In the realm of lawn care, ensuring the optimal performance of your machinery is essential for achieving pristine results. Whether you’re a professional landscaper or a dedicated homeowner, understanding the intricacies of your equipment can make a significant difference in efficiency and longevity. This section delves into the key aspects of maintaining your turf management tools, providing invaluable insights to keep them running smoothly.

The art of upkeep involves not only routine inspections and adjustments but also a comprehensive understanding of the components that contribute to your machinery’s functionality. From engine performance to blade sharpness, each element plays a crucial role in achieving desired outcomes. By familiarizing yourself with essential procedures and troubleshooting techniques, you can address common issues with confidence and ease.

Furthermore, having access to detailed information regarding assembly, disassembly, and repair processes is invaluable for any user. Whether you encounter a minor hiccup or a more significant challenge, this guide aims to equip you with the knowledge needed to tackle repairs effectively. Embracing a proactive approach to maintenance will ultimately lead to enhanced productivity and a longer lifespan for your equipment.

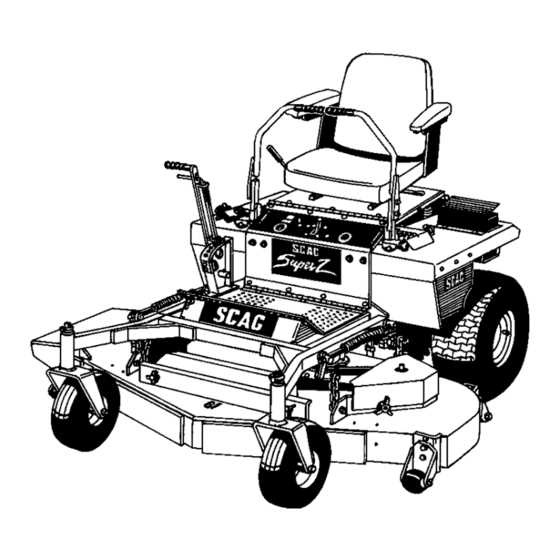

Understanding Scag Tiger Cub Mechanics

Grasping the intricacies of lawn care machinery is essential for maintaining optimal performance and longevity. This section delves into the fundamental components and systems that drive efficiency in compact mowing equipment, equipping users with the knowledge needed for effective upkeep and troubleshooting.

Key Components

- Engine: The heart of the machine, responsible for generating power. Understanding its specifications and maintenance needs is crucial.

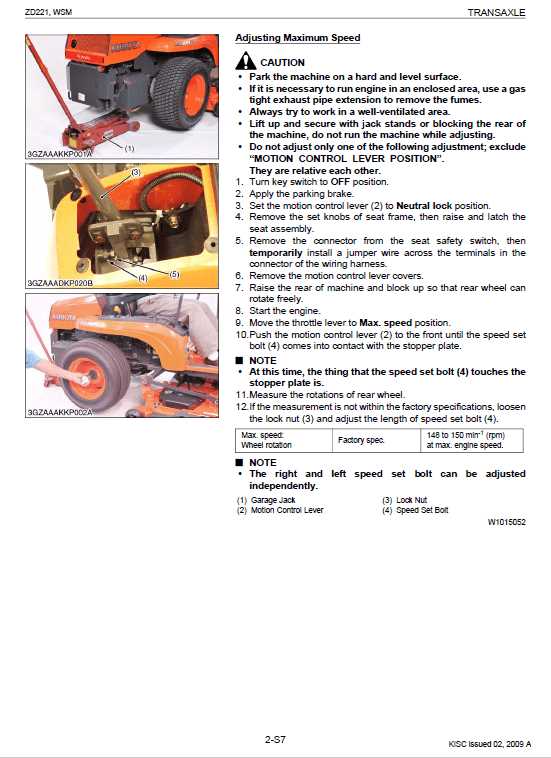

- Transmission: This system transfers power from the engine to the wheels, affecting speed and maneuverability. Regular checks are vital for smooth operation.

- Cutter Deck: The part that houses the blades, responsible for achieving a clean cut. Maintenance involves sharpening blades and ensuring proper alignment.

- Wheels and Tires: Proper inflation and tread condition are essential for traction and stability during operation.

Maintenance Tips

- Regularly check fluid levels and replace filters to ensure the engine runs smoothly.

- Inspect belts and cables for wear and tear, replacing them as necessary to avoid breakdowns.

- Clean the undercarriage frequently to prevent grass buildup that can affect performance.

- Schedule seasonal tune-ups to address any emerging issues before they escalate.

Common Issues with Scag Tiger Cub

When it comes to maintaining high-performance lawn equipment, certain recurring challenges can arise, affecting functionality and efficiency. Understanding these frequent problems is crucial for ensuring smooth operation and longevity of the machinery.

1. Engine Starting Difficulties: One of the most prevalent issues encountered is trouble starting the engine. This can be attributed to various factors, including a weak battery, dirty spark plugs, or fuel system blockages. Regular checks and maintenance can help mitigate these issues.

2. Uneven Cutting: Users often report inconsistencies in cutting height and quality. This can stem from dull blades, improper deck leveling, or tire pressure discrepancies. Ensuring that blades are sharpened and the deck is correctly adjusted can enhance performance.

3. Overheating: Overheating can pose a significant threat to machinery. This may occur due to insufficient oil levels, clogged air filters, or a malfunctioning cooling system. Regular inspections can prevent overheating and promote optimal operation.

4. Hydraulic Problems: Hydraulic system failures can lead to reduced maneuverability and power loss. Common causes include leaks, air in the system, or contaminated fluid. Keeping the hydraulic components clean and regularly servicing the system can address these concerns.

5. Belt Wear: The belts that drive various components can wear out over time, leading to slippage or failure. Routine inspections and timely replacements are essential to maintain efficiency and prevent breakdowns.

By being aware of these common issues and implementing proactive maintenance strategies, operators can significantly enhance the performance and durability of their equipment.

Essential Tools for Repairs

When it comes to maintaining outdoor machinery, having the right instruments at your disposal is crucial. A well-equipped toolkit not only facilitates efficient troubleshooting but also ensures that tasks are completed safely and effectively. This section outlines the fundamental instruments needed for successful maintenance activities.

Basic Hand Tools

Hand tools form the backbone of any maintenance effort. These items are essential for a variety of tasks, from tightening screws to performing intricate adjustments. A basic set should include:

| Tool | Purpose |

|---|---|

| Wrenches | Used for gripping and turning nuts and bolts. |

| Screwdrivers | Ideal for driving screws into place or removing them. |

| Pliers | Useful for bending, twisting, and cutting wire. |

| Socket Set | Provides a range of sizes for tightening and loosening bolts. |

Specialized Equipment

In addition to basic hand tools, having specialized equipment can greatly enhance your ability to diagnose and fix issues. These tools can address specific challenges encountered during upkeep:

| Tool | Function |

|---|---|

| Multimeter | Measures voltage, current, and resistance to troubleshoot electrical problems. |

| Torque Wrench | Ensures that fasteners are tightened to precise specifications. |

| Oil Filter Wrench | Facilitates the removal and installation of oil filters. |

| Diagnostic Scanner | Identifies faults in electronic systems for accurate assessments. |

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a systematic approach can help identify issues early and maintain functionality. This section outlines a comprehensive set of actions to keep your machinery in top shape.

1. Cleaning the Exterior: Begin by removing any debris or grass clippings from the exterior surfaces. Use a soft brush and water to avoid damaging the paint. Ensure that air vents are free of obstructions for efficient cooling.

2. Checking Fluids: Inspect all fluid levels, including oil, fuel, and hydraulic fluids. Top off or replace as necessary. Regularly changing the oil helps to keep the engine running smoothly and prevents wear.

3. Examining the Blades: Inspect the cutting blades for signs of wear or damage. Sharpen or replace blades as needed to maintain cutting efficiency. Always ensure the blades are properly secured before use.

4. Inspecting Belts and Cables: Check all belts and cables for signs of fraying or wear. Replace any damaged components to prevent failure during operation. Ensure that all connections are secure and functioning correctly.

5. Testing the Battery: Conduct a battery test to ensure it is holding a charge. Clean any corrosion from terminals and ensure all connections are tight. Replace the battery if it shows signs of degradation.

6. Reviewing Safety Features: Regularly check safety mechanisms, such as emergency stops and guards, to ensure they are operational. Address any issues immediately to maintain a safe working environment.

7. Storing Properly: When not in use, store the equipment in a dry, sheltered location. This protects it from the elements and prolongs its lifespan. Consider using a cover for additional protection.

Implementing these maintenance steps will contribute significantly to the reliability and efficiency of your machinery, allowing for a smooth and effective operation year-round.

Troubleshooting Electrical Problems

Addressing electrical issues in outdoor machinery requires a systematic approach to identify and resolve faults efficiently. Understanding common symptoms and their potential causes can significantly expedite the troubleshooting process.

Common Symptoms

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Dead battery or faulty connections |

| Lights flicker | Loose wiring or bad ground connection |

| Electrical components malfunction | Blown fuses or damaged circuit |

Diagnostic Steps

Begin by inspecting the battery and connections for corrosion or loose terminals. Next, check fuses and replace any that are blown. Finally, verify the integrity of wiring harnesses to identify any signs of wear or damage.

Replacing the Blades Safely

Ensuring the safe replacement of cutting tools is crucial for both performance and user protection. Proper procedures not only enhance the effectiveness of the equipment but also minimize the risk of injury during the process. By adhering to specific guidelines, users can confidently carry out maintenance tasks without compromising safety.

Before beginning the replacement, it is essential to gather all necessary tools and wear appropriate protective gear, such as gloves and safety glasses. Ensuring that the equipment is turned off and disconnected from any power source is vital to prevent accidental starts. Additionally, working on a stable surface will help maintain control over the equipment throughout the procedure.

When accessing the blades, take care to follow the manufacturer’s recommendations for disassembly. Utilizing the correct tools will facilitate the removal process and reduce the likelihood of damaging components. After removing the old blades, inspect the mounting areas for debris or wear, as a clean workspace promotes effective installation of new tools.

Upon installation of the new blades, ensure they are securely fastened according to specified torque settings. This step is critical to prevent any operational issues during use. Finally, perform a thorough check of the entire assembly before reconnecting to the power source, confirming that everything is aligned correctly and functioning smoothly.

Engine Care and Maintenance Tips

Maintaining optimal performance and longevity of your machine’s engine is crucial for ensuring its reliability and efficiency. Regular upkeep not only prevents potential issues but also enhances overall functionality. Here are essential practices to keep your engine running smoothly.

- Regular Oil Changes: Frequent oil replacement is vital for lubrication and cooling. Check manufacturer guidelines for recommended intervals.

- Air Filter Maintenance: Inspect and replace air filters as needed to ensure proper airflow and prevent debris from entering the engine.

- Fuel Quality: Use high-quality fuel and consider additives to prevent buildup and enhance combustion efficiency.

- Coolant System Checks: Regularly inspect the coolant level and condition. Flushing the system periodically can prevent overheating.

- Spark Plug Inspection: Replace worn or dirty spark plugs to maintain efficient ignition and performance.

- Belt and Hose Checks: Regularly inspect belts and hoses for signs of wear or damage, replacing them as necessary to prevent breakdowns.

Implementing these strategies can significantly improve engine performance and lifespan. Always consult your equipment’s specifications for tailored maintenance advice.

Cleaning and Care of the Deck

Maintaining the surface of your mowing equipment is essential for optimal performance and longevity. Regular cleaning and proper care help prevent rust and deterioration, ensuring that the machinery operates smoothly. This section outlines effective methods for keeping the deck in top condition.

To achieve a thorough cleaning, follow these steps:

| Step | Action | Notes |

|---|---|---|

| 1 | Remove Debris | Use a brush or scraper to remove grass clippings and dirt. |

| 2 | Wash the Deck | Apply water and mild soap using a pressure washer or hose. |

| 3 | Dry Thoroughly | Use a cloth or allow air drying to prevent rust. |

| 4 | Inspect for Damage | Check for dents or corrosion that may require attention. |

| 5 | Apply Protective Coating | Consider using a rust inhibitor or wax for added protection. |

Regular upkeep not only enhances the performance of your machine but also extends its lifespan. By following these guidelines, you can ensure that your equipment remains in excellent working condition for years to come.

When to Seek Professional Help

Understanding when to enlist the assistance of an expert can significantly affect the outcome of your maintenance efforts. While many issues can be addressed with basic tools and knowledge, certain situations may require specialized skills and experience to ensure safety and efficiency.

Identifying Complex Issues

If you encounter problems that seem beyond your expertise or involve intricate components, it is wise to consult a professional. Symptoms such as unusual noises, persistent malfunctions, or erratic performance can indicate underlying issues that need a thorough diagnosis.

Safety Concerns

Always prioritize safety. If you feel uncertain about handling certain tasks or if repairs involve hazardous materials, seeking help from a qualified technician is essential. Professionals are trained to manage risks effectively, providing peace of mind and protecting your equipment from potential damage.

Upgrades and Performance Enhancements

Improving the functionality and efficiency of your outdoor equipment can significantly enhance its overall performance. A variety of modifications can be applied to boost power, reliability, and user experience, ensuring that your machine operates at its best. This section explores several key upgrades that can transform the capabilities of your device.

| Upgrade | Description | Benefits |

|---|---|---|

| Engine Tuning | Adjusting the engine settings for optimal fuel-air mixture. | Increased horsepower and fuel efficiency. |

| High-Performance Blades | Replacing standard blades with specialized, sharper alternatives. | Improved cutting efficiency and a cleaner finish. |

| Suspension Enhancements | Upgrading the suspension system for better stability and comfort. | Enhanced handling and reduced operator fatigue. |

| Advanced Filters | Installing high-efficiency air and fuel filters. | Improved engine performance and longevity. |

| Aftermarket Tires | Replacing tires with specialized options for various terrains. | Better traction and control in diverse conditions. |

Implementing these enhancements can lead to a more effective and enjoyable experience. Each upgrade not only contributes to the machine’s performance but also can extend its lifespan, providing value for your investment.