. Check the fuel lines for blockages or leaks, and inspect the filter for clogs. A clogged filter can restrict fuel flow, causing the engine to struggle or stall.

Next, assess the ignition system. Verify that the spark plug is clean and properly gapped. A worn or faulty spark plug may fail to ignite the fuel-air mixture, resulting in misfires or difficulty starting. Additionally, inspect the ignition coil and wiring for signs of damage or wear.

Air intake issues can also lead to engine problems. Ensure that the air filter is clean and unobstructed. A dirty filter can hinder airflow, affecting engine performance and efficiency. Check for any blockages in the intake system that might restrict airflow.

Finally, examine the overall condition of the engine components. Look for any signs of wear or damage, such as leaks or unusual noises. Regularly monitoring these aspects can help catch issues early and prolong the life of the equipment.

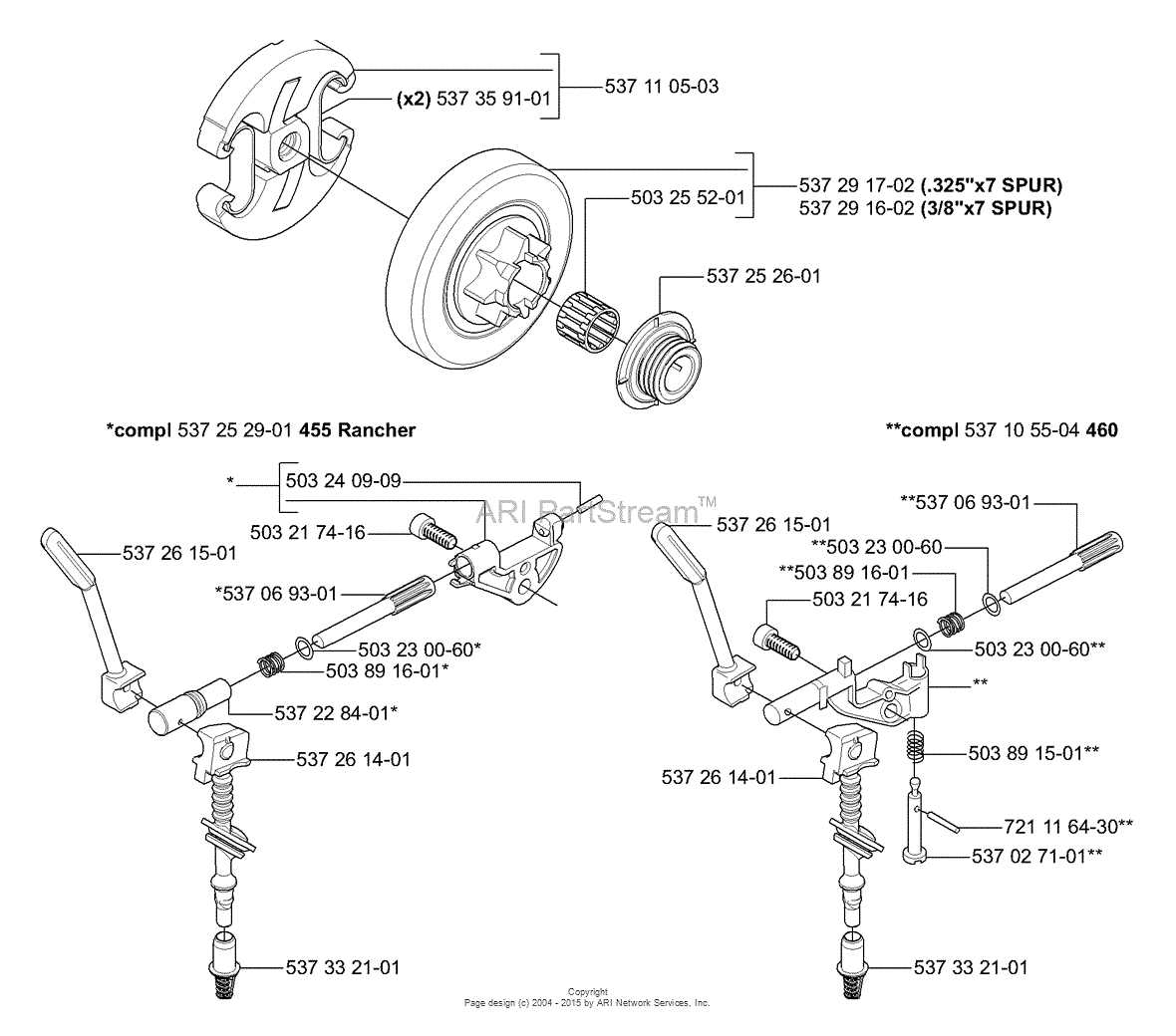

Chain and Bar Replacement Process

Replacing the chain and guide bar on a cutting tool is an essential maintenance task that ensures optimal performance and safety. Regularly updating these components not only enhances cutting efficiency but also prolongs the lifespan of the equipment. This process, while straightforward, requires attention to detail and adherence to specific steps for a successful outcome.

Necessary Tools and Safety Precautions

Before starting the replacement, gather the required tools, which typically include a wrench, screwdriver, and safety gloves. It is crucial to ensure the device is powered off and the spark plug is disconnected to prevent accidental starts. Additionally, wearing protective eyewear is recommended to shield against any debris that may be released during the process.

Step-by-Step Replacement Procedure

Begin by loosening the tensioning mechanism to relieve pressure on the existing chain. Carefully remove the old chain and guide bar, taking note of their orientation for the installation of the new components. Position the new bar and chain, ensuring proper alignment. Once in place, tighten the tensioning mechanism to achieve the correct chain tension–this is vital to avoid excessive wear during operation. Finally, double-check all fastenings and reconnect the spark plug before testing the tool for functionality.

Following these steps will ensure a smooth and efficient replacement process, resulting in improved performance and cutting precision.

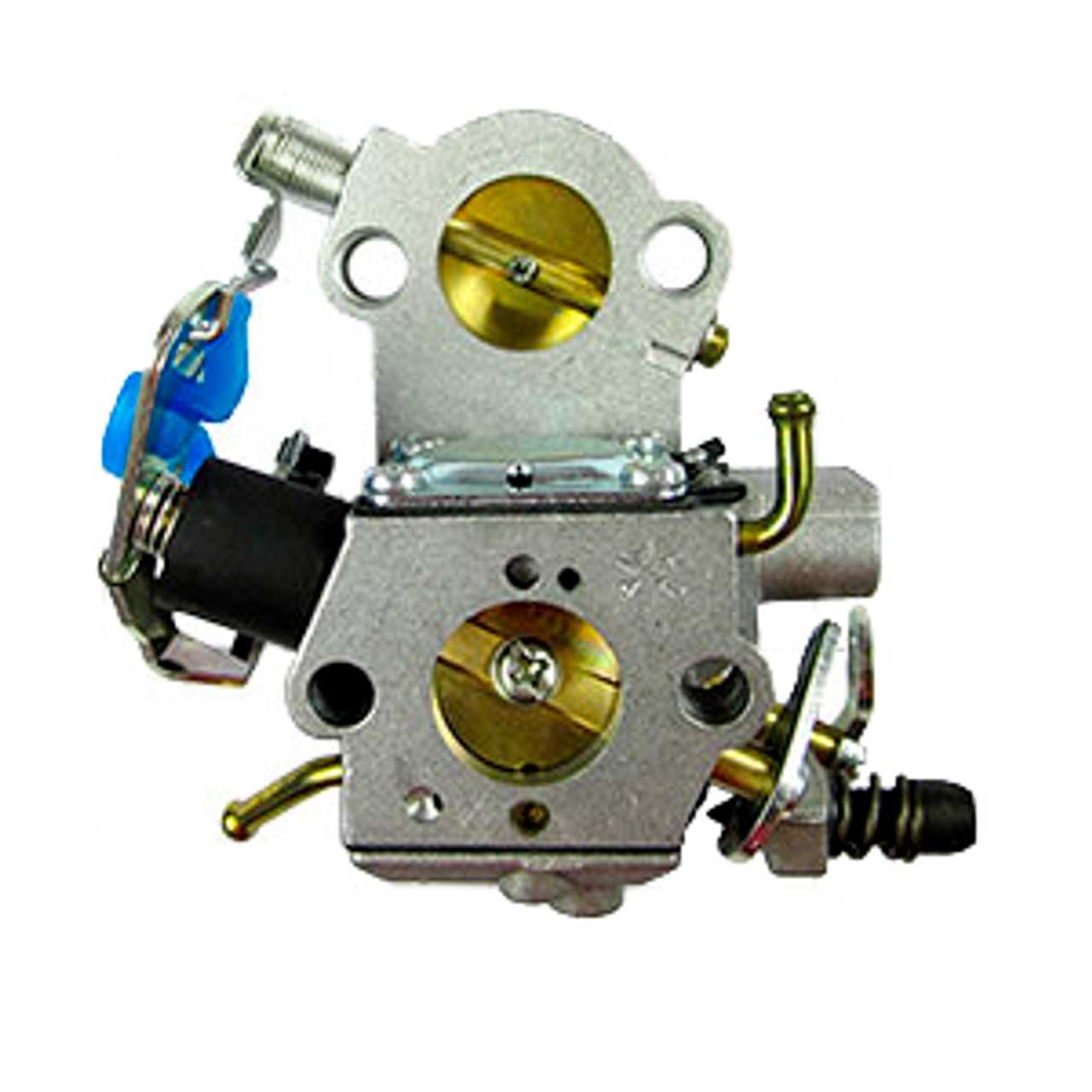

Fuel System Inspection Techniques

Ensuring optimal performance of any engine necessitates a thorough evaluation of its fuel system. This critical component influences efficiency, reliability, and overall functionality. Proper inspection techniques can identify potential issues before they escalate, facilitating timely maintenance and enhancing longevity.

Key Components to Inspect

- Fuel Tank: Check for contamination, rust, or debris.

- Fuel Lines: Inspect for cracks, leaks, or blockages.

- Fuel Filter: Ensure it is clean and free of obstructions.

- Carburetor: Look for signs of wear and ensure proper adjustment.

- Fuel Pump: Test for proper operation and check for leaks.

Inspection Techniques

- Visual Inspection: Start with a thorough visual examination of all components. Look for signs of wear, damage, or corrosion.

- Leak Testing: Apply pressure to the system to identify any leaks. This can be done using specialized tools designed for this purpose.

- Flow Testing: Measure the fuel flow rate to ensure it meets the manufacturer’s specifications.

- Pressure Testing: Check the fuel pressure at various points in the system to ensure it remains within acceptable limits.

- Cleaning Procedures: Regularly clean filters and carburetors to prevent buildup that can affect performance.

By adhering to these techniques, users can maintain a healthy fuel system, thereby enhancing the overall performance and reliability of their equipment.

Electrical Components and Wiring Checks

This section focuses on the crucial aspects of assessing the electrical systems within outdoor power equipment. Ensuring that these components are functioning correctly is vital for the overall performance and safety of the machinery. Regular inspections can help identify potential issues before they lead to significant malfunctions.

Common Electrical Issues

Electrical problems can manifest in various forms, including faulty connections, damaged wires, or malfunctioning components. Recognizing these issues early can prevent costly repairs and enhance the longevity of the equipment. Below are some common symptoms of electrical faults:

| Symptom | Possible Cause |

|---|---|

| Equipment won’t start | Dead battery or faulty ignition switch |

| Intermittent operation | Loose connections or worn wiring |

| Lights flickering | Weak power supply or short circuit |

| Burning smell | Overheating components or damaged insulation |

Inspection Procedure

To conduct a thorough inspection, follow these steps:

- Disconnect the power source to ensure safety.

- Examine all visible wiring for signs of wear or damage.

- Test connections for continuity using a multimeter.

- Inspect electrical components such as switches, fuses, and relays for proper operation.

By adhering to this inspection procedure, users can maintain the efficiency and reliability of their outdoor equipment, ultimately enhancing its performance and safety.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the equipment being serviced. Adhering to specific guidelines can help create a safer work environment.

Essential Safety Measures

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the workspace is well-lit and free from clutter to avoid tripping hazards.

- Disconnect the power source or remove the fuel before beginning any maintenance tasks.

- Utilize the correct tools and equipment for the job to prevent mishandling.

Working with Care

- Read and understand any accompanying documentation before starting work.

- Keep bystanders and pets at a safe distance from the work area.

- Be cautious of sharp edges and moving parts while handling machinery.

- Dispose of any waste materials responsibly to avoid environmental hazards.

Cleaning and Care Recommendations

Proper maintenance is essential for ensuring the longevity and efficiency of your outdoor power equipment. Regular cleaning and care not only enhance performance but also prevent potential issues that could arise from neglect. By following a few straightforward guidelines, you can keep your machine in optimal condition.

Routine Cleaning Steps

To maintain the performance of your equipment, follow these cleaning steps:

- Always disconnect the spark plug before cleaning.

- Remove any debris, such as dirt, leaves, and sawdust, from the exterior surfaces.

- Use a soft brush or cloth to clean the air filter; replace it if damaged.

- Inspect the chain and bar for buildup, cleaning them with a suitable solvent.

- Wipe down any metal parts to prevent rust formation.

Care Recommendations

In addition to regular cleaning, consider the following care tips:

- Check the oil level frequently and top up as necessary.

- Sharpen the cutting tools regularly for effective operation.

- Store the equipment in a dry place to avoid moisture-related issues.

- Inspect all hoses and connections for signs of wear or damage.

- Follow the manufacturer’s guidelines for any seasonal maintenance tasks.

Upgrading Parts for Performance

Enhancing the capabilities of your outdoor equipment can significantly improve its efficiency and longevity. By focusing on specific components, you can achieve better performance, ensuring that your machine operates at its full potential. Upgrading parts not only boosts power but can also lead to smoother operation and increased durability, making your investment worthwhile.

Key Components to Consider

When looking to enhance performance, certain elements are crucial. The engine plays a vital role, and upgrading to a high-performance version can lead to increased horsepower and torque. Additionally, considering the exhaust system can improve airflow, resulting in better combustion and overall performance. Replacing standard parts with high-quality alternatives can lead to significant gains.

Benefits of Enhanced Components

Investing in upgraded components often results in a more reliable and efficient machine. Enhanced parts contribute to better fuel efficiency, allowing for longer operational times without the need for frequent refueling. Furthermore, improved durability means less frequent repairs, ultimately saving you time and money in the long run.

Resources for Further Assistance

When working on equipment, having access to reliable information and support is crucial. This section provides various resources to help users troubleshoot issues, obtain parts, or seek expert advice. By utilizing these tools, you can enhance your experience and ensure optimal performance of your machinery.

| Resource Type | Description | Link/Contact |

|---|---|---|

| Official Website | Access to product specifications, user guides, and updates. | Visit Here |

| Online Forums | A community space for discussing issues, sharing tips, and connecting with other users. | Join the Forum |

| Customer Support | Contact for professional assistance and troubleshooting guidance. | Call: 1-800-123-4567 |

| Instructional Videos | Visual guides that demonstrate maintenance and repair procedures. | Watch Videos |

| Local Dealers | Authorized sellers that offer parts and expert services. | Find a Dealer |