Ensuring the longevity and optimal performance of compact machinery requires a comprehensive understanding of its components and functions. This section provides valuable insights into the maintenance procedures necessary for keeping these powerful machines in top condition. By familiarizing yourself with essential practices, you can effectively enhance the efficiency and durability of your equipment.

The importance of regular upkeep cannot be overstated. Knowledge of specific techniques and troubleshooting methods allows operators to identify potential issues before they escalate. This proactive approach not only minimizes downtime but also significantly reduces repair costs. Through consistent attention to detail, one can ensure the machinery remains reliable and efficient, ready to tackle various tasks.

In this guide, we will explore a range of essential topics that cover everything from routine checks to detailed troubleshooting steps. Emphasis will be placed on safety precautions, effective usage techniques, and best practices for maintenance. By adhering to these guidelines, operators can ensure their machinery performs optimally throughout its lifespan.

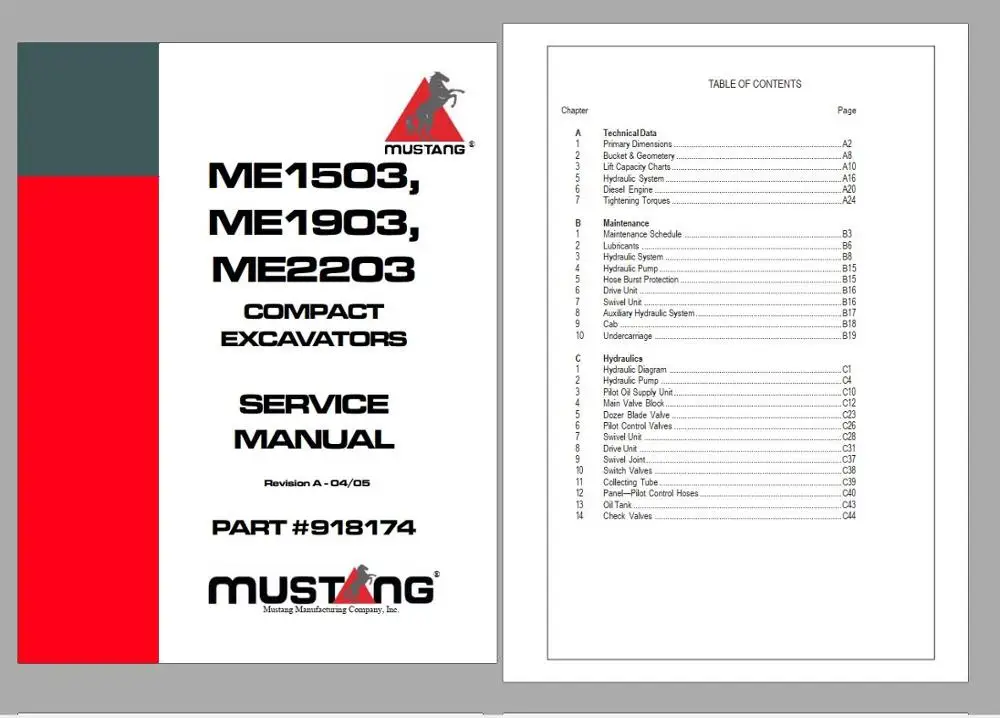

Overview of Mustang Skid Steers

This section provides an insight into compact machinery designed for versatility and efficiency in various tasks. These machines are essential for construction, landscaping, and agricultural applications, enabling operators to perform a wide range of functions with ease.

Key Features

- Compact Design: Ideal for navigating tight spaces.

- Powerful Engine: Offers impressive performance for demanding jobs.

- Versatile Attachments: Compatible with numerous tools for diverse applications.

- Operator Comfort: Designed with ergonomics in mind to reduce fatigue.

Applications

- Construction Sites: Efficient for excavation and material handling.

- Landscaping Projects: Useful for grading and earthmoving tasks.

- Agricultural Use: Aids in various farming activities such as tilling.

Common Issues in Skid Steer Operation

In the realm of compact machinery operation, various challenges can arise that affect performance and efficiency. Identifying these common problems is essential for ensuring smooth functionality and prolonging the lifespan of the equipment.

Operators may frequently encounter several recurring issues, including:

- Hydraulic System Failures: These can manifest as sluggish movement or unresponsive controls.

- Engine Overheating: Overheating can result from insufficient coolant levels or blocked radiators, leading to operational interruptions.

- Wear and Tear on Tracks: Track damage can cause uneven traction, impacting stability and control.

- Electrical Malfunctions: Faulty wiring or corroded connections may lead to intermittent power issues or failure of electrical components.

- Improper Load Handling: Miscalculating load capacities can lead to tipping or loss of control during operation.

Addressing these issues promptly can significantly enhance operational reliability and safety, ensuring that machinery remains effective in various working environments.

Maintenance Tips for Optimal Performance

Regular upkeep is essential to ensure that your equipment operates efficiently and reliably. By following a few key practices, you can enhance longevity and performance, preventing costly repairs and unexpected downtime.

Routine Inspections

Conducting frequent examinations of critical components is vital. Look for signs of wear or damage, and address any issues promptly. This proactive approach helps in identifying potential problems before they escalate, ensuring seamless operation.

Fluid Management

Proper management of fluids is crucial for optimal functionality. Regularly check levels and quality of hydraulic fluid, engine oil, and coolant. Maintaining these fluids not only protects vital systems but also promotes efficient energy use and performance.

In summary, prioritizing consistent maintenance routines leads to enhanced efficiency and reliability. By implementing these practices, you can maximize the performance of your machinery and prolong its lifespan.

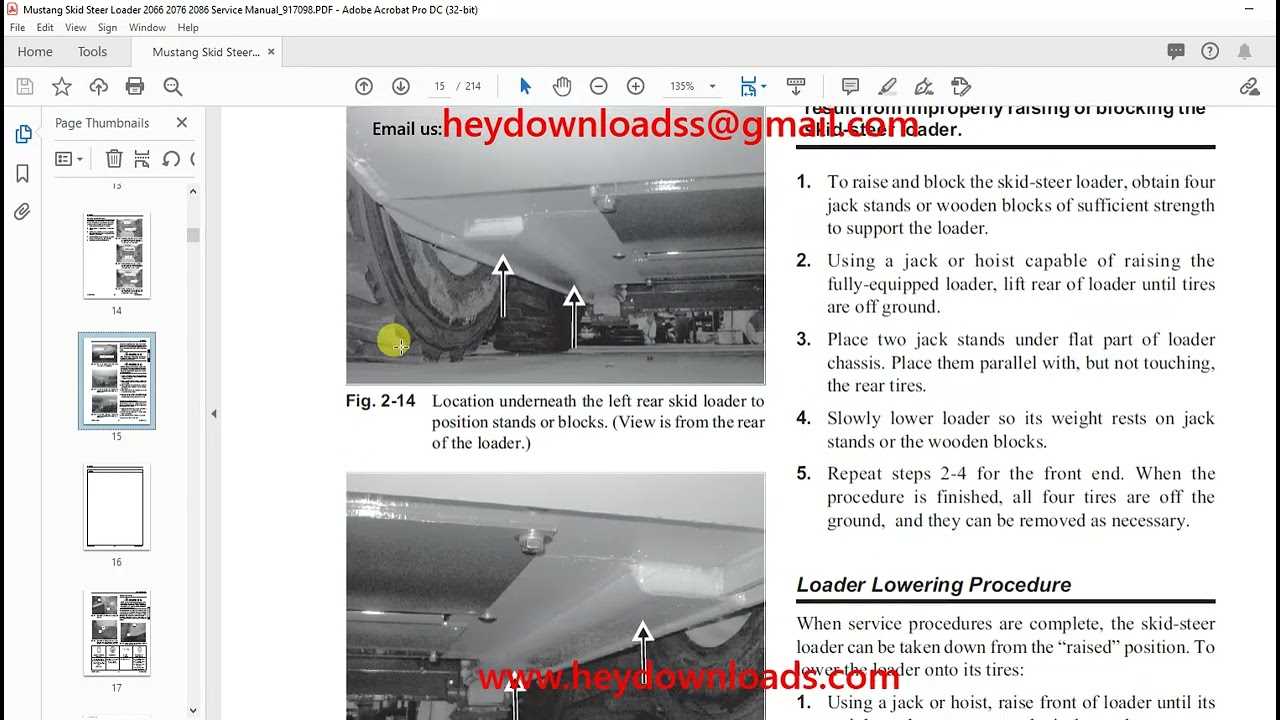

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered during maintenance tasks. Following these guidelines can enhance efficiency and ensure proper functioning of the equipment.

Preparation for the Task

Before commencing any maintenance work, it’s essential to gather the necessary tools and materials. Proper preparation contributes to a smoother process and minimizes interruptions.

- Collect required tools, including wrenches, screwdrivers, and safety equipment.

- Ensure a clean workspace to facilitate organization and safety.

- Review troubleshooting guides to identify specific problems.

Execution of the Maintenance Process

Once you are prepared, proceed with the maintenance following these structured steps:

- Power down the equipment and disconnect the battery to ensure safety.

- Inspect all relevant components for wear or damage.

- Replace any worn-out parts, ensuring that replacements meet the specifications.

- Reassemble all components carefully, double-checking for secure fittings.

- Reconnect the battery and conduct a test run to verify that the issue has been resolved.

Following these procedures can significantly enhance the longevity and performance of the machinery, ensuring it operates at optimal levels.

Tools Required for Effective Repairs

To ensure successful maintenance and restoration of machinery, having the right instruments is essential. These implements not only facilitate the process but also enhance the quality of work. Below is a comprehensive overview of the necessary tools to achieve efficient outcomes.

Basic Hand Tools

- Wrenches – various sizes for different bolt types

- Screwdrivers – flathead and Phillips for versatility

- Pliers – for gripping and twisting tasks

- Hammers – essential for assembly and disassembly

Specialized Equipment

- Torque wrench – to apply precise torque to fasteners

- Diagnostic tools – to identify and troubleshoot issues

- Oil filter wrench – for easy removal of filters

- Jack stands – to safely elevate and support machinery

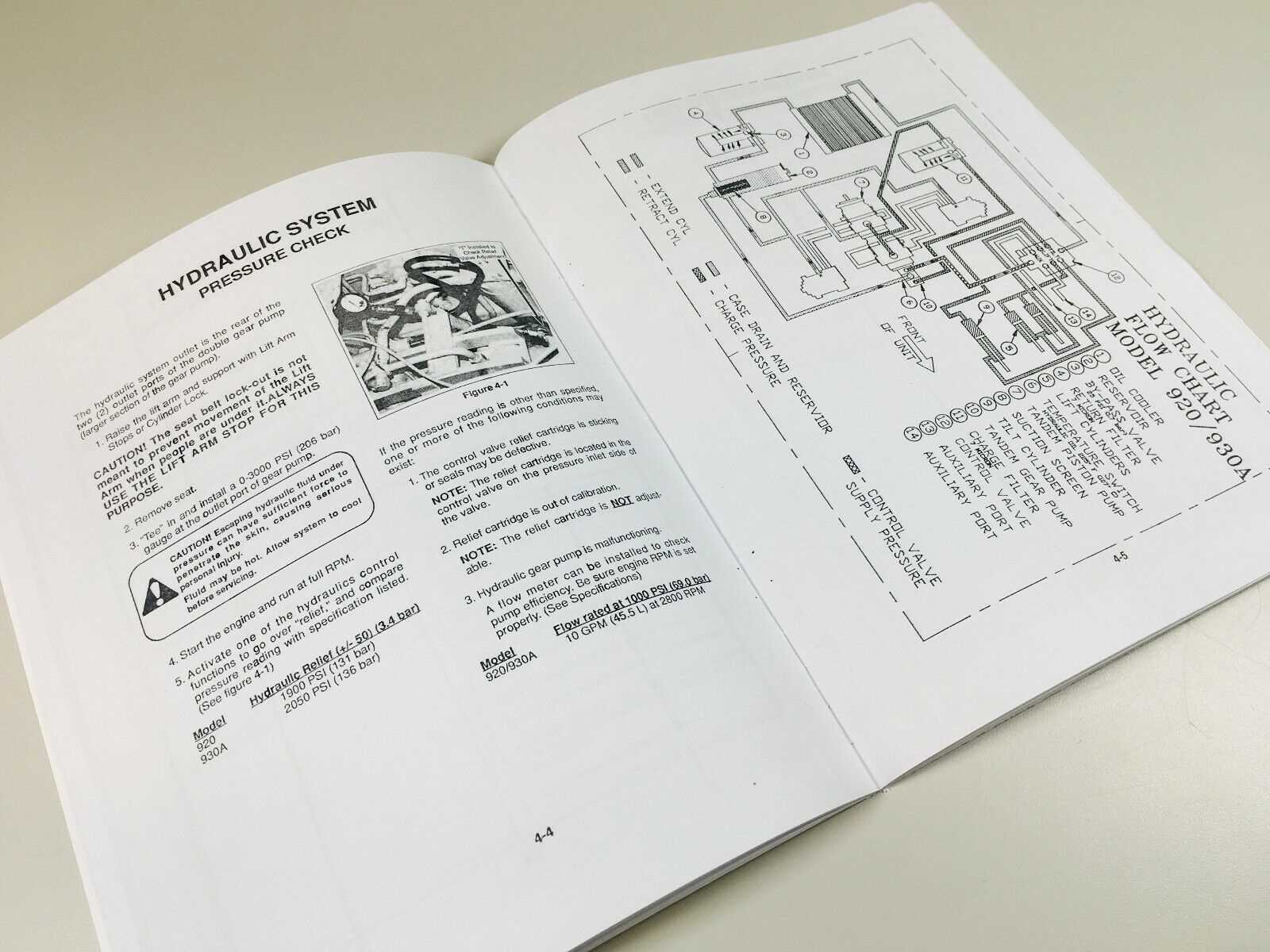

Identifying Hydraulic System Problems

Understanding the complexities of hydraulic systems is essential for maintaining optimal performance. Various issues can arise, affecting efficiency and functionality. Recognizing the signs of these problems early can prevent further damage and costly repairs.

Common indicators of hydraulic issues include unusual noises, erratic movements, and decreased power output. These symptoms often suggest leaks, air in the system, or failing components. Regular inspections and monitoring can help in diagnosing potential failures before they escalate.

To effectively troubleshoot, start by checking fluid levels and ensuring there are no visible leaks. Assessing the integrity of hoses and connections is crucial, as wear and tear can lead to significant complications. Utilizing pressure gauges can also aid in determining if the system is operating within acceptable parameters.

Engine Troubleshooting Techniques

Identifying issues within the engine system is crucial for maintaining optimal performance. This process involves systematic analysis and evaluation of various components to determine the root cause of malfunctions. Understanding the common symptoms and employing effective diagnostic methods can significantly enhance repair efficiency.

Common Symptoms of Engine Problems

Engine complications often manifest through noticeable signs. Recognizing these symptoms early can prevent further damage and reduce repair costs. Here are some prevalent indicators:

| Symptom | Possible Cause |

|---|---|

| Unusual noises | Worn bearings or faulty components |

| Overheating | Low coolant levels or malfunctioning thermostat |

| Excessive smoke | Oil leaks or fuel system issues |

| Loss of power | Fuel delivery problems or air intake restrictions |

Diagnostic Techniques

Utilizing appropriate diagnostic techniques is essential for effective troubleshooting. Here are some methods to consider:

- Visual inspection of engine components for wear or damage

- Using diagnostic tools to read error codes from the onboard computer

- Performing compression tests to assess engine health

Electrical System Diagnostics Guide

This section provides essential insights into assessing and troubleshooting the electrical components of heavy machinery. Understanding the intricacies of the electrical system is crucial for ensuring optimal performance and reliability.

Key elements to consider during diagnostics include:

- Battery status and connections

- Wiring integrity and continuity

- Fuses and relays functionality

- Control module operations

To effectively diagnose electrical issues, follow these steps:

- Begin by inspecting the battery condition and ensuring secure connections.

- Examine the wiring for any signs of wear or damage.

- Test fuses and relays to confirm they are functioning properly.

- Utilize diagnostic tools to evaluate the performance of control modules.

By systematically addressing each component, you can identify and rectify potential issues within the electrical system, enhancing overall functionality.

Safety Practices During Repairs

Ensuring a secure environment during maintenance tasks is crucial for the well-being of both the individual performing the work and the equipment being serviced. Implementing appropriate safety measures can prevent accidents and injuries.

Before commencing any service activities, consider the following precautions:

- Wear appropriate personal protective equipment (PPE) such as gloves, goggles, and steel-toed boots.

- Ensure the work area is well-lit and free from obstructions to minimize the risk of tripping.

- Always secure the machinery by engaging the parking brake and disconnecting the battery before beginning any maintenance.

Additionally, it’s essential to be aware of your surroundings:

- Keep tools organized and within reach to avoid unnecessary movement.

- Notify colleagues of your working area to prevent accidental contact.

- Follow the manufacturer’s guidelines for specific safety procedures related to the machinery.

By adhering to these practices, individuals can create a safer working environment that fosters efficiency and reduces the likelihood of incidents.

Aftercare: Keeping Your Skid Steer Running

Ensuring optimal performance of your equipment requires consistent attention and maintenance. By implementing a routine care schedule, you can prolong its lifespan and enhance efficiency. Regular checks and timely interventions are essential for addressing minor issues before they escalate.

Regular Inspections

Conducting frequent assessments of vital components is crucial. Look for signs of wear, fluid leaks, or irregularities in functionality. Pay close attention to the hydraulic system, engine, and tires to maintain peak operation.

Routine Maintenance Tasks

Establishing a list of essential upkeep tasks helps keep everything in top condition. This includes changing filters, replacing worn-out parts, and ensuring all fluids are at appropriate levels. Adhering to these practices minimizes downtime and ensures reliable performance.