Understanding the intricacies of your two-wheeled companion is crucial for optimal performance and longevity. This section aims to equip enthusiasts and owners with the necessary insights to handle various aspects of upkeep and restoration. By familiarizing yourself with essential components and procedures, you can ensure a smooth riding experience.

Delving into the specifics of care and attention can significantly enhance the functionality of your machine. This guide encompasses practical advice, highlighting the significance of routine checks and timely interventions. Whether you’re tackling minor adjustments or preparing for a comprehensive overhaul, the information provided will serve as a reliable resource.

Every ride should be enjoyable, free from unexpected complications. By applying the knowledge presented here, you can confidently address potential issues before they escalate. Embrace the journey of ownership with a proactive approach, ensuring that your vehicle remains in peak condition throughout its lifespan.

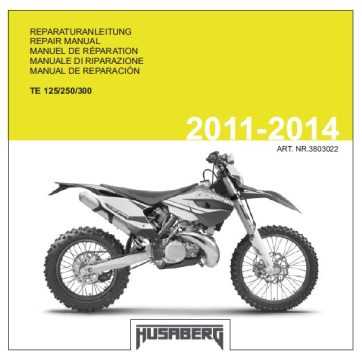

Overview of the 2012 KTM 500 EXC

This section provides a comprehensive insight into a remarkable off-road machine designed for performance and durability. With a focus on both versatility and power, this model stands out in the realm of trail riding and competitive racing. Riders can expect exceptional handling and a responsive engine, making it suitable for various terrains.

Key Features

Equipped with advanced suspension and braking systems, this model ensures optimal stability and control. The lightweight frame contributes to agility, allowing for effortless navigation through challenging landscapes. Riders will also appreciate the ergonomic design, which enhances comfort during extended rides.

Performance Highlights

Notable for its robust engine output, this machine excels in delivering exhilarating speed and acceleration. The efficient fuel system further enhances its performance, providing a balance between power and endurance. Overall, this model exemplifies cutting-edge technology in off-road engineering.

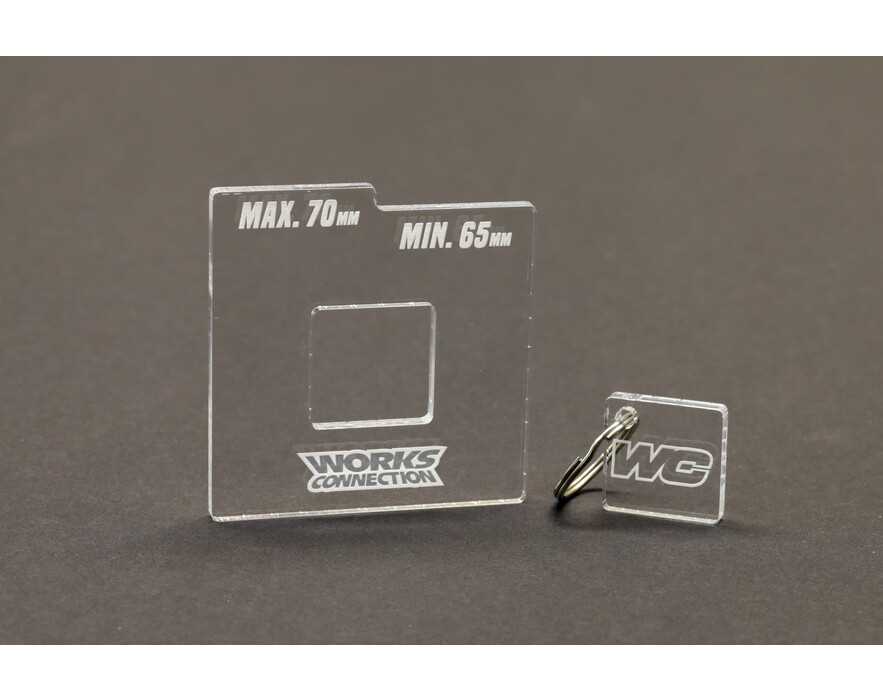

Essential Tools for Repairs

To ensure effective maintenance and restoration of your vehicle, having the right instruments is crucial. This section highlights the fundamental equipment needed to tackle various tasks efficiently.

Here is a list of indispensable tools:

- Wrenches: A set of adjustable wrenches is essential for loosening and tightening bolts of different sizes.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing various components.

- Socket Set: A complete socket set allows for quick and easy removal of fasteners.

- Torque Wrench: This tool ensures that bolts are tightened to the manufacturer’s specifications, preventing damage.

- Pliers: Useful for gripping, bending, and cutting wire or other materials.

- Oil Filter Wrench: A specialized tool for removing and installing oil filters without hassle.

Having these tools on hand will make any maintenance task smoother and more efficient, ensuring your vehicle remains in peak condition.

Common Issues and Solutions

This section highlights frequently encountered problems along with effective remedies that can help restore optimal performance. Understanding these challenges can enhance the overall experience and prolong the longevity of the machine.

One prevalent concern is engine stalling, often attributed to fuel delivery issues. Ensuring the fuel system is clean and free from blockages can mitigate this problem. Regular maintenance of filters and checking fuel lines for leaks are recommended steps.

Another common issue involves electrical malfunctions, which can disrupt functionality. Inspecting wiring connections and testing battery voltage can identify faults. Replacing worn components and securing loose connections are essential for reliable operation.

Lastly, improper handling of the suspension may lead to discomfort while riding. Adjusting the settings according to weight and riding style can improve stability. Regular inspection and maintenance of shock absorbers and forks are advisable to ensure a smooth ride.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your two-wheeled vehicle. This guide offers a comprehensive approach to maintaining your machine, focusing on key areas that require attention to keep everything running smoothly.

1. Check the Fluid Levels

Begin by inspecting the various fluids, including oil, coolant, and brake fluid. Maintaining the appropriate levels is crucial for functionality and safety. Top up any low fluids and replace them if they appear dirty or degraded.

2. Inspect the Air Filter

A clean air filter is vital for engine efficiency. Remove the filter and check for dirt or obstructions. Clean or replace it as needed to ensure proper airflow and optimal engine performance.

3. Examine the Tires

Regularly check the tire pressure and tread condition. Proper inflation enhances handling and fuel efficiency. Replace tires that show significant wear or damage to ensure safe riding.

4. Adjust the Chain

Inspect the chain for tension and lubrication. A well-maintained chain contributes to smoother operation and reduces wear on other components. Adjust the tension as necessary and apply lubricant to keep it running quietly.

5. Brake Inspection

Check the brakes for wear and functionality. Inspect the pads and discs for any signs of damage. Replace any components that are worn to maintain stopping power and safety.

6. Battery Care

Examine the battery for corrosion and ensure that connections are secure. Keep the terminals clean and check the charge level regularly to prevent starting issues.

Following these steps will help ensure your vehicle remains in excellent condition, ready for your next adventure.

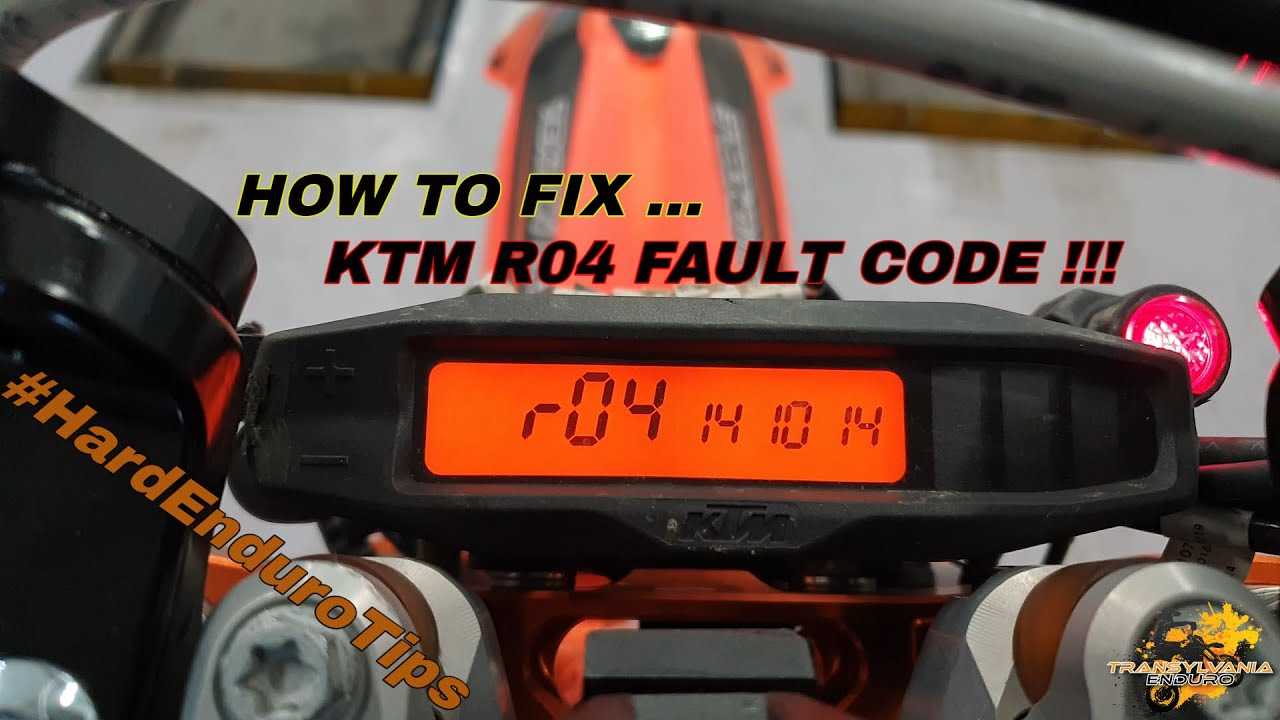

Engine Troubleshooting Techniques

Diagnosing issues within an engine requires a systematic approach to identify and resolve underlying problems. This section outlines essential methods to effectively troubleshoot performance anomalies, ensuring optimal functionality.

Identifying Symptoms

Begin by observing any unusual behavior such as strange noises, irregular vibrations, or warning indicators on the dashboard. Pay close attention to the engine’s response during operation, as these signs can provide valuable clues regarding potential malfunctions.

Performing System Checks

Conduct thorough inspections of key components, including the ignition system, fuel supply, and electrical connections. Utilize diagnostic tools to retrieve error codes and analyze performance metrics. This data can pinpoint areas requiring further investigation, leading to efficient resolutions. Regular maintenance can prevent many common issues, making it crucial to adhere to a routine inspection schedule.

Electrical System Diagnostics

The assessment of the electrical network is crucial for ensuring optimal performance and reliability. This process involves identifying issues within various components that influence functionality. A systematic approach can help pinpoint faults, leading to effective solutions and enhanced operation.

Key Components to Inspect

Start by examining the primary elements of the system, including the battery, wiring, and connectors. Each part plays a significant role in the overall functionality. Look for signs of wear, corrosion, or loose connections that may impede performance. Regular checks can prevent larger issues from arising.

Testing Procedures

Utilizing appropriate diagnostic tools is essential for accurate evaluation. Multimeters and other specialized devices can provide valuable insights into voltage levels and circuit integrity. Conduct tests methodically, comparing results against standard benchmarks to determine the health of the electrical system.

Suspension Adjustments and Repairs

Proper tuning and maintenance of the suspension system are crucial for optimal performance and rider comfort. Adjustments can significantly influence handling, stability, and overall ride quality. Regular evaluations ensure that the system responds appropriately to various terrains and riding conditions.

To achieve the best results, start by assessing the current settings and identifying areas that may require modification. Factors such as preload, compression, and rebound settings play essential roles in how the suspension reacts. Making small adjustments can lead to noticeable improvements in performance.

When addressing issues, inspect components for wear or damage. Regular maintenance, including lubrication and part replacement, is vital to prolonging the lifespan of the suspension system. Be attentive to signs of leaking fluids or unusual noises, as these can indicate the need for more in-depth attention.

Following a systematic approach to adjustments and repairs will not only enhance the riding experience but also ensure safety on the road or trail. Understanding the nuances of the suspension system allows for better decision-making regarding modifications and upkeep.

Transmission Care and Maintenance

Maintaining the drivetrain of your vehicle is essential for ensuring optimal performance and longevity. Proper care can prevent costly repairs and enhance the overall riding experience. Regular attention to this component can lead to improved efficiency and reliability.

Here are some key practices to keep in mind for effective maintenance:

- Regular Fluid Checks: Periodically inspect the transmission fluid levels and quality. Clean or replace fluids as necessary to ensure smooth operation.

- Inspect for Leaks: Routinely examine the area around the transmission for any signs of fluid leakage. Addressing leaks promptly can prevent more significant issues.

- Clean Filters: If applicable, maintain and replace filters to keep contaminants from affecting the fluid’s quality and transmission functionality.

- Monitor Performance: Pay attention to any unusual noises or shifting issues. Early detection of problems can lead to easier and less expensive fixes.

- Scheduled Maintenance: Follow the manufacturer’s recommendations for service intervals to ensure all components are functioning correctly.

By implementing these practices, you can enhance the reliability and performance of your vehicle’s drivetrain, allowing for a more enjoyable riding experience.

Brake System Inspection Process

The evaluation of the braking mechanism is crucial for ensuring safety and optimal performance. This procedure involves a thorough examination of various components to identify any potential issues that may affect functionality.

Begin by visually inspecting the brake pads for wear and tear. Look for uneven surfaces or significant thinning, which may indicate the need for replacement. Next, assess the brake discs for scoring or warping, as these conditions can compromise braking efficiency.

Check the brake fluid level and quality. If the fluid appears contaminated or is below the recommended level, it should be replaced. Additionally, examine the hoses and lines for any signs of leaks or damage, as this can lead to brake failure.

Finally, test the brake lever or pedal for proper feel and responsiveness. Any sponginess or excessive travel may point to air in the hydraulic system, necessitating further attention. Conducting these inspections regularly will help maintain the integrity of the braking system.

Fuel System Cleaning Methods

Maintaining the cleanliness of the fuel delivery system is crucial for optimal performance and longevity of any engine. Regularly removing deposits and contaminants can prevent issues such as reduced efficiency and erratic operation.

Importance of Fuel System Maintenance

Neglecting the upkeep of the fuel system can lead to a variety of complications. Here are some common benefits of routine cleaning:

- Enhanced fuel flow and atomization

- Improved combustion efficiency

- Reduction in harmful emissions

- Increased power output

Cleaning Techniques

Several methods can be employed to cleanse the fuel system effectively:

- Fuel Additives: Utilizing specialized chemicals can help dissolve deposits and maintain cleanliness within the injectors and lines.

- Manual Cleaning: Disassembling components such as injectors and carburetors for a thorough manual scrub is sometimes necessary.

- Ultrasonic Cleaning: This technique uses high-frequency sound waves to agitate a cleaning solution, effectively removing stubborn deposits.

- Pressure Washing: For external components, a gentle pressure wash can remove dirt and grime without damaging sensitive parts.

By implementing these practices, the integrity of the fuel system can be upheld, ensuring smooth operation and enhancing the overall lifespan of the engine.

Preparing for Off-Road Riding

Embarking on an adventure through rugged terrains requires thorough preparation and awareness. The right mindset, equipment, and knowledge can significantly enhance the experience and ensure safety while navigating through challenging landscapes.

Essential Gear and Equipment

Before hitting the trails, it’s crucial to equip yourself with the necessary gear. A sturdy helmet, protective clothing, and appropriate footwear are fundamental for safeguarding against potential injuries. Additionally, investing in a reliable hydration system and a first-aid kit can provide peace of mind during your journey.

Understanding the Terrain

Each off-road environment presents unique challenges. Familiarize yourself with the specific characteristics of the area you plan to explore. Recognizing various obstacles, such as rocky paths, muddy sections, or steep inclines, can help in anticipating difficulties and adapting your riding techniques accordingly.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial to protect both the individual performing the tasks and the machinery being serviced. Adhering to established guidelines can prevent accidents and enhance the overall efficiency of the work process.

Before commencing any maintenance procedures, consider the following essential precautions:

- Personal Protective Equipment: Always wear appropriate gear, including gloves, goggles, and helmets to shield against potential hazards.

- Workspace Organization: Keep the work area tidy and free from clutter to minimize the risk of trips and falls.

- Proper Ventilation: Ensure that the workspace is well-ventilated, especially when working with chemicals or flammable substances.

- Tool Inspection: Regularly check tools for damage or wear before use to prevent malfunctions that could lead to injuries.

By following these safety measures, individuals can significantly reduce risks and promote a safe working environment, allowing for effective maintenance of the equipment.