Understanding the essentials of maintaining your grass trimming equipment is crucial for ensuring its longevity and optimal performance. Regular attention to various components not only enhances efficiency but also helps prevent unexpected breakdowns during crucial moments. This guide offers valuable insights into troubleshooting common issues and performing necessary adjustments.

Whether you are a seasoned user or a beginner, being familiar with the inner workings of your device can significantly ease the process of upkeep. From examining the engine to checking the cutting elements, each aspect plays a vital role in achieving a well-groomed yard. Familiarizing yourself with various functions and specifications can empower you to handle minor challenges independently.

By following systematic steps and utilizing appropriate tools, you can extend the life of your equipment and ensure it operates smoothly. This resource aims to equip you with practical knowledge that simplifies maintenance tasks, thereby enhancing your overall experience. A well-maintained unit not only saves you time and money but also contributes to a healthier outdoor environment.

Briggs and Stratton Lawn Mower Repair Guide

This guide offers essential insights for maintaining and troubleshooting your grass-cutting equipment. It aims to empower users with knowledge on common issues and effective solutions, ensuring optimal performance throughout the cutting season.

Identifying Common Issues

Understanding the typical problems that may arise is crucial. Equipment may face difficulties starting, irregular operation, or inadequate cutting. By recognizing these symptoms early, you can implement timely fixes to enhance functionality.

Basic Troubleshooting Steps

Start with a thorough inspection of the fuel system, ensuring there are no blockages and that the fuel is fresh. Check the ignition components for wear, and examine the blade for sharpness and integrity. Regular cleaning and maintenance of air filters can significantly improve efficiency and longevity.

Remember: Addressing minor issues promptly can prevent major breakdowns, saving time and resources in the long run.

Knowledge is key to successful upkeep.

Common Lawn Mower Issues

Many users encounter various problems with their grass-cutting machines, leading to frustration and decreased performance. Understanding these common difficulties can help in troubleshooting and maintaining optimal functionality.

- Engine Won’t Start:

- Check the fuel level and quality.

- Inspect the spark plug for wear or damage.

- Ensure the air filter is clean.

- Uneven Cutting:

- Verify the blade sharpness and condition.

- Adjust the cutting height as needed.

- Inspect the wheel alignment.

- Excessive Vibration:

- Examine the blade for damage or imbalance.

- Check the engine mounting bolts.

- Ensure the tires are properly inflated.

- Overheating:

- Clean the cooling fins and air intake.

- Check the oil level and quality.

- Inspect the fuel system for blockages.

By identifying these frequent concerns, users can take appropriate actions to maintain their equipment effectively and prolong its lifespan.

Essential Tools for Repairs

When it comes to maintaining outdoor machinery, having the right equipment is crucial for efficient work. Proper tools not only facilitate the repair process but also ensure safety and precision in each task.

- Screwdrivers: A set of various sizes, including flathead and Phillips, is essential for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches allow for better grip and leverage on nuts and bolts.

- Pliers: Needle-nose and regular pliers are useful for gripping, twisting, and cutting wires or small components.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing damage from overtightening.

- Oil Can: Keeping the equipment lubricated is vital for smooth operation, and an oil can simplifies this process.

- Cleaning Brush: A stiff brush is helpful for removing dirt and debris from parts, ensuring optimal performance.

- Safety Gear: Always wear protective eyewear and gloves to safeguard against injury during maintenance tasks.

Having these fundamental instruments on hand will significantly enhance your ability to address various issues effectively and maintain the functionality of your outdoor equipment.

Step-by-Step Troubleshooting Process

When faced with issues in outdoor power equipment, a systematic approach is essential for identifying and resolving problems efficiently. Following a structured troubleshooting process can help you pinpoint the source of the malfunction and implement effective solutions.

-

Identify Symptoms:

Begin by observing the equipment and noting any unusual behavior. Common symptoms may include:

- Failure to start

- Uneven cutting

- Excessive noise

- Vibrations

-

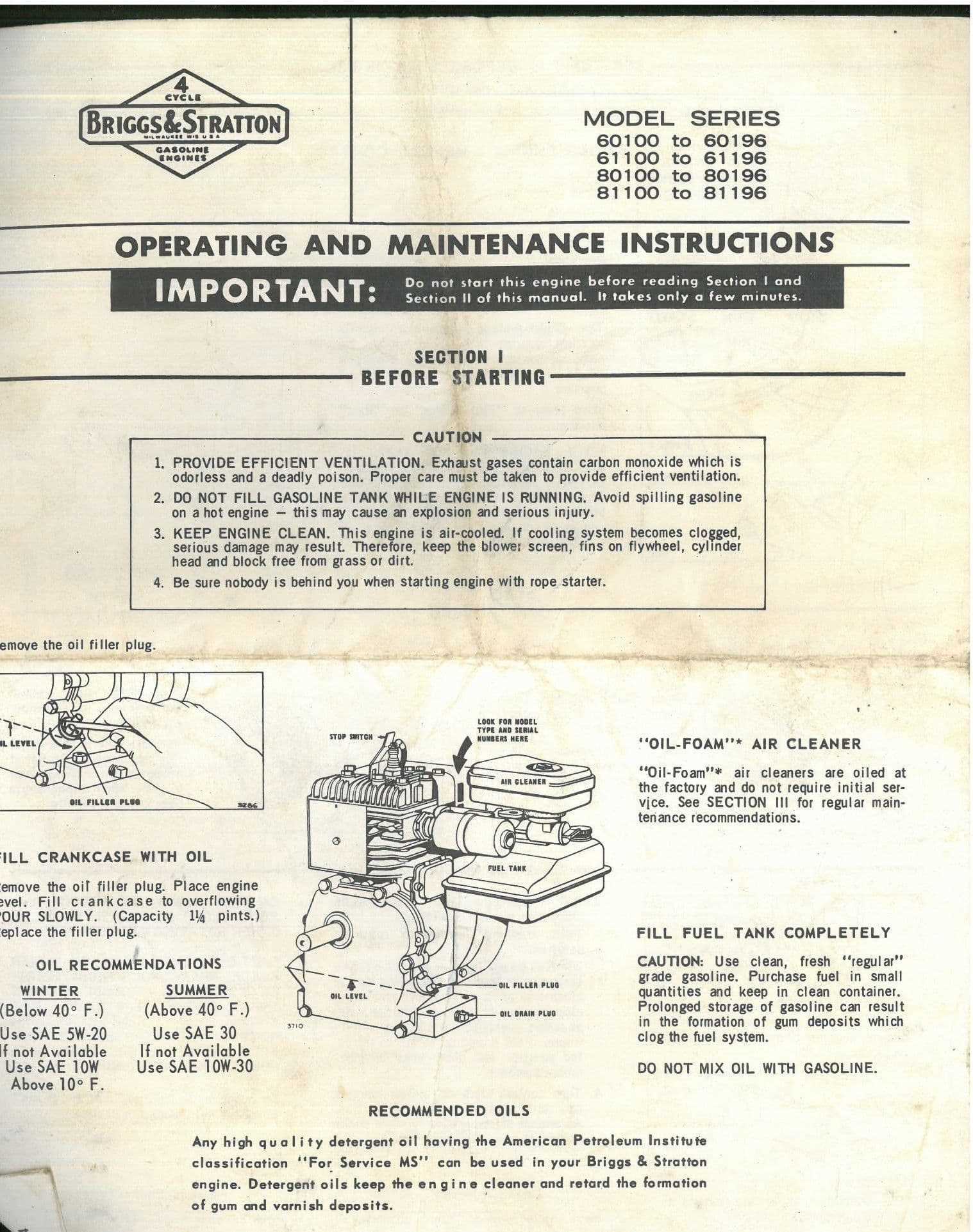

Consult Documentation:

Review the provided guides and specifications for troubleshooting tips related to the specific issues identified.

-

Check Fuel Supply:

Ensure that there is adequate fuel in the tank and that it is fresh. Old or contaminated fuel can cause starting problems.

-

Examine Spark Plug:

Inspect the spark plug for wear or damage. A faulty spark plug may prevent ignition. Clean or replace if necessary.

-

Inspect Air Filter:

A clogged air filter can restrict airflow, leading to performance issues. Clean or replace the filter as needed.

-

Assess Blade Condition:

Check the cutting blade for sharpness and damage. Dull or broken blades can affect cutting quality.

-

Test Electrical Components:

If applicable, inspect the electrical system for loose connections or damage. Ensure that all components are functioning correctly.

-

Perform Final Checks:

After addressing the identified issues, conduct a final inspection to ensure everything is in order. Start the equipment to verify that it operates smoothly.

Following these steps can help ensure that your outdoor power equipment operates effectively and remains in good condition for future use.

Replacing Blades Safely

Changing the cutting edges of your equipment is an essential maintenance task that enhances performance and ensures a clean cut. Performing this procedure safely is crucial to avoid accidents and damage to the machine.

Before beginning the process, follow these important steps:

- Gather Necessary Tools: Ensure you have all required tools, including a wrench, socket set, and safety gloves.

- Disconnect Power: Always disconnect the power source to prevent accidental starting while working.

- Elevate the Machine: Use a stable surface or jack stands to lift the equipment, providing easy access to the underside.

When removing the old blades, keep these precautions in mind:

- Wear protective gear, including gloves and safety glasses, to shield against sharp edges.

- Use the proper size tools to avoid slipping and damaging components.

- Support the blade with one hand while loosening bolts with the other to maintain control.

Installing new cutting edges involves similar care:

- Align Blades Correctly: Ensure the blades are positioned accurately according to the manufacturer’s guidelines.

- Tighten Securely: Use the correct torque specifications to fasten bolts securely, preventing loosening during operation.

- Reconnect Power: After the installation is complete, restore the power source and conduct a test to ensure everything functions smoothly.

By adhering to these safety practices, you can effectively replace cutting edges while minimizing the risk of injury and ensuring optimal performance.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is essential for ensuring optimal performance and longevity of your outdoor equipment. Regular attention to this component can prevent issues such as starting difficulties and inefficient operation.

Regular Inspection

Conduct frequent examinations of the fuel system to identify any potential problems. Look for signs of wear or damage that may affect performance.

- Check for leaks around the fuel lines and connections.

- Inspect the fuel filter for blockages or debris.

- Examine the fuel tank for contaminants.

Fuel Quality Management

Maintaining high-quality fuel is crucial for reliable operation. Use fresh, clean fuel to avoid complications.

- Purchase fuel from reputable sources.

- Avoid using fuel that has been stored for long periods.

- Consider using fuel stabilizers to prolong freshness.

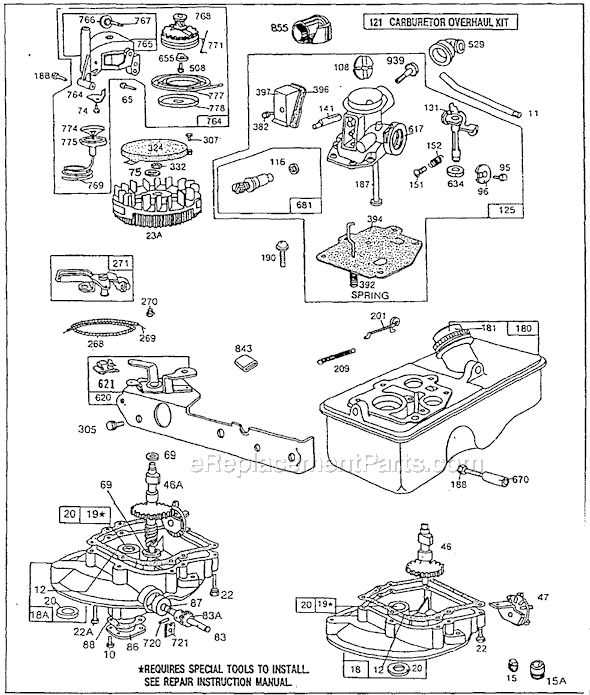

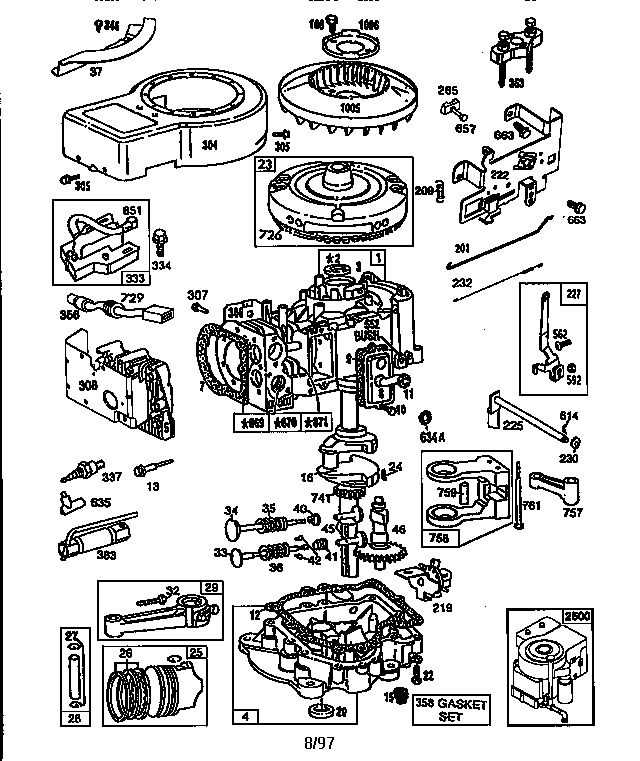

Engine Overhaul Procedures

This section outlines essential steps for performing a comprehensive overhaul of a small engine, ensuring optimal performance and longevity. Properly executing these procedures is vital for maintaining functionality and reliability, allowing for effective restoration of power equipment.

Preparation Steps

Before starting the overhaul, gather all necessary tools and components. This preparation phase is crucial for a seamless process.

| Item | Description |

|---|---|

| Wrench Set | Various sizes for loosening and tightening bolts. |

| Screwdriver Set | Flathead and Phillips for removing covers and components. |

| Replacement Parts | Gaskets, seals, and any worn components that need replacing. |

| Cleaning Supplies | Degreasers and brushes for cleaning parts. |

Disassembly and Inspection

Begin by carefully disassembling the engine, taking note of the arrangement of parts. Inspect each component for wear and damage, noting any areas requiring replacement or repair.

Following these procedures will ensure a successful overhaul, enhancing the overall efficiency and lifespan of the engine.

Cleaning the Air Filter

Maintaining the cleanliness of the air filter is essential for optimal engine performance. A clean filter ensures that the engine receives the right amount of air, promoting efficient combustion and preventing potential damage. Regular cleaning can prolong the life of your equipment and improve its functionality.

Tools Needed

- Soft brush or cloth

- Warm, soapy water

- Clean, dry rag

- Protective gloves

Steps for Cleaning

- Turn off the engine and disconnect the spark plug for safety.

- Remove the air filter from its housing carefully.

- Use a soft brush or cloth to gently remove dirt and debris from the filter surface.

- If necessary, wash the filter in warm, soapy water. Rinse thoroughly and allow it to dry completely.

- Reinstall the filter securely back into its housing once it is dry.

- Reconnect the spark plug and start the engine to ensure proper operation.

Regularly checking and cleaning the air filter can significantly enhance performance, leading to smoother operation and reduced wear on engine components.

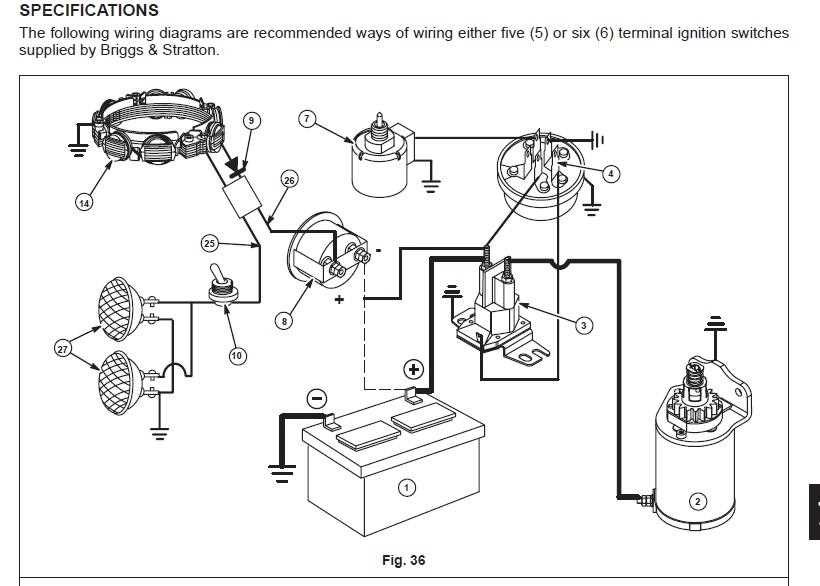

Inspecting Electrical Components

Evaluating the electrical parts of your equipment is essential for ensuring optimal performance. This process involves checking various components for any signs of wear or damage, which can affect functionality. By conducting a thorough inspection, you can identify potential issues before they lead to more significant problems.

Start by examining the wiring for any frays or loose connections. Damaged wires can cause intermittent power loss or complete failure. Ensure that all connectors are secure and free from corrosion, as this can impede electrical flow.

Next, assess the ignition system, which is crucial for starting the machine. Inspect the spark plug for wear and ensure it is clean and properly gapped. A faulty spark plug can result in starting difficulties and decreased efficiency.

Finally, evaluate the battery if applicable. Check for any signs of leakage or corrosion around the terminals. A weak or dead battery can prevent your equipment from starting altogether, so replacing it when necessary is vital for reliable operation.

Wheel and Deck Repair Techniques

Maintaining the functionality of your outdoor equipment requires attention to various components, particularly the wheels and chassis. Proper handling and servicing of these parts ensure smooth operation and longevity. This section outlines effective methods for addressing common issues related to these critical elements.

Identifying Common Issues

Before delving into solutions, it’s essential to recognize typical problems that may arise. Wheels can become misaligned or damaged, affecting mobility. Meanwhile, the chassis may accumulate debris or sustain scratches that compromise its integrity. Regular inspections can help detect these issues early, preventing more significant complications.

Techniques for Resolution

To address wheel misalignment, begin by checking the axle for any bends or obstructions. Loosen the bolts and reposition the wheel as necessary, then retighten securely. For damaged wheels, consider replacing them with compatible alternatives to ensure optimal performance.

For the chassis, cleaning is paramount. Utilize a suitable cleaning agent to remove dirt and grime. If there are scratches or rust spots, gently sand the area and apply a protective coating to prevent further deterioration. These steps will enhance both appearance and functionality, contributing to the overall effectiveness of your equipment.

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. This checklist outlines key tasks to complete at the start of each season, helping to prevent issues and maintain efficiency.

1. Inspect the Engine Oil: Check the oil level and quality. Change the oil if it appears dirty or is below the recommended level.

2. Air Filter Cleaning: Remove the air filter and clean it to prevent debris from affecting engine performance. Replace it if it’s excessively dirty or damaged.

3. Spark Plug Examination: Inspect the spark plug for wear and carbon buildup. Replace it if it shows signs of deterioration to ensure reliable ignition.

4. Fuel System Maintenance: Check the fuel lines for cracks or leaks. Replace any old fuel with fresh gasoline to avoid starting issues.

5. Blade Sharpening: Examine the cutting blades for dullness or damage. Sharpen or replace them to guarantee a clean cut.

6. Tire Pressure Check: Ensure that all tires are properly inflated to the manufacturer’s specifications for optimal handling and performance.

7. Clean the Exterior: Remove grass clippings and debris from the equipment to prevent rust and maintain its appearance.

8. Battery Inspection: If applicable, check the battery for corrosion and ensure it’s fully charged before use.

By adhering to this checklist, you can enhance the reliability of your equipment and enjoy a seamless experience throughout the seasons.

Finding Replacement Parts Easily

Locating suitable components for your outdoor equipment can be a straightforward process if you know where to look. Understanding the options available and utilizing the right resources is essential for a smooth replacement experience.

One effective way to begin your search is by checking manufacturer websites. They often provide comprehensive lists of compatible parts and accessories tailored for specific models. This ensures that you are getting the correct items needed for your equipment.

In addition, local retailers and hardware stores can be valuable resources. Many of these establishments carry a variety of parts, allowing you to view items in person and ask knowledgeable staff for assistance.

Online platforms are also a great option. Websites specializing in outdoor equipment parts typically have detailed catalogs that can help you filter results based on your requirements. Make sure to check customer reviews to ensure the quality of the parts you are considering.

Lastly, joining online forums or community groups focused on outdoor equipment maintenance can provide insights and recommendations from fellow enthusiasts. Sharing experiences can lead to discovering reliable suppliers and tips for your specific needs.