Ensuring the longevity and performance of a high-performance vehicle involves a detailed understanding of its systems and components. This section provides essential insights into the upkeep and troubleshooting processes necessary for optimal functionality. By familiarizing oneself with the intricacies of this vehicle, owners can effectively address common issues and enhance driving experiences.

In this guide, we delve into various techniques and recommendations for maintaining this powerful machine. With practical tips and expert advice, vehicle enthusiasts can navigate through routine checks and potential repairs, empowering them to tackle challenges confidently. A proactive approach to maintenance not only safeguards the vehicle but also improves its efficiency on the road.

Regular upkeep of your vehicle ensures its longevity and optimal performance. To achieve this, having the right set of instruments is crucial. This section outlines the fundamental equipment required for effective servicing, allowing enthusiasts and professionals alike to tackle maintenance tasks efficiently.

Basic Hand Tools

Every workshop should be equipped with a variety of hand tools to address common maintenance challenges. These include wrenches, sockets, and screwdrivers that help with various tasks, from tightening bolts to replacing components.

Diagnostic Equipment

Utilizing diagnostic tools is essential for identifying issues within the vehicle’s systems. These devices provide valuable insights and facilitate precise troubleshooting, ensuring that problems are addressed promptly and effectively.

| Tool Type | Purpose |

|---|---|

| Wrenches | Loosening and tightening bolts |

| Sockets | Accessing hard-to-reach fasteners |

| Screwdrivers | Installing or removing screws |

| Diagnostic Scanner | Identifying electronic system errors |

| Torque Wrench | Ensuring proper fastener tightness |

Common Issues and Troubleshooting

When maintaining a high-performance vehicle, it’s essential to be aware of typical problems that may arise and how to address them effectively. Understanding these common challenges can significantly enhance the longevity and reliability of the automobile.

- Engine Performance:

- Reduced power output

- Unusual noises during operation

- Increased fuel consumption

- Transmission Concerns:

- Difficulty in shifting gears

- Unresponsive automatic transmission

- Fluid leaks

- Electrical System Problems:

- Frequent blown fuses

- Malfunctioning dashboard lights

- Battery drainage issues

- Suspension Issues:

- Uneven tire wear

- Excessive bouncing or swaying

- Noises during turns or bumps

Identifying and addressing these common issues promptly can prevent more significant damage and costly repairs. Regular maintenance checks and being attentive to warning signs are key to ensuring optimal performance.

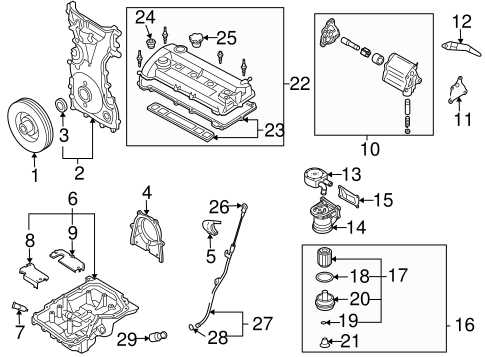

Step-by-Step Engine Repair Guide

This section provides a detailed process for addressing common issues within the powertrain system of your vehicle. By following a systematic approach, you can enhance performance and extend the lifespan of your engine.

Preparation and Safety Measures

Before beginning any work, ensure that you have the necessary tools and safety equipment. Gather items such as wrenches, screwdrivers, and protective goggles. Additionally, it’s crucial to disconnect the battery to prevent any electrical hazards while you are working.

Disassembly and Inspection

Start by removing the engine cover and any components obstructing access to the internal parts. Carefully inspect the engine for signs of wear, leaks, or damage. Make notes of any irregularities, as these will guide your repair process. Once the inspection is complete, proceed with replacing or repairing damaged parts as needed.

Transmission Care and Repairs

Maintaining the functionality of a vehicle’s transmission system is essential for ensuring smooth operation and longevity. Proper care involves regular checks and timely interventions to address any issues that may arise, preventing further complications and costly repairs.

Routine Maintenance Practices

Regular maintenance is crucial for optimal performance. This includes checking fluid levels, inspecting for leaks, and changing the transmission fluid at recommended intervals. Keeping the system clean and well-lubricated can help prevent wear and tear, extending the lifespan of the components.

Troubleshooting Common Issues

Identifying signs of malfunction early can save time and resources. Unusual noises, slipping gears, or warning lights on the dashboard are indicators that attention is needed. Addressing these symptoms promptly can prevent more severe damage and ensure that the system remains in good working condition.

Electrical System Diagnostics

The evaluation of the electrical framework in vehicles is crucial for ensuring optimal performance and reliability. This process involves identifying potential issues within the circuitry and components that may affect functionality.

Initial Assessment: Start by examining the battery condition, as it is the cornerstone of the electrical system. Check for corrosion on terminals and ensure secure connections. A multimeter can be employed to measure voltage and confirm adequate power supply.

Wiring Inspection: Thoroughly inspect the wiring harness for signs of wear or damage. Look for frayed wires, loose connections, and any exposed insulation that could lead to short circuits.

Component Testing: Each electrical component, such as fuses, relays, and sensors, should be tested for functionality. Use diagnostic tools to read fault codes that can provide insight into any underlying issues.

System Monitoring: Employ a scan tool to monitor real-time data from various sensors. This can help pinpoint anomalies in the system’s performance, allowing for more accurate troubleshooting.

By systematically following these steps, one can effectively diagnose issues within the electrical system, ensuring the vehicle operates smoothly and efficiently.

Suspension and Steering Adjustments

This section focuses on the essential modifications required for optimal performance of the vehicle’s suspension and steering systems. Proper alignment and tuning of these components ensure enhanced handling, stability, and comfort during driving.

Key adjustments include:

- Camber Angle: The tilt of the wheels can significantly affect tire wear and cornering ability.

- Toe Settings: Proper toe alignment helps in reducing drag and improving straight-line stability.

- Ride Height: Adjusting the height of the vehicle can influence handling characteristics and weight distribution.

- Shock Absorber Settings: Fine-tuning these components enhances ride quality and responsiveness.

- Steering Rack Position: Ensuring the correct placement aids in achieving precise steering response.

Regular inspection and adjustment of these elements are crucial for maintaining performance and safety. Following the manufacturer’s specifications is recommended for achieving the best results.

Brake System Maintenance Procedures

Maintaining the braking system is crucial for ensuring optimal vehicle safety and performance. Regular inspection and care help to prolong the lifespan of components and enhance overall reliability. Proper maintenance procedures can prevent issues that may arise from wear and tear or improper functioning.

Below are essential steps for effective brake system upkeep:

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Every month | Check for any visible signs of wear, leakage, or damage in brake lines and components. |

| Brake Fluid Check | Every 3 months | Examine the fluid level and quality; replace if it appears dirty or below the recommended level. |

| Pad Thickness Measurement | Every 6 months | Measure the thickness of brake pads to determine if they need replacement. |

| Brake Rotor Inspection | Every 6 months | Assess rotors for wear and warping; resurfacing or replacement may be necessary if damaged. |

| Brake System Bleeding | Annually | Flush and replace brake fluid to eliminate air bubbles and contaminants for optimal performance. |

Following these maintenance steps helps to ensure that the braking system functions effectively, providing peace of mind while driving.

Cooling System Inspection Techniques

The examination of a vehicle’s thermal management system is crucial for ensuring optimal performance and longevity. This section outlines various methods for assessing the integrity and functionality of the cooling mechanism, helping to identify potential issues before they escalate.

Visual Assessment: Start by visually inspecting the components for any signs of wear, leaks, or corrosion. Pay close attention to hoses, clamps, and the radiator for any cracks or bulges that may indicate a failure.

Pressure Testing: Utilizing a pressure tester can help determine the system’s ability to maintain pressure. This test can reveal hidden leaks and assess the condition of the cap, which is vital for maintaining the proper pressure levels within the system.

Temperature Monitoring: Monitor the temperature readings from the engine and radiator during operation. Anomalies in these readings can suggest that the cooling system is not functioning efficiently, potentially leading to overheating.

Fluid Quality Check: Assess the coolant for clarity and proper mix ratios. Contaminated or degraded fluid can significantly impair the cooling system’s effectiveness, so it’s essential to replace it when necessary.

Bodywork and Interior Restoration Tips

Restoring the exterior and interior of a vehicle can breathe new life into its overall appearance and enhance its longevity. This process involves careful attention to detail and a clear understanding of the materials and techniques involved. By following some key practices, you can achieve impressive results that not only improve aesthetics but also add value to your vehicle.

Exterior Restoration Techniques

To achieve a flawless finish on the bodywork, begin by thoroughly cleaning the surface to remove dirt and debris. Inspect for any scratches or dents, and use appropriate tools to address these imperfections. Sanding and priming are essential steps before applying a fresh coat of paint. Choosing high-quality paint products can ensure durability and a professional look.

Interior Revitalization Methods

For the interior, focus on deep cleaning fabrics and surfaces to eliminate stains and odors. Reupholstering worn seats can significantly improve comfort and aesthetics. Additionally, replacing outdated components such as knobs and trims can modernize the interior feel. Regular maintenance and protection from sun exposure will help preserve the quality of materials over time.

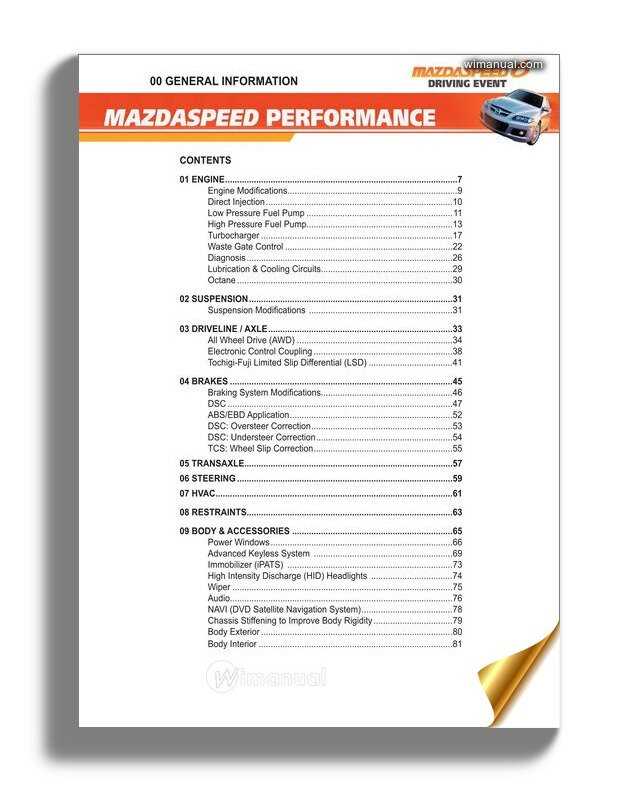

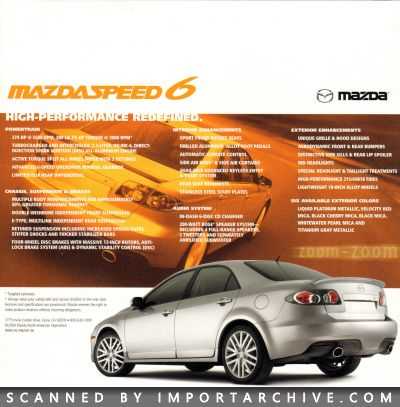

Performance Upgrades and Modifications

Enhancing the capabilities of your vehicle can lead to a more exhilarating driving experience. By implementing specific improvements and alterations, enthusiasts can achieve better handling, increased power output, and overall enhanced performance. This section will explore various options for those looking to elevate their ride.

One of the most effective ways to boost performance is through engine enhancements. These can range from simple modifications like upgrading the air intake system to more comprehensive alterations, such as installing a high-performance turbocharger. Below is a table summarizing common performance upgrades:

| Upgrade | Description |

|---|---|

| Cold Air Intake | Improves airflow to the engine, enhancing combustion efficiency. |

| Performance Exhaust System | Reduces back pressure, allowing for improved exhaust flow and sound. |

| ECU Tuning | Optimizes engine parameters for increased power and responsiveness. |

| Suspension Upgrades | Enhances handling and stability, providing a sportier driving feel. |

| Brake Upgrades | Improves stopping power and reduces brake fade during spirited driving. |

By carefully selecting the right modifications, owners can tailor their vehicle to meet their performance desires, creating a more engaging and dynamic driving experience.

Safety Protocols for Repairs

Ensuring a secure environment during maintenance tasks is essential for both the technician and the vehicle. Adhering to established guidelines minimizes risks and promotes efficient work practices. This section outlines key safety measures to consider before, during, and after the service process.

Pre-Work Preparations

Before starting any servicing, it is crucial to prepare adequately. This includes gathering all necessary tools and equipment, reviewing safety data sheets for any chemicals involved, and ensuring that the workspace is well-ventilated and organized. A clear understanding of the task at hand can significantly reduce the likelihood of accidents.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is vital when engaging in maintenance activities. Technicians should wear safety glasses, gloves, and steel-toed boots to protect against potential hazards. Additionally, hearing protection may be necessary when working with loud machinery.

| Type of PPE | Purpose |

|---|---|

| Safety Glasses | Protects eyes from debris and chemicals |

| Gloves | Prevents skin exposure to hazardous materials |

| Steel-Toed Boots | Offers foot protection against heavy objects |

| Hearing Protection | Reduces noise exposure |

Scheduled Maintenance Intervals

Regular servicing is crucial for ensuring optimal performance and longevity of your vehicle. Adhering to recommended service intervals can help identify potential issues early and maintain efficiency. This section outlines typical timelines and tasks associated with routine upkeep.

Maintenance Schedule Overview

The maintenance timeline typically includes various inspections and replacements. Below is a general guide to the frequency of key services:

| Service Type | Interval (Miles/Kilometers) |

|---|---|

| Oil Change | 5,000 miles / 8,000 km |

| Air Filter Replacement | 15,000 miles / 24,000 km |

| Brake Inspection | 10,000 miles / 16,000 km |

| Tire Rotation | 7,500 miles / 12,000 km |

| Fluid Checks | Every 5,000 miles / 8,000 km |

Importance of Following Guidelines

Adhering to these intervals helps in avoiding costly repairs and ensures that all components function as intended. Regular attention to maintenance needs not only enhances safety but also improves overall driving experience.