In the realm of agricultural machinery, understanding the intricacies of maintenance is crucial for ensuring optimal performance and longevity. This section delves into essential techniques and protocols that empower operators and technicians alike to enhance the functionality of their equipment.

From routine inspections to complex troubleshooting, the knowledge shared here aims to equip users with the tools necessary for effective oversight. Recognizing potential issues before they escalate can save both time and resources, fostering a smoother operation in the field.

Furthermore, by familiarizing oneself with the components and systems of these powerful machines, users can not only improve their proficiency but also contribute to the overall productivity of their agricultural endeavors. Emphasis on preventive measures and systematic approaches will be highlighted throughout this guide.

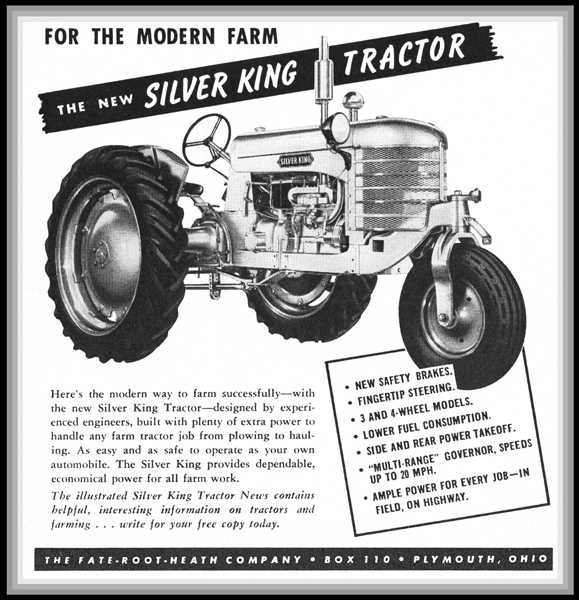

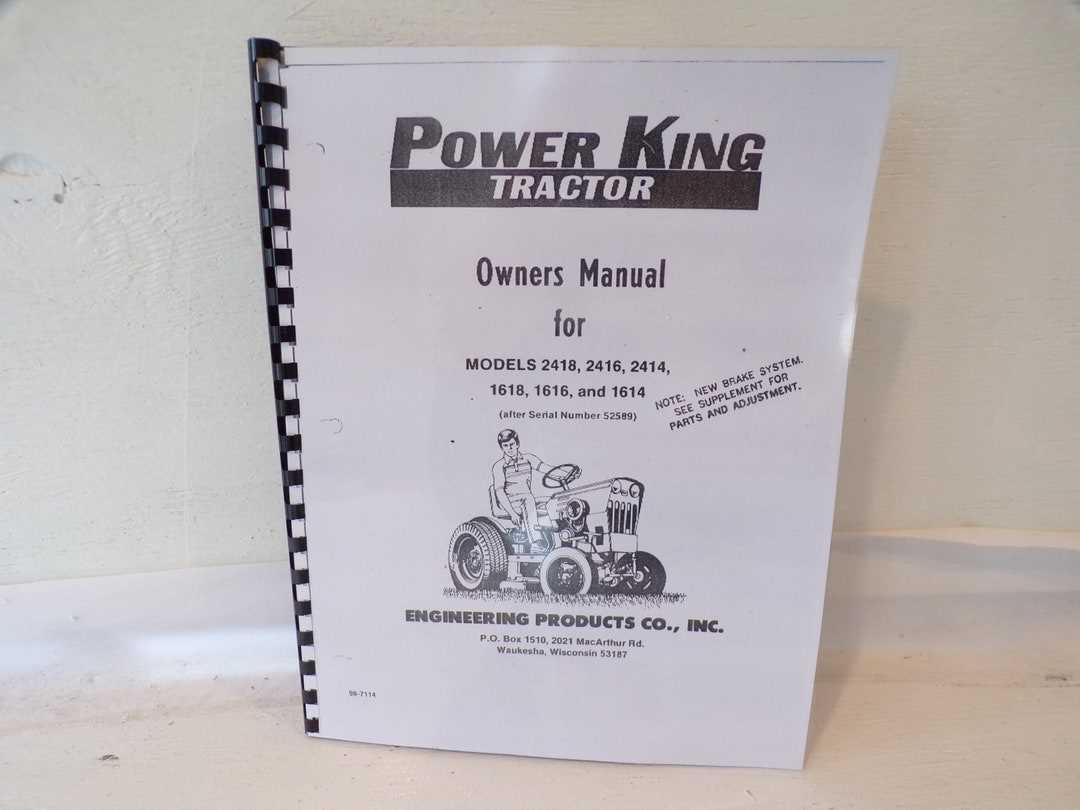

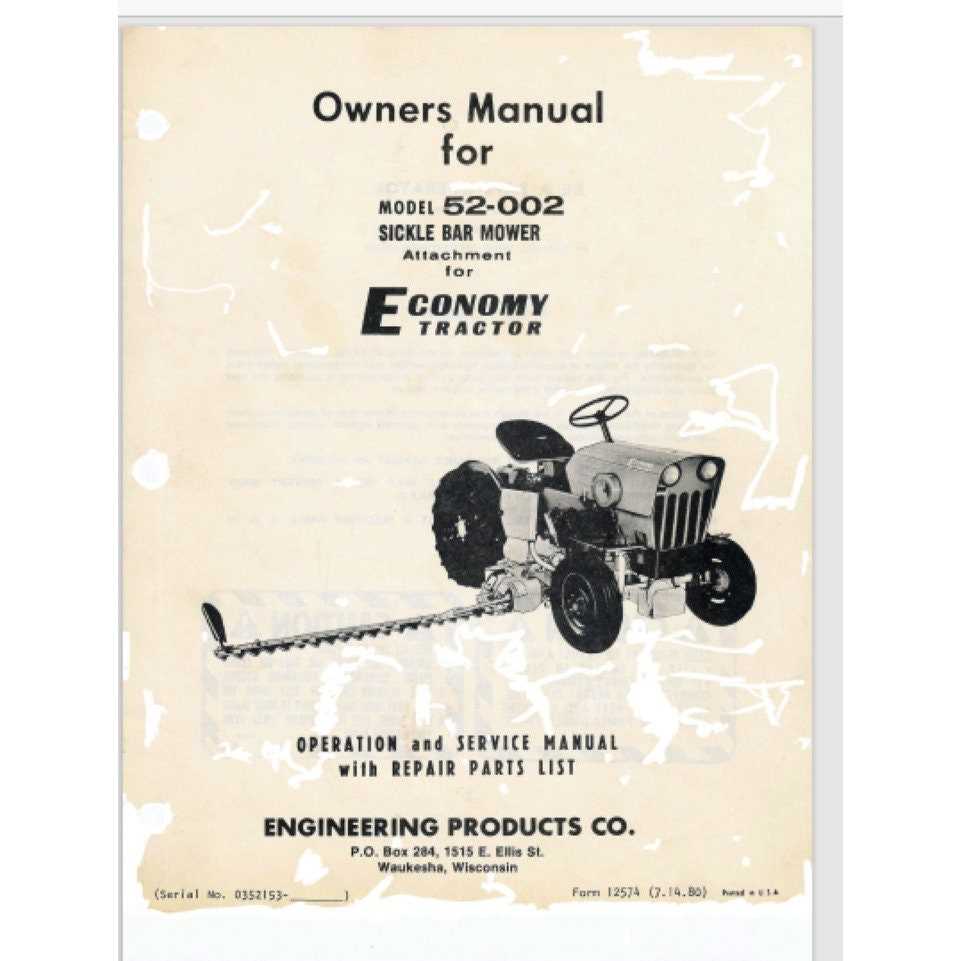

Overview of Power King Tractors

This section provides a comprehensive look at a renowned brand known for its reliable and versatile equipment used in various agricultural and landscaping tasks. These machines are celebrated for their robust design and functionality, catering to both professionals and hobbyists alike.

Key features include:

- Durability and strength suitable for heavy-duty tasks.

- Compact size allowing for easy maneuverability in tight spaces.

- Versatile attachments that enhance productivity across different applications.

Throughout the years, this brand has built a reputation for:

- Providing excellent customer support and service.

- Maintaining a strong community of users who share tips and experiences.

- Innovating with technology to improve performance and efficiency.

In summary, this line of equipment represents a blend of tradition and modernity, ensuring users can achieve their tasks effectively and efficiently.

Common Issues with Power King Tractors

Many owners encounter a range of challenges with their machinery, which can impact performance and longevity. Understanding these frequent problems can help in early identification and effective resolution, ensuring optimal operation.

Engine Difficulties: One prevalent issue is related to the engine, where users may notice hard starting or stalling. This can stem from fuel delivery problems or ignition system failures. Regular maintenance, including checking spark plugs and fuel filters, is essential to mitigate these concerns.

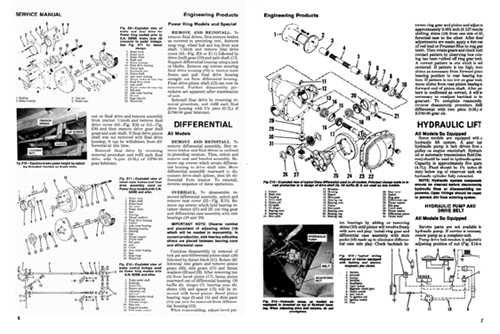

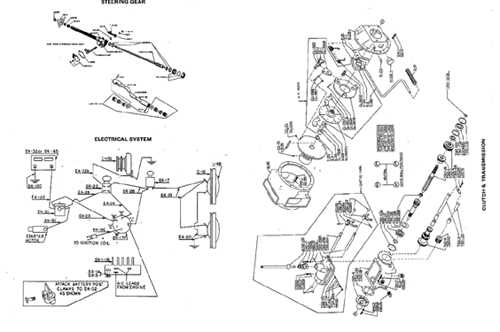

Transmission Troubles: Shifting gears can sometimes be problematic. Users might experience slipping or grinding, often caused by low fluid levels or worn components. It is crucial to monitor fluid conditions and replace worn parts promptly to avoid severe damage.

Electrical System Failures: Electrical issues can lead to a variety of malfunctions, including non-functional lights or starting difficulties. Inspecting wiring for corrosion or damage and ensuring connections are secure can prevent these setbacks.

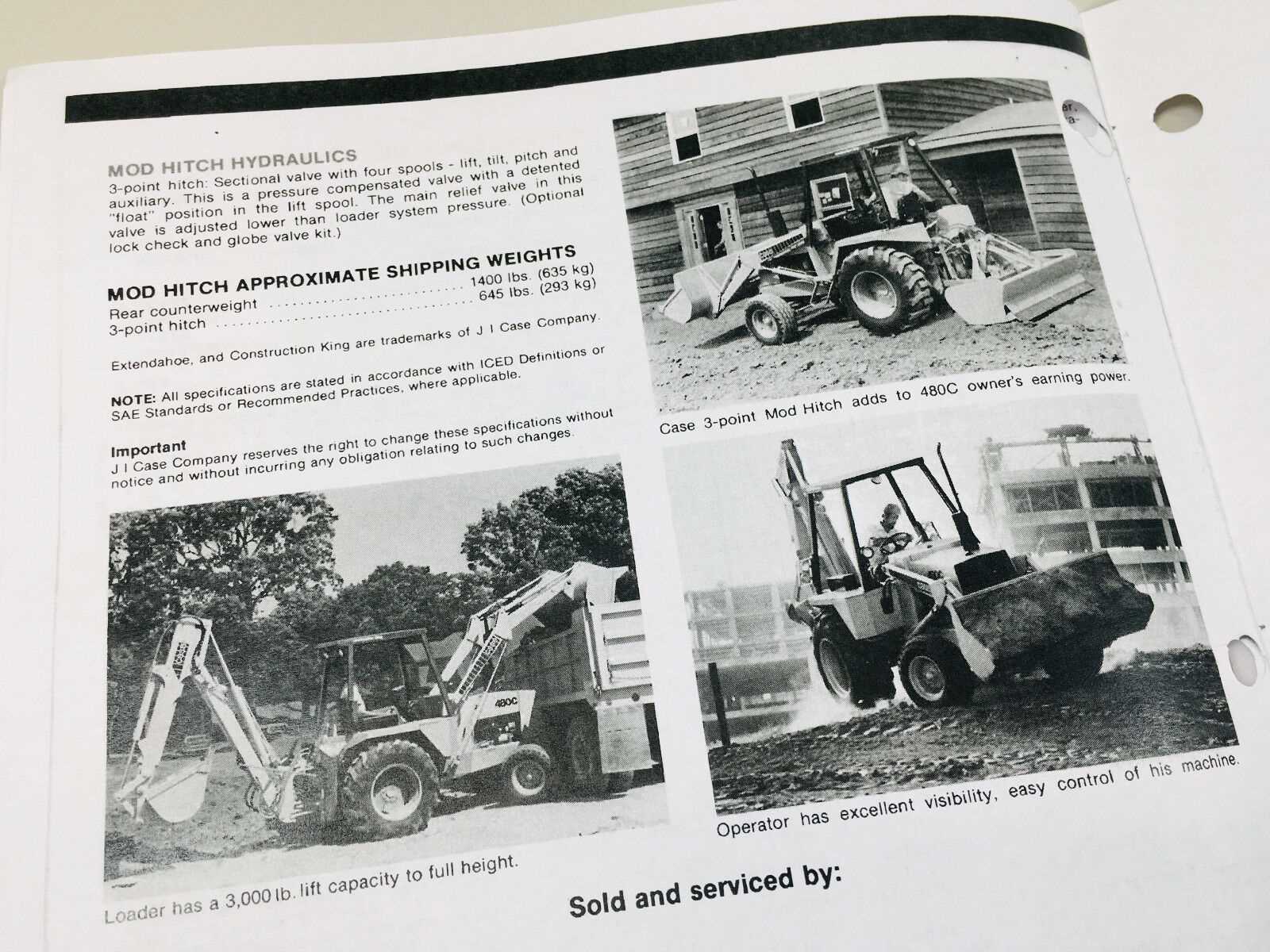

Hydraulic Problems: Leaks or poor performance in the hydraulic system can hinder efficiency. Regularly checking hoses and seals for wear can help maintain optimal hydraulic function and prevent costly repairs.

Maintenance Neglect: Failing to adhere to a proper upkeep schedule often leads to exacerbated issues. Implementing routine inspections and servicing can significantly enhance reliability and performance over time.

Essential Tools for Repairing Tractors

When it comes to maintaining heavy machinery, having the right equipment is crucial for ensuring longevity and optimal performance. A well-equipped workshop can make all the difference in handling various tasks effectively and efficiently.

Here are some indispensable items to consider for your toolkit:

- Wrenches: A variety of sizes is essential for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different fastening applications.

- Socket Set: Allows for quick adjustments and is ideal for reaching tight spaces.

- Pliers: Useful for gripping and bending wires or small components.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

In addition to these basic tools, consider the following specialized instruments:

- Diagnostic Equipment: Helps identify issues through electronic analysis.

- Hydraulic Jacks: Essential for lifting heavy parts safely.

- Grease Gun: Keeps moving parts lubricated, reducing wear and tear.

- Safety Gear: Gloves, goggles, and masks are critical for personal protection during maintenance tasks.

Investing in high-quality tools not only facilitates smoother operations but also contributes to the overall safety and efficiency of your maintenance work.

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure optimal performance and longevity of your machinery. Following a systematic approach to maintenance can help identify potential issues before they escalate and maintain efficiency. This section outlines essential procedures to keep your equipment in top shape.

1. Routine Inspections

Conducting regular checks is crucial for early detection of wear and tear. Follow these steps:

- Check fluid levels: oil, coolant, and hydraulic fluids.

- Inspect belts and hoses for signs of damage or wear.

- Examine filters and clean or replace as necessary.

- Look for any signs of leaks around connections and seals.

2. Cleaning and Lubrication

Keeping components clean and well-lubricated can prevent friction and overheating. Follow these steps:

- Clean external surfaces to remove dirt and debris.

- Apply lubricant to moving parts as recommended by the manufacturer.

- Inspect and clean air intake systems to ensure optimal airflow.

- Check and replace any worn gaskets or seals.

Adhering to these procedures will significantly enhance the reliability and efficiency of your equipment, minimizing the likelihood of unexpected breakdowns.

Engine Troubleshooting Techniques

Troubleshooting issues within a motor system requires a systematic approach to identify and rectify problems effectively. By employing various diagnostic strategies, operators can ensure optimal performance and longevity of their machinery. This section outlines essential methods to pinpoint engine malfunctions and implement solutions.

Identifying Symptoms

The first step in diagnosing engine issues is recognizing specific symptoms. Common indicators may include unusual noises, excessive vibrations, or changes in performance. Paying attention to these signs can provide valuable insights into underlying problems. For instance, a knocking sound might suggest internal wear, while reduced power could indicate fuel delivery issues.

Systematic Testing Procedures

Once symptoms are noted, a methodical approach to testing is crucial. Start by checking fluid levels, including oil and coolant, as insufficient lubrication can lead to severe damage. Next, inspect electrical components such as batteries and wiring for faults. Utilizing diagnostic tools can also facilitate the identification of error codes, which can guide repairs. By following these steps, operators can effectively address and resolve engine-related challenges.

Hydraulic System Repair Guidelines

The hydraulic system is a critical component that ensures efficient operation and performance. Proper maintenance and troubleshooting can prevent significant issues and prolong the lifespan of the equipment. This section provides essential insights for diagnosing and addressing common problems associated with hydraulic systems.

Follow these guidelines to maintain optimal functionality:

- Regularly inspect hydraulic fluid levels and quality.

- Check for leaks in hoses, fittings, and cylinders.

- Examine filters and replace them as needed to ensure clean fluid circulation.

When troubleshooting, consider the following steps:

- Identify symptoms such as inconsistent pressure or slow operation.

- Use gauges to measure pressure at various points in the system.

- Inspect seals and components for wear or damage.

- Test the hydraulic pump for proper function.

Implementing these guidelines can enhance performance and reduce the likelihood of malfunction in the hydraulic system. Regular attention to these areas fosters reliability and efficiency.

Electrical System Diagnostics Explained

Understanding the intricacies of the electrical framework in machinery is essential for efficient troubleshooting and maintenance. This section delves into the methodologies used to identify issues within the electrical components, ensuring optimal performance and longevity of the equipment.

Key Components of Electrical Diagnostics

- Batteries: Assessing charge levels and overall health.

- Wiring Harness: Inspecting for wear, damage, or loose connections.

- Sensors: Evaluating functionality and accuracy of readings.

- Control Modules: Checking for software updates and fault codes.

Steps for Effective Troubleshooting

- Begin with a visual inspection of all electrical connections.

- Utilize a multimeter to measure voltage and continuity.

- Refer to the schematic diagrams for accurate component identification.

- Test individual components systematically to isolate the problem.

By following these guidelines, one can effectively diagnose and resolve electrical issues, enhancing the functionality and reliability of the machinery in question.

Replacing Tires and Tracks Safely

Ensuring the safety and efficiency of agricultural machinery is crucial for optimal performance. This section focuses on the proper techniques and precautions to follow when changing the wheels or continuous belts of your equipment. Adhering to these guidelines will help prevent accidents and extend the lifespan of your machinery.

Before beginning the replacement process, it is essential to gather all necessary tools and equipment. This includes jack stands, wrenches, and appropriate safety gear. Always work on a flat, stable surface to minimize the risk of equipment tipping or rolling.

Start by securely lifting the machine with a reliable jack, ensuring it is stable before proceeding. Remove the old tires or tracks carefully, taking note of their orientation and any specific features that may affect installation. It’s advisable to clean the mounting surfaces to promote better adhesion and fit of the new components.

When installing new tires or tracks, follow the manufacturer’s specifications for torque settings and alignment. This ensures that everything is fitted correctly, reducing wear and enhancing safety during operation. After installation, inspect all connections and perform a test run at low speed to confirm proper functionality.

Regular maintenance and timely replacement of wheels and tracks are vital for maintaining the effectiveness of your equipment. By following these safety procedures, you can achieve optimal performance and reduce the risk of accidents in the field.

Maintaining Power King Attachments

Regular upkeep of implements is essential for optimal performance and longevity. Proper maintenance not only ensures efficient operation but also enhances safety and reduces the risk of costly breakdowns. Understanding how to care for these tools can significantly extend their lifespan and maintain their functionality.

Routine Checks and Cleaning

Conducting periodic inspections is crucial. Look for signs of wear, such as cracks or corrosion, and address them promptly. Clean all components after use to prevent buildup of dirt and debris, which can impair functionality. Pay special attention to moving parts, ensuring they are free of obstructions and adequately lubricated.

Storage and Seasonal Care

When not in use, store implements in a dry, sheltered area to protect them from harsh weather conditions. For seasonal care, consider performing a thorough inspection before the start of heavy usage periods. Replace any worn or damaged parts to ensure readiness and reliability. This proactive approach will help maintain peak performance throughout the year.

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Understanding the potential hazards associated with the equipment and the environment can significantly reduce risks. Proper preparation, protective gear, and adherence to safety protocols are crucial components of a successful and secure operation.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective equipment is vital. Always wear safety goggles to shield your eyes from debris, gloves to protect your hands from sharp objects and chemicals, and sturdy footwear to prevent slips and injuries. Additionally, consider wearing ear protection if working in noisy environments to safeguard your hearing.

Workspace Organization

Maintaining a tidy workspace can greatly enhance safety. Ensure that tools and materials are organized and easily accessible. Remove any unnecessary items from the area to minimize tripping hazards. Furthermore, be mindful of your surroundings, and ensure proper ventilation when working with fumes or chemicals.

How to Source Replacement Parts

Finding suitable components for your machinery can be a challenging yet essential task. It ensures optimal performance and longevity of your equipment. The right sourcing strategies can save you time and money while ensuring that you maintain the integrity of your device.

Here are several effective methods to locate the necessary parts:

- Manufacturer Websites: Start by visiting the official websites of the equipment manufacturers. They often have dedicated sections for parts and accessories.

- Authorized Dealers: Check with authorized dealers who specialize in your equipment type. They can provide genuine components and expert advice.

- Online Marketplaces: Utilize popular online platforms that specialize in industrial parts. Ensure to read reviews and verify seller ratings.

- Local Supply Stores: Visit local supply shops that cater to machinery needs. They may carry a variety of components suitable for your device.

- Second-Hand Options: Consider looking for used parts through auctions, classifieds, or online forums. This can be a cost-effective alternative.

By employing these strategies, you can effectively locate the parts you need, ensuring your equipment continues to operate at its best.

Tips for Long-Term Tractor Care

Maintaining your agricultural vehicle is essential for ensuring its longevity and optimal performance. Regular attention to various aspects of upkeep not only prevents potential breakdowns but also enhances efficiency and reliability. Here are some key practices to consider for sustained health and functionality.

Regular Maintenance Checks

Consistent inspections are crucial for early detection of issues. Create a routine that covers the following:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 100 hours of operation |

| Filter Replacement | Every 200 hours of operation |

| Tire Inspection | Monthly |

| Fluid Levels Check | Weekly |

Proper Storage Techniques

When not in use, it’s important to store your equipment properly. Consider the following strategies:

- Park in a dry, covered area to protect against the elements.

- Use protective covers to prevent dust accumulation.

- Keep the fuel tank full to minimize condensation.

By following these guidelines, you can enhance the lifespan and performance of your equipment, ensuring it remains a valuable asset for years to come.

Resources for Additional Assistance

When it comes to maintaining and troubleshooting heavy machinery, having access to a variety of support materials can make a significant difference. These resources can enhance your understanding, provide detailed insights, and offer solutions to common issues encountered during operation.

Online Forums and Communities: Engaging with fellow enthusiasts and experts in dedicated online platforms can provide valuable tips and firsthand experiences. These forums often host discussions that delve into specific challenges, offering ultimate guidance from seasoned users.

Instructional Videos: Visual learners may find video tutorials particularly helpful. Numerous channels focus on equipment maintenance and can walk you through various processes step-by-step, making complex tasks more manageable.

Manufacturer Support: Don’t overlook the value of reaching out directly to the manufacturer. Their official websites often contain FAQs, troubleshooting guides, and contact information for technical support, ensuring you receive authoritative assistance.

Local Workshops and Classes: Participating in hands-on training sessions can significantly boost your skills. Local community colleges or machinery suppliers frequently offer workshops that cover maintenance techniques and repair strategies.