Maintaining your outdoor equipment is essential for ensuring optimal performance and longevity. This section provides valuable insights into the necessary steps for keeping your machine in top shape. Understanding how to address common issues will help you enjoy your tools to their fullest potential.

Effective upkeep not only enhances functionality but also prevents more significant problems from arising. Familiarizing yourself with the inner workings and standard practices can save you time and resources in the long run. This guide aims to equip you with the knowledge required to handle various challenges that may arise.

Whether you’re facing minor adjustments or more complex troubleshooting tasks, having a reliable reference can make all the difference. From routine maintenance to problem resolution, this comprehensive resource is designed to assist you in achieving success with your equipment. Explore the essential techniques that will empower you to take charge of your machinery’s upkeep.

Overview of Craftsman YT 3000

This section provides a comprehensive look at a popular model known for its versatility and performance in lawn care. Designed for both residential and light commercial use, this unit combines functionality with user-friendly features.

Key characteristics include:

- Powerful engine that ensures efficient operation.

- Robust cutting deck for effective grass management.

- Adjustable speed settings to cater to different mowing conditions.

- Comfortable seating and ergonomic controls for ease of use.

Additionally, the following benefits enhance its appeal:

- Durable construction designed to withstand regular use.

- Wide range of attachments available for various tasks.

- Simple maintenance procedures to prolong lifespan.

This model stands out for its reliability and ability to tackle diverse yard challenges, making it a favored choice among homeowners.

Common Issues and Troubleshooting Steps

This section outlines frequent challenges encountered with lawn care equipment and offers practical solutions for resolving them. Understanding these common problems can help users maintain optimal performance and extend the lifespan of their machines.

- Engine Won’t Start

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear or damage.

- Examine the battery connections and charge if necessary.

- Uneven Cutting

- Ensure the blades are sharp and properly adjusted.

- Check tire pressure for uniformity.

- Inspect the cutting deck for debris buildup.

- Excessive Vibration

- Examine the blades for bending or damage.

- Ensure all bolts and fasteners are tightened.

- Check for uneven wear on tires.

- Loss of Power

- Inspect the air filter for clogs and replace if needed.

- Ensure fuel lines are clear and not leaking.

- Check for any obstructions in the exhaust.

By addressing these typical concerns with the recommended troubleshooting steps, users can effectively enhance their equipment’s functionality and reliability.

Maintenance Guidelines for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Following a structured approach to maintenance can prevent issues and enhance performance, allowing you to get the most out of your investment.

Routine Inspections

Conducting frequent checks on key components can help identify potential problems before they escalate. Focus on the following areas:

- Inspect the air filter for dirt and debris; clean or replace as necessary.

- Examine belts and cables for signs of wear or fraying.

- Check fluid levels, including oil and coolant, and top off as needed.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication will prevent excessive wear and enhance performance. Consider these practices:

- Clean the exterior to remove dirt and grime that can cause overheating.

- Lubricate moving parts according to the manufacturer’s recommendations.

- Ensure that any debris around the engine and undercarriage is cleared to prevent blockages.

Essential Tools for Repair Work

Effective maintenance requires a set of key instruments that ensure tasks are performed efficiently and safely. Whether addressing minor adjustments or significant overhauls, having the right equipment at hand simplifies the process and enhances results.

Basic Tool Kit

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are crucial for loosening and tightening screws.

- Wrenches: Adjustable and socket wrenches allow for the removal and installation of nuts and bolts of different sizes.

- Pliers: Needle-nose and slip-joint pliers are versatile tools for gripping, bending, and cutting.

Specialized Equipment

- Torque Wrench: Essential for applying a specific torque to fasteners, ensuring proper tension.

- Multimeter: Useful for measuring voltage, current, and resistance, aiding in electrical diagnostics.

- Safety Gear: Gloves, goggles, and ear protection are important to prevent injuries during any maintenance tasks.

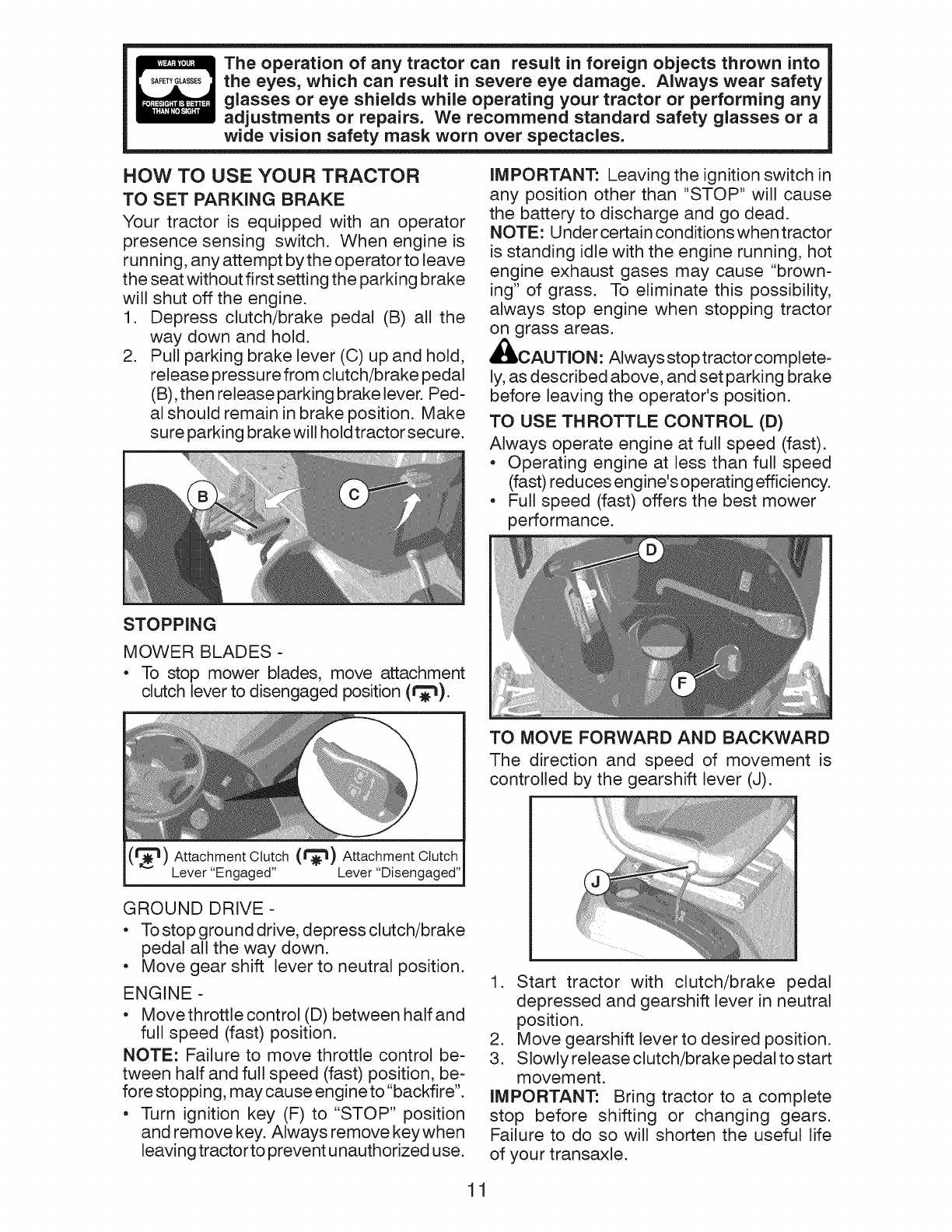

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered during maintenance. By following these organized steps, users can effectively diagnose and resolve problems, ensuring optimal functionality.

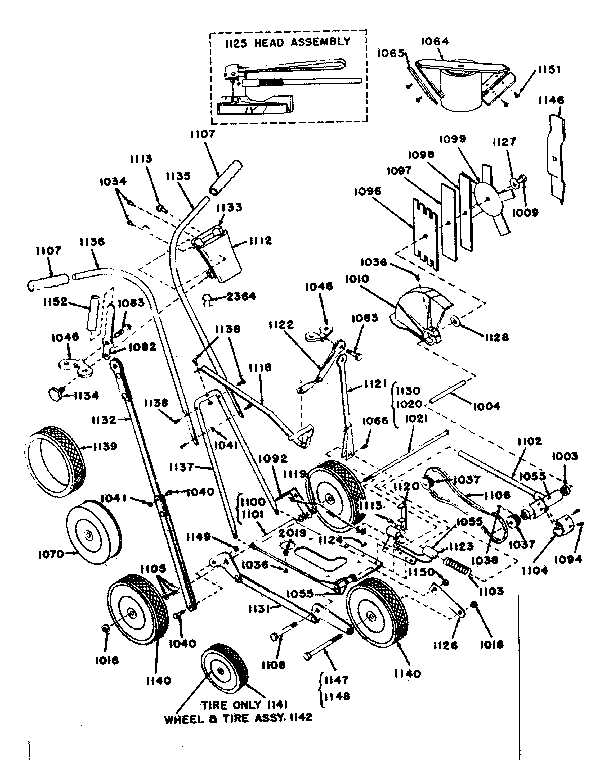

Begin by gathering the necessary tools and materials, ensuring a clean workspace. Identify the specific issue at hand, whether it involves the engine, electrical components, or mechanical parts. Next, consult relevant diagrams or schematics to understand the layout and connections involved.

Proceed to disassemble the affected components carefully. Document each step to avoid confusion during reassembly. Inspect all parts for signs of wear or damage, replacing any that do not meet operational standards. After replacement, reassemble the unit in reverse order, ensuring all connections are secure.

Finally, conduct a thorough test to verify that the issue has been resolved. Adjust settings as needed to optimize performance, and always refer back to this guide for future maintenance tasks.

Parts Replacement and Sourcing

Ensuring the longevity and optimal performance of your equipment often requires the timely replacement of components. Identifying reliable sources for obtaining quality parts is crucial for maintaining functionality.

When seeking replacements, consider the following approaches:

- Manufacturer’s Website: Many brands offer direct sales of parts through their official sites, providing access to genuine items.

- Authorized Dealers: Local dealers may stock various components, ensuring you receive authentic products backed by warranty.

- Online Marketplaces: Websites such as eBay or Amazon can be good sources, but verify seller ratings and return policies.

- Local Repair Shops: These establishments often have parts on hand or can order specific items for you.

Before making a purchase, it’s important to:

- Verify the compatibility of the part with your model.

- Check for customer reviews to gauge quality.

- Compare prices across different platforms to ensure a fair deal.

By following these guidelines, you can effectively source the necessary components to keep your equipment running smoothly.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial for preventing accidents and injuries. Adhering to recommended guidelines can greatly enhance the safety of the work environment and protect individuals from potential hazards.

- Personal Protective Equipment (PPE): Always wear appropriate gear such as gloves, goggles, and sturdy footwear to shield against injuries.

- Work Area Organization: Keep the workspace tidy and free from clutter to minimize risks of tripping or other accidents.

- Proper Tools: Use the correct tools for the job to ensure efficiency and reduce the likelihood of injury.

Before commencing any tasks, it is essential to read the manufacturer’s guidelines and understand the equipment thoroughly.

- Disconnect Power: Always ensure that the power source is disconnected before starting any maintenance work.

- Ventilation: Ensure adequate ventilation when working with fuels or chemicals to prevent inhalation of harmful fumes.

- Emergency Procedures: Familiarize yourself with emergency procedures in case of accidents or injuries.

By following these precautions, individuals can create a safer environment and effectively carry out necessary tasks with confidence.

Understanding the Engine Specifications

This section delves into the vital characteristics of the power unit, which play a crucial role in the overall performance of the equipment. By examining these specifications, users can better appreciate how each component contributes to efficient operation and maintenance.

The engine typically features a single-cylinder design, allowing for a balance of power and fuel efficiency. An air-cooled system ensures that the unit remains at optimal temperatures during operation, enhancing longevity. Key metrics such as displacement and horsepower are fundamental in assessing the engine’s capabilities, influencing both speed and torque.

Understanding the fuel type recommended for the engine is essential for maintaining its functionality. Additionally, the importance of regular oil changes cannot be overstated, as proper lubrication significantly affects performance and wear on internal components.

Repairing Electrical Components

The functionality of any mechanical system heavily relies on its electrical parts. Proper maintenance and troubleshooting of these elements are crucial for optimal performance. Identifying issues early can prevent further complications and ensure longevity.

Diagnosing Issues: Begin by systematically checking connections and components for any signs of wear or damage. Loose wires or corroded contacts can often be the source of malfunction. Use a multimeter to assess voltage and continuity, which helps pinpoint the exact location of the problem.

Replacing Faulty Parts: Once the defective components have been identified, replacing them with high-quality alternatives is essential. Ensure that new parts match the specifications of the original components to maintain compatibility. Follow manufacturer guidelines when installing replacements to avoid further complications.

Testing After Repairs: After making the necessary adjustments, conduct thorough tests to verify that all systems are functioning correctly. This step is vital to confirm that the issues have been resolved and the device is operating as intended.

Regular maintenance of electrical systems not only enhances performance but also extends the life of the entire mechanism.

Seasonal Care and Preparation Tips

Ensuring optimal performance of your equipment throughout the year requires thoughtful maintenance tailored to the changing seasons. By implementing seasonal care strategies, you can enhance the longevity and reliability of your machinery, keeping it in peak condition for every task.

During each season, certain maintenance tasks should be prioritized to address the unique challenges presented by the weather and environmental conditions. Below is a helpful table outlining key care activities for each season:

| Season | Maintenance Task | Frequency |

|---|---|---|

| Spring | Inspect and clean air filters | Every month |

| Summer | Check fluid levels and replenish as needed | Bi-weekly |

| Autumn | Sharpen blades and inspect for wear | Monthly |

| Winter | Store properly and protect from freezing | Seasonal |

Adopting these seasonal strategies will not only safeguard your equipment but also ensure that it operates effectively when you need it most. Regular attention to maintenance can prevent costly repairs and enhance overall performance.

Warranty Information and Claims Process

This section provides essential details regarding the coverage offered for your equipment and the steps necessary to file a claim should any issues arise. Understanding your rights and the procedures involved can streamline the process of obtaining support for your product.

The warranty typically encompasses:

- Coverage duration

- Components included under the warranty

- Exclusions and limitations

To initiate a claim, follow these general steps:

- Gather all relevant documentation, including proof of purchase.

- Contact customer support to report the issue and seek guidance on the next steps.

- Complete any required claim forms provided by the manufacturer.

- Submit your claim along with the necessary documentation.

- Await confirmation and further instructions regarding repairs or replacements.

Always keep a copy of all submitted documents for your records. Timely action and clear communication can greatly enhance the likelihood of a successful resolution to your concerns.