When it comes to ensuring optimal performance of your sewing apparatus, having access to a detailed resource can make all the difference. Understanding the various components and their functions is essential for both novice and experienced users. This section aims to provide valuable insights into common issues that may arise during operation, as well as effective solutions to address them.

Throughout this guide, you’ll find step-by-step instructions tailored to enhance your familiarity with the device. By following these guidelines, you can improve your overall experience and prolong the life of your equipment. Whether it’s adjusting settings or resolving mechanical challenges, this resource is designed to empower you with the knowledge needed for seamless use.

Additionally, we will explore essential upkeep procedures that can help maintain functionality over time. Regular maintenance not only enhances performance but also prevents potential complications that could disrupt your sewing projects. With the right approach, you can keep your machine in excellent condition and enjoy crafting with confidence.

Overview of Singer Futura Models

This section provides a comprehensive look at various sewing machine models designed for both hobbyists and professionals. These machines offer a range of features that enhance creativity and efficiency in sewing projects. Understanding the distinctions among the different types is essential for users to make informed choices and effectively utilize their devices.

Key Features Across Models

The devices in this category are known for their user-friendly interfaces and advanced capabilities. Here are some prominent features:

| Model | Stitch Options | Embroidery Features | Max Speed (Stitches/min) |

|---|---|---|---|

| Model A | 50 | Yes | 800 |

| Model B | 100 | Yes | 1000 |

| Model C | 80 | No | 750 |

Choosing the Right Model

Selecting the appropriate sewing machine involves assessing personal needs and project types. Users should consider factors such as intended use, available features, and budget. Each model provides unique benefits, ensuring that there is an option for everyone, from beginners to experienced sewers.

Common Issues with Futura Machines

Users often encounter various challenges with their sewing devices, which can disrupt their projects. Recognizing these common problems is crucial for effective troubleshooting and ensuring a smooth sewing experience.

One frequent issue involves thread tension. If the thread appears too loose or too tight, it can lead to uneven stitches and fabric puckering. Adjusting the tension settings can often resolve this complication.

Another common concern is needle breakage. This can occur due to using the wrong needle type for the fabric or sewing too quickly. Regularly inspecting and replacing needles can help mitigate this problem.

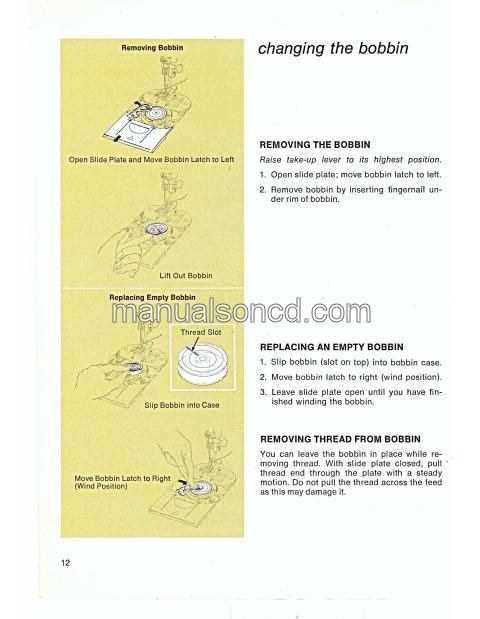

Additionally, users may experience difficulties with thread jamming. This often happens when the bobbin is incorrectly threaded or if there’s lint buildup in the machine. Regular cleaning and correct threading are essential to prevent this issue.

Lastly, electrical problems can arise, leading to the machine not powering on or malfunctioning during operation. Ensuring proper maintenance and checking power connections can help avoid such situations.

Troubleshooting Electrical Problems

Addressing issues related to electrical components can often be a challenging task. This section aims to provide a structured approach to identify and resolve common malfunctions that may arise during usage. By following systematic procedures, users can efficiently diagnose problems and restore functionality.

| Issue | Potential Cause | Solution |

|---|---|---|

| No power | Power source not connected | Check the power cord and outlet connections. |

| Intermittent operation | Loose wiring | Inspect and secure all internal connections. |

| Overheating | Blocked ventilation | Ensure vents are clear of obstructions. |

| Error messages displayed | Software malfunction | Reset the device and check for updates. |

Maintenance Tips for Longevity

To ensure the lasting performance and reliability of your sewing machine, regular upkeep is essential. Proper care not only enhances its functionality but also extends its lifespan, allowing you to enjoy your creative projects without interruptions.

Regular Cleaning

Frequent cleaning is crucial in preventing dust and lint buildup, which can hinder performance. Use a soft brush or cloth to wipe the exterior and remove debris from the machine’s interior. Pay special attention to the feed dogs and bobbin area to maintain smooth operation.

Lubrication and Care

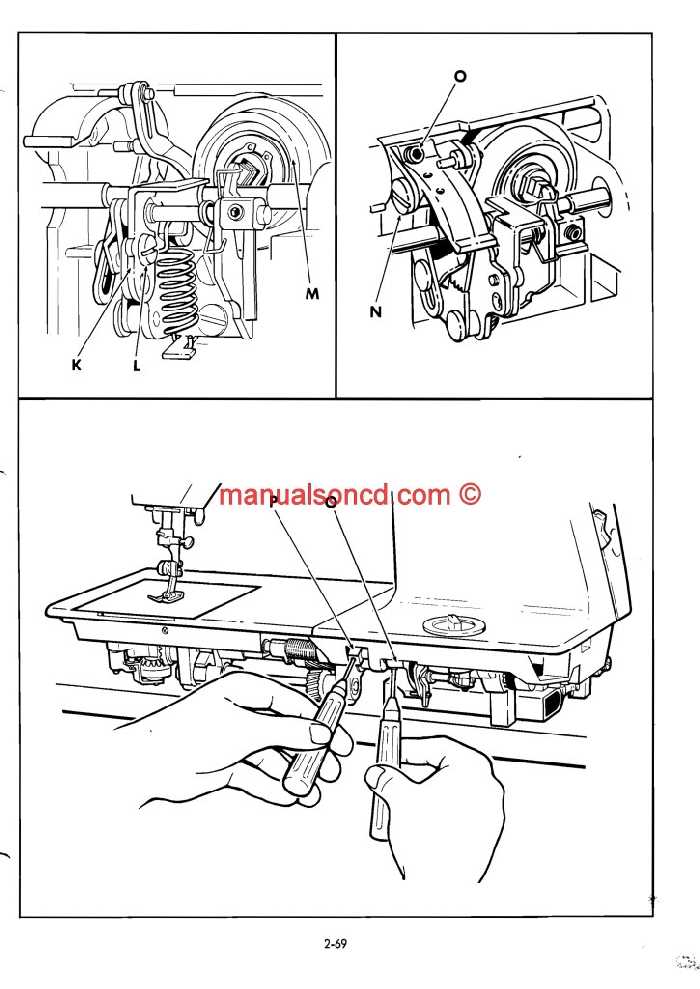

Regular lubrication helps keep moving parts functioning smoothly. Consult the manufacturer’s guidelines for appropriate lubricants and application methods. Additionally, check for any loose screws or components, tightening them as necessary to avoid operational issues.

Replacing Worn-Out Parts

Over time, certain components of a sewing machine may experience wear and tear, leading to decreased performance and efficiency. Recognizing when to replace these elements is crucial for maintaining optimal functionality. Addressing worn-out parts not only enhances the longevity of the equipment but also ensures smoother operation during projects.

Identifying Worn Parts: Regular inspections can help detect signs of deterioration, such as fraying, discoloration, or unusual noises. It is essential to be vigilant about these indicators to prevent further damage to the machine.

Choosing Replacement Components: When sourcing new parts, prioritize high-quality materials that match the specifications of the original components. This ensures compatibility and reliability in performance.

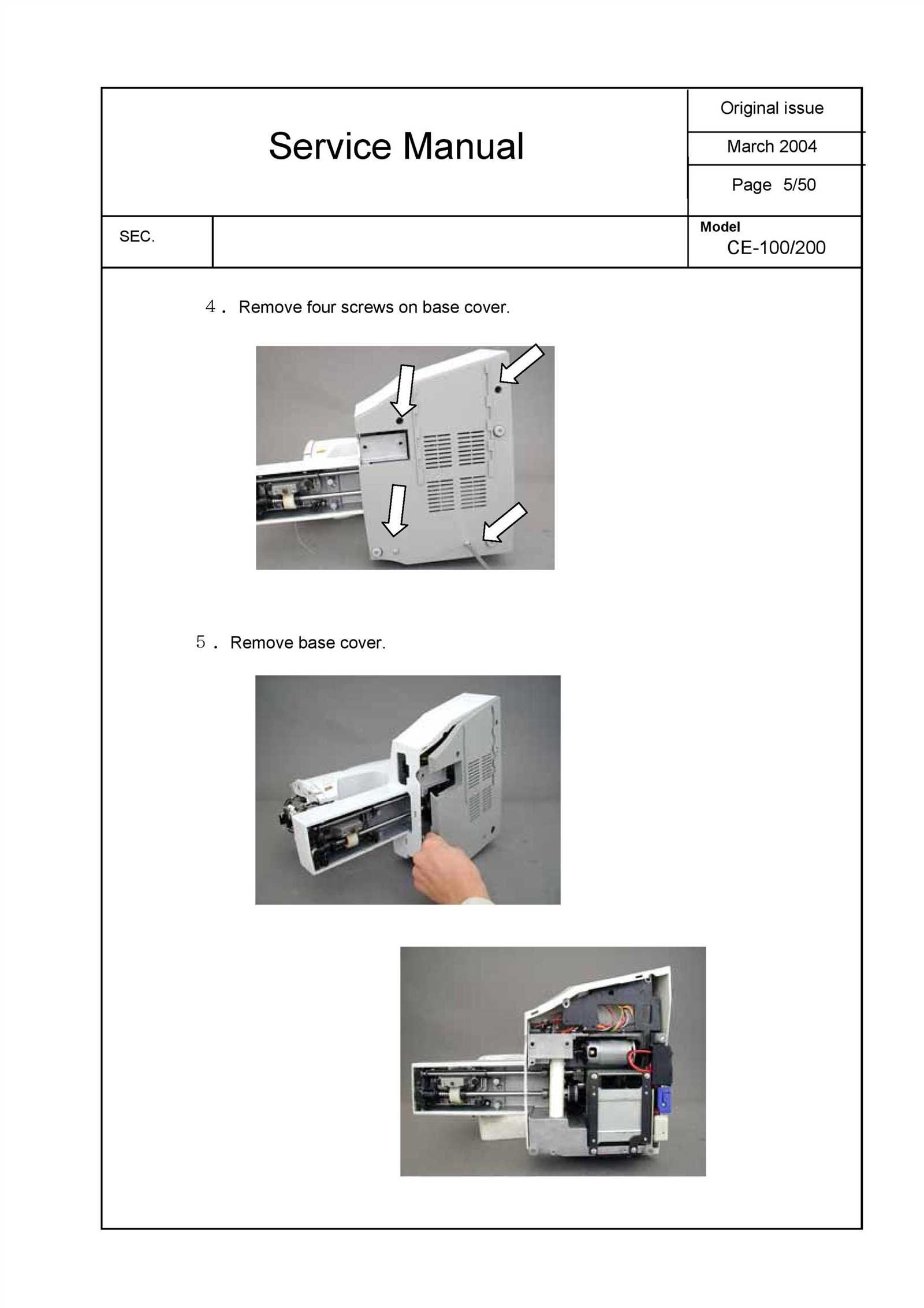

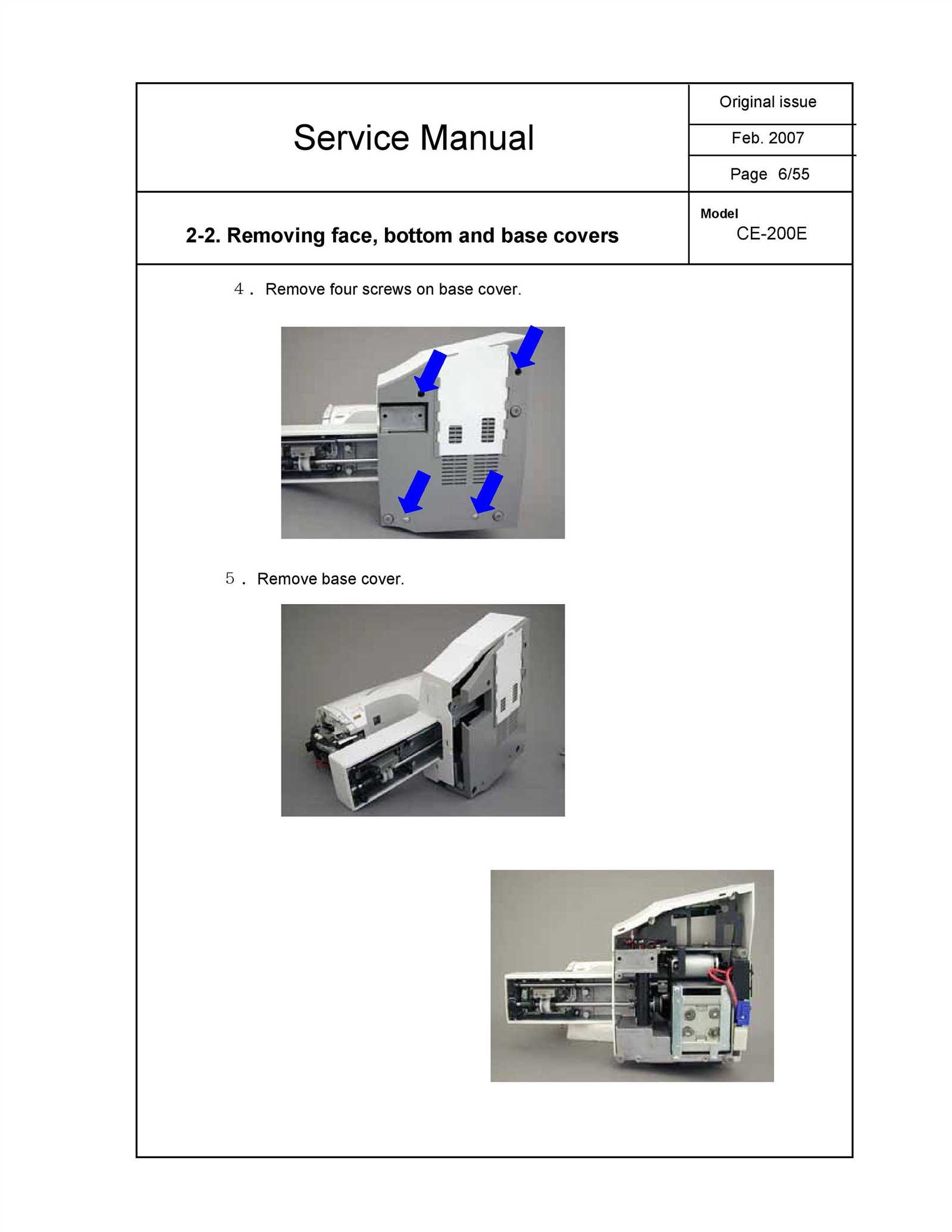

Installation Process: Carefully follow guidelines for removing the old parts and installing the new ones. Proper technique is key to avoiding misalignment or damage during the process. Always refer to available resources for detailed instructions tailored to your specific model.

Regular Maintenance: After replacing any components, establish a routine maintenance schedule. This includes cleaning, lubrication, and periodic checks to ensure all parts are functioning correctly and to extend the machine’s lifespan.

Calibration and Settings Adjustments

Proper calibration and adjustment of settings are crucial for ensuring optimal performance of your stitching device. These processes help in achieving accurate results and maintaining the longevity of the equipment. Regular checks and fine-tuning can prevent common issues and enhance overall functionality.

Importance of Calibration

Calibration involves aligning the internal components to operate harmoniously. This ensures that the needle positions and tension settings are precise, which directly affects the quality of stitching. Regular calibration helps in identifying any discrepancies early, allowing for timely corrections.

Adjusting Settings for Optimal Performance

Settings adjustments include modifying stitch length, width, and tension according to the material being used. Properly configuring these parameters not only improves the final product but also minimizes wear on the machine. Consulting the user guide for specific recommendations can assist in achieving the best results for various fabrics.

Software Updates and Installations

Keeping your device up to date is essential for optimal performance and enhanced functionality. Regular software updates can introduce new features, fix existing bugs, and improve overall user experience. Understanding the process of installation and updates will ensure your equipment operates smoothly and efficiently.

To begin with, check the manufacturer’s website or software platform for the latest versions available. It is crucial to follow the provided instructions carefully to avoid potential issues during the update process. Backing up your current settings and data is also recommended before proceeding.

Once you have downloaded the necessary files, initiate the installation by following the on-screen prompts. Depending on the complexity of the update, your device may require a restart to complete the process. After installation, verify that the updates have been successfully applied and explore any new features that may enhance your workflow.

In summary, staying informed about software updates and their installations can greatly benefit the functionality of your device. By regularly checking for updates and understanding the installation process, you can ensure your equipment remains reliable and up to date.

Using the Manual Effectively

Maximizing the benefits of a guidance document requires a strategic approach. Understanding how to navigate the resources available can significantly enhance your experience and efficiency. By familiarizing yourself with the structure and key sections, you can quickly find the information you need to address any challenges.

Begin by identifying the main categories outlined in the resource. This will allow you to pinpoint relevant topics more effectively. Consider using the following table as a reference for common sections and their purposes:

| Section | Description |

|---|---|

| Introduction | An overview of the content and objectives. |

| Troubleshooting | Common issues and their solutions. |

| Maintenance | Guidelines for keeping equipment in optimal condition. |

| Setup | Instructions for initial configuration and installation. |

Utilizing a structured approach not only saves time but also improves your ability to resolve issues independently. Be sure to bookmark essential pages for quick access in the future.

Safety Precautions During Repairs

When engaging in maintenance activities, it is essential to prioritize safety to prevent accidents and injuries. Proper precautions can help ensure a secure environment for both the individual performing the tasks and the equipment involved.

Before starting any work, it is advisable to disconnect the power supply to eliminate the risk of electric shock. Additionally, wearing appropriate personal protective equipment, such as gloves and safety glasses, can safeguard against potential hazards. It is also important to work in a well-ventilated area to reduce exposure to harmful fumes or particles.

Furthermore, keeping the workspace organized and free of clutter can minimize the chances of tripping or accidentally damaging components. Always follow the guidelines provided in the instructional documentation to ensure that each step is performed correctly and safely. By adhering to these safety measures, individuals can effectively minimize risks during maintenance activities.

Resources for Additional Support

Accessing reliable assistance is essential when navigating challenges with your sewing equipment. Numerous avenues can provide guidance, troubleshooting advice, and helpful tips to enhance your experience and ensure optimal performance.

Online Communities

Participating in online forums and social media groups dedicated to sewing enthusiasts can be incredibly beneficial. These platforms often feature discussions where users share their experiences, solutions, and insights, creating a supportive environment for both novice and experienced sewists.

Manufacturer Support

Reaching out to the manufacturer’s customer service can yield valuable information. Many companies offer comprehensive assistance, including FAQs, instructional videos, and direct contact with knowledgeable representatives who can address specific queries and concerns.