This section provides essential information for the upkeep and troubleshooting of a popular electric propulsion system, widely used for enhancing boating experiences. Understanding the intricacies of this device can significantly improve its longevity and performance. Whether you are a novice user or an experienced enthusiast, having access to comprehensive guidance is crucial for effective maintenance.

In this guide, you will discover step-by-step procedures, helpful tips, and troubleshooting techniques to ensure optimal functionality of your electric motor. Each part of the unit plays a vital role in its overall performance, and knowing how to address common issues can save time and resources. Through clear instructions and detailed explanations, you will gain the confidence to tackle any challenges that may arise during operation.

Proper care not only enhances the reliability of your propulsion device but also enriches your time on the water. Emphasizing routine checks and maintenance tasks can prevent minor issues from escalating into major repairs. This resource aims to empower you with the knowledge needed to enjoy uninterrupted adventures on the water.

Understanding Common Issues with Terrova Motors

When utilizing electric propulsion systems for watercraft, users may encounter various challenges that can impact performance and functionality. Recognizing these frequent problems is essential for maintaining optimal operation and ensuring a smooth experience on the water. Below, we explore some of the most prevalent concerns associated with these motors.

Power Failure: One of the most common issues is unexpected power loss. This can occur due to battery depletion, poor connections, or damaged wiring. Regular checks on the power source and connections can help prevent this situation.

Steering Malfunctions: Users may notice difficulty in maneuvering their vessels. This could be a result of misalignment in the steering system or wear in the motor components. Ensuring proper calibration and routine maintenance can mitigate these complications.

Noisy Operation: Unusual sounds during operation may indicate internal wear or debris obstructing moving parts. Identifying and addressing these noises promptly can help avoid more severe damage.

Overheating: Excessive heat can lead to reduced efficiency and potential failure. This often stems from prolonged use or inadequate ventilation. Regular inspections and allowing for cooling periods can prolong motor life.

Signal Interference: Communication issues between the remote and the propulsion system can disrupt functionality. Ensuring a clear line of sight and minimizing obstructions can help maintain a stable connection.

Being aware of these potential issues and understanding their causes can empower users to take proactive steps in maintenance and troubleshooting. A comprehensive approach to care can enhance the longevity and reliability of electric propulsion systems.

Essential Tools for Minn Kota Repairs

Having the right set of instruments is crucial when addressing issues with electric propulsion systems. Proper tools not only ensure efficiency but also enhance safety during maintenance tasks. This section outlines the necessary equipment that will help you effectively troubleshoot and fix common problems associated with these units.

Basic Hand Tools

Standard hand tools form the foundation of any maintenance toolkit. They are versatile and can be used for a variety of tasks, from tightening screws to replacing components. Here’s a list of basic hand tools you should have:

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws on the unit. |

| Wrench Set | Essential for removing nuts and bolts. |

| Pliers | Useful for gripping and manipulating small parts. |

| Utility Knife | Handy for cutting cables or materials. |

Specialized Instruments

In addition to basic tools, certain specialized instruments are invaluable for specific maintenance tasks. These tools are designed to address particular issues that may arise in electric propulsion systems:

| Instrument | Function |

|---|---|

| Multimeter | For testing voltage, current, and resistance. |

| Heat Gun | Useful for heat-shrinking connectors and cables. |

| Wire Strippers | Essential for preparing wires for connections. |

| Socket Set | Facilitates the removal of larger fasteners. |

How to Diagnose Power Failures

Identifying electrical issues is crucial for ensuring the optimal performance of your device. Understanding the common signs of power loss can help you quickly address the underlying problems. This section will guide you through systematic steps to pinpoint where the malfunction may be occurring.

Begin by checking the power source to confirm it is functioning properly. Inspect any connections to ensure they are secure and free from corrosion. A loose or damaged cable can often be the culprit behind unexpected shutdowns or failures.

Next, examine the battery and its connections. Look for signs of wear or damage that could affect performance. Testing the voltage output with a multimeter can provide valuable insights into the battery’s condition and help determine if it requires replacement.

If the power supply appears normal, assess the internal components for any visible issues. Listen for unusual noises or smells that may indicate an electrical fault. Take note of any error codes displayed by the device, as they can offer specific information regarding the nature of the failure.

Lastly, if basic troubleshooting does not resolve the issue, consider consulting more detailed resources or seeking professional assistance. Systematic diagnosis is essential for restoring functionality and ensuring reliability in the long term.

Step-by-Step Guide to Motor Disassembly

This section provides a comprehensive approach to dismantling a motor for maintenance or troubleshooting. Understanding the disassembly process is crucial for ensuring that components are correctly handled and reassembled, ultimately extending the life of the device. Following these steps will help you navigate the process smoothly and efficiently.

Required Tools and Safety Precautions

Before beginning the disassembly, gather all necessary tools, including screwdrivers, pliers, and wrenches. Ensure you have a clean workspace to avoid losing small parts. Always wear appropriate safety gear, such as gloves and goggles, to protect yourself from potential hazards during the process.

Disassembly Procedure

Start by disconnecting the power source to prevent any electrical accidents. Next, carefully remove any external covers or casings using the appropriate tools. As you proceed, take note of the order in which components are removed and keep them organized. This will simplify reassembly later. Once all exterior parts are off, begin detaching internal elements, ensuring to follow any specific guidelines related to the motor’s design.

Inspecting the Foot Pedal for Malfunctions

Regular assessment of the foot-operated control device is crucial for ensuring optimal performance of your propulsion system. This component is responsible for relaying user commands to the motor, and any issues may lead to erratic behavior or complete failure to respond. By systematically checking for faults, users can maintain functionality and extend the life of their equipment.

Begin by examining the exterior for any signs of damage, such as cracks or broken parts. Pay special attention to the pedal mechanism; ensure it moves smoothly without obstruction. Any stiffness or unusual resistance could indicate a need for further investigation.

Next, inspect the connections. Detach the pedal from its main interface and check the wiring for frays or corrosion. A reliable electrical connection is essential for proper functionality. If you notice any discrepancies, consider replacing damaged components or cleaning the contacts to restore proper conductivity.

Testing the device can help identify operational issues. Connect the foot pedal to the system and monitor its responsiveness. If the device fails to operate as expected, there may be internal issues that require deeper inspection, possibly involving disassembly.

Finally, consult with professionals or refer to specific guidelines for advanced troubleshooting techniques. Ensuring your foot-operated control device is in top shape will enhance your overall experience and efficiency on the water.

Replacing Worn or Damaged Propellers

Over time, the propellers used in watercraft can experience wear and tear due to exposure to various elements and frequent usage. This deterioration can lead to reduced performance and efficiency, making it essential to address any damage promptly. Replacing these components is crucial for maintaining optimal functionality and ensuring a smooth operation on the water.

Before proceeding with the replacement process, it’s important to assess the condition of the propeller. Look for signs such as:

- Cracks or chips on the blades

- Significant discoloration or corrosion

- Deformed or bent blades

- Unusual noise or vibration during operation

Once you’ve determined that a replacement is necessary, follow these steps to ensure a successful installation:

- Gather the required tools and a suitable replacement propeller.

- Disconnect the power supply to prevent any accidental activation.

- Remove the retaining nut or bolt that holds the current propeller in place.

- Carefully detach the damaged propeller from the drive shaft.

- Align the new propeller with the drive shaft, ensuring proper fit.

- Secure the new propeller by fastening the retaining nut or bolt firmly.

- Reconnect the power supply and perform a test run to verify the replacement.

By following these steps, you can effectively replace worn or damaged propellers, restoring the functionality and performance of your watercraft.

Battery Maintenance for Optimal Performance

Proper upkeep of the power source is essential for ensuring peak efficiency and longevity. Regular maintenance not only maximizes performance but also helps prevent unexpected failures during use. By following a systematic approach, you can extend the life of your energy cells and maintain reliable operation.

Routine Inspection

Conducting frequent checks is crucial for identifying potential issues before they escalate. This involves examining the terminals for corrosion, ensuring tight connections, and verifying that the battery is clean and free of debris.

Charging Practices

Adhering to appropriate charging methods enhances battery health. It’s vital to use compatible chargers and avoid overcharging, which can lead to reduced capacity and shortened lifespan. Additionally, maintaining a consistent charging schedule can prevent deep discharges that may harm the unit.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Inspect terminals for corrosion | Monthly | Clean as necessary with a mixture of baking soda and water. |

| Check fluid levels (if applicable) | Every 3 months | Maintain levels within manufacturer recommendations. |

| Test voltage | Every 6 months | Ensure voltage remains within operational range. |

| Clean battery casing | As needed | Keep free from dirt and grime to prevent buildup. |

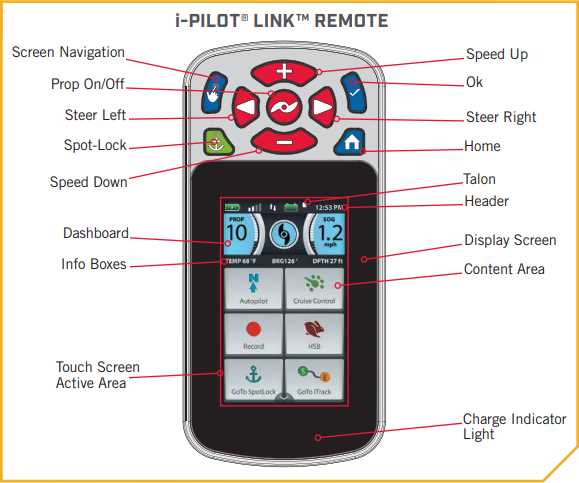

Troubleshooting Remote and Control Functions

This section focuses on identifying and resolving issues related to the operation of remote devices and control mechanisms. Users may encounter various problems that affect the performance of their equipment, leading to frustration and inconvenience. Understanding common malfunctions and their solutions can enhance overall user experience and prolong the lifespan of the unit.

Common Issues and Solutions

Below is a list of typical problems that may arise with remote and control functionalities, along with suggested remedies.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Remote not responding | Low battery, interference, damaged components | Replace batteries, check for obstacles, inspect remote for damage |

| Inconsistent control response | Weak signal, misalignment, or calibration issues | Reposition control device, recalibrate system, ensure clear line of sight |

| Control functions malfunctioning | Faulty wiring, software glitches | Examine wiring connections, reset the device, update firmware if applicable |

Steps for Effective Troubleshooting

To effectively troubleshoot any issues, follow these general guidelines:

- Start by checking the power supply to the remote and control systems.

- Ensure all connections are secure and free from corrosion.

- Consult the device’s documentation for specific error codes or indicators.

- If problems persist, consider seeking professional assistance to avoid further damage.

Upgrading Terrova Parts for Longevity

Enhancing the components of your propulsion system is essential for extending its lifespan and ensuring optimal performance. By investing in superior materials and modern upgrades, you can significantly improve the durability and efficiency of your setup. This proactive approach not only maximizes functionality but also minimizes maintenance issues over time.

Choosing High-Quality Components

When replacing parts, opt for high-quality alternatives that are known for their robustness. Upgrading to durable materials can lead to better resistance against wear and tear. For instance, consider options such as reinforced cables, corrosion-resistant connectors, and stronger housing materials. These enhancements contribute to a more reliable and long-lasting performance.

Regular Maintenance and Inspection

In addition to upgrading parts, routine checks are crucial. Regularly inspect your system for signs of wear, and replace any components that show deterioration. Implementing a consistent maintenance schedule will help identify potential issues early on, allowing for timely interventions that can prevent more significant problems down the line. This approach ensures that your investment continues to operate at peak efficiency.

Preventive Care and Regular Inspections

Regular maintenance and thorough examinations are essential to ensure the longevity and efficient operation of your equipment. By implementing a proactive approach, you can identify potential issues before they escalate into significant problems. This practice not only enhances performance but also extends the lifespan of your device.

Routine checks should focus on key components such as wiring, connections, and mechanical parts. Pay attention to any signs of wear, corrosion, or damage that could compromise functionality. Ensuring all parts are clean and free from debris will help maintain optimal performance.

Additionally, it is wise to consult the manufacturer’s recommendations regarding specific intervals for inspections. Following these guidelines will help you establish a reliable schedule for examining and servicing your equipment. Remember, consistent upkeep is an investment in performance and reliability.

Incorporating preventive measures into your maintenance routine will not only safeguard against unexpected failures but also enhance your overall experience. By prioritizing these practices, you can enjoy uninterrupted use and peace of mind.