Owning a dependable vehicle requires an understanding of its intricate systems and a readiness to handle potential issues as they arise. Knowing how to address common technical challenges can keep your vehicle running smoothly and save on costly service trips. This guide provides essential insights into preserving engine health, diagnosing electrical faults, and maintaining overall performance.

Whether tackling engine misfires, examining the fuel system, or navigating routine upkeep, this resource offers a structured approach for each aspect of vehicle maintenance. From step-by-step procedures to practical tips, you’ll find invaluable support for a range of mechanical and electrical components. Familiarity with these topics can empower you to handle most tasks independently, enhancing the longevity and efficiency of your vehicle.

With easy-to-follow advice on diagnostic procedures, this guide equips both beginners and seasoned drivers with knowledge to ensure a safe and dependable journey. Key sections address troubleshooting methods and provide clarity on essential tools, making upkeep and repairs more accessible than ever.

2006 Chevy Trailblazer Repair Manual

For owners of this mid-size SUV, maintaining optimal condition is key to ensuring reliable performance. Keeping up with recommended servicing, addressing common issues proactively, and having a solid guide to repairs allows for a smoother experience both on the road and in the garage. This guide provides essential insights into vehicle upkeep and addresses specific areas of focus that may require regular attention or occasional repairs.

Routine Maintenance is foundational to vehicle longevity. Regular tasks, such as changing oil, replacing filters, and checking fluid levels, are vital for preserving engine efficiency. Additionally, inspecting brake systems, tires, and suspension components can prevent unexpected issues, extending both performance and lifespan.

Engine Diagnostics and Troubleshooting can help identify early signs of wear or damage before they escalate. Understanding warning lights and being able to pinpoint the source of irregular sounds or decreased performance may reduce the likelihood of costly repairs. With the right resources, owners can confidently approach minor issues or determine when professional assistance is necessary.

Electrical System Checks play a crucial

Engine Maintenance and Troubleshooting

Effective engine care is essential to ensure optimal performance, fuel efficiency, and a longer lifespan for your vehicle. This guide outlines key maintenance tasks and troubleshooting tips for identifying and addressing common engine issues, helping you maintain smooth operation and avoid costly repairs.

- Regular Oil Changes: Clean oil is critical for lubrication, cooling, and protecting engine components from wear. Replace the oil at recommended intervals and check levels frequently to prevent damage.

- Inspect Belts and Hoses: Worn belts and leaking hoses can lead to overheating, reduced performance, or complete engine failure. Look for cracks, frays, or leaks, especially around connections, and replace any damaged parts promptly.

- Air Filter Replacement:

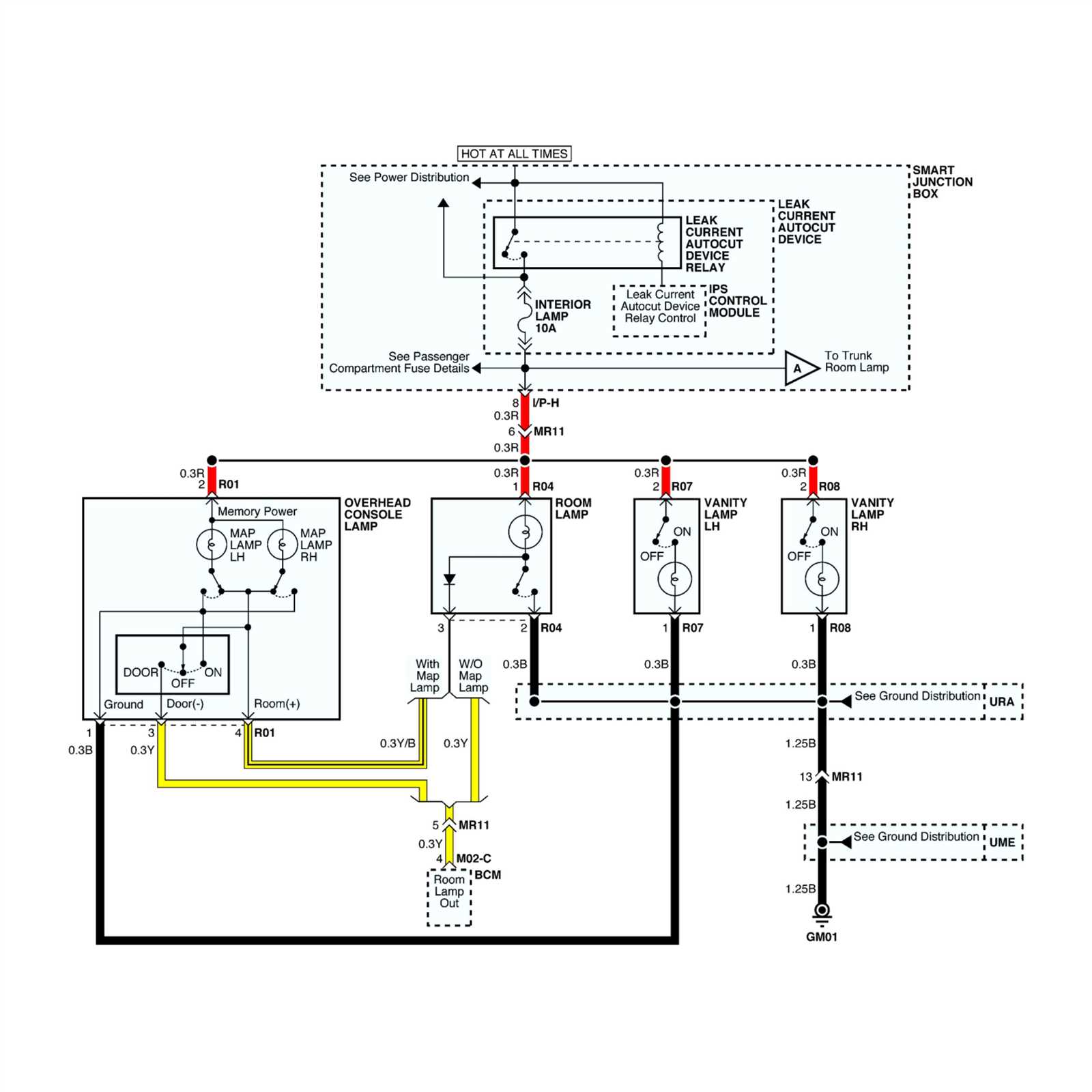

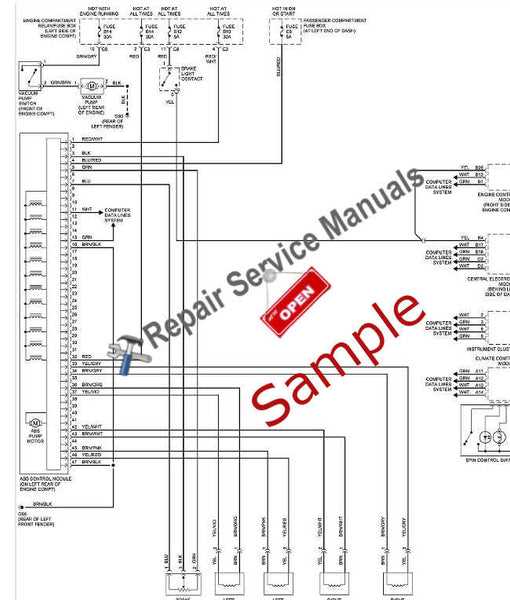

Electrical System Diagnostics

Effective electrical system diagnostics involves a structured approach to identifying and addressing potential issues within a vehicle’s electrical network. From evaluating battery health to assessing wiring integrity, each component plays a role in ensuring reliable performance. Understanding the common points of failure, as well as how different systems interact, is essential for accurately pinpointing faults and ensuring long-term functionality.

Key diagnostic steps include voltage testing, continuity checks, and visual inspections of connectors and cables. Each of these steps helps uncover problems such as poor grounding, corroded terminals, or worn insulation, which can disrupt the system’s efficiency. Technicians often use specialized tools like multimeters and circuit testers to verify readings and locate the source of electrical issues with precision.

Systematic examination of sensors and control modules also aids in diagnosing more complex problems. In modern vehicles, modules communicate with one another via data buses, and any interruption in this communication can impact performance. By analyzing error codes and observing real-time data, technicians can assess the state of individual modules

Transmission Repair Guidelines

The transmission system is essential for ensuring smooth power transfer and optimal vehicle performance. Addressing issues in this system requires a thorough understanding of its components and the common problems that can arise. With careful attention to detail and methodical inspection, common faults can often be corrected before they lead to major breakdowns.

Diagnosis and Inspection: Early diagnosis is crucial for efficient maintenance of transmission components. Start with a visual inspection for signs of leaks around seals and gaskets. Unusual noises, such as grinding or whining, may indicate internal wear or fluid contamination. Regularly checking fluid levels and quality is also vital, as low or dirty fluid can signal underlying issues.

Fluid Replacement: Transmission fluid plays a crucial role in cooling an

Suspension and Steering Adjustments

Suspension and steering adjustments are essential for maintaining a vehicle’s stability, ride comfort, and precise handling. Regularly tuning these components ensures that the vehicle responds accurately to the driver’s inputs, maintains proper alignment, and provides a balanced ride. By making specific modifications to the suspension and steering, one can optimize control and stability, especially under various driving conditions.

Proper suspension adjustment begins with checking the ride height and ensuring the springs, shocks, and struts are functioning correctly. Any worn-out parts should be replaced to restore full performance. This is critical in maintaining even tire wear and minimizing vibrations, which improves handling and comfort.

Steering adjustments often involve tuning the alignment angles such as camber, caster, and toe. These adjustments ensure that the wheels are aligned according

Brake System Servicing

Maintaining the braking system is crucial for ensuring safety and performance. Proper care involves regular inspections, component replacements, and adjustments as needed. This section will explore essential practices for maintaining the braking system effectively.

Inspection is the first step in brake system maintenance. Regularly check for wear on brake pads and rotors, as well as fluid levels. Any signs of damage or uneven wear should prompt further investigation.

When replacing brake pads, choose high-quality materials to ensure optimal performance. It’s important to install them correctly, following manufacturer guidelines for torque specifications.

The brake fluid should be replaced according to the vehicle’s service schedule. Contaminated fluid can lead to reduced braking efficiency and potential system failure. Always use the recommended type of fluid for the best results.

In addition to these practices, periodic bleeding of the brake lines is necessary to remove air bubbles that can cause a spongy pedal feel. This process should be performed whenever brake components are replaced or if the fluid has not been changed for an extended period.

Maintaining the brake system not only enhances vehicle safety but also extends the lifespan of its components. Regular service will ensure optimal functionality and reliability during operation.

Cooling System Checks and Fixes

The cooling system plays a vital role in maintaining the optimal temperature of the engine, preventing overheating and ensuring efficient performance. Regular inspections and timely repairs are essential to keep this system functioning effectively. Understanding the components and their maintenance will help in identifying issues before they escalate.

Common Issues to Look For

Several problems can arise within the cooling system, affecting the vehicle’s operation. These include leaks, thermostat malfunctions, and radiator clogs. Identifying these issues early can save time and costly repairs down the line.

Issue Symptoms Potential Fixes Coolant Leak Puddles under the vehicle, low coolant levels Inspect hoses and connections; replace damaged parts Overheating Engine Temperature gauge rising, steam from engine Check coolant level; replace thermostat or radiator if needed Clogged Radiator Reduced heating efficiency, engine running hot Flush radiator and replace coolant; check for debris Preventive Measures

To enhance the longevity of the cooling system, regular maintenance is crucial. This includes checking coolant levels, inspecting hoses for wear, and flushing the system periodically. By adhering to a maintenance schedule, potential problems can be mitigated before they impact performance.

Fuel System Components and Repairs

The fuel system plays a crucial role in the overall performance of a vehicle, ensuring that the engine receives the appropriate amount of fuel for efficient operation. Understanding the various elements of this system and their maintenance requirements can help enhance vehicle reliability and longevity.

Key Components

- Fuel Pump: Responsible for transferring fuel from the tank to the engine.

- Fuel Filter: Cleans the fuel by removing impurities before it reaches the engine.

- Fuel Injectors: Spray fuel directly into the combustion chamber for optimal mixing with air.

- Fuel Lines: Transport fuel between the tank, filter, and injectors.

- Fuel Pressure Regulator: Maintains consistent pressure within the fuel system.

Common Issues and Solutions

- Pump Failure: Symptoms include engine sputtering or failure to start. Replace the pump if necessary.

- Clogged Fuel Filter: Reduced performance or fuel flow. Regularly replace filters as part of maintenance.

- Leaking Fuel Lines: Look for signs of fuel odor or visible leaks. Repair or replace damaged lines promptly.

- Injector Problems: Symptoms include rough idling or decreased fuel efficiency. Clean or replace injectors if they are faulty.

Regular inspection and maintenance of the fuel system components are essential for ensuring optimal vehicle performance and avoiding costly repairs in the future.

Interior Components Restoration

Restoring the interior of a vehicle can significantly enhance its overall aesthetic and comfort. This process involves careful assessment and refurbishment of various elements, ensuring that each component not only looks appealing but also functions optimally. From upholstery and dashboards to door panels and console systems, every detail contributes to the driving experience.

Assessing the Condition

The first step in the restoration journey is to evaluate the state of the interior components. Identifying areas of wear, damage, or discoloration helps in determining the necessary repairs or replacements. Attention should be paid to upholstery, trim, and electronic systems that may require attention.

Restoration Techniques

Various techniques can be employed to restore interior components effectively. Cleaning, reupholstering, and refinishing are common practices. In some cases, replacement of parts may be necessary, particularly for damaged or outdated elements. Below is a summary of popular restoration methods:

Technique Description Benefits Cleaning Deep cleaning of surfaces and materials to remove dirt and stains. Improves appearance and hygiene. Reupholstering Replacing or repairing worn upholstery with new fabric or leather. Enhances comfort and visual appeal. Refinishing Applying new finishes to wood, plastic, or metal components. Restores original luster and protects surfaces. Replacement Substituting damaged parts with new or refurbished items. Ensures functionality and improves safety. By implementing these strategies, vehicle owners can achieve a refreshed and inviting interior space that enhances both functionality and aesthetics, ensuring a satisfying experience every time they take to the road.

Exterior Care and Restoration Tips

Maintaining the appearance of your vehicle is essential for preserving its value and ensuring it remains visually appealing. Regular care not only enhances aesthetics but also protects against environmental factors that can lead to deterioration over time. Below are some effective strategies for keeping the exterior in prime condition.

Regular Washing and Waxing

Frequent washing helps remove dirt, grime, and contaminants that can damage the paint. Use a gentle soap designed for automotive surfaces and a soft sponge to avoid scratches. After washing, applying a high-quality wax can create a protective barrier against UV rays and moisture. This not only enhances shine but also makes future cleaning easier.

Addressing Scratches and Dents

Over time, minor scratches and dents may appear on the surface. It’s crucial to address these issues promptly to prevent rust and further damage. For small scratches, consider using a touch-up paint that matches the vehicle’s color. For more significant dents, specialized tools or professional services may be necessary to restore the original look effectively. Taking these steps can significantly extend the lifespan of your vehicle’s exterior.

Exhaust System Repair Techniques

Addressing issues within the exhaust framework is crucial for maintaining optimal vehicle performance and compliance with emission standards. Effective strategies involve a thorough understanding of components and potential failure points, enabling technicians to execute precise interventions.

Identification of Problems: The initial step involves inspecting the system for visible damage, such as cracks or corrosion. Utilizing diagnostic tools can assist in detecting leaks or irregularities in pressure, which are common indicators of malfunction.

Component Replacement: When specific elements, like the muffler or catalytic converter, exhibit significant wear, replacing them can restore efficiency. It’s essential to ensure compatibility with the existing setup to avoid further complications.

Sealing Leaks: Small gaps or holes can often be mended using high-temperature sealants designed for exhaust applications. This method provides a cost-effective solution to prevent gas leaks without the need for complete component replacement.

Alignment and Fitting: Proper alignment of exhaust pipes is vital. Misalignment can lead to premature wear and excessive vibration. Adjusting hangers and brackets ensures the system is securely positioned, minimizing stress on joints.

Maintenance Practices: Regular inspection and cleaning of the exhaust system can prevent the buildup of debris and corrosion. Applying protective coatings can also enhance the longevity of components, particularly in regions exposed to harsh weather conditions.

Diagnostic Tools and Techniques

Effective troubleshooting of automotive issues requires a combination of appropriate instruments and methodologies. Utilizing the right diagnostic tools can significantly enhance the accuracy of identifying problems, ultimately leading to efficient repairs. This section explores essential devices and approaches that facilitate thorough assessments of vehicle performance and functionality.

Essential Diagnostic Instruments

One of the primary instruments used in automotive diagnostics is the OBD-II scanner. This device interfaces with the vehicle’s onboard computer to retrieve diagnostic trouble codes (DTCs) that indicate malfunctions. Additionally, multimeters are indispensable for measuring electrical parameters, allowing technicians to pinpoint issues with wiring or components. Pressure gauges, oscilloscopes, and specialized sensors also play crucial roles in assessing various systems, from fuel delivery to ignition performance.

Methodical Assessment Approaches

In conjunction with diagnostic tools, adopting systematic evaluation techniques is vital for effective problem-solving. Starting with a visual inspection can uncover obvious signs of wear or damage. Following this, a logical approach to testing components, beginning with the most accessible and working towards the more complex systems, ensures that potential issues are addressed methodically. Utilizing flowcharts can also aid in troubleshooting by providing clear pathways to isolate faults.