In the realm of outdoor power equipment, understanding the intricacies of your tools can significantly enhance their longevity and performance. This section delves into the essential aspects of upkeep and common issues that may arise with specific machinery, providing valuable insights for users aiming to maximize efficiency.

Whether you are an experienced operator or a novice, familiarizing yourself with the components and functionality of your equipment is crucial. This guide will equip you with the knowledge to identify potential problems and undertake effective solutions, ensuring that your device operates at its best.

By following the structured approach outlined herein, you will gain confidence in handling various challenges. Emphasis will be placed on practical steps and troubleshooting techniques that empower you to address issues independently, making maintenance a more manageable task.

Overview of Echo SRM 225

This section provides a comprehensive look at a popular outdoor power tool designed for efficient landscaping and gardening tasks. Known for its reliability and user-friendly features, this device has become a preferred choice among both professionals and hobbyists.

Key Features

- Powerful engine for high-performance cutting.

- Lightweight design for easy maneuverability.

- Adjustable handles for user comfort.

- Versatile attachments for various tasks.

Applications

Utilized in a range of gardening activities, this tool excels in:

- Trimming grass and weeds.

- Shaping bushes and shrubs.

- Maintaining large open areas.

- Performing detailed landscaping work.

Its robust construction ensures durability, making it suitable for both light and heavy-duty applications, while its efficient operation minimizes downtime.

Common Issues with Echo SRM 225

When operating a handheld grass trimmer, users may encounter various challenges that can affect performance and efficiency. Understanding these frequent problems can aid in maintaining the equipment and ensuring its longevity. This section highlights some of the most prevalent complications experienced by operators.

Starting Difficulties

One of the most common problems users face is trouble starting the machine. This can be attributed to several factors, including fuel quality, a clogged air filter, or issues with the ignition system. Regular maintenance, such as replacing the spark plug and ensuring the fuel is fresh, can help mitigate these issues.

Power Loss

Another frequent concern is a noticeable loss of power during operation. This may result from a dirty carburetor, obstructed fuel lines, or insufficient lubrication. Cleaning the fuel system and checking for any blockages can restore the tool’s efficiency and performance.

Essential Tools for Repair

To effectively maintain and troubleshoot garden equipment, having the right set of instruments is crucial. These tools not only simplify the process but also enhance safety and efficiency. A well-equipped workspace can make all the difference when addressing mechanical issues.

Basic Toolkit

Every enthusiast should have a foundational toolkit ready. Here are the must-have items:

- Wrenches of various sizes

- Screwdrivers (flathead and Phillips)

- Socket set

- Pliers (needle-nose and standard)

- Utility knife

Specialized Equipment

In addition to basic tools, certain specialized instruments can be beneficial:

- Torque wrench for precise tightening

- Feeler gauge for checking gaps

- Multimeter for electrical diagnostics

- Chain saw file for maintenance

- Oil can for lubrication

Step-by-Step Repair Instructions

This section provides a comprehensive guide to addressing common issues with your trimmer. By following these detailed steps, you can effectively troubleshoot and resolve problems, ensuring your equipment runs smoothly and efficiently. Each procedure is outlined clearly to assist you in performing necessary maintenance tasks with confidence.

Before starting, gather all required tools and safety gear to ensure a safe working environment. Familiarize yourself with the components involved in the process.

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental start-up. |

| 2 | Inspect the fuel system for leaks or blockages. Replace any damaged parts. |

| 3 | Examine the cutting head for wear. Replace the line or head if necessary. |

| 4 | Check the air filter and clean or replace it to ensure proper airflow. |

| 5 | Review the spark plug condition. Clean or replace it to improve ignition. |

| 6 | Reassemble all components securely and refill with fuel if applicable. |

| 7 | Test the equipment to ensure it operates correctly. |

Following these steps will help you maintain optimal performance and extend the lifespan of your tool. Regular maintenance is key to preventing future complications.

Maintenance Tips for Longevity

Proper upkeep of your outdoor equipment is essential for maximizing its lifespan and ensuring optimal performance. Regular attention to key components can prevent breakdowns and costly repairs, while also enhancing efficiency during use. Below are some vital tips to keep your machinery in excellent condition.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris from the equipment after each use to prevent wear and corrosion. |

| Check Fuel Quality | Use fresh fuel and check for contamination to ensure proper engine performance. |

| Inspect Blades | Regularly examine cutting tools for dullness and damage; sharpen or replace as needed. |

| Air Filter Maintenance | Clean or replace air filters periodically to promote optimal airflow and engine efficiency. |

| Oil Changes | Change oil according to the manufacturer’s guidelines to maintain engine health. |

| Battery Care | Inspect battery connections and charge levels to prevent starting issues. |

Following these guidelines will not only extend the life of your machinery but also improve its reliability and performance in the long run.

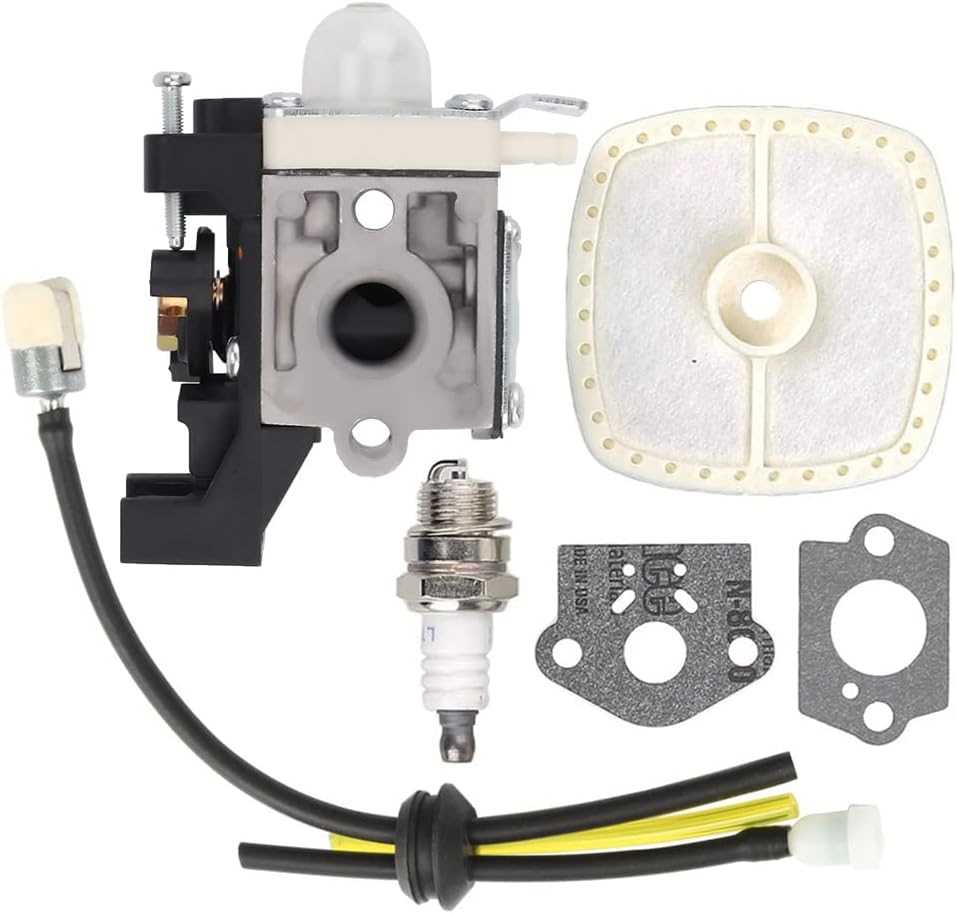

Parts Replacement Guide

This section provides essential information on how to effectively replace components in your outdoor equipment. Understanding the importance of timely parts replacement ensures the longevity and efficiency of your device, preventing potential issues that could arise from wear and tear.

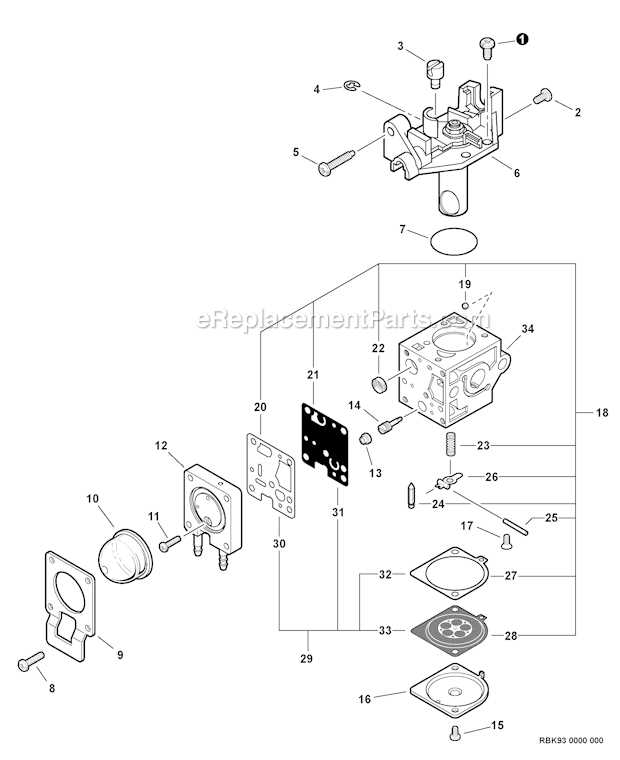

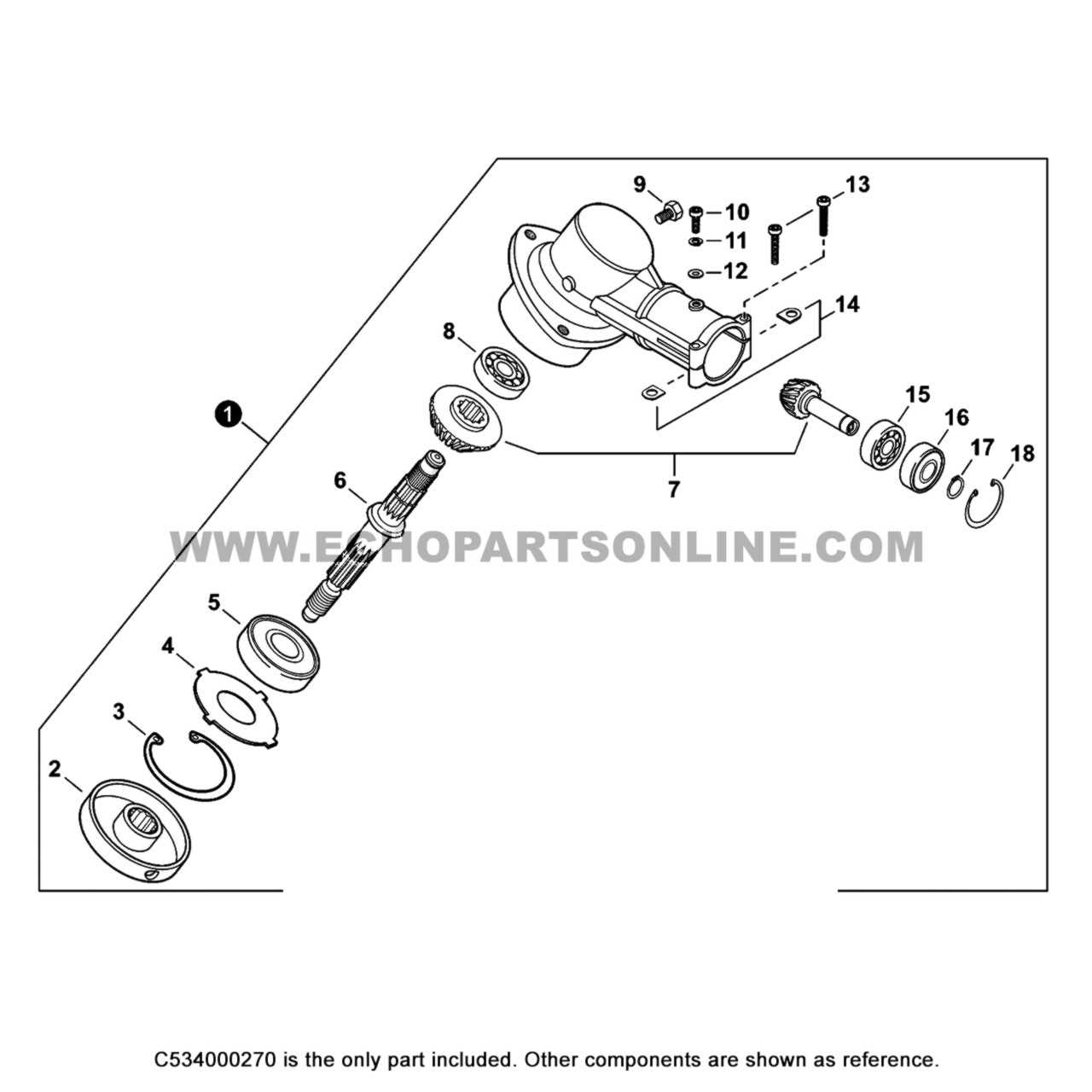

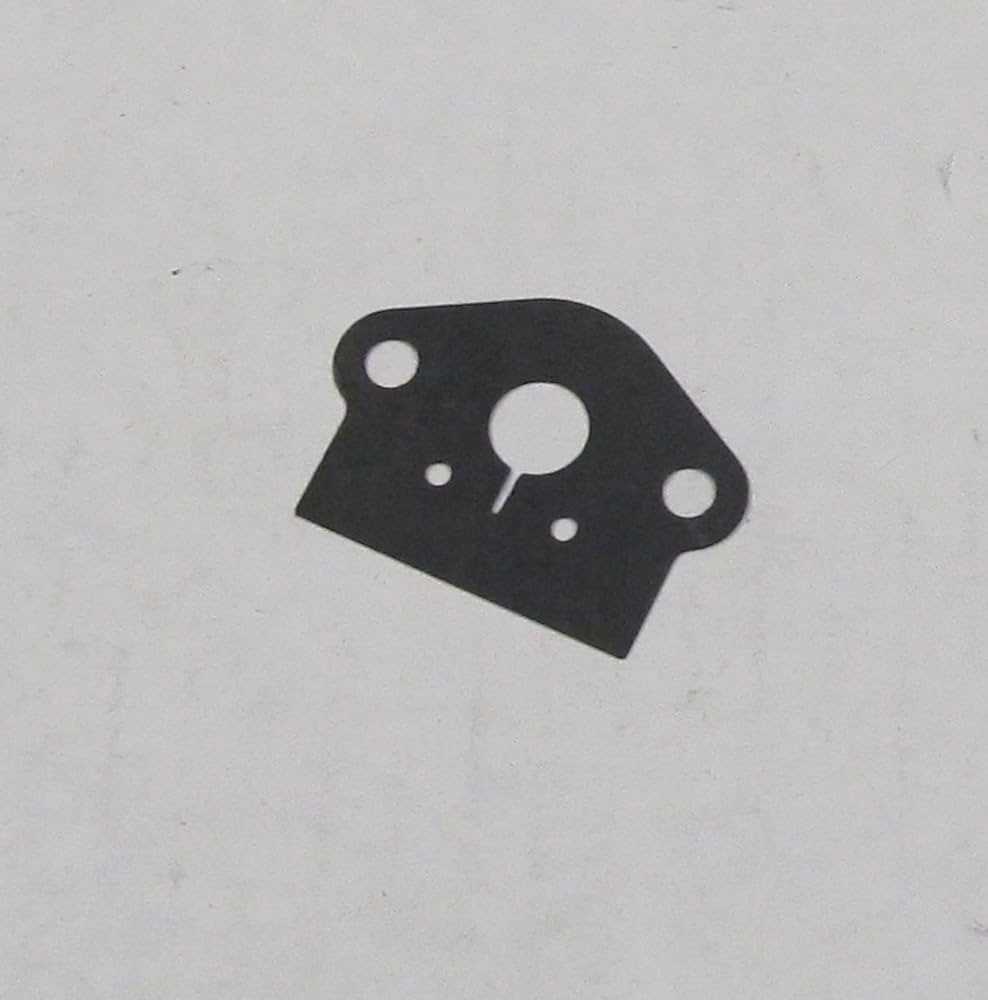

Identifying Components: Begin by familiarizing yourself with the key parts of your machine. Regular inspection helps in spotting any signs of damage or degradation, allowing for proactive maintenance. Consult diagrams or part lists to identify the specific items needing attention.

Acquiring New Parts: When sourcing replacement items, prioritize quality and compatibility. Original components are often recommended for their reliability, but reputable aftermarket options can also provide satisfactory performance. Always verify that the parts match the specifications of your equipment.

Replacement Procedure: Follow a systematic approach for replacing parts. Start by disconnecting the power source to ensure safety. Use appropriate tools and techniques, referring to any available resources or guides for detailed instructions. Take your time to ensure each component is installed correctly.

Testing: After the replacement is complete, conduct thorough tests to ensure everything operates smoothly. Monitor the equipment for any unusual sounds or behaviors, which may indicate further adjustments are necessary.

Regular maintenance and timely parts replacement will significantly enhance the performance and lifespan of your outdoor machinery. Stay vigilant and proactive to enjoy optimal functionality for years to come.

Safety Precautions During Repair

When engaging in maintenance activities on outdoor power equipment, it is crucial to prioritize safety to prevent accidents and injuries. Implementing proper guidelines can ensure a secure working environment and enhance overall efficiency. Awareness of potential hazards and adherence to safety measures is essential for anyone performing such tasks.

Before commencing work, familiarize yourself with the specific device you are handling. Understanding its components and functions will minimize risks and improve the effectiveness of the procedure.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate gear, including gloves, safety glasses, and sturdy footwear to protect against injuries. |

| Work Area Organization | Maintain a clean and organized workspace. Remove any clutter that could pose a tripping hazard or obstruct tools. |

| Power Disconnection | Ensure the device is powered off and disconnected from any energy source before starting any maintenance tasks. |

| Tool Inspection | Inspect all tools for damage or wear before use. Using faulty tools can lead to accidents. |

| Follow Instructions | Adhere strictly to guidelines and instructions to prevent errors that could lead to hazardous situations. |

By taking these safety measures into account, individuals can effectively reduce the risk of accidents, ensuring a smoother and more secure maintenance process.

Troubleshooting Engine Problems

Identifying and resolving engine issues can be essential for maintaining optimal performance. Various symptoms can signal underlying problems, ranging from poor starting to unusual noises. Understanding these signs and their potential causes is crucial for effective diagnostics.

Common Symptoms

- Engine won’t start

- Rough idling

- Excessive smoke

- Loss of power during operation

- Unusual sounds

Potential Causes

- Fuel Issues: Contaminated or old fuel can lead to poor combustion.

- Air Filter Blockage: A dirty air filter restricts airflow, affecting performance.

- Ignition Problems: Faulty spark plugs or ignition coils can prevent proper starting.

- Exhaust Blockage: Restrictions in the exhaust system can cause back pressure.

- Mechanical Failures: Internal components may wear out, leading to engine failure.

By methodically assessing these symptoms and potential causes, users can effectively troubleshoot and restore proper engine function.

Fuel System Inspection Techniques

Inspecting the fuel system is essential for ensuring optimal performance and longevity of small engine equipment. A thorough examination can help identify issues such as leaks, blockages, and contamination that could hinder operation. Employing systematic inspection techniques allows for efficient troubleshooting and maintenance, ensuring that the equipment runs smoothly.

Visual Inspection

The first step in assessing the fuel system involves a visual examination. This technique focuses on identifying obvious signs of wear, damage, or leaks. Key components to inspect include:

| Component | Inspection Criteria |

|---|---|

| Fuel Lines | Look for cracks, bulges, or signs of leakage. |

| Fuel Filter | Check for clogging or contamination in the filter media. |

| Carburetor | Inspect for corrosion or build-up of debris around openings. |

| Fuel Tank | Ensure there are no leaks and that the tank is free from rust. |

Functional Testing

After completing a visual check, functional testing is crucial to confirm the integrity of the fuel system. This involves running the engine to evaluate performance and response. During this phase, pay attention to:

- Engine starting ease and stability.

- Unusual noises indicating fuel delivery issues.

- Acceleration response when throttle is applied.

Regular inspections using these techniques can prevent minor issues from escalating, ensuring reliable operation and extending the lifespan of the equipment.

Cleaning and Care Recommendations

Maintaining your equipment is essential for ensuring optimal performance and longevity. Regular cleaning and proper care not only enhance functionality but also prevent potential issues that could arise from neglect. By following these straightforward guidelines, you can keep your tools in top condition and ready for any task.

1. Regular Inspection: Before each use, take a moment to inspect your device for any visible damage or wear. Check the cutting components for signs of dullness or chipping, as this can affect performance.

2. Cleaning After Use: After each operation, it’s important to clean the exterior and any attachments. Use a soft brush or cloth to remove debris and dirt, ensuring that no residue is left to cause corrosion or build-up.

3. Blade Maintenance: Keep blades sharp and free from sap or grass clippings. A clean blade not only improves cutting efficiency but also minimizes strain on the engine. Use a specialized cleaner or a mixture of water and mild soap to maintain the blade’s condition.

4. Fuel System Care: Regularly check and clean the fuel system components. Ensure that the fuel lines are free from clogs and that the fuel filter is clean. This will help maintain smooth operation and prevent starting issues.

5. Storage Tips: When storing your equipment, ensure it is in a dry and cool environment. If possible, store it upright and away from direct sunlight. This will help prevent damage from moisture and extreme temperatures.

6. Periodic Professional Servicing: Consider scheduling periodic check-ups with a professional to address any potential issues that might not be easily noticeable. This proactive approach can save time and money in the long run.

By following these recommendations, you can significantly extend the life of your equipment and ensure it operates at peak efficiency whenever you need it.

When to Seek Professional Help

Understanding when to turn to an expert is crucial for maintaining your equipment effectively. While many minor issues can be resolved independently, certain situations warrant professional intervention to avoid further damage or safety risks.

If you encounter persistent problems that do not improve with basic troubleshooting, it’s advisable to consult a specialist. Additionally, unusual sounds, vibrations, or smoke during operation are red flags indicating that the machinery may need immediate attention. Complex repairs involving electrical components or internal mechanisms should always be handled by trained technicians to ensure safety and compliance with manufacturer standards.

Moreover, if you find yourself unsure about the proper procedures or lack the necessary tools for a repair, reaching out for professional guidance can save you time and potential costs associated with improper handling. Prioritizing safety and efficiency is key, so don’t hesitate to seek expert assistance when needed.