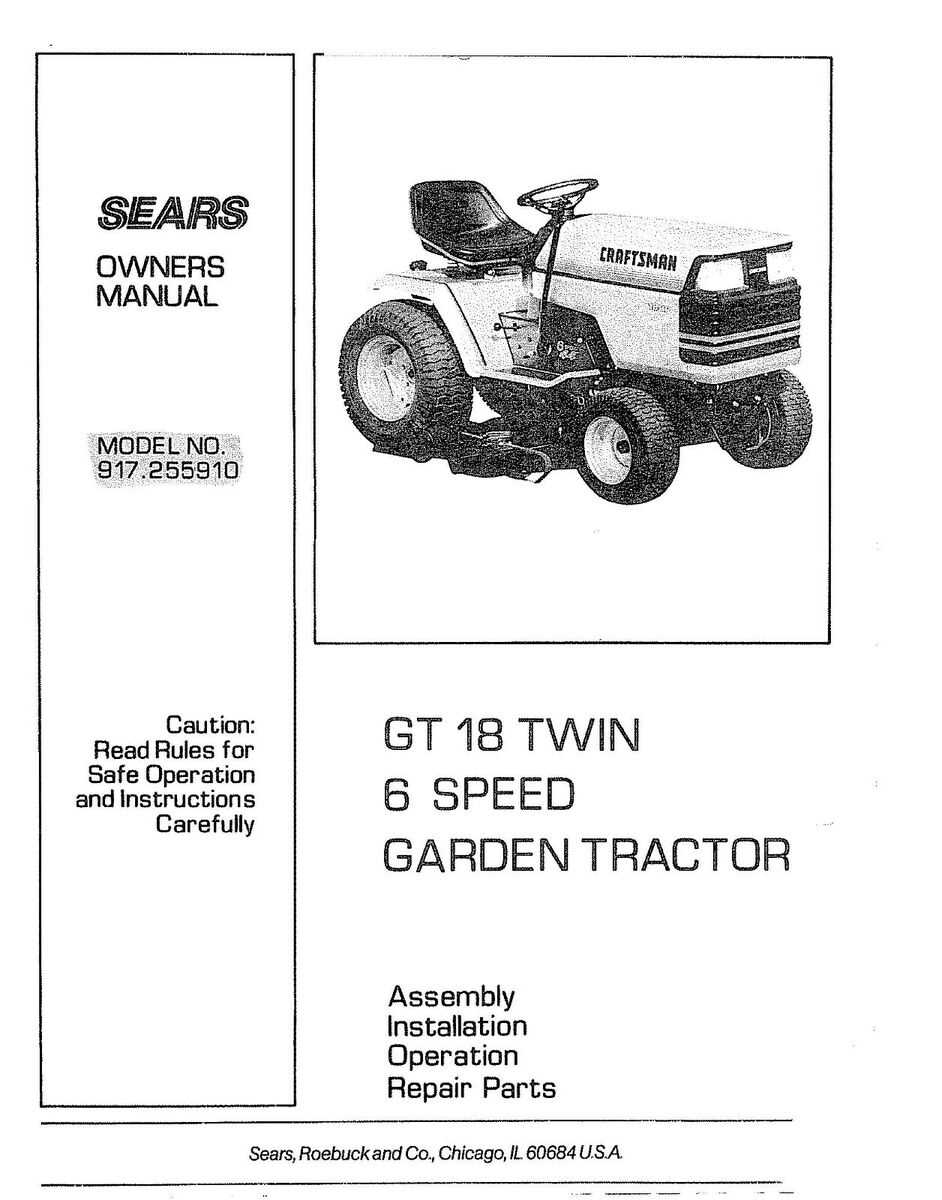

Maintaining outdoor machinery is essential for ensuring longevity and optimal performance. This section provides comprehensive insights into the upkeep of various garden machines, focusing on techniques and best practices to enhance their functionality. Understanding how to care for these tools can prevent unexpected issues and improve overall efficiency.

In this guide, you will discover a range of troubleshooting tips and techniques tailored to enhance your machine’s durability. By following these recommendations, you can effectively address common challenges and keep your equipment running smoothly. Emphasizing preventive measures will not only save you time but also extend the lifespan of your valuable tools.

Whether you’re a seasoned enthusiast or a newcomer to garden machinery, this section aims to empower you with the knowledge necessary to tackle maintenance tasks confidently. Explore the various aspects of caring for your equipment, and ensure it remains a reliable ally in your outdoor endeavors.

When operating garden machinery, users may encounter various challenges that can hinder performance. Recognizing these problems early can prevent further complications and ensure smooth functionality.

| Issue | Symptoms |

|---|---|

| Engine Won’t Start | Clicking noise, no ignition |

| Uneven Cutting | Strips of uncut grass, uneven height |

| Excessive Vibration | Shaking during operation, unusual sounds |

| Fuel Leaks | Visible puddles, strong fuel odor |

| Battery Drain | Frequent jump starts required, dim lights |

Tools Required for Repairs

Having the right equipment is crucial when performing maintenance tasks on your equipment. Utilizing appropriate instruments not only enhances efficiency but also ensures safety during the process. Below is a list of essential tools that will aid in addressing common issues.

- Wrenches: A variety of sizes, including adjustable, for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types for various screws.

- Socket Set: Useful for dealing with nuts and bolts in hard-to-reach areas.

- Pliers: Ideal for gripping, twisting, and cutting wires.

- Torque Wrench: Ensures bolts are tightened to the correct specifications.

- Jack Stands: Necessary for safely elevating the equipment during work.

- Oil Filter Wrench: Specialized tool for easy removal of oil filters.

Having these tools at hand can significantly simplify the process and allow for effective troubleshooting and adjustments. Regular inspections and maintenance tasks become more manageable when equipped with the right instruments.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. This section outlines a systematic approach to routine care, helping you maintain functionality and prevent potential issues.

Begin with a Thorough Inspection: Examine all components for wear and damage. Pay special attention to belts, blades, and wheels. Identifying problems early can save time and resources.

Clean the Exterior: Remove any debris or dirt accumulated on the surface. Use a soft brush and water to gently cleanse the exterior, ensuring that air vents remain unobstructed.

Check Fluid Levels: Regularly inspect and top off necessary fluids, including fuel, oil, and coolant. Maintaining appropriate levels is crucial for smooth operation.

Sharpen Blades: Keep cutting tools in peak condition by sharpening them periodically. Dull blades can lead to uneven cuts and increased strain on the engine.

Inspect Tires: Ensure that tires are properly inflated and in good condition. This is vital for stability and maneuverability during use.

Store Properly: At the end of the season, clean thoroughly and store in a dry, sheltered location. This helps protect against weather damage and prolongs the lifespan of your equipment.

Engine Troubleshooting Techniques

Identifying issues with the engine can be a crucial step in ensuring optimal performance. Understanding common symptoms and utilizing effective diagnostic methods can help pinpoint the source of problems.

Common Symptoms to Watch For

- Difficulty starting the engine

- Unusual noises during operation

- Excessive smoke from the exhaust

- Poor acceleration or stalling

Diagnostic Steps

- Check the fuel supply to ensure adequate levels and quality.

- Inspect the air filter for clogs or dirt that may restrict airflow.

- Examine electrical connections for corrosion or loose wiring.

- Test the spark plug for wear or damage, replacing it if necessary.

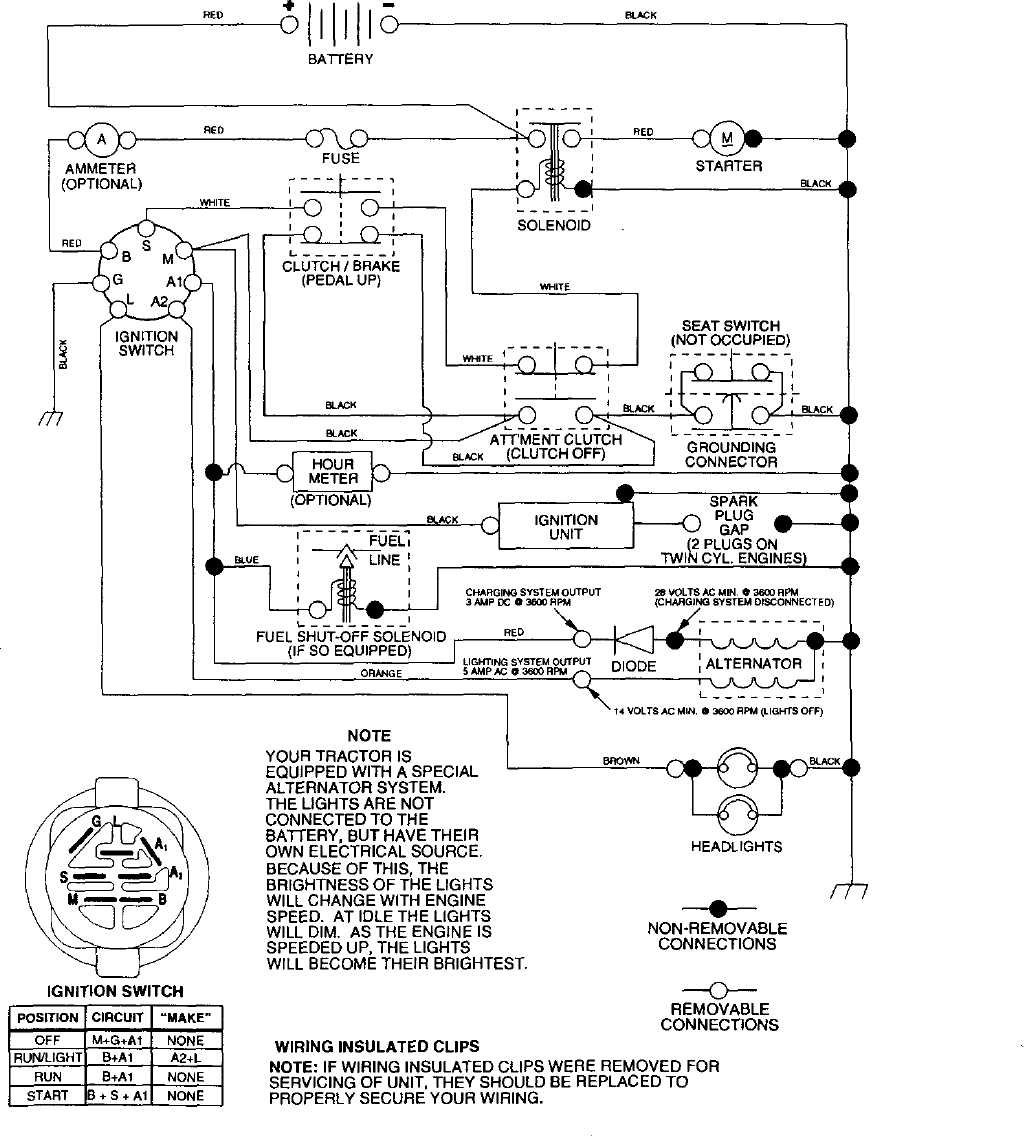

Electrical System Diagnosis

Understanding the electrical system is crucial for ensuring optimal performance and functionality. Proper evaluation of the components involved can help identify potential issues before they escalate into more significant problems.

The following steps outline the diagnostic process:

- Check the battery condition:

- Inspect for corrosion on terminals.

- Measure voltage using a multimeter.

- Ensure proper connections are secure.

- Identify any blown fuses.

- Replace with fuses of the correct amperage.

- Check the fuse box for damage.

- Verify spark plug condition.

- Inspect ignition wires for wear or damage.

- Ensure proper timing adjustments are in place.

- Look for frayed or broken wires.

- Check for loose connections throughout the system.

- Trace wiring diagrams to confirm proper routing.

Following these guidelines will assist in diagnosing electrical concerns effectively, ensuring reliable operation and longevity of the equipment.

Blade and Deck Maintenance Tips

Maintaining the cutting components and surface of your equipment is essential for optimal performance and longevity. Regular care not only enhances efficiency but also ensures safety during operation. Here are some key practices to consider.

- Cleaning: After each use, remove grass clippings and debris from the cutting surface to prevent rust and build-up.

- Inspection: Regularly check blades for damage or dullness. Sharp blades ensure clean cuts and reduce strain on the engine.

- Sharpening: Sharpen blades at least once a season or more frequently if used often. A sharp edge promotes healthier grass and smoother operation.

- Alignment: Ensure blades are properly aligned to prevent uneven cutting and excessive wear.

- Lubrication: Apply lubricant to moving parts to reduce friction and extend the lifespan of your equipment.

By following these simple maintenance steps, you can keep the cutting assembly in top shape, resulting in better performance and a healthier yard.

Tire Care and Replacement Advice

Maintaining optimal performance and safety of your vehicle involves proper attention to the tires. This section provides essential tips for ensuring longevity and functionality, helping you to recognize when tire replacement is necessary.

Regular maintenance can significantly extend the life of your tires. Here are some key practices to follow:

- Check Pressure: Maintain proper inflation levels to ensure stability and efficiency.

- Inspect Tread Depth: Use a tread depth gauge to measure wear; insufficient tread can lead to poor traction.

- Rotate Tires: Change the position of your tires periodically to promote even wear.

- Clean Tires: Remove dirt and debris to prevent buildup that can damage the rubber.

Knowing when to replace your tires is crucial for safety. Look for these indicators:

- Visible cracks or cuts on the tire surface.

- Bulges or blisters indicating internal damage.

- Excessive tread wear, often signaled by a smooth surface.

- Aged tires that have been in service for more than six years.

By following these guidelines, you can ensure your vehicle remains in peak condition and ready for use.

Transmission Issues and Solutions

Understanding common problems related to the drive system is crucial for maintaining optimal performance. This section addresses typical challenges that users may encounter, along with effective strategies to resolve them.

Common Symptoms

Users often notice a range of signs indicating potential troubles within the drive mechanism. These may include unusual noises during operation, difficulty in shifting gears, or a complete lack of movement despite the engine running. Recognizing these symptoms early can prevent more severe complications.

Effective Strategies

To tackle the identified challenges, several approaches can be employed. First, inspecting the fluid levels and quality is essential, as low or contaminated fluid can lead to inadequate operation. Additionally, checking for any obstructions or damage in the linkage system can help restore functionality. Regular maintenance practices, such as cleaning and replacing filters, will also contribute significantly to the longevity of the drive system.

Seasonal Preparation and Storage

Properly getting ready for seasonal changes and ensuring appropriate storage can greatly enhance the longevity and performance of your equipment. Taking the time to prepare before transitioning between different weather conditions is essential for maintaining functionality and preventing issues during use.

To effectively prepare your machine for the upcoming season, follow these steps:

| Task | Description | Frequency |

|---|---|---|

| Cleaning | Remove debris and dirt from the surface and underneath to prevent corrosion. | After each use |

| Fluid Check | Inspect and replace oil, fuel, and coolant to ensure optimal performance. | Seasonally |

| Battery Care | Disconnect and store the battery in a cool, dry place to avoid discharge. | End of season |

| Tire Maintenance | Check tire pressure and tread condition to ensure safety and efficiency. | Monthly |

| Storage | Cover the equipment or store it indoors to protect from harsh weather. | End of season |

Following these guidelines will help preserve your equipment’s functionality, ensuring it remains in peak condition for future use. Regular attention to these details is key to enjoying a reliable experience season after season.

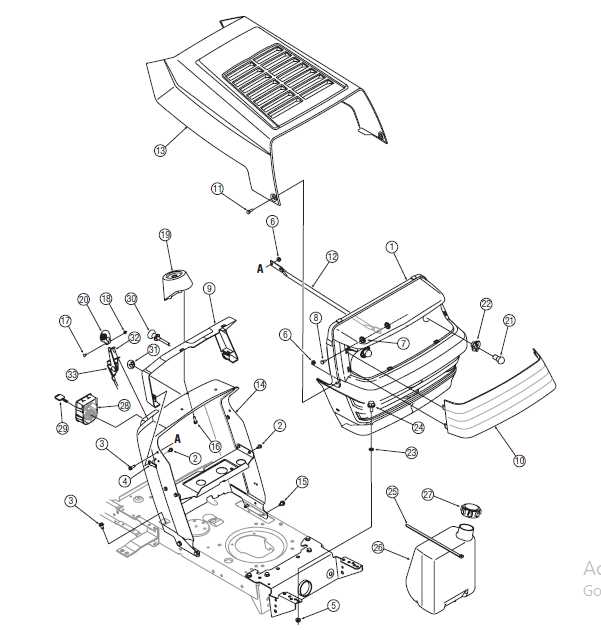

Finding Replacement Parts

Locating suitable components is crucial for maintaining optimal performance and longevity of your equipment. Understanding where to source these items can streamline the upkeep process and ensure you have the necessary parts readily available.

Identifying Compatible Components

Before initiating your search, it’s essential to identify the specific components needed. Check the model number and specifications to find parts that are compatible. This ensures a proper fit and functionality, minimizing the risk of issues down the line.

Where to Source Parts

There are various avenues to explore when looking for components. Local dealers often have a selection of parts, and their staff can offer valuable insights. Additionally, online retailers provide extensive inventories, allowing for easy comparison and selection. Don’t forget to consider aftermarket options, which may offer competitive pricing and quality.

Safety Precautions During Repairs

Ensuring a secure environment is crucial when undertaking maintenance tasks on outdoor equipment. Proper precautions not only safeguard the individual performing the work but also help prevent damage to the machinery. Adhering to safety guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment (PPE) is essential. Always wear appropriate gear, such as gloves, safety goggles, and sturdy footwear. This minimizes the chances of injury from sharp objects or debris while working. Additionally, long sleeves and pants can protect against minor cuts and scrapes.

Before starting any maintenance activity, it is vital to disconnect the power source. Whether it involves removing the battery or disconnecting spark plugs, ensuring that the equipment cannot accidentally start is a fundamental safety step. This precaution prevents unintended activation during servicing.

Ventilation is another important aspect, especially when working with fuel or chemicals. Conduct tasks in a well-ventilated area to avoid inhaling harmful fumes. If indoors, consider using fans or opening windows to facilitate airflow, reducing the risk of exposure to toxic substances.

Lastly, keeping a first aid kit nearby is advisable. In case of an emergency, having basic supplies readily available can make a significant difference. Knowing how to respond to common injuries can further enhance safety while maintaining and caring for equipment.