This section aims to provide essential insights into the upkeep and troubleshooting of automotive systems. Understanding the intricacies of vehicle operations can greatly enhance longevity and performance. By following detailed guidelines, owners can ensure their machines run smoothly and efficiently.

In this informative resource, users will find a wealth of information tailored to facilitate proper care and management of various components. Each aspect is covered with precision, allowing for a thorough understanding of the necessary procedures. Knowledge of these processes empowers individuals to address common issues independently.

Utilizing this guide will not only assist in routine maintenance but also aid in diagnosing potential problems before they escalate. Committing to regular checks and adjustments is crucial for optimal functionality and safety on the road.

Vehicle Maintenance Guide Overview

This section provides a comprehensive overview of the essential documentation designed for automotive servicing and upkeep. It aims to assist technicians and enthusiasts in understanding the critical components and procedures necessary for maintaining optimal performance and longevity of vehicles.

Key Features of the Documentation

The resource encompasses various attributes that contribute to efficient vehicle servicing. It includes detailed descriptions, diagrams, and troubleshooting tips that facilitate a thorough understanding of the maintenance process.

Structure of the Resource

The documentation is typically organized into several categories, making it easier for users to navigate through different topics. Below is a summary of its common sections:

| Section | Description |

|---|---|

| Overview | General information about vehicle systems. |

| Maintenance Procedures | Step-by-step guidance on regular upkeep. |

| Troubleshooting | Common issues and their solutions. |

| Specifications | Technical details and requirements. |

Purpose of Factory Repair Manuals

The primary aim of such documentation is to provide comprehensive guidance for maintenance and troubleshooting procedures. These resources serve as essential tools for technicians, ensuring that vehicles operate at optimal levels while minimizing the risk of errors during servicing.

These references not only detail step-by-step processes but also highlight the necessary tools and safety measures required for effective vehicle upkeep. By standardizing procedures, they help maintain quality control and enhance efficiency in automotive service operations.

| Key Benefits | Description |

|---|---|

| Detailed Instructions | Step-by-step guidance for servicing tasks. |

| Standardization | Uniform procedures that ensure consistent quality. |

| Enhanced Safety | Guidelines to mitigate risks during maintenance. |

| Efficiency | Streamlined processes that save time and resources. |

Accessing the Repair Manual

Locating the comprehensive documentation for vehicle maintenance is essential for both enthusiasts and professionals. These resources provide critical insights into troubleshooting and servicing various components, ensuring optimal performance and longevity.

Online Resources

Many manufacturers offer digital platforms where users can easily access technical guides. These platforms typically include interactive features, allowing individuals to search for specific topics or components. Utilizing these online databases can significantly streamline the process of obtaining necessary information.

Printed Resources

In addition to digital formats, hard copies of technical documentation are also available. These publications can be purchased from authorized dealers or specialized retailers. Having a physical version can be advantageous for those who prefer traditional reference methods while working on their vehicles.

Key Features of Toyota Manuals

The documentation provided by the manufacturer serves as an essential resource for vehicle owners and technicians alike. It encompasses a wide range of information that facilitates understanding and maintenance of the automobile. These guides are crafted to enhance user experience and ensure optimal performance.

Comprehensive Coverage: The materials include detailed explanations of various systems, components, and their functionalities. This extensive information aids in troubleshooting and effective maintenance procedures.

Step-by-Step Instructions: Each guide features systematic instructions that break down complex tasks into manageable steps. This approach empowers users to perform maintenance tasks confidently and accurately.

Illustrative Diagrams: Visual aids are a key element, providing clear representations of parts and assemblies. These illustrations enhance comprehension and support users in identifying components easily.

Diagnostic Tools: The documentation often includes diagnostic procedures and troubleshooting techniques. These resources help users identify issues quickly, ensuring timely repairs and reducing downtime.

Specifications and Standards: Precise specifications regarding torque settings, fluid capacities, and recommended parts are provided. This information is vital for maintaining the vehicle’s integrity and performance over time.

Understanding Repair Procedures

Grasping the protocols for vehicle maintenance is crucial for ensuring optimal performance and longevity. This section delves into the essential steps and techniques necessary for effective troubleshooting and servicing. A systematic approach not only enhances efficiency but also minimizes the risk of errors during the process.

Key Components of Maintenance Protocols

Understanding the various elements involved in maintenance procedures is vital. This includes identifying the specific issues, gathering necessary tools, and following structured guidelines. Each component plays a significant role in achieving successful outcomes.

Importance of Systematic Approaches

Implementing a methodical strategy during maintenance tasks can greatly improve the overall effectiveness. By adhering to established practices, individuals can avoid common pitfalls and ensure that each task is completed to the highest standards.

| Step | Description |

|---|---|

| 1 | Assess the vehicle to identify issues. |

| 2 | Gather the necessary tools and materials. |

| 3 | Follow structured guidelines for servicing. |

| 4 | Evaluate the outcomes and make adjustments as needed. |

Maintenance Guidelines for Toyota Vehicles

Ensuring the longevity and optimal performance of your automobile involves adhering to a systematic approach to upkeep. Regular inspections, timely servicing, and attentive care can significantly enhance reliability and safety on the road.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 5,000 miles | Use recommended oil type for best performance. |

| Tire Rotation | Every 6,000 miles | Helps to ensure even wear and prolongs tire life. |

| Brake Inspection | Every 10,000 miles | Check pads, rotors, and fluid levels. |

| Fluid Checks | Monthly | Inspect coolant, transmission, and brake fluids. |

| Battery Maintenance | Every 6 months | Clean terminals and check for corrosion. |

Troubleshooting Common Issues

Addressing frequent problems encountered during vehicle operation can significantly enhance performance and extend lifespan. Understanding typical malfunctions helps in identifying root causes and implementing effective solutions. This section provides insights into some prevalent challenges and their respective remedies.

One common concern involves the engine not starting. This issue may stem from a depleted battery, faulty ignition system, or issues with the fuel supply. Checking the battery charge and ensuring connections are secure can often resolve this problem.

Another frequent complication is the overheating of the engine. This situation might arise due to coolant leaks, a malfunctioning thermostat, or a defective water pump. Regular monitoring of coolant levels and inspecting hoses for wear can prevent overheating incidents.

Additionally, abnormal noises while driving can indicate underlying issues. These sounds could result from worn-out brake pads, loose components, or transmission problems. Conducting routine checks and addressing any unusual sounds promptly can avert more severe damage.

By being aware of these common issues and their solutions, vehicle owners can maintain optimal functionality and ensure a smoother driving experience.

Electrical Systems Documentation

This section provides comprehensive information regarding the electrical systems used in modern vehicles. Understanding these components is crucial for efficient diagnostics, maintenance, and troubleshooting. The documentation encompasses various aspects, including wiring diagrams, component specifications, and operational principles.

Key Components

- Wiring Schematics

- Fuses and Relays

- Sensors and Actuators

- Control Units

Importance of Accurate Documentation

Maintaining precise records is essential for ensuring the reliability and safety of electrical systems. Accurate documentation aids technicians in:

- Identifying faults quickly.

- Performing effective repairs.

- Implementing modifications or upgrades.

Overall, detailed electrical documentation enhances the understanding and functionality of a vehicle’s systems, leading to improved performance and longevity.

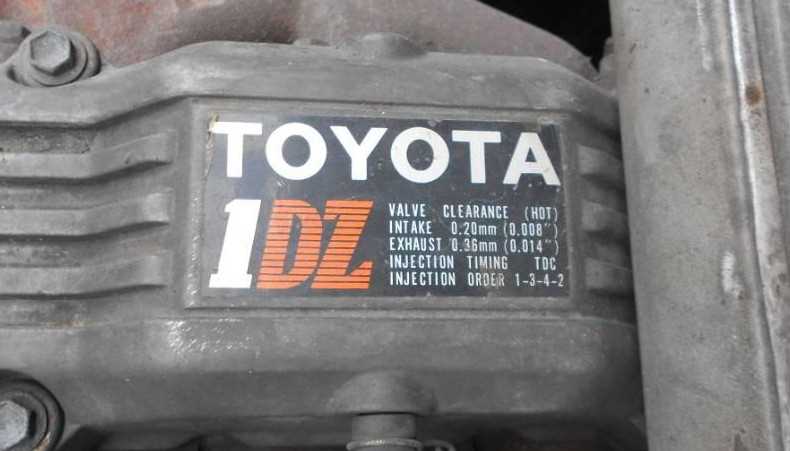

Engine Repair and Specifications

This section provides an overview of the essential procedures and requirements for maintaining and restoring the performance of automotive powertrains. Understanding the intricacies of engine components and their specifications is vital for ensuring optimal functionality and longevity.

Key Specifications

Accurate specifications are crucial for effective maintenance and troubleshooting. Here is a table summarizing important engine parameters:

| Specification | Value |

|---|---|

| Cylinder Capacity | 2.5 L |

| Max Horsepower | 203 hp |

| Torque | 180 lb-ft |

| Fuel Type | Gasoline |

Common Repair Techniques

Various techniques are employed to address common issues that may arise in engine systems. Proper diagnostic methods, along with recommended practices for component replacement and adjustment, ensure reliability and performance. Regular inspections and adherence to maintenance schedules play a significant role in preventing major breakdowns.

Transmission Service Instructions

This section outlines essential guidelines for maintaining and servicing the gear shifting system of your vehicle. Proper attention to this component ensures optimal performance and longevity, reducing the risk of operational issues.

Routine Maintenance Procedures

- Check fluid levels regularly and replenish as necessary.

- Inspect for leaks around the transmission and repair promptly.

- Replace the transmission filter according to the service schedule.

- Flush the transmission fluid to remove contaminants periodically.

Troubleshooting Common Issues

- Slipping Gears: Check fluid levels and look for any signs of wear on the clutch components.

- Unusual Noises: Investigate for loose parts or low lubrication.

- Delayed Engagement: Examine the hydraulic system for any faults.

Body and Interior Repairs

This section focuses on the procedures and techniques necessary for maintaining and restoring the exterior and interior components of vehicles. Understanding these processes is essential for ensuring both aesthetics and functionality.

Common Exterior Issues

- Dents and scratches on the surface

- Corrosion and rust treatment

- Replacing damaged panels

Interior Maintenance Techniques

- Cleaning upholstery and surfaces

- Fixing or replacing trim components

- Addressing electrical issues with interior features

Mastering these tasks will enhance the longevity and appeal of the vehicle, ensuring it remains in optimal condition over time.

Safety and Compliance Standards

Ensuring the highest levels of safety and adherence to regulatory requirements is crucial in the automotive industry. These standards govern the design, production, and operation of vehicles, aiming to protect both users and the environment.

Regulatory Framework

Compliance with established regulations involves a comprehensive understanding of various safety norms and testing procedures. This framework is designed to ensure that vehicles meet specific performance criteria, which ultimately enhances the safety of all road users.

Quality Assurance

Implementing rigorous quality assurance protocols is essential to uphold safety standards. Continuous monitoring and assessment during the manufacturing process help identify potential issues early, ensuring that every vehicle is built to the highest safety specifications.

Environmental Considerations

In addition to user safety, compliance standards also address environmental impacts. Regulations are in place to minimize emissions and promote sustainability, reflecting a commitment to both public health and ecological preservation.

Using Diagrams and Illustrations

Visual aids play a crucial role in understanding complex information related to vehicle maintenance and troubleshooting. By utilizing detailed diagrams and illustrations, users can gain clarity on various components and processes, enhancing their overall comprehension of the subject matter.

Benefits of Visual Aids

Diagrams and illustrations offer several advantages when navigating through technical documentation. They help to simplify intricate concepts, making it easier for individuals to grasp essential information. Furthermore, visual representations can highlight key areas of focus, enabling users to quickly identify specific parts or procedures.

Types of Visual Representations

There are various forms of visual aids that can be employed to convey information effectively. These include:

| Type | Description |

|---|---|

| Diagrams | Simple sketches that outline systems or components. |

| Flowcharts | Visual representations of processes or workflows. |

| Illustrations | Detailed drawings that provide a closer look at specific parts. |

| Exploded Views | Views that show individual components separated from the assembly. |

Incorporating these visual elements into documentation not only aids in understanding but also improves retention, making it easier for individuals to apply their knowledge practically.