For those who rely on their vehicle for demanding tasks, ensuring it performs reliably is essential. A thorough understanding of various systems and components can go a long way in preventing issues and improving efficiency. Whether you’re managing complex machinery or simply looking to extend the life of a hard-working truck, an organized approach to upkeep is invaluable.

In this guide, we explore ways to approach maintenance with confidence. From understanding the intricacies of mechanical and electrical systems to tackling common concerns, the sections ahead provide insights into the needs of robust vehicles designed for rigorous use. Each step is tailored to provide clarity, helping users make informed decisions on diagnostics and solutions.

Equipped with practical advice, this resource serves as an essential reference for anyone interested in maximizing vehicle longevity and reliability. With detailed explanations and useful recommendations, it aims to empower users with the knowledge to keep their vehicles operating smoothly under any conditions.

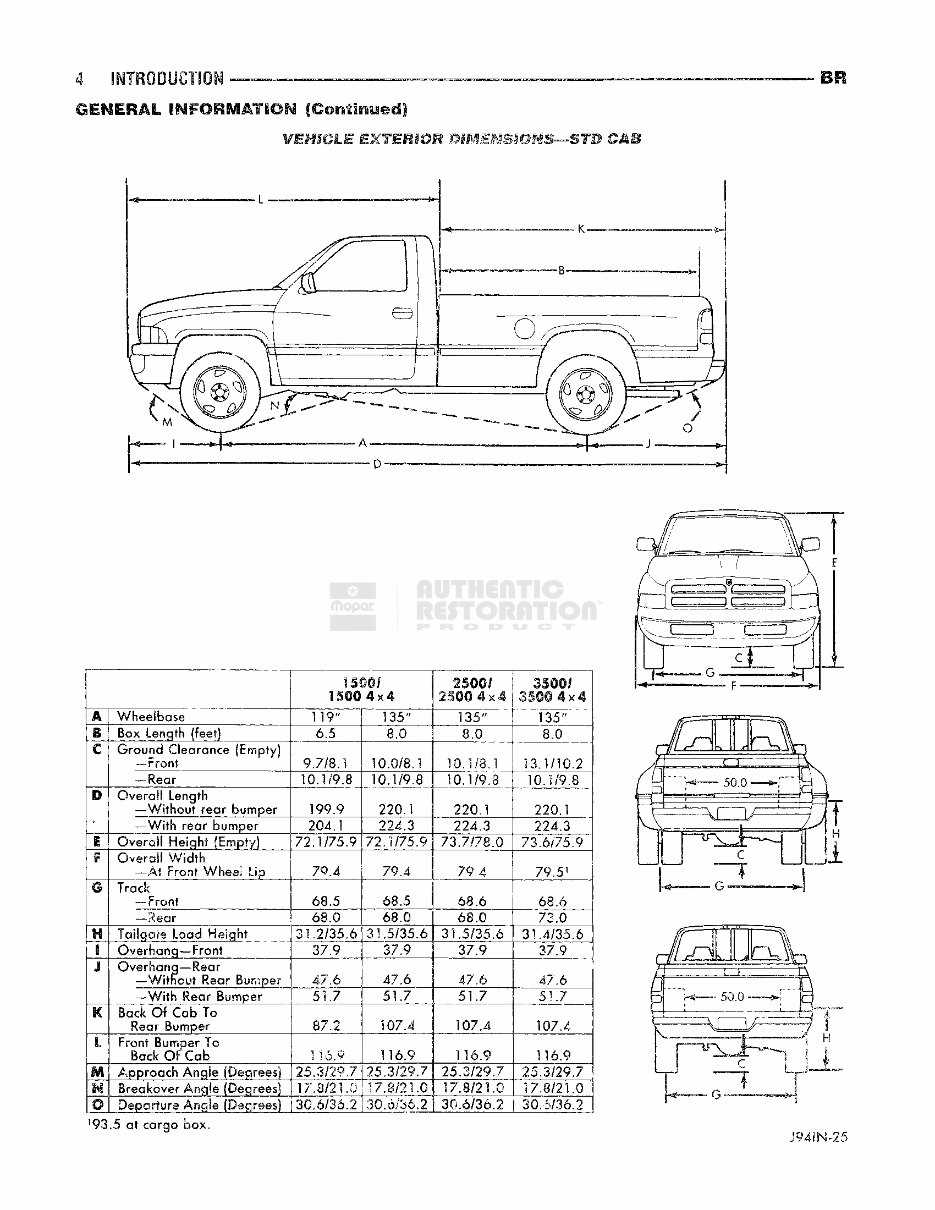

Ram 3500 Repair Manual

This guide serves as a comprehensive resource for the maintenance and troubleshooting of heavy-duty vehicles, focusing on addressing both common issues and detailed procedures. By following this structured guide, owners and technicians can ensure the longevity and optimal performance of their vehicles.

Regular Maintenance Checklist

To keep the vehicle in peak condition, routine upkeep is essential. This section outlines the primary steps for inspecting vital components, ensuring that all systems function smoothly. Regular inspections help prevent costly repairs by addressing small issues before they escalate.

- Engine Health: Periodically check for unusual sounds, leaks, and maintain proper oil levels.

- Transmission: Inspect fluid levels and ensure that shifting is smooth and responsive.

- Braking System: Monitor pad wear, fluid levels, and any noises that could indicate issues.

- Electrical System: Confirm battery condition and ensure all lights and indicators function correctly.

- Suspension and Tires: Regularly inspect tire pressure and tread

Identifying Common Mechanical Issues

Understanding the typical mechanical concerns that arise with heavy-duty vehicles can help owners and drivers maintain better performance and prevent costly downtime. These vehicles, due to their workload, often face specific challenges that require early detection and routine checks.

Engine and Powertrain Concerns

One of the primary areas where problems can occur is within the engine and powertrain. These components undergo significant stress and can show signs of wear or failure if not monitored regularly. Recognizing early indicators of potential issues helps in planning timely interventions.

- Oil leaks: Common around seals and gaskets, leaks can lead to low oil levels and eventual engine damage.

- Unusual noises: Ticking, knocking, or rattling sounds can indicate worn components or issues with engine timing.

- Overheating: Frequent temperature spikes may suggest cooling system malfunctions or clogged filters.

Suspension and Steering Systems

The

Essential Tools for Effective Repairs

Having the right equipment on hand is crucial for addressing a wide range of vehicle needs efficiently and precisely. Whether addressing routine tasks or tackling more complex fixes, a well-prepared toolkit ensures both safety and accuracy in every step. This section outlines key items that enhance the overall process, helping you approach each task with the confidence that you have what’s necessary to complete it successfully.

Basic Hand Tools

A collection of reliable hand tools forms the foundation of any successful work on vehicles. Wrenches, screwdrivers, pliers, and sockets are indispensable and serve multiple purposes, from loosening bolts to making precise adjustments. Quality matters for these tools; investing in durable hand tools ensures they last through frequent use and heavy-duty tasks.

Specialized Equipment

Specialized tools cater to specific requirements and make certain procedures far more

Engine Troubleshooting and Maintenance

Proper upkeep and timely issue identification are essential for ensuring the engine operates smoothly and efficiently. Recognizing signs of wear or malfunction early can prevent more extensive problems, helping to extend the vehicle’s lifespan and maintain performance levels.

Identifying Common Engine Issues

Several signs indicate potential issues with the engine, such as unusual noises, vibrations, or a drop in power. If the engine struggles during startup, hesitates when accelerating, or stalls unexpectedly, these are signs that some components may need attention. It’s crucial to check warning lights on the dashboard, as they can indicate a variety of underlying issues, from low oil levels to cooling system malfunctions.

Basic Maintenance Practices

Ro

Transmission Care and Problem Solving

Ensuring the optimal performance of your vehicle’s transmission is essential for smooth driving and long-term reliability. Proper attention to this complex component can prevent many issues, keeping the vehicle responsive and reducing potential repair needs. Regular maintenance, timely fluid checks, and understanding common problems are key to achieving a resilient and dependable transmission system.

One of the primary maintenance tasks is monitoring the transmission fluid. This fluid lubricates and cools the transmission, minimizing wear on the components. Regularly checking its level and quality helps detect signs of trouble early, such as discoloration or burnt odors, which may indicate overheating or contamination. Replacing the fluid based on the manufacturer’s recommendation ensures the system operates efficiently.

Identifying issues early can prevent more severe problems down the line. Common symptoms, like unusual noises, delayed shifting, or slipping gears, often hi

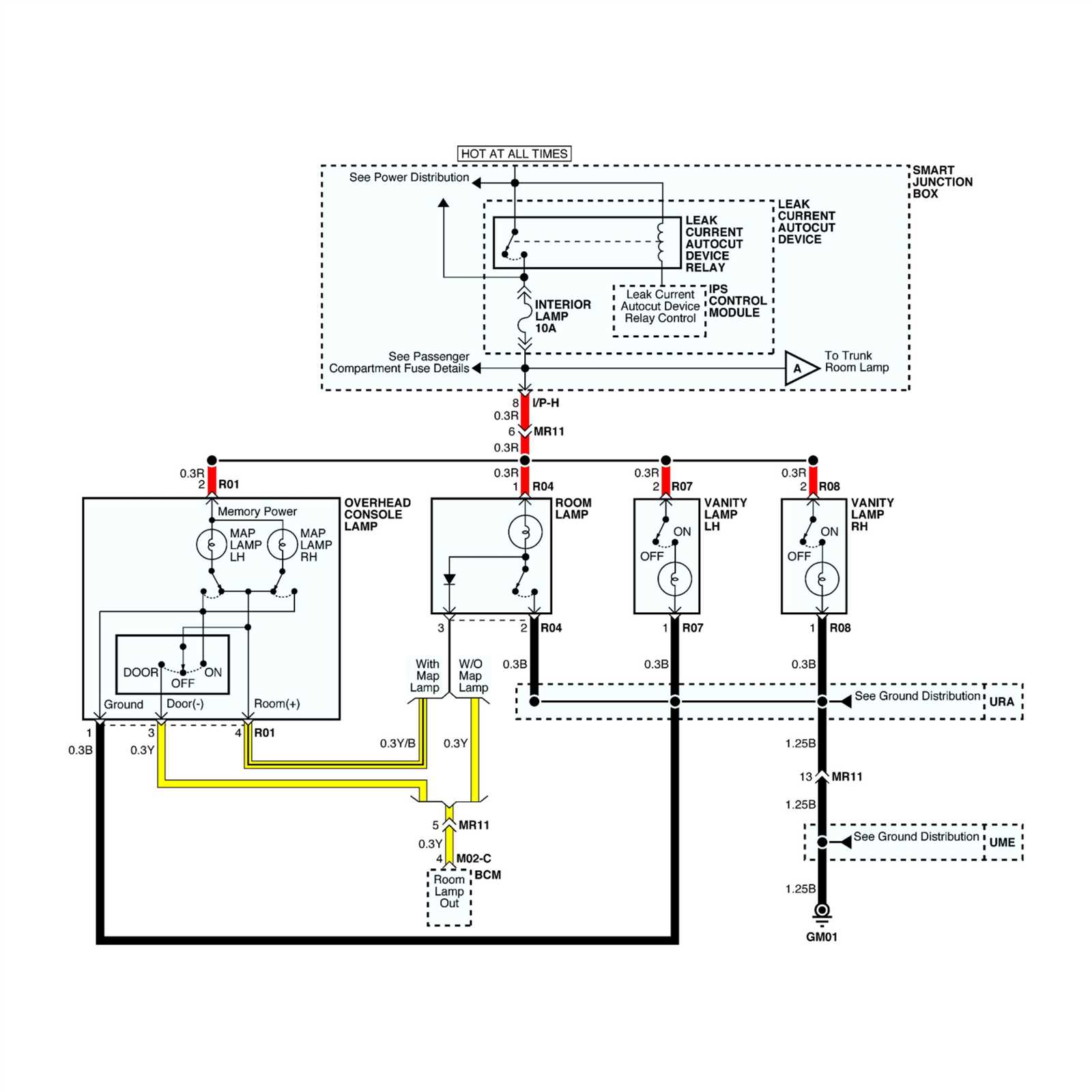

Electrical System Diagnostics Guide

This section provides essential insights into assessing and troubleshooting the electrical framework of a heavy-duty vehicle. Understanding the intricacies of the electrical system is vital for ensuring optimal performance and reliability. The following guidelines will aid in identifying common issues, interpreting diagnostic codes, and implementing effective solutions.

1. Preliminary Checks: Before delving into complex diagnostics, begin with a visual inspection. Examine all wiring harnesses for signs of wear, corrosion, or loose connections. A thorough assessment of the battery condition and its terminals is also crucial, as poor connections can lead to various electrical malfunctions.

2. Diagnostic Tools: Employ diagnostic equipment such as multimeters, oscilloscopes, and scan tools to evaluate the electrical system. These tools help measure voltage, current, and resistance, enabling technicians to pinpoint issues accurately. Familiarize yourself with the specific diagnostic procedures for different components, including sensors and actuators.

3. Interpreting Diagnostic Codes: Utilize the onboard diagnostic system to retrieve trouble codes. Understanding these codes is essential for diagnosing specific issues within the electrical network. Refer to manufacturer specifications for detailed explanations of the codes and suggested troubleshooting steps.

4. Component Testing: Conduct tests on individual components such as fuses, relays, and modules. Check for continuity and functionality to ensure each part operates within its intended parameters. Pay special attention to ground connections, as poor grounding can lead to erratic performance.

5. Document Findings: Keep detailed records of all diagnostic procedures and findings. Documenting tests, codes, and any repairs made can provide valuable insights for future troubleshooting and maintenance.

By following these guidelines, technicians can effectively diagnose and address issues within the electrical system, leading to improved vehicle reliability and performance.

Brake System Repair Techniques

The proper functioning of a vehicle’s stopping mechanism is crucial for safety and performance. Addressing issues within this system requires a systematic approach, ensuring that all components work harmoniously. Understanding the intricacies of these systems will enable efficient troubleshooting and maintenance, ultimately enhancing vehicle reliability.

Identifying Common Issues

Before diving into maintenance procedures, it’s vital to recognize the typical problems that can arise within the braking system. Common symptoms include unusual noises, decreased responsiveness, and vibrations during operation. Inspecting brake pads and rotors for wear, checking fluid levels, and examining hoses for leaks are essential first steps in diagnosing issues. Early detection of these signs can prevent more significant damage and ensure safer driving conditions.

Maintenance Procedures

Regular upkeep is essential for sustaining optimal performance. Replacing worn-out components, such as brake pads and rotors, is a fundamental task. Ensure that the replacement parts meet the manufacturer’s specifications. Additionally, bleeding the brake lines to remove air bubbles is crucial for maintaining hydraulic pressure, which is vital for effective braking. Finally, always test the system after any adjustments or replacements to confirm that everything operates smoothly.

Cooling System Inspection and Repair

The effectiveness of an engine’s cooling mechanism is crucial for optimal performance and longevity. Regular examination and maintenance of this system can prevent overheating and costly damage. This section outlines essential procedures for assessing and fixing the cooling apparatus, ensuring that it operates efficiently.

Begin by conducting a visual assessment of the entire cooling assembly. Look for signs of wear or damage, such as:

- Cracks or leaks in hoses and connections

- Corrosion on the radiator and coolant reservoir

- Loose or damaged clamps

- Debris obstructing airflow to the radiator

Once a visual check is complete, proceed to check the coolant level and condition:

- Ensure the engine is cool before removing the reservoir cap.

- Verify that the coolant is at the recommended level.

- Inspect the coolant for discoloration or contamination, indicating the need for a flush.

If any issues are identified, repairs should be prioritized. Common repair tasks include:

- Replacing damaged hoses or fittings

- Flushing and refilling the cooling system with fresh coolant

- Fixing leaks in the radiator or reservoir

- Inspecting and possibly replacing the thermostat if overheating occurs

Finally, after performing repairs, it is vital to conduct a functional test. Start the engine and monitor the temperature gauge, ensuring it remains within the normal operating range. Look for any signs of leaks or abnormal noises, indicating further issues may need to be addressed.

Exhaust System Maintenance Tips

Maintaining the exhaust system is crucial for ensuring optimal vehicle performance and longevity. Regular care not only enhances efficiency but also helps in minimizing emissions. Proper attention to this system can prevent costly repairs and ensure a smooth driving experience.

Here are some essential tips for keeping the exhaust system in top condition:

Tip Description Regular Inspections Periodically check the exhaust components for signs of wear, rust, or damage to ensure everything is functioning correctly. Check for Leaks Inspect joints and connections for leaks, which can affect performance and increase emissions. Maintain Proper Mounting Ensure all hangers and mounts are secure to prevent excessive vibration that can cause premature wear. Clean the System Regularly remove carbon buildup and other deposits to maintain efficiency and reduce noise. Listen for Unusual Noises Be attentive to any changes in sound, which may indicate a problem within the exhaust system. Replace Damaged Parts Immediately replace any worn or damaged components to maintain system integrity and performance. Suspension and Steering Adjustments

This section addresses essential modifications to the suspension and steering systems, which play a crucial role in vehicle handling and ride quality. Proper alignment and adjustments ensure optimal performance, stability, and safety while driving. Understanding these components and how to adjust them can significantly enhance the driving experience.

Correctly aligning the wheels and adjusting the steering mechanism can help prevent uneven tire wear and improve overall handling. Here are the primary adjustments to consider:

Adjustment Type Description Recommended Frequency Camber The angle of the wheels in relation to the road. Adjusting camber helps maintain even tire wear and improves cornering stability. Every 6,000 miles or as needed Toe The alignment of the wheels relative to the centerline of the vehicle. Proper toe settings ensure stable straight-line tracking and prevent tire scrubbing. Every 6,000 miles or after replacing tires Caster The angle of the steering axis. Adjusting caster can enhance steering responsiveness and stability during cornering. Every 12,000 miles or as needed Steering Gear Adjustment Ensures proper function and responsiveness of the steering system. Adjusting the gear can reduce play in the steering wheel. As necessary based on wear Regular inspections and adjustments of these components are vital for maintaining peak performance and prolonging the lifespan of the vehicle’s systems. A thorough understanding of suspension and steering adjustments contributes to a safer and more enjoyable driving experience.

Fuel System Service Procedures

The effective maintenance of the fuel delivery system is crucial for ensuring optimal performance and efficiency of any vehicle. This section outlines essential steps and best practices for servicing the fuel system, focusing on components such as the fuel pump, injectors, filters, and lines. Regular upkeep not only enhances functionality but also helps in preventing costly repairs in the future.

Preparation for Service

Before beginning any servicing tasks, it is important to follow a few preparatory steps:

- Ensure the vehicle is parked on a level surface.

- Disconnect the battery to prevent any electrical issues.

- Gather all necessary tools and replacement parts.

- Consult any relevant documentation for specific guidelines related to the fuel system.

Fuel System Components Maintenance

Each component of the fuel system requires careful attention. Below are key procedures to follow:

- Fuel Pump:

- Inspect for any signs of leakage or damage.

- Test the fuel pump operation by listening for unusual sounds during ignition.

- Replace if any issues are detected.

- Fuel Injectors:

- Check for clogs or blockages by inspecting injector nozzles.

- Clean or replace injectors as necessary to ensure proper fuel atomization.

- Fuel Filter:

- Replace the fuel filter at recommended intervals to maintain system cleanliness.

- Check for signs of contamination or buildup.

- Fuel Lines:

- Examine lines for cracks, leaks, or corrosion.

- Ensure all connections are secure and replace any damaged sections.

Following these procedures will help maintain the integrity of the fuel system, ensuring reliable performance and longevity of the vehicle.

Bodywork and Cosmetic Repairs

Maintaining the exterior aesthetics of a vehicle is essential for preserving its value and ensuring a pleasing appearance. This segment covers various techniques and practices aimed at restoring the surface integrity and visual appeal of automobiles. Whether addressing minor scratches, dents, or more extensive damage, understanding the fundamental aspects of bodywork can significantly enhance the longevity and attractiveness of your vehicle.

Common Cosmetic Issues

Every vehicle is susceptible to a range of cosmetic issues, including scratches, chips, and rust. Scratches can occur from contact with other objects, while chips may result from flying debris. Rust poses a more serious concern as it can lead to structural damage if not addressed promptly. Identifying these problems early can save time and resources in the long run.

Repair Techniques

Various methods are available for addressing cosmetic damage. For minor scratches, a simple touch-up paint application can effectively mask the blemish. Dents may require more specialized tools, such as a dent puller or heat application methods. Professional services can provide more advanced solutions, including full panel replacements or comprehensive repainting for extensive damage, ensuring a seamless finish.

Preventative Maintenance Recommendations

Regular upkeep is essential for ensuring the longevity and reliability of any vehicle. Implementing a structured maintenance schedule not only enhances performance but also minimizes the risk of unexpected issues. By focusing on key components and systems, owners can enjoy a smoother driving experience while avoiding costly repairs down the line.

Key Areas for Maintenance

- Engine Care: Regularly check and replace the engine oil and filter to ensure optimal performance.

- Fluid Levels: Monitor and top off essential fluids, including coolant, transmission fluid, and brake fluid.

- Battery Maintenance: Inspect the battery for corrosion and ensure secure connections; consider testing the charge regularly.

Inspection Schedule

- Every Month:

- Check tire pressure and tread depth.

- Inspect lights and signals for functionality.

- Every 3 Months:

- Replace air filters as needed.

- Examine brake pads for wear.

- Every 6 Months:

- Perform a thorough inspection of the suspension system.

- Check the exhaust system for leaks and damage.

By adhering to these recommendations, owners can ensure their vehicles operate efficiently and safely over the long term.